Abstract

PURPOSE

Veneering porcelain might be delaminated from underlying zirconia-based ceramics. The aim of this study was the evaluation of the effect of different surface treatments and type of zirconia (white or colored) on shear bond strength (SBS) of zirconia core and its veneering porcelain.

MATERIALS AND METHODS

Eighty zirconia disks (40 white and 40 colored; 10 mm in diameter and 4 mm thick) were treated with three different mechanical surface conditioning methods (Sandblasting with 110 µm Al2O3 particle, grinding, sandblasting and liner application). One group had received no treatment. These disks were veneered with 3 mm thick and 5 mm diameter Cercon Ceram Kiss porcelain and SBS test was conducted (cross-head speed = 1 mm/min). Two and one way ANOVA, Tukey's HSD Past hoc, and T-test were selected to analyzed the data (α=0.05).

RESULTS

In this study, the factor of different types of zirconia ceramics (P=.462) had no significant effect on SBS, but the factors of different surface modification techniques (P=.005) and interaction effect (P=.018) had a significant effect on SBS. Within colored zirconia group, there were no significant differences in mean SBS among the four surface treatment subgroups (P=0.183). Within white zirconia group, "Ground group" exhibited a significantly lower SBS value than "as milled" or control (P=0.001) and liner (P=.05) groups.

All-ceramic restorations have high esthetic performance and excellent biocompatible properties and because of these characteristics are used more than before.1-3 Recently, high-strength zirconium oxide ceramics (Zirconia) are used because of their chemical stability, physical and mechanical charactristics and using of new technologies (CAD/CAM) for fabricating a substructure for all-ceramic restorations.4-6

For esthetical reasons, appropriate veneering ceramic can be veneered onto zirconia core by either a hand-layered powder build-up or a pressed technique.7 However, to-date hand-layering technique is more common.8 Delamination of veneering porcelain in zirconia-based restorations or "Chipping" is described to be the most frequent failure reason3,6,9-14 with a rate of 15% after 24 months,15 25% after 31 months16 and 13% after 38 months.11 It is reported the chipping is multi-factorial.17 Porcelain chipping may be caused by insufficient bond strength,18 excessive tensile stress due to a thermal mismatch between veneering porcelain and underlying framework,19 firing shrinkage of ceramic,20 the framework/veneer thickness ratio,14 restoration geometry and inadequate framework design.11 Furthermore, some failure factors of the veneering ceramic are magnitude, direction and frequency of the applied load and the location of occlusal contact areas.6,16,21 Although, Manicone et al.20 did not detect any differences between chipping failure of veneered zirconia specimens and porcelain fused to metal (PFM) specimens, but one of the weakest aspects of these restorations is the bonding between veneering ceramic and zirconia core.10,22

There is a little information about the bond quality between veneering ceramic and zirconia core.6,8,14,19,23,24 It has been stated that the success of all of veneer/core bilayer restorations depends on the mechanical adhesion between veneering ceramic and zirconia core.16 The core-veneer bonding strength may be affected by different factors such as mechanical retention due to the surface roughness of the core, mismatch in thermal expansion coefficient (TEC) of the core and veneer ceramics and its resulting pre-stresses, transformation of zirconia crystals at core-veneer interface due to thermal influences or stress loading (interface toughness), structure defects or flaws developments at the interface between zirconia core and veneering ceramic and wetting properties and firing shrinkage of the veneering ceramics.25-28

It was reported that the bonding strength and the mode of failure were significantly affected by some surface treatments such as air-borne particle abrasion or use of liner material, and type of zirconia framework material.6,14,22,24,26,29 However, bonding mechanisms and the effect of different surface treatments on the bond strength of veneering ceramics to zirconia core are unclear.24

Yttrium-stabilized zirconia (Y-TZP), also known as tetragonal zirconia polycrystal (TZP) is a polymorphic material with three different allotropes (M, T and C).30 Inserting force on its surface can lead to transition between its different crystalline reticulations that produces a volumetric change and creates compressive stresses that seals the crack.5,20 This is the reason why zirconia toughened ceramics exhibit relatively high fracture toughness compared to conventional brittle ceramics.31 The process of fabricating all-ceramic restorations include some steps involving surface modifications such as grinding, polishing and air-borne particle abrasion. The exact influence of such steps on the bond strength of different veneering ceramics to zirconia core material is not understood. On the other hand, there are various commercially available zirconia core materials with different fabrication procedures. Thus, each manufacturer recommends various surface treatments.29 It is stated that for inducing the T→M transformation, the hand grinding is more effective than lapper-machine grinding, and air-borne particle abrasion is more effective than grinding.5 But some authors stated that the locally developed temperature in grinding may have exceeded the T→M transformation temperature.31 Air-borne particle abrasion is a process that can induce transformation without developing high temperatures or creating severe surface damage.5,6,14 However, air-borne particle abrasion can initiate some surface defects and compromise the mechanical strength of the ceramic.32,33 Fischer et al.24,34 stated that airborne-particle abrasion cannot be consider as a necessary surface pretreatment to enhance bond strength. Although it has been said that liner-applied zirconia specimens had higher bond strength than specimens prepared with other surface treatments, but there are also reports about weakening the bond strength due to liner application.25,34

The purpose of this study was to evaluate the effect of different surface treatments and type of zirconia (white or colored) on the shear bond strength of one commercial zirconia core ceramic and its veneering ceramic. Fractured surfaces were microscopically analyzed to determine the characteristics of bond failure.

The first null hypothesis to be tested was that the type of zirconia (white or colored) does not have any effect on the shear bond strength between zirconia core and veneering ceramic; and the second null hypothesis was that the surface treatments do not have any effect on the shear bond strength between zirconia core and veneering ceramic.

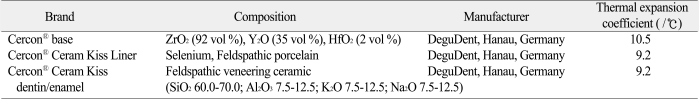

The materials tested and their properties were listed in Table 1. Eighty zirconia ceramic disks (10 mm diameter, 4 mm thick) were made from Cercon Base ceramic (DeguDent, Hanau, Germany) and divided into two groups of 40 disks according to their color shade [White and Colored (Ivory)]. All the disks were sintered to full density in the Cercon Heat furnace (6 hours at 1350℃). For each zirconia color shade, the disk specimens were divided into four subgroups (n=10):

Group 1 ("as milled"): This group (Control) had received no treatment after milling.

Group 2 (Ground): The specimen in this group were ground under water-spray jet incorporated in the hand-piece with a nominally 90 µm grit bur (Komet, Salzburg, Austria) to provide a gentle grinding regime. The surface grinding regimes were carried out using a W&H Synea TA-98 hand-piece (W&H Dentalwerk Bürmoos GmbH, Bürmoos, Austria) at the maximum revolutions/min (200,000 rpm) to ensure a consistent grinding speed. A 'gentle stroking motion' was employed to grind the specimen surface with minimal pressure. high stress concentration. The burs were replaced after grinding of every five specimen to maintain a consistent amount of grit. The hand-piece water-spray was run for 30s prior to grinding to avoid oil leakage and ensure the bur was seated correctly.

Group 3 (Air-borne particle abrasion): The specimens were mounted in a special sample holder at a distance of 15 mm between the surface of the sample and the tip of the airborne particle abrasion unit and then air-borne particle abraded (Kavo EWL, Type 5423, Biberach, Germany) with 110 µm Al2O3 at a pressure of 3.5 bars for a period of 5s.

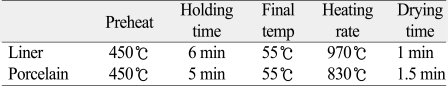

Group 4 (Liner): The specimens in this group were airborne particle abraded as in group 3 and then the liner material (Cercon Ceram Kiss Liner) was applied using a glass ball to create an even well condensed layer.26 The liner was fired independently according to the manufacturer's instructions.

All of surface treatments were conducted only on the surface of the specimens that would have been subjected to tensile stress during strength testing. Finally, the disk specimens were ultrasonically cleaned in distilled water at room temperature for 15 minutes and then steam-cleaned and air-dried.

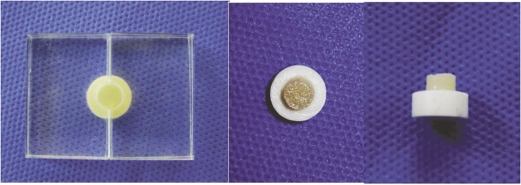

The prepared zirconia discs were placed in an adjustable Plexiglas mold (Fig. 1) where a space with 5 mm diameter and 3 mm height was available above the core material for condensing the veneering ceramic. The veneering ceramic powder (Cercon Ceram Kiss dentin, DeguDent) was mixed with an appropriate amount of the respective liquid according to the manufacturer's instructions and the obtained slurry was plotted with absorbent paper to draw excess water. The mold was filled and ultrasonically condensed. Layered zirconia discs were fired according to the firing program of the manufacturer (Table 2) in a firing furnace (Programat P300, Ivoclar Vivadent AG, Schaan, Liechtenstein). To compensate for the porcelain shrinkage during the sintering process, two separate firings with the same conditions were required to establish the correct diameter and thickness (Fig. 1).

After surface examinations with a magnifying glass (2 ×), specimens displaying visible defects were replaced.

The final dimensions were obtained by calculating the average of three measurements for each dimension. A digital micrometer (Absolute 500, Kitutoyo, Aura, IL, USA) was used for the measurements and disc dimensions were recorded.

According to Guess et al.17 all of the specimens were subjected to thermocycling for 20,000 cycles at temperatures alternating between 5 and 55℃.

By means of a surveyor, each specimen was embedded in a mounting jig using PMMA resin (Meliodent, Heraeus Kulzer GmbH, Hanau, Germany) with the core-veneer interface positioned at the top level of the jig and then shear force was applied as close as possible to the veneer-core interface at a crosshead speed of 1 mm/min using a universal testing machine (TLCLO, Dartec Ltd., Stourbridge, England) until fracture occurred. The ultimate load to failure was recorded in Newton (N) and then was calculated with suitable mathematical method to express the bond strength in MPa.

The fractured surfaces were visually analyzed with a stereomicroscope (MBC-10, St. Petersburg, Russia; 20× magnifications) to determine the failure modes of specimens. Failure modes were classified as follows:

Group C: Cohesive fracture within the zirconia core,

Group V: Cohesive fracture within the veneer ceramic,

Group I: Adhesive fracture between the core and veneer, and

Group Group V/I: A combination of both fractures that begin at the zirconia-ceramic interface and proceeded into the veneering ceramic.

The collected data were analyzed using a statistical software (SPSS ver 16.0, SPSS Inc., Chicago, IL, USA) using one and two way analysis of variance (ANOVA) and Tukey's HSD (Honestly Significant Difference) test at P<.05 level of significance.

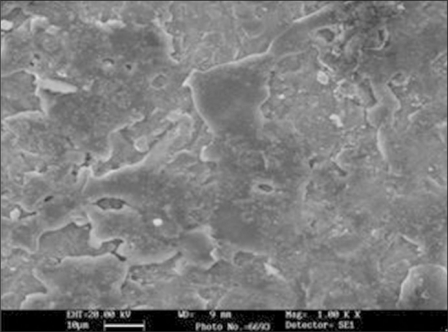

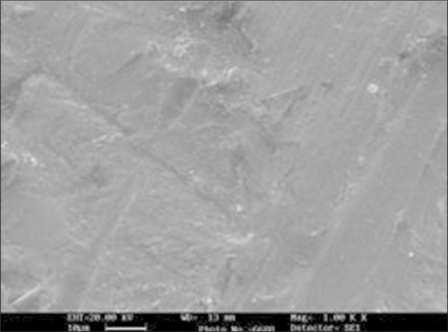

One fractured veneer-zirconia disc from each experimental group was rinsed with 96% ethanol and air-dried, mounted on metallic stubs, Carbon coated (CS300; Dynavac, Sydney, Australia) and evaluated under a SEM (LEO 440, LEO Electron Microscopy Ltd, Cambridge, England) at different magnifications to assess the surface topography.

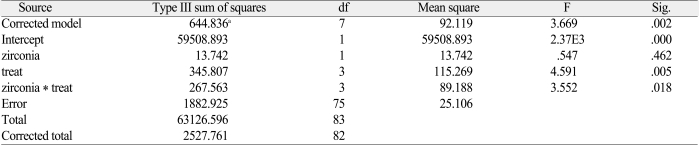

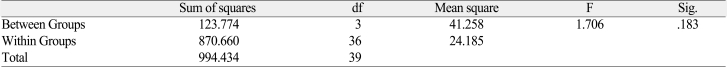

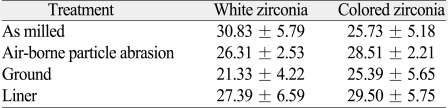

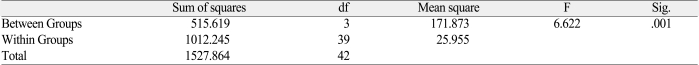

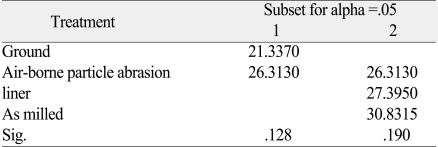

The results of the shear bond strength tests of the core-veneer interface of tested zirconia ceramics and different surface treatments are presented in Table 3. Table 4 summarizes the statistical analysis results on the effects of zirconia, surface treatments, and their interaction on SBS. The two-way ANOVA revealed that different types of zirconia ceramics (P=.462) had no significant effect on SBS, but different surface modification techniques (P=.005) and interaction between the type of zirconia and surface treatment (P=.018) had a significant effect on SBS. Further, Tukey's HSD test showed that there were significant difference only between "as milled" and ground groups (P=.005) and other groups had no significant differences.

For all the four types of surface treatments within each zirconia group, their SBS differences were analyzed with one-way ANOVA. Within colored zirconia group, there were no significant differences in mean SBS among the four surface treatment subgroups (P=.183) (Table 5). In white zirconia group, there were significant differences in mean SBS among the four surface treatment ceramics (P=.001) (Table 6). In particular, ground group exhibited a significantly lower SBS value than "as milled" (P=.001) and liner (P=.05) groups (Table 7).

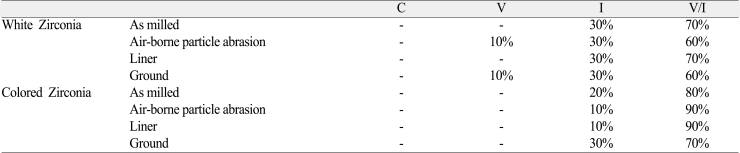

The results of fracture mode after shear bond testing as observed with a stereomicroscope (MBC-10, St. Petersburg, Russia; ×20 magnifications) are summarized in Table 8. None of the test groups demonstrated cohesive failure within the zirconia core material. Most of the specimens demonstrated a combination of cohesive and adhesive fracture modes especially in colored zirconia group.

Based on the results of this in vitro study, the first null hypothesis was accepted for two types of zirconia (white or colored). However, the second null hypothesis that the surface treatments do not have any effects on the shear bond strength of zirconia core and veneering ceramic was rejected.

Different test methods (shear test, three/four point flexure, and biaxial flexure strength test) have been used to evaluate core-veneer bond strength. Estimating the bond strength values from these tests was very complicated due to the structural damage associated with the testing method and with the fracture mechanism.27 Using the SBS test to determine the core veneer bond strength resulted in more standardized data, because the applied forces are perpendicular to the bonding area, and the small cross-sectional area of the bonded surface eliminates incorporation of structural flaws, which significantly affect test readings.25,27 However, development of a stricter standardized method is necessary to obtain clinically valuable data.35

The mean shear strength in as milled (control) groups were about 25-30 MPa that was in the same level as reported by Al-Dohan et al.35 (22-31 MPa) and Fischer et al.36 (21-31 MPa). But in Ozkurt et al. study22 mean shear strength for Cercon group was about 20.19 ± 5.12 MPa that is less than mean shear strength for Cercon specimens in our study. These differences in bond strengths between these studies may be due to the use of different study methods and/or conditions. Aboushelib et al.29 reported bond strength value of 37.9 ± 5.1 MPa between the Cercon framework and Cercon Ceram Express (press-on veneering ceramic), which was higher than other studies that were done with Cercon Ceram veneering ceramic. This difference is attributed to the use of press-on veneering ceramic versus the layering veneer ceramic.29

Ozkurt et al.22 stated that the bonding of manufacturer-recommended veneering ceramic to the zirconia framework differed according to zirconia type but they concluded that zirconia type was not a decisive factor in the fracture pattern. Aboushelib et al.29 concluded that the bonding strength between core and veneering ceramic is affected by the type of zirconia core material. They concluded that mean SBS value in colored zirconia group is lower than white zirconia group. They stated that the addition of coloring pigments to zirconia cores resulted in structural changes that require different surface treatment before veneering. In the present study there was no significant difference between two types of used zirconia (white and colored), but the mean SBS value of the colored zirconia was lower (Table 3). Color pigments in zirconia frameworks cause structural changes that affect the core-veneer bond strength29 due to increased concentration of these pigments at grain boundaries and reducing the percentage of the stabilizing elements.37 This would increased percentage of tetragonalmonoclinic transformation on the framework surface and would result in grain pullout and surface lifts and producing the surface characteristics of the colored frameworks.38 It is suggested that this finding can be due to this fact that the melting point of the main coloring pigment (ferric-oxide) is much lower than the melting point of yttrium and hafnium oxides. This would result in competitive displacement of the stabilizing elements by the metallic pigments which can occur during the zirconia sintering.29

It is described that a fatigue process can be started in some surface areas, leading to monoclinic spots, resulting in microcracking and surface lifts.29 However, it is claimed that for Cercon, the coloring pigments are added before iso-statically pressing the milling blocks, which guarantees homogenous and equal distribution of the pigments.29 Coloring of zirconia frameworks can be made by different techniques, such as adding metallic pigments to the zirconia milling blocks, dipping the milled frameworks in the coloring agents, or application of liner material to the sintered white cores.25 Veneer thickness required to mask the underlying framework can be reduced by using colored zirconia cores. Another advantage of colored zirconia cores is eliminating masking liner material, which is applied before layering the veneer ceramic.29 It is proven that using liner material decreases the zirconia-veneer bond strength.26,39 In the present study, liner application reduced the mean SBS in white zirconia group but increased it in colored zirconia group (Fig. 2). However, these values were not significantly different from "as milled" groups in both types of zirconia. This was similar to results achieved by Aboushelib et al.29 So it can be concluded that in the case of white zirconia cores, liner application decreases bond strength between core and veneering ceramic and increases the percentage of interfacial failure. Kim et al.6 stated that the liner application significantly decreases the shear bond strength compared to airborne-particle abrasion. Tinschert et al.40 stated that, the liner application can significantly weaken the bond strength and increase the percentage of interfacial failure between zirconia core and pressable veneer ceramics.

The bonding nature between the liner and zirconia may be mechanical or chemical.6 However, it has been said that the liner material should be air-abraded to reduce chipping of the veneering ceramic.26

Air-borne particle abrasion was found to decrease the percentage of interfacial failure pattern25 because it is able to induce transformation without developing high temperatures or creating severe surface damage.5,14,41 However, air-borne particle abrasion might compromise the mechanical strength of the ceramic by initiating surface defects that can become stress concentration sources, leading to failure.32,33,39 Kosmac et al.31 concluded that air-borne particle abrasion is a gentle process that removes considerably less material from the surface. In spite of lower stresses occurring during air-borne particle abrasion, the thickness of the transformed surface layer was found to be larger than in ground samples, indicating that not only stresses, but also the locally developed temperatures during air-borne particle abrasion were lower. However, Guess et al.17 concluded that surface roughening with 110 µm Al2O3 (2.4 bar) air-borne particle abrasion had no significant effect on the bond strength between core and veneering ceramic. However, Aboushelib et al.29 said that the coreveneer bond strength is affected by surface finish of zirconia core material.

In contrast to the assumption that a rougher surface provides higher bond strength due to a larger surface area for bonding24 the results of the present study showed that surface grinding have a counteracting effect on the shear bond strength, especially in white zirconia group (significant lower SBS value than "as milled" (P=.001) and liner (P=.05) groups). It has been said that grinding can develop high stresses and form severe surface cracks which can lower the strength and reliability of the material.31 The ground surface is characterized by deformed and displaced material at the edge of the scratches, large defects unevenly distributed and micro-cracks (Fig. 3). It is stated that hand grinding is more effective than lapper-machine grinding, and air-borne particle abrasion is more effective than grinding in inducing the T→M transformation.5 But some authors stated that the locally developed temperature in grinding may have exceeded this transformation temperature.31 Kosmac et al.31 stated that air-borne particle abrasion can produces the highest amount of the monoclinic phase and the lowest amount of the monoclinic phase can be obtained after grinding procedure. They concluded that air-borne particle abrasion may be considered as a powerful clinical technique for strengthening Y-TZP. In contrast, grinding may decrease the strength and reliability of prefabricated zirconia elements. According to Kim et al. observations,6 air-borne particle abrasion increases surface roughness and contact surface area and can decrease the percentage of interfacial failure of zirconia and veneering ceramic.

The fracture pattern of the veneer specimens was mainly combined as adhesive at the interface and cohesive in the veneering ceramic (Table 8). These failure modes are comparable to the results of other laboratory studies.17,22,26,35 Guess et al.17 interpreted this finding in two ways: First, crack deflection could be an excellent property of Y-TZP to resist crack propagation. Second, the inter-laminar crack deflection could be related to the poor bonding strength between zirconia and veneering ceramic. They concluded that the chipping of the veneering ceramic is happened more than failure of the core structure in zirconia based restorations. It can be related to the weaker interfacial adhesion and the greater fracture toughness of zirconia that can stop, turn and propagate the cracks along the interface.22

A limitation of this study is that the design and dimensions of the specimens does not fully reflect the clinical situation. Another limitation of this study was using static test in a dry environment that cannot compare it with actual oral environment, which would undergo repeated temperature and pH changes.42 In routine laboratory procedures, layering and firing processes of porcelain are repeated more than in vitro studies. The contraction and expansion that occurs with these repeated procedures result in variable bonding strength.6

Within the limitations of this in vitro study, the following conclusions are made:

1. Type of zirconia does not have any effect on bond strength between zirconia core and veneer ceramic.

2. Surface treatment has different effects on the SBS of the different zirconia types.

3. Grinding dramatically decreases the SBS of white zirconia and veneering porcelain.

Predominant failure modes between zirconia core and the veneer were combined and adhesive failures.

References

1. Barnfather KD, Brunton PA. Restoration of the upper dental arch using Lava all-ceramic crown and bridgework. Br Dent J. 2007; 202:731–735. PMID: 17589454.

2. Coli P, Karlsson S. Precision of a CAD/CAM technique for the production of zirconium dioxide copings. Int J Prosthodont. 2004; 17:577–580. PMID: 15543914.

3. Della Bona A, Mecholsky JJ Jr, Anusavice KJ. Fracture behavior of lithia disilicate- and leucite-based ceramics. Dent Mater. 2004; 20:956–962. PMID: 15501324.

4. Casucci A, Osorio E, Osorio R, Monticelli F, Toledano M, Mazzitelli C, Ferrari M. Influence of different surface treatments on surface zirconia frameworks. J Dent. 2009; 37:891–897. PMID: 19616882.

5. Guazzato M, Quach L, Albakry M, Swain MV. Influence of surface and heat treatments on the flexural strength of Y-TZP dental ceramic. J Dent. 2005; 33:9–18. PMID: 15652163.

6. Kim HJ, Lim HP, Park YJ, Vang MS. Effect of zirconia surface treatments on the shear bond strength of veneering ceramic. J Prosthet Dent. 2011; 105:315–322. PMID: 21530757.

7. Bonfante EA, Coelho PG, Guess PC, Thompson VP, Silva NR. Fatigue and damage accumulation of veneer porcelain pressed on Y-TZP. J Dent. 2010; 38:318–324. PMID: 20026232.

8. Beuer F, Schweiger J, Eichberger M, Kappert HF, Gernet W, Edelhoff D. High-strength CAD/CAM-fabricated veneering material sintered to zirconia copings--a new fabrication mode for all-ceramic restorations. Dent Mater. 2009; 25:121–128. PMID: 18620748.

9. Al-Dohan HM, Yaman P, Dennison JB, Razzoog ME, Lang BR. Shear strength of core-veneer interface in bi-layered ceramics. J Prosthet Dent. 2004; 91:349–355. PMID: 15116036.

10. Fischer J, Stawarczyk B, Hämmerle CH. Flexural strength of veneering ceramics for zirconia. J Dent. 2008; 36:316–321. PMID: 18339469.

11. Sailer I, Fehér A, Filser F, Lüthy H, Gauckler LJ, Schärer P, Franz Hämmerle CH. Prospective clinical study of zirconia posterior fixed partial dentures: 3-year follow-up. Quintessence Int. 2006; 37:685–693. PMID: 17017630.

12. Komine F, Saito A, Kobayashi K, Koizuka M, Koizumi H, Matsumura H. Effect of cooling rate on shear bond strength of veneering porcelain to a zirconia ceramic material. J Oral Sci. 2010; 52:647–652. PMID: 21206169.

13. Fahmy NZ. Bond strength, microhardness, and core/veneer interface quality of an all-ceramic system. J Prosthodont. 2010; 19:95–102. PMID: 20040030.

14. Saito A, Komine F, Blatz MB, Matsumura H. A comparison of bond strength of layered veneering porcelains to zirconia and metal. J Prosthet Dent. 2010; 104:247–257. PMID: 20875529.

15. Vult von Steyern P, Carlson P, Nilner K. All-ceramic fixed partial dentures designed according to the DC-Zirkon technique. A 2-year clinical study. J Oral Rehabil. 2005; 32:180–187. PMID: 15707428.

16. Raigrodski AJ, Chiche GJ, Potiket N, Hochstedler JL, Mohamed SE, Billiot S, Mercante DE. The efficacy of posterior three-unit zirconium-oxide-based ceramic fixed partial dental prostheses: a prospective clinical pilot study. J Prosthet Dent. 2006; 96:237–244. PMID: 17052467.

17. Guess PC, Kulis A, Witkowski S, Wolkewitz M, Zhang Y, Strub JR. Shear bond strengths between different zirconia cores and veneering ceramics and their susceptibility to thermocycling. Dent Mater. 2008; 24:1556–1567. PMID: 18466964.

18. De Jager N, Pallav P, Feilzer AJ. The influence of design parameters on the FEA-determined stress distribution in CAD-CAM produced all-ceramic dental crowns. Dent Mater. 2005; 21:242–251. PMID: 15705431.

19. Aboushelib MN, de Jager N, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Dent Mater. 2005; 21:984–991. PMID: 16085302.

20. Manicone PF, Rossi Iommetti P, Raffaelli L. An overview of zirconia ceramics: basic properties and clinical applications. J Dent. 2007; 35:819–826. PMID: 17825465.

21. Drummond JL, King TJ, Bapna MS, Koperski RD. Mechanical property evaluation of pressable restorative ceramics. Dent Mater. 2000; 16:226–233. PMID: 10762684.

22. Ozkurt Z, Kazazoglu E, Unal A. In vitro evaluation of shear bond strength of veneering ceramics to zirconia. Dent Mater J. 2010; 29:138–146. PMID: 20379023.

23. Chaiyabutr Y, McGowan S, Phillips KM, Kois JC, Giordano RA. The effect of hydrofluoric acid surface treatment and bond strength of a zirconia veneering ceramic. J Prosthet Dent. 2008; 100:194–202. PMID: 18762031.

24. Fischer J, Stawarczyk B, Sailer I, Hämmerle CH. Shear bond strength between veneering ceramics and ceria-stabilized zirconia/alumina. J Prosthet Dent. 2010; 103:267–274. PMID: 20416409.

25. Aboushelib MN, de Jager N, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Dent Mater. 2005; 21:984–991. PMID: 16085302.

26. Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Part II: Zirconia veneering ceramics. Dent Mater. 2006; 22:857–863. PMID: 16376981.

27. Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Part 3: double veneer technique. J Prosthodont. 2008; 17:9–13. PMID: 17931369.

28. Saito A, Komine F, Blatz MB, Matsumura H. A comparison of bond strength of layered veneering porcelains to zirconia and metal. J Prosthet Dent. 2010; 104:247–257. PMID: 20875529.

29. Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Effect of zirconia type on its bond strength with different veneer ceramics. J Prosthodont. 2008; 17:401–408. PMID: 18355163.

30. Curtis AR, Wright AJ, Fleming GJ. The influence of surface modification techniques on the performance of a Y-TZP dental ceramic. J Dent. 2006; 34:195–206. PMID: 16112791.

31. Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater. 1999; 15:426–433. PMID: 10863444.

32. Guazzato M, Proos K, Quach L, Swain MV. Strength, reliability and mode of fracture of bilayered porcelain/zirconia (Y-TZP) dental ceramics. Biomaterials. 2004; 25:5045–5052. PMID: 15109867.

33. Kern M, Barloi A, Yang B. Surface conditioning influences zirconia ceramic bonding. J Dent Res. 2009; 88:817–822. PMID: 19767578.

34. Fischer J, Grohmann P, Stawarczyk B. Effect of zirconia surface treatments on the shear strength of zirconia/veneering ceramic composites. Dent Mater J. 2008; 27:448–454. PMID: 18717175.

35. Al-Dohan HM, Yaman P, Dennison JB, Razzoog ME, Lang BR. Shear strength of core-veneer interface in bi-layered ceramics. J Prosthet Dent. 2004; 91:349–355. PMID: 15116036.

36. Fischer J, Stawarczyk B, Trottmann A, Hämmerle CH. Impact of thermal properties of veneering ceramics on the fracture load of layered Ce-TZP/A nanocomposite frameworks. Dent Mater. 2009; 25:326–330. PMID: 18804856.

37. Chevalier J, Deville S, Münch E, Jullian R, Lair F. Critical effect of cubic phase on aging in 3mol% yttria-stabilized zirconia ceramics for hip replacement prosthesis. Biomaterials. 2004; 25:5539–5545. PMID: 15142736.

38. Ardlin BI. Transformation-toughened zirconia for dental inlays, crowns and bridges: chemical stability and effect of low-temperature aging on flexural strength and surface structure. Dent Mater. 2002; 18:590–595. PMID: 12385900.

39. Fischer J, Stawarczyk B, Sailer I, Hämmerle CH. Shear bond strength between veneering ceramics and ceria-stabilized zirconia/alumina. J Prosthet Dent. 2010; 103:267–274. PMID: 20416409.

40. Tinschert J, Schulze KA, Natt G, Latzke P, Heussen N, Spiekermann H. Clinical behavior of zirconia-based fixed partial dentures made of DC-Zirkon: 3-year results. Int J Prosthodont. 2008; 21:217–222. PMID: 18548959.

41. Guazzato M, Albakry M, Quach L, Swain MV. Influence of surface and heat treatments on the flexural strength of a glass-infiltrated alumina/zirconia-reinforced dental ceramic. Dent Mater. 2005; 21:454–463. PMID: 15826702.

42. Choi BK, Han JS, Yang JH, Lee JB, Kim SH. Shear bond strength of veneering porcelain to zirconia and metal cores. J Adv Prosthodont. 2009; 1:129–135. PMID: 21165268.

Fig. 1

Adjustable Plexiglas mold for condensing the veneering ceramic and prepared specimens for SBS test.

Fig. 2

SEM micrographs of liner application subgroup in colored zirconia group after shear bond strength testing (original magnification × 1000).

Fig. 3

SEM micrographs of ground subgroup in white zirconia group after shear bond strength testing (original magnification × 1000).

Table 4

Two-way ANOVA results on the effects of zirconia, surface treatments, and their interaction on shear bond strength

Table 5

One-way ANOVA results on the shear bond strength values of colored zirconia with the veneering ceramics with different surface treatments

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download