1. Oliver T. Dangerous Trades. London, UK: John Murray;1902.

2. Koh DH, Locke SJ, Chen YC, Purdue MP, Friesen MC. Lead exposure in US worksites: a literature review and development of an occupational lead exposure database from the published literature. Am J Ind Med. 2015; 58(6):605–616. PMID:

25968240.

3. McFarland MJ, Hauer ME, Reuben A. Half of US population exposed to adverse lead levels in early childhood. Proc Natl Acad Sci U S A. 2022; 119(11):e2118631119. PMID:

35254913.

4. Kumar S. Occupational and environmental exposure to lead and reproductive health impairment: an overview. Indian J Occup Environ Med. 2018; 22(3):128–137. PMID:

30647514.

5. Navas-Acien A, Guallar E, Silbergeld EK, Rothenberg SJ. Lead exposure and cardiovascular disease--a systematic review. Environ Health Perspect. 2007; 115(3):472–482. PMID:

17431501.

6. World Health Organization. The Public Health Impact of Chemicals: Knowns and Unknowns. Data Addendum for 2019. Geneva, Switzerland: World Health Organization;2021.

7. Wilson N, Horrocks J. Lessons from the removal of lead from gasoline for controlling other environmental pollutants: a case study from New Zealand. Environ Health. 2008; 7(1):1. PMID:

18179712.

8. Maher L, Wolfson S. Growing momentum toward the global elimination of lead paint international collaboration and national engagement. Nat Res Env. 2018; 33(2):12–15.

9. National Minerals Information Center. Minerals Yearbook, Volume III, Area Reports—International. Reston, VA, USA: National Minerals Information Center;2023.

10. Koh DH, Park JH, Lee SG, Kim HC, Choi S, Jung H, et al. Development of Korean CARcinogen EXposure: an initiative of the occupational carcinogen surveillance system in Korea. Ann Work Expo Health. 2021; 65(5):528–538. PMID:

33528514.

11. Koh DH, Park JH, Lee SG, Kim HC, Jung H, Kim I, et al. Development of Korean CARcinogen EXposure: assessment of the exposure intensity of carcinogens by industry. Saf Health Work. 2022; 13(3):308–314. PMID:

36156867.

12. Koh DH, Won J, Ahn YS, Kim HR, Koh SB. Asthma mortality in male workers of the dye industry in Korea. J Occup Health. 2008; 50(2):130–135. PMID:

18403863.

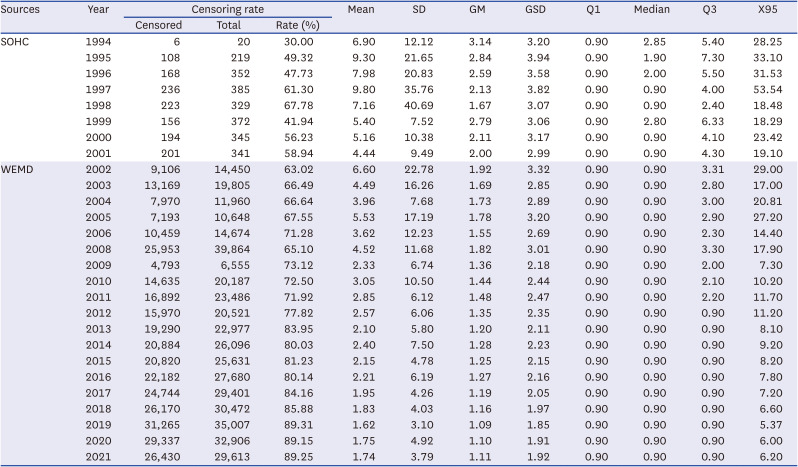

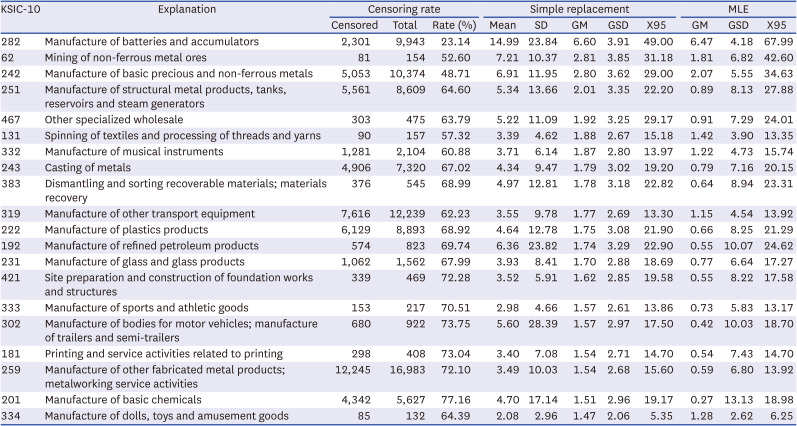

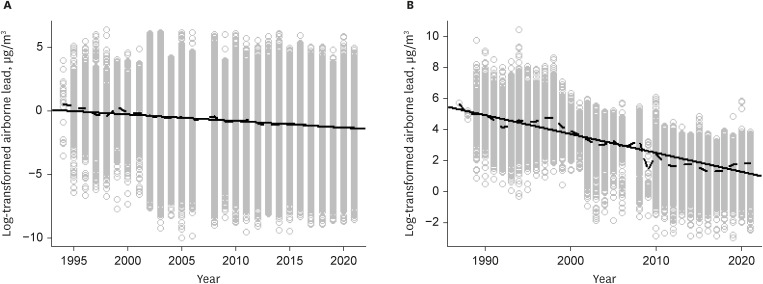

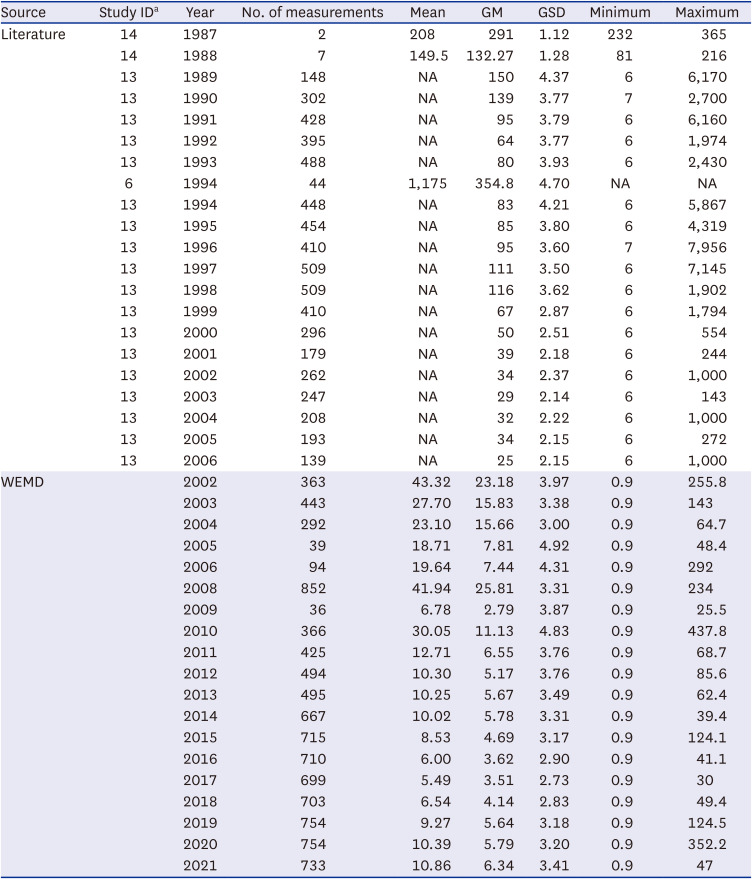

13. Choi S, Seo SC, Park JH, Koh DH, Kim HC, Park D, et al. Evaluation of lead exposure characteristics using domestic occupational exposure literature data. J Korean Soc Occup Environ Hyg. 2022; 32(1):1–9.

14. Park JH, Choi S, Koh DH, Lim DS, Park D, Kim HC, et al. A pilot establishment of the job-exposure matrix of lead using the standard process code of nationwide exposure databases in Korea. Saf Health Work. 2022; 13(4):493–499. PMID:

36579012.

15. Koh DH, Park JH, Lee SG, Kim HC, Choi S, Jung H, et al. Combining lead exposure measurements and experts’ judgment through a Bayesian framework. Ann Work Expo Health. 2017; 61(9):1054–1075. PMID:

29136412.

16. Koh DH, Park JH, Lee SG, Kim HC, Jung H, Kim I, et al. Estimation of lead exposure intensity by industry using nationwide exposure databases in Korea. Saf Health Work. 2021; 12(4):439–444. PMID:

34900362.

17. Hornung RW, Reed LD. Estimation of average concentration in the presence of nondetectable values. Appl Occup Environ Hyg. 1990; 5(1):46–51.

18. Millard SP. EnvStats, an R Package for Environmental Statistics. New York, NY, USA: Springer;2014.

19. Lubin JH, Colt JS, Camann D, Davis S, Cerhan JR, Severson RK, et al. Epidemiologic evaluation of measurement data in the presence of detection limits. Environ Health Perspect. 2004; 112(17):1691–1696. PMID:

15579415.

20. Koh DH, Lee MY, Chung EK, Jang JK, Park DU. Comparison of personal air benzene and urine t,t-muconic acid as a benzene exposure surrogate during turnaround maintenance in petrochemical plants. Ind Health. 2018; 56(4):346–355. PMID:

29643270.

21. Koh DH, Nam JM, Graubard BI, Chen YC, Locke SJ, Friesen MC. Evaluating temporal trends from occupational lead exposure data reported in the published literature using meta-regression. Ann Occup Hyg. 2014; 58(9):1111–1125. PMID:

25193938.

22. Bates D, Maechler M, Bolker B, Walker S. Fitting linear mixed-effects models using lme4. J Stat Soft. 2015; 67(1):1–48.

23. Grund S, Lüdtke O, Robitzsch A. Multiple imputation of multilevel missing data: an introduction to the R package pan. SAGE Open. 2016; 6(4):2158244016668220.

24. Rubin DB. Multiple Imputation for Nonresponse in Surveys. Hoboken, NJ, USA: Wiley;1987.

25. Perperoglou A, Sauerbrei W, Abrahamowicz M, Schmid M. A review of spline function procedures in R. BMC Med Res Methodol. 2019; 19(1):46. PMID:

30841848.

26. Baxter P, Igisu H. Lead. Baxter P, Aw TC, Cockcroft A, Durrington P, Harrington JM, editors. Hunter's Diseases of Occupations. 10th ed. London, UK: Hodder Arnold;2010. p. 188–198.

27. Landrigan PJ, Bellinger D. It's time to end lead poisoning in the United States. JAMA Pediatr. 2021; 175(12):1216–1217. PMID:

34570192.

29. Hamilton A. Exploring the Dangerous Trades: The Autobiography of Alice Hamilton, M.D. Boston, MA, USA: Little Brown;1943.

30. Okun A, Cooper G, Bailer AJ, Bena J, Stayner L. Trends in occupational lead exposure since the 1978 OSHA lead standard. Am J Ind Med. 2004; 45(6):558–572. PMID:

15164400.

31. Koh DH, Bhatti P, Coble JB, Stewart PA, Lu W, Shu XO, et al. Calibrating a population-based job-exposure matrix using inspection measurements to estimate historical occupational exposure to lead for a population-based cohort in Shanghai, China. J Expo Sci Environ Epidemiol. 2014; 24(1):9–16. PMID:

22910004.

32. Kim JH, Kim EA, Koh DH, Byun K, Ryu HW, Lee SG. Blood lead levels of Korean lead workers in 2003-2011. Ann Occup Environ Med. 2014; 26(1):30. PMID:

25379187.

33. Bates D, Pinheiro C. Linear and nonlinear mixed-effects models. In : Proceedings of 1998 - 10th Annual Conference Proceedings. Conference on Applied Statistics in Agriculture; 1988; Manhattan, KS, USA: Kansas State University;1988.

34. Paek D, Park DY. The development and regulation of occupational exposure limits in Korea. Regul Toxicol Pharmacol. 2006; 46(2):126–130. PMID:

16564609.

33. Lee BK. Occupational health management in the lead industry: the Korean experience. Saf Health Work. 2011; 2(2):87–96. PMID:

22953192.

36. Jeong JY, Choi S, Kho YL, Kim PG. Extensive changes to occupational exposure limits in Korea. Regul Toxicol Pharmacol. 2010; 58(2):345–348. PMID:

20709131.

37. Black H. Getting the lead out of electronics. Environ Health Perspect. 2005; 113(10):A682–A685. PMID:

16203230.

38. Wäger PA, Schluep M, Müller E, Gloor R. RoHS regulated substances in mixed plastics from waste electrical and electronic equipment. Environ Sci Technol. 2012; 46(2):628–635. PMID:

22126427.

39. Jang YC. Waste electrical and electronic equipment (WEEE) management in Korea: generation, collection, and recycling systems. J Mater Cycles Waste Manag. 2010; 12(4):283–294.

40. Rezaee M, Esfahani Z, Nejadghaderi SA, Abbasi-Kangevari M, Saeedi Moghaddam S, Ghanbari A, et al. Estimating the burden of diseases attributable to lead exposure in the North Africa and Middle East region, 1990-2019: a systematic analysis for the Global Burden of Disease study 2019. Environ Health. 2022; 21(1):105. PMID:

36309664.

41. Koo BH, Kim YK, Lee SG, Kang DM, Kim JE. Detection of cases and a cause of lead exposure in Korean steel company. Korean J Occup Environ Med. 2012; 24(4):441–448.

42. Park C, Park Y, Oh Y, Choi I, Cha W, Choi S. Comparison of airborne lead concentration in and around lead production plant. J Korean Soc Occup Environ Hyg. 2019; 20(1):34–41.

PDF

PDF Citation

Citation Print

Print

XML Download

XML Download