1. Blatz MB, Sadan A, Kern M. Resin-ceramic bonding: a review of the literature. J Prosthet Dent. 2003; 89:268–274. PMID:

12644802.

2. Derand T, Molin M, Kvam K. Bond strength of composite luting cement to zirconia ceramic surfaces. Dent Mater. 2005; 21:1158–1162. PMID:

16005508.

3. Thompson JY, Stoner BR, Piascik JR, Smith R. Adhesion/cementation to zirconia and other non-silicate ceramics: where are we now? Dent Mater. 2011; 27:71–82. PMID:

21094526.

4. Burke FJ, Fleming GJ, Nathanson D, Marquis PM. Are adhesive technologies needed to support ceramics? An assessment of the current evidence. J Adhes Dent. 2002; 4:7–22. PMID:

12071631.

5. Nagaoka N, Yoshihara K, Feitosa VP, Tamada Y, Irie M, Yoshida Y, Van Meerbeek B, Hayakawa S. Chemical interaction mechanism of 10-MDP with zirconia. Sci Rep. 2017; 7:45563. PMID:

28358121.

6. Okada M, Taketa H, Torii Y, Irie M, Matsumoto T. Optimal sandblasting conditions for conventional-type yttria-stabilized tetragonal zirconia polycrystals. Dent Mater. 2019; 35:169–175. PMID:

30502226.

7. Inokoshi M, De Munck J, Minakuchi S, Van Meerbeek B. Meta-analysis of bonding effectiveness to zirconia ceramics. J Dent Res. 2014; 93:329–334. PMID:

24563487.

8. Özcan M, Bernasconi M. Adhesion to zirconia used for dental restorations: a systematic review and meta-analysis. J Adhes Dent. 2015; 17:7–26. PMID:

25646166.

9. Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Selective infiltration-etching technique for a strong and durable bond of resin cements to zirconia-based materials. J Prosthet Dent. 2007; 98:379–388. PMID:

18021827.

10. Sriamporn T, Thamrongananskul N, Busabok C, Poolthong S, Uo M, Tagami J. Dental zirconia can be etched by hydrofluoric acid. Dent Mater J. 2014; 33:79–85. PMID:

24492116.

11. Chaiyabutr Y, McGowan S, Phillips KM, Kois JC, Giordano RA. The effect of hydrofluoric acid surface treatment and bond strength of a zirconia veneering ceramic. J Prosthet Dent. 2008; 100:194–202. PMID:

18762031.

12. Kim HE, Lim MJ, Yu MK, Lee KW. Changes in bond strength and topography for Y-TZP etched with hydrofluoric acid depending on concentration and temperature conditions. Medicina (Kaunas). 2020; 56:568.

13. Liu D, Tsoi JK, Matinlinna JP, Wong HM. Effects of some chemical surface modifications on resin zirconia adhesion. J Mech Behav Biomed Mater. 2015; 46:23–30. PMID:

25771253.

14. Jevnikar P, Krnel K, Kocjan A, Funduk N, Kosmač T. The effect of nano-structured alumina coating on resin-bond strength to zirconia ceramics. Dent Mater. 2010; 26:688–696. PMID:

20381854.

15. Papia E, Larsson C, du Toit M, Vult von Steyern P. Bonding between oxide ceramics and adhesive cement systems: a systematic review. J Biomed Mater Res B Appl Biomater. 2014; 102:395–413. PMID:

24123837.

16. Wegner SM, Kern M. Long-term resin bond strength to zirconia ceramic. J Adhes Dent. 2000; 2:139–147. PMID:

11317401.

17. Wolfart M, Lehmann F, Wolfart S, Kern M. Durability of the resin bond strength to zirconia ceramic after using different surface conditioning methods. Dent Mater. 2007; 23:45–50. PMID:

16427692.

18. Lim MJ, Yu MK, Lee KW. The effect of continuous application of MDP-containing primer and luting resin cement on bond strength to tribochemical silica-coated Y-TZP. Restor Dent Endod. 2018; 43:e19. PMID:

29765899.

19. Özcan M, Vallittu PK. Effect of surface conditioning methods on the bond strength of luting cement to ceramics. Dent Mater. 2003; 19:725–731. PMID:

14511730.

20. Lee JJ, Kang CK, Oh JW, Seo JM, Park JM. Evaluation of shear bond strength between dual cure resin cement and zirconia ceramic after thermocycling treatment. J Adv Prosthodont. 2015; 7:1–7. PMID:

25722830.

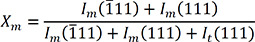

21. Garvie RC, Nicholson PS. Phase analysis in zirconia systems. J Am Ceram Soc. 1972; 55:303–305.

22. Toraya H, Yoshimura M, Somiya S. Calibration curve for quantitative analysis of the monoclinic-tetragonal ZrO2 system by X-ray diffraction. J Am Ceram Soc. 1984; 67:C119–C121.

23. Aboushelib MN, Feilzer AJ, Kleverlaan CJ. Bonding to zirconia using a new surface treatment. J Prosthodont. 2010; 19:340–346. PMID:

20202104.

24. Kosmac T, Oblak C, Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater. 1999; 15:426–433. PMID:

10863444.

25. Sato H, Yamada K, Pezzotti G, Nawa M, Ban S. Mechanical properties of dental zirconia ceramics changed with sandblasting and heat treatment. Dent Mater J. 2008; 27:408–414. PMID:

18717169.

26. Guazzato M, Quach L, Albakry M, Swain MV. Influence of surface and heat treatments on the flexural strength of Y-TZP dental ceramic. J Dent. 2005; 33:9–18. PMID:

15652163.

27. Smielak B, Klimek L. Effect of hydrofluoric acid concentration and etching duration on select surface roughness parameters for zirconia. J Prosthet Dent. 2015; 113:596–602. PMID:

25799283.

28. Kang YJ, Shin Y, Kim JH. Effect of low-concentration hydrofluoric acid etching on shear bond strength and biaxial flexural strength after thermocycling. Materials (Basel). 2020; 13:1409.

29. Subaşı MG, Demir N, Kara Ö, Ozturk AN, Özel F. Mechanical properties of zirconia after different surface treatments and repeated firings. J Adv Prosthodont. 2014; 6:462–467. PMID:

25551006.

30. Lee JH, Lee CH. Effect of the surface treatment method using airborne-particle abrasion and hydrofluoric acid on the shear bond strength of resin cement to zirconia. Dent J (Basel). 2017; 5:23.

31. Yu MK, Lim MJ, Na NR, Lee KW. Effect of hydrofluoric acid-based etchant at an elevated temperature on the bond strength and surface topography of Y-TZP ceramics. Restor Dent Endod. 2019; 45:e6. PMID:

32110535.

32. Attia A. Bond strength of three luting agents to zirconia ceramic - influence of surface treatment and thermocycling. J Appl Oral Sci. 2011; 19:388–395. PMID:

21710091.

33. Ding Q, Zhang L, Bao R, Zheng G, Sun Y, Xie Q. Effects of different surface treatments on the cyclic fatigue strength of one-piece CAD/CAM zirconia implants. J Mech Behav Biomed Mater. 2018; 84:249–257. PMID:

29803139.

PDF

PDF Citation

Citation Print

Print

XML Download

XML Download