Abstract

In order to create a worker-friendly environment for institutional foodservice, facilities operating with a dry kitchen system have been recommended. This study was designed to compare the work safety and work environment of foodservice between wet and dry kitchen systems. Data were obtained using questionnaires with a target group of 303 staff at 57 foodservice operations. Dry kitchen facilities were constructed after 2006, which had a higher construction cost and more finishing floors with anti-slip tiles, and in which employees more wore non-slip footwear than wet kitchen (76.7%). The kitchen temperature and muscular pain were the most frequently reported employees' discomfort factors in the two systems, and, in the wet kitchen, "noise of kitchen" was also frequently reported as a discomfort. Dietitian and employees rated the less slippery and slip related incidents in dry kitchens than those of wet kitchen. Fryer area, ware-washing area, and plate waste table were the slippery areas and the causes were different between the functional areas. The risk for current leakage was rated significantly higher in wet kitchens by dietitians. In addition, the ware-washing area was found to be where employees felt the highest risk of electrical shock. Muscular pain (72.2%), arthritis (39.1%), hard-of-hearing (46.6%) and psychological stress (47.0%) were experienced by employees more than once a month, particularly in the wet kitchen. In conclusion, the dry kitchen system was found to be more efficient for food and work safety because of its superior design and well managed practices.

The importance of the role of employees in school foodservice operations has been increasing with the growth of the foodservice industry. Thus, interest in improving work environment and work safety during foodservice operation has been on the rise [1,2]. School foodservice workers usually do not only handle food ingredients directly during food production but also serve meals to students. Therefore, their roles in school foodservice operation are vital to food quality and work productivity. However, the working conditions for foodservice employees have only improved slightly when compared to their crucial roles in this industry [3-5]. Most current foodservice facilities operate with a wet kitchen, where its floor is usually covered with water in operation and has designed without consideration on how to keep floor dry or get rid of water quickly in facility design [6]. Besides, the reasons of kitchen floor being wet are several: no consideration in selection of floors materials easy to dry, insufficient drainage provision for dealing in waste water [2,7]. Moreover, according to a study on schools in Gyeonggi-do, the average temperature in the kitchen environment during the middle of food production (around noon) was reported to be 31.5℃ [8]. Also, the kitchen humidity was determined to be as high as 71.6-75.0%, which was significantly higher than the recommended relative humidity (40-70%). This work environment decreases the labor efficiency of employees as well as increases the harmful effects of sanitary food production [9]. These are the reasons why a dry kitchen is recommended. A dry kitchen has special design points that allow the floors to remain dry. The features follow as: sufficient drainages installed for fast elimination of solid water waste, the selection and use of floor materials easy-to-dry, or use of specially designed equipment having a drainage system which prevents its floor from cross-contamination from waste water [2,6,7]. There have been several reported problems with wet kitchen floors. First, this is the potential hazard of falls on slippery floors due to the excessive use of water [2,10]. Second, the hazards associated with an electric leakage via the water in the middle of cleaning floor or operating equipment are increased [2,11]. Finally, these conditions will increase the exhaustion of employees and decrease labor efficiency [2].

However, little work has been performed to examine which factors and workstations are potential hazards to the work safety of wet kitchens even though foodservice facilities in Korea are mostly operated under a wet kitchen system. Furthermore, little research has examined the types and severity of disease related on employees in Korea regardless of the importance of the work environment, which significantly affects food quality, health of employees, and work safety.

Therefore, this study was designed to investigate the work safety and work environment of institutional foodservice in Korea, especially comparing the differences between the wet and dry kitchen system. The specific purposes of this research included analyzing the opinions of dietitians and employees operating in the work environment of foodservice facilities by kitchen types (e.g. wet kitchen and dry kitchens) in terms of workplace design and construction of the kitchen. Second, the perception from dietitians and employees on work safety hazards (e.g. slippery incident, electric leakage) in wet and dry kitchens was analyzed. Finally, the types and frequency of work-related diseases that employees experienced during food production procedures between the two types of kitchen were investigated.

Participants included a total of 303 with 57 dietitians and 246 employees of 57 elementary, secondary school, and business foodservice operations in south region of Gyeonggi Province and Seoul. Dry kitchen facilities (n = 5) in the study were selected and participated by the recommendation of a contract foodservice company which provides a consulting service on designing a dry kitchen facility. The remaining facilities (n = 52) were categorized as the wet kitchen. A questionnaire was used for data collection. The preliminary test was performed using 6 food service operations from February 1 to February 20, 2008. The main survey was conducted from May 20 to July 21, 2008 with the revision on the first version of the questionnaire. The questionnaire was distributed to a total of 365 with 65 for dietitians and 300 for employees in 65 schools and 3 business companies, and collected a total 303 (83.1%) with 57 from dietitians and 246 from employees.

Two types of the questionnaire for dietitians and employees were developed based on previous studies, with slight modifications [7,11,12]. This questionnaire involved analysis of the work life of employees and characteristics of the work environment. The questionnaire for employees consisted of three parts: work environment, work safety, and general characteristics of respondents. As for the opinion of the work environment, the following 7 items were analyzed: the satisfaction level with the work environment, discomfort factors in work, degree of the slipperiness on the floor, the causes of slip by work areas, frequency of slip accident, type of shoes worn (anti-slip shoes or not), and degree of fear of electric leakage. For the section of work safety, the types of diseases experienced in the work were evaluated using a 5-point scale (1 = never, 2 = 1-2/year, 3 = 1-2/6month, 4 = 1-2/month, 5 = 1-2/week), and its severity was tested using a 6-point scale (1 = never, 2 = one day, 3 = a week, 4 = a month, 5 = six month, 6 = over six month). The demographic variables recorded were sex, age, work position, and work experience.

In the questionnaire for dietitians, one more section was added and included the followings 8 items: kitchen type, scale of meals, space of facility, space of functional area, construction cost, floor material, frequency of foodborne disease, and frequency of work safety accidents.

All statistical analyses were conducted with SPSS (Statistical Package for Social Science) for Windows, version 12.0. Percentages, means, standard deviations and frequency were calculated to obtain general information of samples and facilities, work environments and work safety of facilities. Chi-square analysis or t-test was used for comparison of types of kitchen floor (dry/wet) and work positions (dietitian/employee).

Fifty-seven dietitians and two hundred forty-six employees participated in this study. Among the 303 respondents, five (8.8%) dietitians and 25 (10.2%) employees worked in a dry kitchen system and 52 (91.2%) dietitians and 221 (89.8%) employees worked in wet kitchen operations. From the 57 dietitians that responded, two (40%) dietitians were between the age of 25 and 29 years old among the five working in the dry kitchen system and twenty (38.5%) dietitians were the ages from 35 to 39 years old among the 52 dietitians working in the wet kitchen system. Among the employee respondents, 72% worked in a dry kitchen and 90% worked in wet kitchen were the age of 40 and over. For the dry kitchen employees, 60% were cooks, 20% were servers, and 20% washed dishes. Among the wet kitchen employees, 85.5% responded their job as cooking, which indicated that sharing tasks were more common in the wet kitchen than dry kitchen.

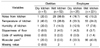

Among the total 57 foodservice facilities, the majorities of elementary schools (91.2%) have wet kitchens and are operated by a self managed system. Meanwhile high school food service operations, which have dry kitchen systems, are managed through contracts with foodservice companies. The number of daily meals (1840 meals) from a dry kitchen was more than that from a wet kitchen (949 meals). The dining area of facilities with a dry kitchen had a mean area of 839.6 m2, which was larger than the mean area of the wet kitchens (313.3 m2). Although the number of seats in the dining area (456 seats) with dry kitchens were greater than those with wet kitchens (247 seats), the cooking area of the dry kitchen (144 m2) was less spacious than the cooking area for the wet kitchen (175 m2).

Regarding the number of outbreaks of food borne disease of 2007, zero cases were reported for the dry kitchens and 0.42 cases were reported for the wet kitchens. Work related accidents occurred in 0.6 of the cases in the dry kitchen and 0.61 of the cases in the wet kitchen, which was not significantly different. Most facilities (75%) with dry kitchen were constructed after 2006 and the majority of facilities (83.3%) with wet kitchen were built before 2005. The building cost of dry kitchen systems is higher than that of the wet kitchen.

The most frequently used materials for finishing the kitchen floor was ceramic tile, quarry tile, or artificial marble (not shown as Table). Only 20% of the dry kitchens and 12.2% of the wet kitchen finished floors were made of non-slip tile. One facility constructed with a dry kitchen used waterproof paint to cover the floor for the prevention of slip accidents.

In the questionnaire, we asked whether kitchen areas were equipped and differentiated by work functions, in that pointing to prevention of cross-contamination and alleviation of work stress. The majority of facilities with wet kitchens were reported to be less equipped for work functions than those with dry kitchens, whereas facilities with dry kitchen were well constructed based on work function. Especially, a pre-preparation area (75.7%), where much water is commonly used, in the wet kitchen was less allocated than those in dry kitchen (100%). Some facilities with wet kitchens were not fully differentiated by work function and not preparation area, convenience room for employee, or shower room was available. (Table 3)

Now that work environments could be varied by the kitchen types, we asked the degree of the satisfaction on work environment. The responses of dietitians for satisfaction with the work environment showed that dietitians who worked in the dry kitchen system were significantly more satisfied (3.8) than those that worked in a wet kitchen system (3.0) (x2-value = 19.498, P < 0.001, not shown as Table). However, the difference between employees that worked in a dry kitchen and wet kitchen were not significantly different.

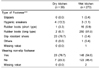

According to the responses of dietitians in Table 4, dietitians indicated that the causes of employees' feeling discomfort during work were kitchen temperature (40%) in the dry kitchen and noise from inside of kitchen (56%) in the wet kitchen. Meanwhile, employees in the dry kitchen reported that kitchen temperature (33.3%) and muscular pain (33.3%) were the major sources of discomfort, while wet kitchen employees reported that muscular pain (43.8%), kitchen temperature (24.2%), and noise of kitchen (19.2%) were the main causes of discomfort.

As shown (a) and (c) in Fig. 1, 40% of dietitians that worked in the dry kitchen reported their kitchen was slippery and 91.8% of wet kitchen dietitians reported that their kitchen was slippery. About 61.5% of dietitians in wet kitchen responded that slip related incidents occurred 1-2 times a year, which was more often than reported in the dry kitchen (x2-value = 9.490, P < 0.01).

Nearly 64% of employees in dry kitchens reported that the kitchen floors were slippery, whereas 79.5% of employees in wet kitchens reported slippery kitchen floors. Employees accounting for 30.4% in the dry kitchen reported "never experienced work related accidents" and 43.5% reported a work related accident "once a year". Meanwhile, 25.2%, of wet kitchen employees responded "never experienced" a work related accident, 39.9% reported an accident once a month and 28.9% responded an accident "once a month".

Interestingly, unlike with the above results, employees working in a dry kitchen perceived that the floors were more slippery in the food preparation area, fryer, refrigerator, and tray-drop and water service area than those in the wet kitchen (P < 0.05). According to the results of the perception rating scores of the slippery area by employees (Table 5), employee that worked in a dry kitchen responded that the degree of slipperiness was in the following order: fryer floor (3.5 points), ware-washing room floor (3.2 points), and table floor of plate waste (3.2 points), meanwhile, employees in wet kitchen rated the degree of slipperiness as follows: fryer floor (4.1 points), gas range floor (3.1 points), and table floor of plate waste (3.1 points).

The causes of slipperiness on the floor were varied by the functional areas. In the pre-preparation area, water was the main cause of slipperiness. But under the fryer, the floor was slippery due to the presence of oil. In the dry kitchen facility, the floors in the pre-preparation area, service area, food storage, dining hall were slippery due to water (100%). However, floors under the fryer (60%) or gas range (14.3%) were slippery because of oil. The cause of slipperiness on the floor under the table of plate waste (83.3%) and gas range (71.4%) was reported to be water and oil.

The types of employee's footwear were reported to be slip resistant shoes (76.7%) and hygienic sneakers (13.3%) in dry kitchen, and as rubber boots of long type (91.9%) and short type (5.9%) in the wet kitchen (Table 6). The result of the x2-test analysis showed significant differences between the wet and dry kitchen (P < 0.001). Employees (76.7%) from the dry kitchen wore non-slip footwear more than those in the wet kitchen (54.6%). Hygienic rubber footwear was mostly used by employees in the wet kitchen for the reason of preventing their feet from being wet. Meanwhile, in the dry kitchen, slip resistant shoes or hygienic sneakers were more often used due to prevent slip-related injuries.

In regards to the concern of an electric leakage incident from water usage by dietitians, worry in the wet kitchen was higher than that in the dry kitchen ((e) and (f) in Fig. 1) and the difference was statistically significant (P < 0.05). Concerns about electrical leakages were also higher for employees who worked in a wet kitchen than those in a dry kitchen, but not showing statistically significant difference. Especially, these concerns were higher for employees who worked in that ware-washing area in the dry kitchen and for those worked in pre-preparation, preparation, or dishwashing area in the wet kitchen.

The types of work-related disease, which occurs during food production, were classified into chemical burn, scratch, dermatitis, itching, cutting, arthritis, headache, difficulty in hearing, and psychological stress in this study (Table 7). According to the dietitians' responses to diseases that employees experienced monthly or weekly, psychological stress was found to be the highest, and all types of diseases except cutting tend to occur highly in the wet kitchen compared to the dry kitchen. Specifically, dietitians in dry kitchens reported that the top work-related disorders occurred as often or very often were scratch/cutting (40%), headache (40%), and psychological stress (40%). Dietitians in wet kitchens also reported that muscular pain (59.6%) was the most frequent disorder occurred as often or more, followed by psychological stress (47.1%), and difficulty in hearing (26.9%). In contrast to the opinion of managers, employees in the dry kitchens reported that bruise/muscular pain (47.8%), psychological stress (40%) and difficulty in hearing (21.7%) were the most frequent work-related diseases occurred often or more. Similarly, employees in the wet kitchen also reported that muscular pain (often 33%, very often 39.2%), psychological stress (often 23.1%, very often 23.6%), difficulty in hearing (often 22.3%, 24.3%) were the most frequent work-related diseases, which were similar to the results reported for the dry kitchen even though the response rate was higher. In short, from the response of dietitian, heat burn, bruise (muscular pain) and scratch cutting showed statistically difference between the two system (P < 0.05). Similarly, at the employees' response, heat burn, bruise (muscular pain) and headache showed statistically significant different between dry and wet kitchen, indicating these type of disease more frequently occurred in wet kitchen than in dry kitchen (P < 0.05).

Continuation of disease can be used as a measure of the degree of disease. In regards to the duration of disease, employees working in a wet kitchen reported a longer duration of disease than those working in a dry kitchen. The difference between dry and wet kitchen was reported in terms of muscular pain, arthritis, difficulty in hearing, and psychological stress. These results also showed that the degree of disease symptom for employees in the wet kitchen was more severe. We found that health hazard aggravation of employees belong to wet kitchen was more serious due to the high frequency and continuation of symptoms.

Generally, kitchen floors in western countries are kept dry by restricting the use of water in floor cleansing, finishing it with materials easy-to-dry, or installing sufficient drainage easy-tohandling waste water [2,10,13]. However, a majority of Korean foodservice settings including restaurants, like others East Asian countries, have wet kitchens, meaning that the floor remains wet and little consideration on keeping its floor dry in facility design [7,13,14]. It was expected that the organization with dry kitchen would be well controlled and improve work safety because the managers are more consciousness of food and work safety [6,9]. Thus, this study examined the status of work safety and work environment in foodservices by comparing dry kitchens and wet kitchens, especially, in terms of the slipperiness and work injuries.

Management and managers in dry kitchen system, rather than wet kitchen, paid more attention to work safety. An article indicated that employees should wear slip resistant shoes to prevent slipping and falling accidents [10]. Non-slip shoes were more frequently worn in dry kitchen facilities than wet kitchen facilities (76.7% in dry kitchen, 54.6% in wet kitchen). In addition, most wet kitchens floors were finished with conventional tiles which are non-resilient and slippery in wet condition. But very few operations, particularly in the dry kitchen, contained non-slip tiles or waterproof paint. Since the floor of a wet kitchen could be more harmful in regards to work safety, the floor should be constructed with slip resistant tiles and kept dry by periodically eliminating water, oil or litter.

On top of that, work environments in the dry kitchen workplaces were more adequately controlled through air conditioning, ventilation system or differentiation of workstation, which improved the comfort of employees. There was a tendency of being functionally less differentiated and equipped and less attentive to work safety and efficiency in wet kitchen. In this study, dietitians reported the main discomfort factor which employee felt in work to be temperature in the dry kitchen and noises or temperature in the wet kitchen. High temperature and humid working environments had been reported as main contributors to fever, prickly heat and skin disease of workers [8]. This result was similar to a previous study that found dry kitchen systems that were well designed in regards to proper temperature and humidity by using ventilation system and air-conditioning units was more pleasant for working [6]. Ministry of Educational Science and Technology stated that the kitchen temperature in school foodservices should be maintained below 22℃ [15]. Nevertheless, the kitchen temperature during elementary foodservice operation was between 26.1℃ and 27.2℃. Moreover, the noise in kitchen was between 70.0-76.8 dB, which was much higher than the standard living value (55-60 dB) [8]. In a study on accidents occurrence in contract foodservice management companies, employees reported that the most important factor for efficient operation of the foodservice was "improvement of high temperature and ventilation in kitchen" [16].

Even though a high temperature in the kitchen was commonly perceived by dietitians and employees, muscular pain was reported to be the most uncomfortable factor during food production by employees, which was not reported by dietitians. These results indicate that dietitians do not exactly understand the causes of discomforts for employees. Therefore, the gaps between the perceptions of dietitians and employees in regards to work safety risk factors should be adjusted. Dietitian should pay more attention to discomfort factors felted by employees during works. Facility design in foodservice greatly impacts work safety, food safety, ease of maintaining and work efficiency [7]. Thus, design principles should be considered by foodservice facilities, including simplicity for efficiency and labor saving, one direction flow of production, and human engineering leading to efficient work should be emphasized in foodservice construction [17].

Slippery incidents were also reported to be more common in wet kitchens than in dry kitchens. Moreover, employees that work in dry kitchen seemed to be more conscious of wet and slippery floors than employees that worked in wet kitchens due to effective slip resistant programs. In this study, the most slippery workstations were determined to be fry area, under gas range, preparation area, and dish-washing area. Causes of slipperiness on the floor varied by functional area. In the case of the dry kitchen facility, the floor in the pre-preparation area, service area, food storage, dining hall were slippery due to water. However, the floor under the fryer or gas range was slippery because of oil. The causes of slipperiness on the floor under table of plate waste and gas range were determined to be water and oil. Thus, for prevention measures, foodservice managers should take into consideration the causes of slipperiness and develop different solutions based on the functional areas. In a case study in Taiwan and the USA, the correlation between the perception rating scores and friction values was determined and both the friction coefficient and perception score of slipperiness were shown to be indicators of the slipperiness of floors [14]. Back vat (0.69), grill (0.69), and sink had significantly lower friction coefficients values, and thus were more slippery than others. In contrast, the front counter (0.77), and fryer area and walk through (0.73) had higher friction coefficients. Similar results were observed in this study.

Lastly, Gregoire and Spears [2] pointed out that most work related accidents were due to human error, severe workloads, leaving spills on the floor [10], blocking the corridor, or leaving greasy stuff on floor. Usually, foodservice workers were exposed to higher workloads, especially at the peak demand for lunch, thanks to the characteristics of high-density and simply repeated work under high temperature and humidity. The top three causes of injuries in institutional foodservices were reported to be "lack of safety awareness of foodservice employees", "aging of facilities and equipment" and "excessive workloads of foodservice employees" in order [18]. In a study on accidents occurrences in contracted foodservice, 38.5% of the injuries occurred in the middle of movement and transportation [16].

Our study showed employees who worked in dry kitchen system suffered less from work related disease than those in wet kitchens. The sort of diseases reported by dietitians were as follows: bruise or muscular pain (59.6%), physical stress (47.1%) of the wet kitchen facilities; scratch (40.0%), headache (40%) of the dry kitchen facilities. Meanwhile, the responses on diseases from employees were bruise or muscular pain (72.2%), arthritis (39.1%), hard-of-hearing (46.6%), physical stress (47.0%) in the wet kitchen and bruise or muscular pain (47.8%) and physical stress (40.0%) in the dry kitchen. This result has two implications. One is that work-related incidents such as bruise/muscular pain, arthritis, hard-of-hearing or physical stress tended to be underreported. Another is that dietitian did not take notice of work related diseases experienced by employees. Dietitians only know the employees' work related disease that had been reported by the employee or in accident cases. However, in real work situations, more occupational injuries from trivial incidents go unreported to management. Therefore, dietitians should periodically communicate with employees about occupational injuries and develop a plan of action to prevent such diseases.

Injury and illness covered by the Indusial Accident Compensation Insurance Act of Korea in education service industry has gradually increased. It reached 35% of the total number of occupational patients [19]. According to the report of the KOSHA, the status of injury and illness in institutional foodservice of educational service sector from the year of 2006 to 2010 was as follows: falls 25% (2,183 persons), burn 21% (1,801 persons), collision 11% (925 persons), musculoskeletal disorder 8% (731 persons), cutting 6% (561 persons) in descending order [19].

Musculoskeletal disease is defined as damage to health due to repeated motion, improper posture, or excessive use of force in certain direction repeatedly [20]. Among manufacturing workers, 71.3% had musculoskeletal symptoms, especially on shoulder and waist [20]. To prevent musculoskeletal disease in work, employees are recommended to stretch their body twice a day at 9:00 AM and 1:00 PM [19-21]. In addition, to prevent slips and falls, proper working practices, such as allocating sufficient aisle space for securing safety passage [7], immediately removing oil, water, or litters from floors after spills [10], keeping the kitchen floor clean and wearing of non-slip shoes [10,22,23] should be implemented in the workplace. Once disaster prevention actions are set, new employees or staff should be educated about the causes of the accidents, the safety procedures, and equipment handling method, etc. If necessary, safety notices or warning signs should be posted in working places [24]. A study showed that the top four time consuming tasks in a restaurant setting were arrangement (17%), cooking (16%), handling before cooking (16%), and cutting (15%). Thus, to prevent these works related occupational diseases, the height and width of worktable should be adjusted for the height of the employees (e.g. the 85 cm of height recommended of the working table). For employees working long hours in a narrow space in a standing posture, an anti-fatigue mat or foot stand should be provided [24].

We conclude that facilities in dry kitchens were better partitioned into functional areas than those in wet kitchens and the managers were more sensitive and attentive to the food and work safety in these facilities. Dry kitchens also had lower numbers of accidents than wet kitchens in terms of occupational disorder experience by employees, risk of electrical short circuits, and incidents of slipperiness. In conclusion, a dry kitchen was found to be more efficient for food safety and work safety because of a better design and managed practices for keeping the floor dry and preventing occupational accidents. Therefore, it is necessary to shift to dry kitchens for the efficient operation of foodservice. Moreover, dietitians must make continuous efforts to improve work environments by identifying potential risks during work through good communications with foodservice workers and developing and implementing plans of action.

Figures and Tables

Fig. 1

Degree of experiencing slip accidents and electric leakage. (A) Degree of slipperiness reported by dietitians, (B) Degree of slipperiness reported by employees, (C) slip accidents reported by dietitians, (D) slip accidents reported by employees, (E) concerns about electric leakage reported by dietitians, and (F) concerns about electric leakage reported by employee. *P < 0.05, **P < 0.01

Acknowledgements

We thank the staff in the participated foodservice facilities for their dedicated supports.

References

1. Ministry of Education and Human Resources Development. Integrated Plans for Improving School Food Services (2007-2011). 2007. Seoul: Ministry of Education and Human Resources Development;5–19.

2. Gregoire MB, Spears MC. Foodservice Organizations. A Managerial and Systems Approach. 2006. 6th ed. Upper Saddle River, NJ: Pearson/Prentice Hall.

3. Lee OS, Lee YM, Oh YJ. A study on the differences of the school foodservice cooks' job satisfactions between dietitian and cooks in Gyeonggi Province. J Korean Diet Assoc. 2007. 13:183–193.

4. Chang HJ, Son HJ, Choi GG. Current status of functional areas' space and suggestion of their equipment requirements for school foodservices in Gyeonggi province. Korean J Food Cookery Sci. 2009. 25:474–487.

5. Jung JW. On kitchen workers' job stress caused by kitchen facilities. Korean J Culinary Res. 2007. 13:263–277.

6. Choi GG. Development of the facility model based on the HACCP and dry kitchen concept for improving sanitary condition of school foodservice establishment [master's thesis]. 2005. Seoul: Yonsei University, Graduate School of Human and Environmental Science.

7. Birchfield JC, Sparrowe RT, Kim TH, Chang HJ, Yoon JH. Design and Layout of Foodservice Facilities. 2004. 2nd ed. Seoul: Sigma Press Co.;59–76.

8. Kim JG, Lee KM. A study on the sanitary condition of kitchens and facilities of school food-service programs in elementary schools-part 2. temperature, humidity, noise and microbiological examination. Korean Public Health Res. 2003. 29:259–268.

9. Ko ES. Effectiveness of the dry kitchen system on the food and work safety in the institutional foodservice [master's thesis]. 2009. Yongin: Dankook University.

10. Howard R. Slip tips. Foodserv Dir. 2004. 17:62.

11. Kwak TK, Rye ES, Lee HS, Rye Kyung, Choi SK, Hong WS, Jang MR, Shin ES, Moon HK, Chang HJ, Park SJ, Choi EH, Lee KE. Institutional Foodservice Operation. 2008. Seoul: Shinkwang Publishing Co.;287–298.

12. Park KO. Work environments and work conditions associated with stress symptoms among Korean manufacturing factory workers. J Environ Health Sci. 2004. 30:272–282.

13. Chang WR, Cotnam JP, Matz S. Field evaluation of two commonly used slipmeters. Appl Ergon. 2003. 34:51–60.

14. Chang WR, Li KW, Huang YH, Filiaggi A, Courtney TK. Objective and subjective measurements of slipperiness in fast-food restaurants in the USA and their comparison with the previous results obtained in Taiwan. Saf Sci. 2006. 44:891–903.

15. Ministry of Education and Human Resources Development [Internet]. School lunch act rules. c2007. cited 2009 July 15. Seoul: Available from: http://likms.assembly.go.kr.

16. Kim OS, Oh SI. Assessment of accidents occurrence and cuisine employees' awareness of workplace safety in contract foodservice management company. J Korean Diet Assoc. 2010. 16:299–317.

17. Jang SH, Chang HJ. A facility design model for 1300 capacity school foodservice with adjacency and bubble diagrams. Korean J Community Nutr. 2011. 16:98–112.

18. Park HR, Moon HK. Dietitians' perceptions of safety supervision in institutional foodservices (1)-status of accidents and assessment of hazards. J Korean Diet Assoc. 2010. 16:318–331.

19. Korea Occupational Safety and Health Agency [Internet]. Prevention of occupational disorder in the educational service sectors. c2010. cited 2012 Feb 2. Seoul: Available from: http://www.kosha.or.kr.

20. Kim SY, Kim HJ, Jeon HJ. Influencing factors on work-related musculoskeletal disorders of women workers. Korean J Occup Health Nurs. 2005. 14:5–15.

21. Alamgir H, Swinkels H, Yu S, Yassi A. Occupational injury among cooks and food service workers in the healthcare sector. Am J Ind Med. 2007. 50:528–535.

22. Pater K. Floor plans. Restaurants and Institutions. 2000. 11:99–100.

23. Oh ST. A study on shoes for culinarian use in the kitchen environment. Korean J Culinary Res. 2009. 15:296–308.

24. Hwang J, Jung MC, Kin H, Jung-Choi K, Bahk J, Lee I. Man-machine system safety : Evaluation of working postures of catering workers in a restaurant. J Korean Soc Saf. 2011. 26:81–88.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download