Abstract

PURPOSE

To evaluate the polishing effect on roughness and color change of pressed and layering ceramics after immersion in coffee solution.

MATERIALS AND METHODS

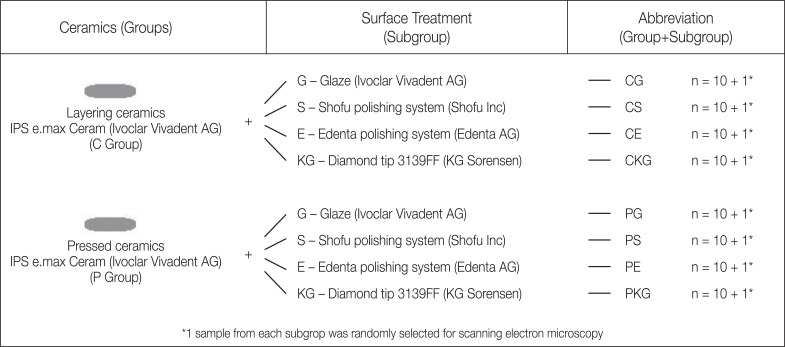

88 ceramic discs (1.0 mm × 10.0 mm) were manufactured - 44 nano-fluorapatite layering ceramics (IPS e.max Ceram. Group C) and 44 pressed lithium disilicate ceramic discs (IPS e. max Press - Group P). Each group was divided into 4 subgroups according to surface treatments: (G) Glaze, (S) Shofu polishing system (Shofu Inc.), (E) Edenta AG polishing System, (KG) 30-µm diamond granulation tip. Surface roughness (Ra) and color change (ΔE) measurings after the surface treatments were performed, before and 12 days after the immersion in coffee solution. A samples' qualitative analysis was conducted with a scanning electron microscopy (SEM). Data were statistically-treated with one-way-ANOVA and Duncan's tests, apart from paired t-test and Pearson's correlation test (α=5%).

RESULTS

The decrescent order, both for surface roughness (Ra) and ΔE for both ceramics were: KG > E > S > G (P<.05). With exception for PG and CG subgroups, which did not present statistical difference between them, all other pressed ceramics subgroups presented smaller Ra values and greater ΔE values than the layering ceramics subgroups (P<.05).

The search for clinical materials that may promote the closest reproduction of optical characteristics to the dental element has increased the demand for ceramic restorations.123 As they present biocompatibility, clinical longevity, color, translucency, and superficial texture similar to dental enamel, the ceramics have become the material of choice in esthetic restorative dentistry.4567

Ideally, after finished in laboratory, the ceramic restorations should not be ajusted during the clinical adaptation, therefore avoiding a loss of brightness and superficial smoothness promoted by glaze application. However, minor esthetic and functional adjustments are common in this phase, and the restricted worn glaze layer may be lost, exposing the rough surface.8910

To minimize the risk of degradation and wear of the ceramic, the wearing of the opposite teeth, biofilm accumulation, gingival irritation, ceramics' stains and fracture, the utilization of polishing systems to adjust surface roughness is required.11121314 Such systems are capable of promoting similar brightness and smoothness to those achieved by the glaze,8101516 improving the ceramics' physical and mechanical properties.

Another very important aspect for the clinical success of ceramic restorations is its color stability.1718 Despite presenting chemical stability,51719 worn restorations due to adjustments and/or polishing may also be subject to color changes, but the use of adequate ceramic compatible polishing materials may reduce the superficial staining possibility.20212223

Several studies have been carried out to evaluate surface roughness2425262728 and color stability of different ceramics.15293031323334 Only a few studies correlate ceramics color change with its roughness after immersion in a pigmenting solution.1121223536 In view of the above, the objective of this study is to evaluate the polishing effect on roughness and the color change of pressed and layering ceramics after immersion in coffee solution. The null hypotheses in this study were: (1) the lithium disilicate pressed ceramics and the nanofluorapatite layering ceramics do not suffer color change after immersion in coffee solution, regardless of received surface treatment, and (2) there is no correlation between the surface roughness and the color change of the different ceramics from this study.

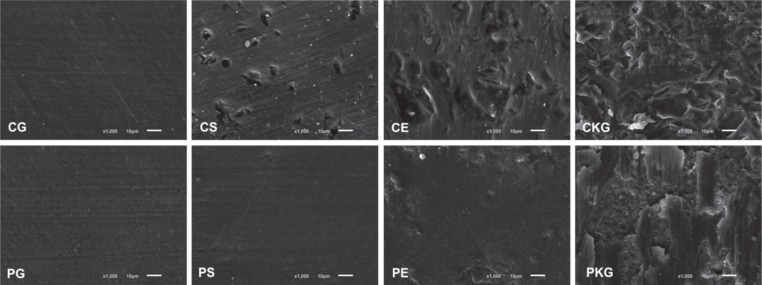

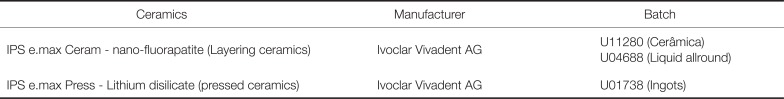

Eighty-eight ceramic discs (1.0 mm × 10.0 mm) were manufactured - 44 nano-fluorapatite vitreous layering ceramics (IPS e.max Ceram-A1 TI 1, Ivoclar Vivadent AG, Schaan, Liechtenstein) and 44 pressed lithium disilicate ceramics (IPS e. max Press - LT A1; Ivoclar Vivadent AG) (Table 1). The samples were randomly distributed into 4 groups according to received surface treatments: (G) Glaze (control) (Ivoclar Vivadent AG), (S) Shofu polishing system (CeraMaster Coarse, Ceramaster, Dura-Polish Dia; Shofu Inc., Ratingen, Germany), (E) Edenta AG polishing System (Ceragloss; Edenta AG, Hauptstrasse, Switzerland), and (KG) diamond granulation tip number 3139FF (KG Sorensen). One sample from each subgroup was randomly selected for SEM (scanning electron microscopy) (Fig. 1).

For the layering ceramics discs manufacturing (C Group), 5 drops of Build-Up Liquid (Ivoclar Vivadent AG, Schaan, Liechtenstein) were added to 200 mg of ceramic powder, which were introduced in a matrix (1.4 mm × 12.0 mm). With calibrated pressure at 1 Kg, the ceramic mass was compressed and the excess humidity was removed with the aid of absorbent paper (Snob; Santher, São Paulo, Brazil). Then, the disc-shaped ceramic mass was removed from the matrix and taken to the oven (EP3000, Ivoclar Vivadent AG, Schaan, Liechtenstein) for curing at final temperature of 770℃, according to the manufacturer's instructions.

The pressed ceramic samples (P Group) were obtained through the lost-wax casting method, according to manufacturer's instructions. With the aid of an acrylic matrix, wax discs (Inowax; Formaden, São José dos Pinhais, Brazil) were cast, included in investment material (IPS PressVest; Ivoclar Vivadent AG, Schaan, Liechtenstein) and placed in the oven (A200; Oga, Belo Horizonte, Brazil) at 850℃ for an hour of wax evaporation. Then, the investment cylinder was taken to the IPS e.max oven system for the injection of lithium disilicate ingots (915 – 920℃). After cooling, the investment was eliminated and the reaction layer was removed with the immersion of the discs into an acid solution for 10 minutes (Invex Liquid; Ivoclar Vivadent AG, Schaan, Liechtenstein), followed by 50 µm aluminium oxide sandblasting (Monojato Gold Line, Essence Dental VH, Araraquara, Brazil).

The samples' surface thickness adjustments were made with silicon carbide sandpapers (#600, #800, #1000, and #1200, NORTON, Guarulhos, Brazil) attached to a politrix (APL-04D; Arotec Indústria e Comércio, Cotia, Brazil) under irrigation. The thickness control and the final standardization of samples were attributed with the assistance of a digital paquimeter (502.150BL, King Tools, Joinville, Brazil) assuring thickness uniformity of 1.0 mm (+/− 0.1 mm) to all samples. Once this step was concluded, glaze was applied (Glaze Paint and Stain Liquid, Ivoclar Vivadent AG, Schaan, Liechtenstein) onto all samples surfaces, according to the manufacturer's instructions.

The Glaze subgroup samples (CG and PG) were not submitted to any other type of surface treatment and were considered as the control groups. The remaining samples received superficial adjustments in one of the sides with the 3139FF diamond tip of 30-µm granulation, at 20,000 rpm under constant digital pressure measurement and water cooling during 30 s, and a new diamond tip was used after every 5 adjusted samples. The KG subgroups (CKG and PKG) consisted of the diamond-tip adjusted discs that did not receive any posterior polishing after the adjustment. Within the S subgroups (CS and PS), the samples had their surfaces polished via Shofy polishing system. Following an abrasive-decrescent order, the CeraMaster Coarse and CeraMaster tips were used under constant digital pressure at 20,000 rpm for 10 s each, followed by the polishing paste (Dura-Polish Dia) and cotton felt polishing at 10,000 rpm/10 s, totalizing 30 s of complete system utilization for each sample. Likewise, in subgroups E (CE and PE), the samples had their surfaces adjusted via Edenta AG polishing system (Ceragloss), through which green tip, followed by blue tip were used at the constant digital pressure of 20,000 rpm/10 s each, followed by the yellow tip at 10,000/10 s; however, without the use of polishing paste, as per manufacturer's instructions. All steps were executed by a single calibrated operator. After surface treatment, the samples were cleaned in an ultrasonic tank (Ultrasonic Washer L100, Schuster, Santa Maria, Brazil) for 180 s, washed under running water for 15 s and dried with absorbant paper (Snob, Santher, São Paulo, Brazil).

The surface roughness (Ra) was verified through a profilometer (Surftest 301/178–928; Mitutoyo, Kawasaki, Japan) with which four readings in different directions were made with evaluation length of 5 mm and range of readings in 0.25 mm, followed by the arithmetic average calculation of the readings. Then, the initial sample color data were registered according to the CIE L* a* b* (Commission Internationale de I'Eclairage) color system. Using a spectrophotometer (Vita Easyshade Advance 4.0, Vita-Zahnfabrik, Bad Säckingen, Germany), 3 readings were made on each sample and the arithmetic average of reading values was calculated for each coordinate (L*, a* and b*). Before color registration of each sample, the device was calibrated according to the manufacturer's instructions.

The samples were placed in plastic recipients with lids and the recipients were filled with coffee solution. For the pigmenting solution preparation, an espresso coffee maker (Nespresso, Nestlé, Lausanne, Switzerland) and intensity 4 coffee capsules were used (Volluto, Nestlé, Lausanne, Switzerland), producing 40 mL of coffee solution per capsule. Then, the samples were immersed in the coffee solution and stored in a incubator (incubator kiln, Qimis, Diadema, Brazil) at 37℃ for 12 days, simulating one year of this beverage consumption.37 To assure homogeneity, the solution was stirred every 3 days with a sterilized metallic spatula (Number 4, Golgran, São Caetano do Sul, Brazil). After 12 days, the samples were removed from the incubator and, with the aid of a sterilized tweezer (clinical tweezer number 317, Golgran, São Caetano do Sul, Brazil), they were washed under running water and dried with absorbent paper (Snob, Santher, São Paulo, Brazil).

Using the same device and under the same conditions, the samples were submitted to final color registration. The ΔE was calculated for the final color analysis, using the following formula ΔE= [(ΔL*)2 + (Δa*)2 + (Δb*)2]1/2. One sample from each subgroup, unsubmitted to the pigmenting agent, was randomly selected for surface qualitative analysis using SEM (scanning electron microscopy) analysis (JSM-6610LV, Jeol, Akishima, Japan).

For statistical analysis, the data was submitted to one-way ANOVA, followed by Duncan's test (surface treatment comparison), t-test (ceramics comparison), and Pearson's correlation test (correlation between color change and surface roughness). The adopted significance level was 5%.

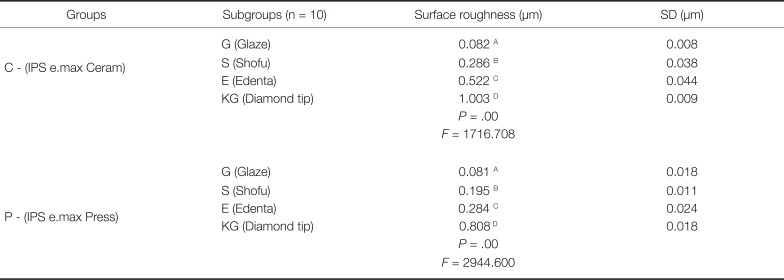

In Table 2, the surface roughness (Ra) mean and standard deviations are expressed in micrometers according to oneway ANOVA and Duncan's Tests (P < .05). The surface treatments interfere in the Ra of all groups (P < .05). The smallest Ra values were found in the subgroups G (Glaze) and the largest values were in KG subgroups (Diamond tip). The S subgroups (Shofu) presented smaller Ra than the ones of E subgroups (Edenta) (CS < CE and PS < PE).

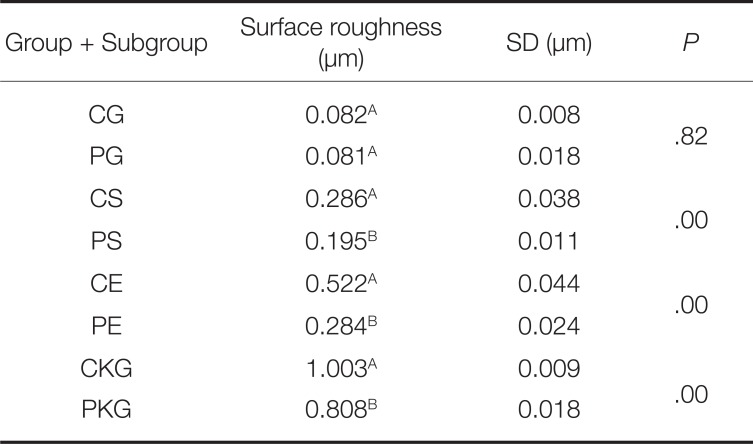

According to the t-test (P < .05), with exception of samples from G subgroups, which presented statistically similar superficial smoothness to C and P, overall Ra values in C were larger than the ones from P, so CS < PS, CE > PE, and CKG > PKG (Table 3).

The SEM images qualitatively illustrate the results found through profilometer testing. In both ceramics, the following increasing roughness order was observed in subgroups: G < S < E < KG (Fig. 2).

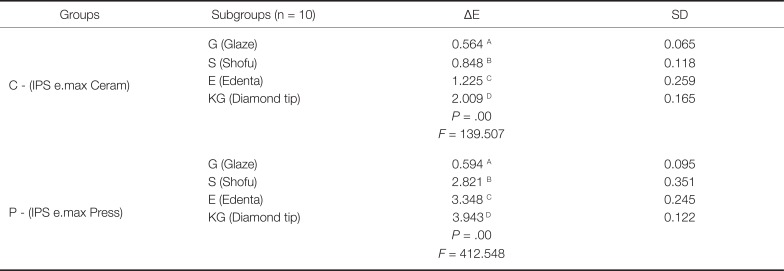

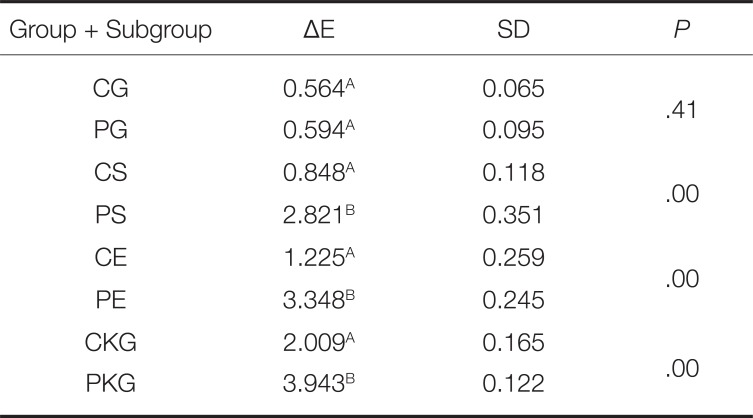

The one-way ANOVA and the Duncan's test for color change (ΔE) mean and standard deviations are described in Table 4 (P < .05). For both C and P, the increasing order of ΔE for the different surface treatments was: G < S < E < KG.

The t-test (P < .05) shows that except in G subgroups, in which no statistically significant differences were found, the ΔE values were higher in P than in C, so PS > CS, PE > CE, and PKG > CKG (Table 5).

In an overall analysis, there was no statistically significant difference between CG and PG (control groups) for any of the analysis (roughness and ΔE) and the lowest values were found within these groups.

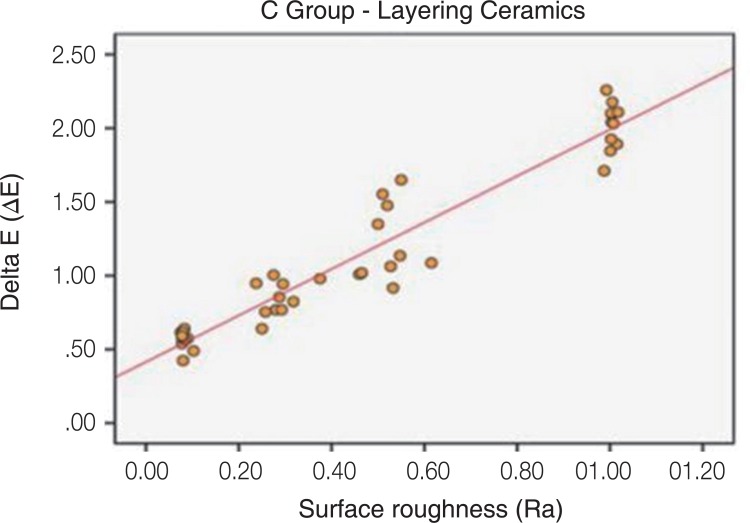

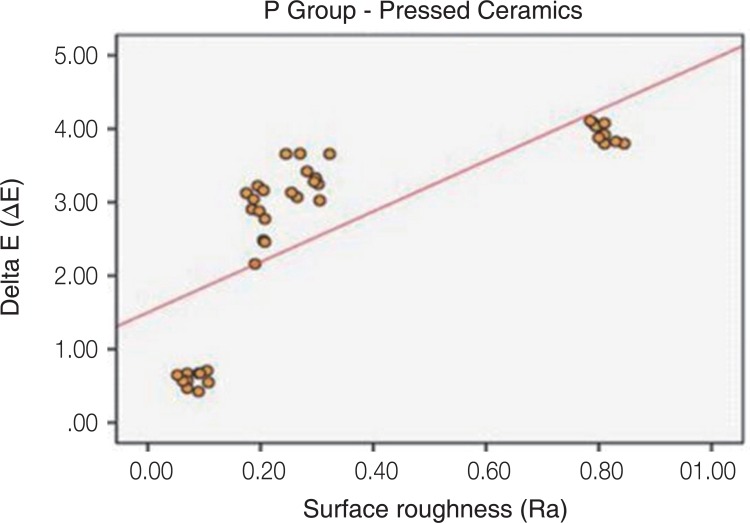

In the present study, the influence of surface treatment on roughness and color change of two commonly used ceramics utilized in dental esthetics was evaluated after immersion in coffee solution. Based on the results of this study, both null hypotheses were rejected, as the samples of both ceramics, when immersed in coffee for 12 days, suffered color changes, regardless of surface treatment received; and in both pressed and layering ceramics, the larger the surface roughness, the larger the observed color change.

The esthetic and functional adjustments made to the ceramic pieces may affect their surfaces resulting in roughness and brightness changes to the previously achieved by the glaze.910 One option to regain lost smoothness and brightness due to adjustments is a new glaze application; however, this process demands time and may result in ceramics color change. To replace this surface treatment, finishing and polishing systems have been used.73839 With the disadvantages of a new glaze, Al-Wahadni and Martin9 and Goldstein et al.40 described that the utilization of diamond tips and abraive rubber might also promote clinically-accepted smoothness.

In laboratorial tests, Manjuran and Sreelal41 stated that the combination of polishing system and polishing paste (Shofu Inc.) produced smoother surfaces than the feldspathic ceramics (Vintage Halo, Shofu Inc.). Sarac et al.24 described that the use of both a polishing system (Shofu Inc.) and the polishing paste (Ultra II, Shofu Inc.) together generated surfaces as smooth as the ones of the feldspathic ceramic glaze (Vitadur Alpha, VITA). Nevertheless, several authors21223042 demonstrated that the polishing systems are less effective than the glaze. This is in accordance with the results obtained in the present study, in which it was verified that both polishing systems (Shofu Inc and Edenta AG) did not promote superficial smoothness similar to the glaze on the tested ceramics (IPS e.max Ceram e IPS e.max Press). All polishing subgroups demonstrated smaller surface roughness than the ones treated only with diamond tips. The SEM images illustrated the ceramic surfaces after the different surface treatments (Fig. 4).

Fuzzi et al.43 reported that the polishing paste offers a slight improvement in the surface brightness and roughness when used after the polishing system. Similarly, Bottino et al.44 affirmed that the polishing paste must be used after polishing rubbers, promoting better results. In this study, one significantly smoother surface could be observed in S subgroups (PS and CS) when compared to E subgroups (PE and CE). All polishing procedures followed the manufacturers' instructions; however, in accordance to some studies,21264243 such findings may be attributed to the probable difference between systems, apart from the polishing paste utilization in S subgroups, in contrast with the non-utilization in E subgroups.

Although several studies have used ΔE as parameters to establish acceptable limits for color change, there still is no consensus in literature regarding the value of ΔE noticed by human eye and may be considered clinically relevant. It is necessary to establish reference values for the evaluation of color change results. Like in previous works, the color changes are considered noticeable when ΔE < 1.0,3045 visually noticeable but clinically acceptable when ΔE > 1.045 and clinically unacceptable when ΔE > 3.5.17

Atay et al.35 described that after 30 days immersion in coffee, the feldspathic ceramic samples (VMK, Vita Zahnfabrik) treated with a polishing system followed by polishing paste (ECOMET-III, Buehler) presented ΔE = 1.1396 and the samples receiving glaze (Vita Zahnfabrik) presented ΔE = 0.9065, values which are considered acceptable by the authors. In this study, it was possible to observe that the nano-fluorapatite ceramics, whose structure resembles the ones of the feldspathic ceramics, presented ΔE = 0.848 and ΔE = 0.564 when polished with a polishing system, followed by polishing paste (CS), and when received glaze as surface treatment (CG), respectively. These values, which are lower than the ones found by Atay et al.,35 could be related to the differences between ceramics, between the polishing systems and, especially between the different coffee solution exposure period.

In the study of Sarikaya and Güler,20 the feldspathic ceramics (VMK 95, Vita Zahnfabrik and Ceramico III, Degudent GmbH) exposed to coffee solution for 48 hours and received glaze presented smaller ΔE values. Although no statistical differences were verified between the polishing systems (NTI CeraGlaze, NTI-Kahla GmbH, Kahla, Germany and Dialite II, Brasseler, Savannah, GA, USA) and the groups that were adjusted with just silicon carbide sandpaper #600, all groups presented ΔE values clinically acceptable by the authors (ΔE < 3.7). In this study, when analyzing the layering ceramics, the subgroups that received glaze also showed the smallest ΔE value. However, the subgroup, whose samples were adjusted only with the diamond tip, presented the greatest ΔE value, and the polishing system subgroups presented intermediate and statistically different values from the other subgroups. Nonetheless, all layering ceramics subgroups presented clinically acceptable ΔE values (ΔE < 3.5).

Motro et al.21 evaluated the effect of surface treatment techniques on nano-fluorapatite ceramics color change applied over lithium disilicate ceramics after immersion in pigmenting solution (coffee). Like in other studies,1120223546 the smaller ΔE value was also found within the glaze group samples (0.596). The ΔE value within the polishing + polishing paste groups (Veramaster Coarse, Ceramaster and Ultra II, Shofu Inc.) was 1.282, and that within the 3-µm diamond tip groups (Komet, Brasseler GmbH & Co KG) was 2.293. The surface roughness test showed a decreasing roughness order: Glaze (0.071 µm) < polishing system + Shofu Inc polishing paste (0.309 µm) < 30-µm diamond tip (1.279 µm). The authors described a strong correlation between the color change and the surface roughness of the nano-fluorapatite ceramics. Similar results of surface roughness analysis and of ΔE and the correlation between color change and surface roughness were found in this study, in which differences were only found in quantitative aspects. This may be explained by the different operators between the studies, both in the polishing execution and in measuring procedures, as the ceramics, the pigmenting solution, the period of immersion, the materials and the polishing techniques were the same.

It may be suggested by this study's results that for smaller changes in color, in view of the pigmenting agent (coffee solution), the best nano-fluorapatite ceramics surface treatment is glazing, and that both the glaze and the Shufu Inc. polishing system promote clinically accepted ΔE for this ceramics. Moreover, different from Motro et al.,21 the ΔE values for the diamond tip subgroup (2.009), as well as the Edenta AG subgroup (1.225), were considered as visually noticeable, but clinically acceptable.

Kursoglu et al.22 correlated surface texture with ceramics staining. They used an identical methodology to the one applied by Motro et al.,21 but with leucite-reinforced vitreous pressed ceramics (IPS Empress Esthetic, Ivoclar Vivadent) as the surface to be treated. They stated that the ΔE found within the IPS e.max Ceram samples in the study by Motro et al.21 were greater than that found within the IPS Empress Esthetic. This fact may be attributed to the porous surface after layering ceramics adjustments, leading to its greater color change, whereas after adjustments, the pressed ceramics presented a dense structure and low porosity, which would lead to a lower coloring degree. However, the present study showed different results. Comparing IPS e.max Ceram layering ceramics and the pressed IPS e.max Press, it could be verified that, with exception of Glaze subgroups (CG and PG) and despite IPS e.max Ceram presenting greater Ra values, the greater ΔE values were found within samples of IPS e.max Press.

It should be highlighted that although surface roughness is the factor associated with ceramic color change, this is not the only cause of staining. One probable explanation for this is that ceramics pigmentation may be associated, not only to extrinsic factors, but also to intrinsic ones.30 The IPS e.max Press has a translucid structure with a different crystalline form from the other ceramics and its reactive level makes it more translucid.47 Moreover, this apparent advantage becomes a disadvantage when associated to pigment molecules impregnation onto its surface, altering luminosity and, therefore, negatively affecting the final restoration color.

More laboratorial studies with different ceramics, thicknesses, pigmenting solutions and periods of immersion, with the objective of understanding the functional behavior and possible clinical implications that encompass the use of different dental ceramics and polishing systems is important, allowing the opportunity to find results that may sustain their indications and ponderations.

Within the limitations of this in vitro study, it may be concluded that the surface roughness influences the color change in both tested ceramics; however, it is not the only factor associated with this change. The Shofu Inc polishing system presented better performance when compared to Edenta AG polishing system, for both ceramics. After adjusted by the 30-µm diamond tip, the IPS e.max Press ceramic presented clinically unacceptable color change (ΔE = 3.943). Thus, the use of adequate polishing materials for each ceramic type may bring aesthetic benefits to restorations.

References

1. Höland W, Rheinberger V, Apel E, Ritzberger C, Rothbrust F, Kappert H, Krumeich F, Nesper R. Future perspectives of biomaterials for dental restoration. J European Ceram Soc. 2009; 29:1291–1297.

2. Bayne SC, Ferracane JL, Marshall GW, Marshall SJ, van Noort R. The evolution of dental materials over the past century: Silver and gold to tooth color and beyond. J Dent Res. 2019; 98:257–265. PMID: 30784370.

3. de Kok P, Pereira GKR, Fraga S, de Jager N, Venturini AB, Kleverlaan CJ. The effect of internal roughness and bonding on the fracture resistance and structural reliability of lithium disilicate ceramic. Dent Mater. 2017; 33:1416–1425. PMID: 29032826.

4. Dalkiz M, Sipahi C, Beydemir B. Effects of six surface treatment methods on the surface roughness of a low-fusing and an ultra low-fusing feldspathic ceramic material. J Prosthodont. 2009; 18:217–222. PMID: 19141045.

5. Kelly JR, Benetti P. Ceramic materials in dentistry: historical evolution and current practice. Aust Dent J. 2011; 56:84–96. PMID: 21564119.

6. Anusavice KJ, Shen C, Rawls HR. Phillips' science of dental materials. 12th ed. St. Louis: Elsevier/Saunders;2012. p. 418–473.

7. Wright MD, Masri R, Driscoll CF, Romberg E, Thompson GA, Runyan DA. Comparison of three systems for the polishing of an ultra-low fusing dental porcelain. J Prosthet Dent. 2004; 92:486–490. PMID: 15523338.

8. Chang CW, Waddell JN, Lyons KM, Swain MV. Cracking of porcelain surfaces arising from abrasive grinding with a dental air turbine. J Prosthodont. 2011; 20:613–620. PMID: 22017480.

9. al-Wahadni A, Martin DM. Glazing and finishing dental porcelain: a literature review. J Can Dent Assoc. 1998; 64:580–583. PMID: 9785688.

10. Rashid H. The effect of surface roughness on ceramics used in dentistry: A review of literature. Eur J Dent. 2014; 8:571–579. PMID: 25512743.

11. Yilmaz C, Korkmaz T, Demirköprülü H, Ergün G, Ozkan Y. Color stability of glazed and polished dental porcelains. J Prosthodont. 2008; 17:20–24. PMID: 17971115.

12. Vichi A, Fonzar RF, Goracci C, Carrabba M, Ferrari M. Effect of finishing and polishing on roughness and gloss of lithium disilicate and lithium silicate zirconia reinforced glass ceramic for CAD/CAM systems. Oper Dent. 2018; 43:90–100. PMID: 29284101.

13. Yuzugullu B, Celik C, Erkut S, Ozcelik TB. The effects of extraoral porcelain polishing sequences on surface roughness and color of feldspathic porcelain. Int J Prosthodont. 2009; 22:472–475. PMID: 20095196.

14. Sarikaya I, Güler AU. Effects of different polishing techniques on the surface roughness of dental porcelains. J Appl Oral Sci. 2010; 18:10–16. PMID: 20379676.

15. Al-Shammery HA, Bubb NL, Youngson CC, Fasbinder DJ, Wood DJ. The use of confocal microscopy to assess surface roughness of two milled CAD-CAM ceramics following two polishing techniques. Dent Mater. 2007; 23:736–741. PMID: 16914192.

16. Mohammadibassir M, Rezvani MB, Golzari H, Moravej Salehi E, Fahimi MA, Kharazi Fard MJ. Effect of two polishing systems on surface roughness, topography, and flexural strength of a monolithic lithium disilicate ceramic. J Prosthodont. 2019; 28:e172–e180. PMID: 28273681.

17. Turgut S, Bagis B. Colour stability of laminate veneers: an in vitro study. J Dent. 2011; 39:e57–e64. PMID: 22101122.

18. Lee YK, Yu B, Lim JI, Lim HN. Perceived color shift of a shade guide according to the change of illuminant. J Prosthet Dent. 2011; 105:91–99. PMID: 21262406.

19. Kelly JR. Ceramics in restorative and prosthetic dentistry. Annual Rev Mater Sci. 1997; 27:443–468.

20. Sarikaya I, Güler AU. Effects of different surface treatments on the color stability of various dental porcelains. J Dent Sci. 2011; 6:65–71.

21. Motro PF, Kursoglu P, Kazazoglu E. Effects of different surface treatments on stainability of ceramics. J Prosthet Dent. 2012; 108:231–237. PMID: 23031729.

22. Kursoglu P, Karagoz Motro PF, Kazazoglu E. Correlation of surface texture with the stainability of ceramics. J Prosthet Dent. 2014; 112:306–313. PMID: 24484857.

23. Sarıkaya I, Yerliyurt K, Hayran Y. Effect of surface finishing on the colour stability and translucency of dental ceramics. BMC Oral Health. 2018; 18:40. PMID: 29534712.

24. Sarac D, Sarac YS, Yuzbasioglu E, Bal S. The effects of porcelain polishing systems on the color and surface texture of feldspathic porcelain. J Prosthet Dent. 2006; 96:122–128. PMID: 16911889.

25. Camacho GB, Vinha D, Panzeri H, Nonaka T, Gonçalves M. Surface roughness of a dental ceramic after polishing with different vehicles and diamond pastes. Braz Dent J. 2006; 17:191–194. PMID: 17262123.

26. Saraç D, Turk T, Elekdag-Turk S, Saraç YS. Comparison of 3 polishing techniques for 2 all-ceramic materials. Int J Prosthodont. 2007; 20:465–468. PMID: 17944333.

27. Boaventura JM, Nishida R, Elossais AA, Lima DM, Reis JM, Campos EA, de Andrade MF. Effect finishing and polishing procedures on the surface roughness of IPS Empress 2 ceramic. Acta Odontol Scand. 2013; 71:438–443. PMID: 22724660.

28. Carrabba M, Vichi A, Vultaggio G, Pallari S, Paravina R, Ferrari M. Effect of finishing and polishing on the surface roughness and gloss of feldspathic ceramic for chairside CAD/CAM systems. Oper Dent. 2017; 42:175–184. PMID: 27723423.

29. Ertan AA, Sahin E. Colour stability of low fusing porcelains: an in vitro study. J Oral Rehabil. 2005; 32:358–361. PMID: 15842245.

30. Samra AP, Pereira SK, Delgado LC, Borges CP. Color stability evaluation of aesthetic restorative materials. Braz Oral Res. 2008; 22:205–210. PMID: 18949304.

31. Niu E, Agustin M, Douglas RD. Color match of machinable lithium disilicate ceramics: effects of foundation restoration. J Prosthet Dent. 2013; 110:501–509. PMID: 24169080.

32. Akar GC, Pekkan G, Çal E, Eskitaşçıoğlu G, Özcan M. Effects of surface-finishing protocols on the roughness, color change, and translucency of different ceramic systems. J Prosthet Dent. 2014; 112:314–321. PMID: 24513427.

33. Niu E, Agustin M, Douglas RD. Color match of machinable lithium disilicate ceramics: Effects of cement color and thickness. J Prosthet Dent. 2014; 111:42–50. PMID: 24210729.

34. Alp G, Subasi MG, Johnston WM, Yilmaz B. Effect of surface treatments and coffee thermocycling on the color and translucency of CAD-CAM monolithic glass-ceramic. J Prosthet Dent. 2018; 120:263–268. PMID: 29551378.

35. Atay A, Karayazgan B, Ozkan Y, Akyil MS. Effect of colored beverages on the color stability of feldspathic porcelain subjected to various surface treatments. Quintessence Int. 2009; 40:e41–e48. PMID: 19626223.

36. Sagsoz O, Demirci T, Demirci G, Sagsoz NP, Yildiz M. The effects of different polishing techniques on the staining resistance of CAD/CAM resin-ceramics. J Adv Prosthodont. 2016; 8:417–422. PMID: 28018558.

37. Guler AU, Yilmaz F, Kulunk T, Guler E, Kurt S. Effects of different drinks on stainability of resin composite provisional restorative materials. J Prosthet Dent. 2005; 94:118–124. PMID: 16046965.

38. Raimondo RL Jr, Richardson JT, Wiedner B. Polished versus autoglazed dental porcelain. J Prosthet Dent. 1990; 64:553–557. PMID: 2090814.

39. Patterson CJ, McLundie AC, Stirrups DR, Taylor WG. Efficacy of a porcelain refinishing system in restoring surface finish after grinding with fine and extra-fine diamond burs. J Prosthet Dent. 1992; 68:402–406. PMID: 1331431.

40. Goldstein GR, Barnhard BR, Penugonda B. Profilometer, SEM, and visual assessment of porcelain polishing methods. J Prosthet Dent. 1991; 65:627–634. PMID: 2051383.

41. Manjuran NG, Sreelal T. An in vitro study to identify a ceramic polishing protocol effecting smoothness superior to glazed surface. J Indian Prosthodont Soc. 2014; 14:219–227. PMID: 25183905.

42. Steiner R, Beier US, Heiss-Kisielewsky I, Engelmeier R, Dumfahrt H, Dhima M. Adjusting dental ceramics: An in vitro evaluation of the ability of various ceramic polishing kits to mimic glazed dental ceramic surface. J Prosthet Dent. 2015; 113:616–622. PMID: 25794914.

43. Fuzzi M, Zaccheroni Z, Vallania G. Scanning electron microscopy and profilometer evaluation of glazed and polished dental porcelain. Int J Prosthodont. 1996; 9:452–458. PMID: 9108746.

44. Bottino MC, Valandro LF, Kantorski KZ, Bressiani JC, Bottino MA. Polishing methods of an alumina-reinforced feldspar ceramic. Braz Dent J. 2006; 17:285–289. PMID: 17262140.

45. Seghi RR, Hewlett ER, Kim J. Visual and instrumental colorimetric assessments of small color differences on translucent dental porcelain. J Dent Res. 1989; 68:1760–1764. PMID: 2600257.

46. Gupta R, Parkash H, Shah N, Jain V. A spectrophotometric evaluation of color changes of various tooth colored veneering materials after exposure to commonly consumed beverages. J Indian Prosthodont Soc. 2005; 5:72–78.

47. Heffernan MJ, Aquilino SA, Diaz-Arnold AM, Haselton DR, Stanford CM, Vargas MA. Relative translucency of six all-ceramic systems. Part II: core and veneer materials. J Prosthet Dent. 2002; 88:10–15. PMID: 12239473.

Fig. 2

Scanning electron microscopy (× 1,000) of layering ceramics (C Group) and pressed ceramics (P Group) after different surface treatments: (G) Glaze, (S) Shofu Inc polishing system, (E) Edenta AG polishing system and (KG) 30 µm diamond tip.

Fig. 3

Pearson correlation analysis. Graph of dispersal between the surface roughness (Ra) and the color change (ΔE) in Group C.

Fig. 4

Pearson correlation analysis. Graph of dispersal between the surface roughness (Ra) and the color change (ΔE) in Group P.

Table 1

Data on the ceramics systems used in this study

Table 2

Mean and standard deviations on surface roughness (Ra) expressed in µm in the comparison between the different surface treatments

Table 3

Mean and standard deviations on surface roughness (Ra) expressed in µm in the comparison between the two ceramics submitted to the same surface treatments

| Group + Subgroup | Surface roughness (μm) | SD (μm) | P |

|---|---|---|---|

| CG | 0.082A | 0.008 | .82 |

| PG | 0.081A | 0.018 | |

| CS | 0.286A | 0.038 | .00 |

| PS | 0.195B | 0.011 | |

| CE | 0.522A | 0.044 | .00 |

| PE | 0.284B | 0.024 | |

| CKG | 1.003A | 0.009 | .00 |

| PKG | 0.808B | 0.018 |

Table 4

Means and SD of color change (ΔE)

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download