Abstract

PURPOSE

The purpose of this study was to evaluate the effect of two coloring liquids (aqueous and acid-based coloring liquids) and the position of multilayered zirconia on the flexural strength of multilayered zirconia.

MATERIALS AND METHODS

The multilayered zirconia specimens were divided into upper and lower positions. The specimens were divided into three subgroups (n=10): non-shaded, acid-based coloring liquid, and aqueous coloring liquid. The specimens were cut using a milling machine and were immersed in either a acid-based coloring liquid or aqueous coloring liquid 2 times for 5 seconds. The specimens were sintered in a sintering furnace according to the manufacturer's introduction. The flexural strength of the specimen was measured using a universal testing machine and the surface of the specimen was observed using a field emission scanning electron microscope.

RESULTS

The flexural strength of multilayered zirconia was 400 – 500 MPa. There was no statistically significant difference among all groups (P>.05).The flexural strength of the multilayered zirconia was not influenced by the kind of coloring liquid used (P>.05). The flexural strength of the multilayered zirconia colored with the coloring liquids was not influenced by its position (P>.05).

Among various dental materials, zirconia has recently attracted much attention because of its high strength and excellent mechanical properties. In addition, zirconia has been applied to various fields of dentistry due to the development of computer-aided design and computer-aided manufacturing (CAD/CAM) systems. The initially used white zirconia blocks were stabilized tetragonal zirconia prepared by adding 3 mol% yttrium to pure zirconia powder.12 White zirconia has been used only as a core for veneer ceramics because it could not reproduce natural hues with high opacity and low saturation.3 However, failure due to the thermal expansion coefficient difference between the two materials has often been reported.456 As an alternative to this, monolithic or full-contour zirconia restorations have been developed and commercialized.7

The monolithic zirconia restorations showed a high strength with a thin thickness, but have been not used in the anterior region but only in the posterior crown due to their optical properties.7 However, several coloring techniques89 and a variety of zirconia blocks such as a high-translucency monolithic zirconia block1011 and a multilayered zirconia block1213 have been introduced and the applications of monolithic zirconia have been expanded.14

Methods of imparting color to zirconia blocks include additive techniques and painting techniques.1516 In the additive techniques, metal oxides or other materials capable of reproducing a color are added in the process of forming the zirconia powder, and after pressing zirconia powder, the resultant colored zirconia block is presintered. The painting techniques are a method of directly dipping zirconia into coloring liquids, or applying coloring liquids to zirconia with a brush to obtain a desired color. The coloring liquids used in the painting techniques include acid-based coloring liquids that contain a strong aqueous hydrogen chloride solution, which impart the color via an acid-based reaction, and aqueous coloring liquids that do not contain an acid component.17

Transparency is an important criterion in the selection of materials and is the main factor affecting esthetics.1112 High-transparency zirconia has been introduced with properties superior to those of the opaque monolithic zirconia. High-transparency zirconia blocks have been produced by increasing the content of the transparent yttria powder to more than 7 wt% or by decreasing the particle size.18 As the content of yttria increases, the cubic phase in the zirconia increases, resulting in the higher translucency.1920 Different manufacturers prepare high-transparency zirconia blocks using different powder blending ratio, sintering temperature, molding method, and other factors.11 The development of high-transparency zirconia blocks has extended the application of single zirconia restorations to both the anterior and posterior regions.19

Recently, various multilayered zirconia materials have been introduced to improve the color of monolithic zirconia. The multilayered zirconia block has transparency and color similar to those of natural tooth, and has various color layers corresponding to the enamel and dentin in the block itself. It has various color layers corresponding to the incisal layer to the cervical layer similar to the natural tooth.20 There are two methods for manufacturing a multilayered zirconia block: immersing in coloring liquids and adjusting the ratio of constituent components' contents.

The method of immersing in coloring liquids includes two techniques: manufacturing a zirconia block using a coloring liquid with adjustable brightness/saturation21 and manufacturing a zirconia block by varying the absorption rate of the coloring solution by varying the particle size of the zirconia layer.22 Further, the content ratio of constituent components can be adjusted via four methods: manufacturing a multilayered zirconia block by adjusting the content of yttrium oxide23; manufacturing a multilayered zirconia block by adjusting white zirconia-based powder/colored zirconiabased powder content24; manufacturing a block having various light transmittance values, colors, and strengths by varying the content of zirconia powder, rare earth raw material (yttrium oxide powder), and colorant powder25; manufacturing a zirconia block with improved light transmittance by selectively controlling the content ratio of yttria and the color component and by adding alumina.26

Previous studies have reported that coloring liquids affected the mechanical properties of zirconia.9272829 Hjerppe et al.27 reported that dipping white zirconia in a coloring liquid had a negative effect on the flexural strength of the specimen. Orhun9 reported that prolonged immersion of zirconia in a coloring liquid negatively affected the fracture load of the monolithic zirconia. Nam and Park29 reported that applying aqueous and acid-based coloring liquids to monolithic zirconia resulted in a decrease in the hardness value only in the case of specimens painted with acid-based coloring liquids. Ban et al.28 reported that the flexural strength and fracture toughness of zirconia, Cercon base (white ziconia), ZENOSTAR Pure and Zirkonzahn Prettau (monolithic zirconia), were lowered when Er and Nd ions were included in the coloring liquids. On the other hand, Sedda et al.30 reported that the coloring liquids had no effect on the flexural strength of zirconia, In-Ceram YZ (monolithic zirconia) and In-Ceram YZ Color LL1p (preshaded monolithic zirconia). In addition, Kong et al.31 reported that there was almost no difference in flexural strength between specimens formed by immersing shaded high-transparency zirconia in two acid-based coloring liquids with different pH. However, to our knowledge, no study has considered the effects of the coloring liquid on multilayered zirconia.

Further, previous studies have shown that the zirconia strength decreases with increasing transparency.3103233 In the studies of Muñoz et al.33 and Carrabba et al.,10 there was a negative correlation between transparency and flexural strength, and with increasing yttria content in the zirconia block, the flexural strength decreased. Pereira et al.3 also reported that the higher the transparency, the lower the flexural strength of multilayered zirconia. In addition, Park32 compared the fracture strengths of multilayered zirconia, nonpreshaded monolithic zirconia, and preshaded monolithic zirconia. Although the strength of multilayered zirconia was the lowest, it was reported that sufficient flexural strength was obtained with acceptable occlusal force at the posterior portion.

However, there is no study on the effect of coloring liquids on the strength of multilayered zirconia. The purpose of this study was to evaluate the effect of the two coloring liquids (aqueous and acid-based coloring liquids) and the position of multilayered zirconia on the flexural strength of multilayered zirconia. The first null hypothesis was that the coloring liquids do not affect the flexural strength of the multilayered zirconia. The second null hypothesis was that the flexural strength of multilayered zirconia does not vary depending on the position.

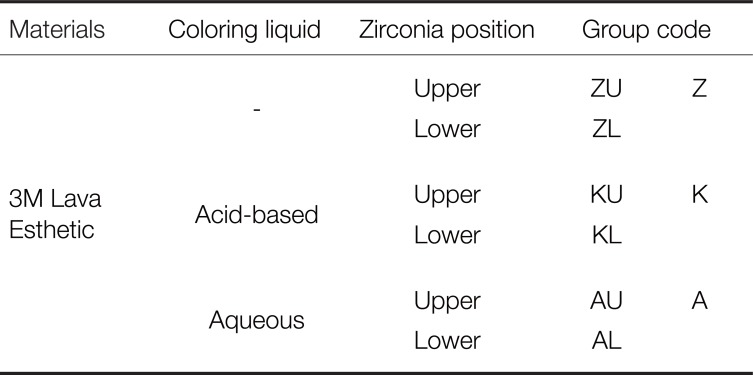

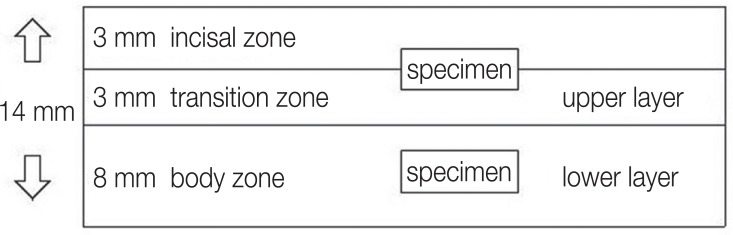

In this study, specimens were fabricated using multilayered zirconia blocks A3 (3M Lava Esthetic, 3M Deutschland GmbH, Germany, Lot No. 669633) with 5 mol% yttria as stabilizer. The size of the multilayered zirconia specimen used in the flexural strength test was selected according to the ISO 6872: 2015 standard.34 The specimens were designed using CAD software (Auto CAD 2006, Autodesk, Mill Valley, CA, USA) and specimens were cut using a milling machine (Roland DWX-52D, Roland, Hamamatsu, Japan) by considering the shrinkage percentage of the green-stage zirconia blocks. Specimens were prepared by dividing the multilayered zirconia block into upper and lower layers. The upper layer is where the incisal part of the restorations is located, and the lower layer is where the cervical part of the restorations is located (Fig. 1). The size of all specimens was measured using vernier calipers (Digimatic Caliper, Mitutoyo, Kawasaki, Japan) and polished with #1,000 grit SiC paper to a final size of 25 × 4.2 × 1.2 mm. A total of 60 specimens were divided into 6 groups (n = 10) (Table 1). The specimens were immersed in A3 acid-based (Ko's Liquid, Kuwotech, Gwangju, Korea) and aqueous coloring liquids (Colour Liquid for Prettau® Aquarell, Zirkonzahn, Italy Lot No. CB4484) 2 times for 5 seconds. After immersion, all specimens were dried in an oven at 150℃ for 15 minutes. The dried specimens were sintered in a sintering furnace (LHT 02/17 / LB, Nabertherm, Lilienthal, Germany) according to the schedule specified by the manufacturer. The temperature was raised at a rate of 20℃/min to 800℃ and then at a rate of 10℃/min to 1,500℃. The specimens were sintered for 2 hours at 1,500℃, after which the temperature decreased at a rate of 15℃/min to 800℃ and then at a rate of 20℃/min to 250℃ and were slowly cooled to room temperature. The specimens of the control group were sintered without being immersed in the coloring liquids.

A universal tester (STM-5; United Calibration Corporation, Fullerton, CA, USA) was used to measure the flexural strength of the multilayered zirconia specimens. The specimens were placed at the center of the support with a width of 20 mm and the load was applied vertically at the center of the specimen with a crosshead speed of 1 mm/min until the specimen was fractured. The average value was considered to be the flexural strength of the specimens. The maximum load (fracture load) was recorded in Newton, and the flexural strength (σ) was calculated as follows in megapascal:

where P is the applied load (in N), l is the test interval (in mm), w is the width of specimen (in mm), and b is the thickness of the specimen (in mm).

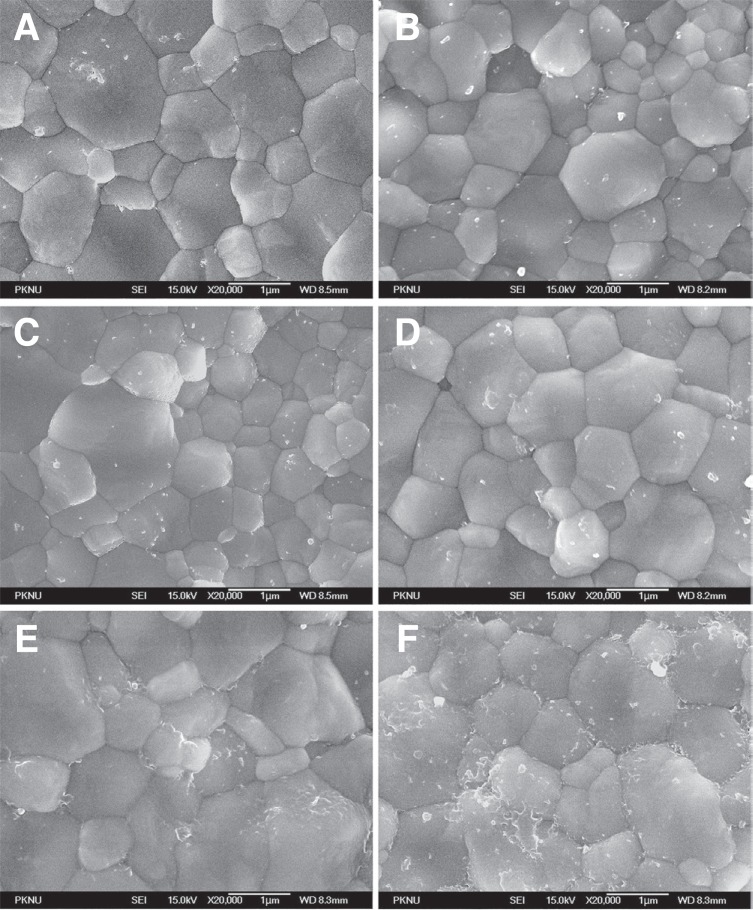

In order to observe the effect of the coloring liquids, each specimen of 6 groups was immersed in an 80% alcohol solution and ultrasonically cleaned for 3 minutes. The surface was coated with osmium as a Pure Osmium Coster (NEOC, Meiwafosis, Japan), and then, the surface was analyzed using a field emission scanning electron microscope (JSM-6700F, JEOL, Tokyo, Japan). A one way analysis of variance (ANOVA) and a two way ANOVA were performed using the software (SPSS v.25.0, SPSS Inc., Chicago, IL, USA) to test the statistical significance of the test results. Post-test Scheffe test was performed for multiple comparisons (α = .05).

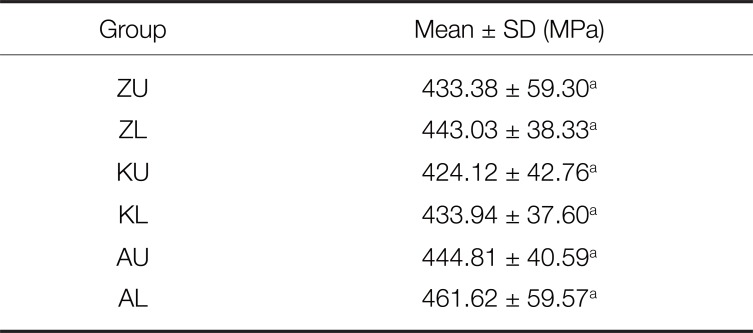

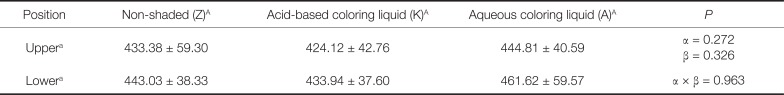

Table 2 shows the results of the flexural strength of the multilayered zirconia specimens according to the application of the coloring liquids. The flexural strength of multilayered zirconia was 400 – 500 MPa. There was no statistically significant difference among all groups (P > .05). The flexural strength of the multilayered zirconia did not show significant differences among the coloring liquids (P > .05) (Table 3). The flexural strength of the multilayered zirconia did not show significant differences between the positions (P > .05) (Table 3).

Further, the changes in the multilayered zirconia specimens as a result of the coloring liquid application were observed by field scanning electron microscopy (Fig. 2). The microstructure of the zirconia specimen was isotropic. In the specimen to which the aqueous coloring liquid was applied, a coloring liquid was absorbed and a surface was similar to that of the control. On the other hand, it was observed that the coloring liquid remained partially on the surface of the specimen to which the acid-based coloring liquid was applied. Further, no significant change in the grain size with the application of a coloring liquid was observed.

There was no statistically significant difference in the flexural strength among the coloring liquids. Therefore, the first null hypothesis that coloring liquid applications would not affect the flexural strength of zirconia was confirmed.

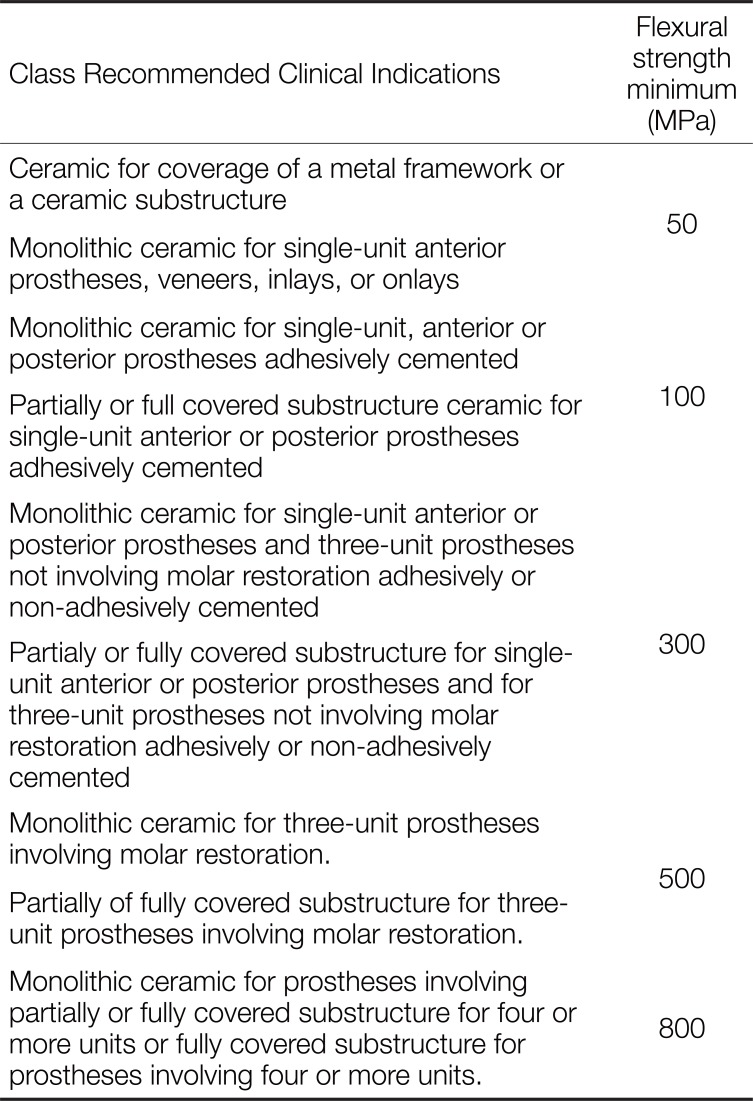

There was no statistically significant difference in the flexural strength between the positions, so a second null hypothesis that zirconia flexural strength did not differ according to the position was confirmed. In all specimens, the flexural strength was between 400 and 500 MPa, which is higher than 300 MPa, so according to ISO 6872:2015 (Table 4),34 the flexural strength is acceptable for the monolithic ceramic for single-unit anterior or posterior prostheses and three-unit prostheses not involving molar restoration.

Sedda et al.30 compared the flexural strengths according to the coloring techniques: monolithic zirconia blocks, preshaded monolithic zirconia blocks, and zirconia blocks immersed in coloring liquid. Their results showed that there was no significant difference among the groups and that the coloring liquid did not affect the flexural strength of the zirconia. Further, Kong et al.31 compared three-point flexural strength of the pre-shaded high-translucency zirconia treated with coloring liquids having a pH of 3.8 and 5.6. The specimens immersed in the pH of 5.6 liquid showed a higher flexural strength than that treated with the other liquid, but no significant difference in the flexural strength was observed. The results of our study are consistent with the findings of Sedda et al.30 and Kong et al.31 in that the coloring liquid did not affect the flexural strength of zirconia.

On the other hand, Orhun9 and Hjerppe et al.27 reported that coloring liquid application and increasing coloring time decreased the strength of zirconia. Ban et al.28 reported that most of the crystal phase of the zirconia colored with coloring liquid containing Er and Nd ions was cubic, resulting in lower flexural strength and fracture toughness. Nam and Park29 reported that the hardness of the monolithic zirconia treated with the acid-based coloring liquid was significantly lower than that of the zirconia treated with the aqueous coloring liquid. It was also observed that the former had a surface covered with the coloring liquid component that was not completely absorbed between the crystal grains. In this study, it was also observed that in the specimens treated with the acid-based coloring liquid (with the low flexural strength), the coloring liquid remained on the surface and was not completely absorbed into the crystal grains of zirconia.

Pereira et al.3 and Park32 reported that the grain size affected the strength of multilayered zirconia. Park32 compared the fracture strengths of multilayered zirconia, non-pre-shaded monolithic zirconia, and pre-shaded monolithic zirconia. Non-shaded monolithic zirconia showed the highest fracture strength and multilayered zirconia showed the lowest strength. This was because the grains of untreated zirconia were small and this had a positive effect on the fracture strength. Pereira et al.3 studied the flexural strength of multilayered zirconia blocks with different transparency: ML (high-translucent), STML (super-translucent), UTML (ultra-translucent). ML with the lowest transparency showed the highest strength of 889 MPa, STML showed 507 MPa, and UTML with the highest transparency showed the lowest strength of 470.2 MPa. STML and UTML had an yttrium oxide content of 8.15% and 9.32%, and these showed fully stabilized crystal structures in the tetragonal and cubic phases, while ML contained 5.66 wt% yttrium oxide and was mainly composed of tetragonal crystals. ML had the highest strength because zirconia grains were denser than those in UTML and STML. In this study, the grain size did not change with the coloring liquid applications, which seems to be related to the lack of significant difference in the flexural strength.

Zirconia exists in three phases depending on the temperature. As the temperature increases, it has a monoclinic phase up to 1,170℃ at room temperature, a tetragonal phase up to 2,370℃, and a cubic phase above 2,370℃. However, when zirconia is allowed to remain at a low temperature for a long period of time in moisture, or when cracks are generated by external stimuli during the cooling process, zirconia mechanical properties begin to deteriorate. At this time, the tetragonal to monoclinic phase transition occurs, and yttria is added as a stabilizer to suppress the phase transition.35

Previous studies have reported that the strength of zirconia blocks containing yttria are much lower.1033 Muñoz et al.33 reported that as zirconia contains more yttria, grain size was larger and transparency was higher, but biaxial flexural strength decreased. Carrabba et al.10 also compared the three-point flexural strength of zirconia containing 3 mol% and 5.5 mol% yttria. The latter presented a lower flexural strength. That is, as the content of yttria was increased, the flexural strength of zirconia decreased. Denry et al.1 reported that the flexural strength of white zirconia containing 3 mol% yttria as a stabilizer (3Y-TZP) was 800 – 1,000 MPa. In the case of conventional white 3Y-TZP, 3 mol% yttria was added as a stabilizer, but the multilayered zirconia used in this study was composed of 5 mol% yttria. In this study, the flexural strength of multilayered zirconia was 400 – 500 MPa, which was similar to that reported by Pereira et al.3 This decrease in the flexural strength was thought to be due to an increase in the yttria content.1033

The color of the coloring liquid and multilayered zirconia used in this study was A3, the most commonly used coloring liquid in clinical practice. In preliminary experiments, multilayered zirconia specimens were divided into upper, middle, and lower positions because the multilayered zirconia block used in this study consists of 3 layers: incisal zone, transition zone, body zone. There was no difference in flexural strength between the upper and middle positions. In this study, multilayered zirconia specimens were divided into upper and lower parts. In this study, the effect of the coloring liquid and zirconia position on the flexural strength of one kind of multilayered zirconia was investigated. However, it is necessary to investigate mechanical properties such as compressive strength and hardness through various strength tests as well as to analyze the flexural strength of various multilayered zirconia blocks. In addition, the influence of the components on the zirconia strength by analyzing the components of the coloring liquids in multilayered zirconia has to be investigated. Further, analysis of the penetration depth of the coloring liquids in the multilayered zirconia and color and transparency change due to the coloring liquid application is also necessary.

Within the limits of this study, the following conclusions were obtained. The flexural strength of the multilayered zirconia specimen according to the coloring liquid application was 400 – 500 MPa to be acceptable for the monolithic ceramic for single-unit anterior or posterior prostheses and three-unit prostheses not involving molar restoration. The coloring liquid application did not reduce the flexural strength of multilayered zirconia of all position.

References

1. Denry I, Kelly JR. State of the art of zirconia for dental applications. Dent Mater. 2008; 24:299–307. PMID: 17659331.

2. Tholey MJ, Berthold C, Swain MV, Thiel N. XRD2 micro-diffraction analysis of the interface between Y-TZP and veneering porcelain: role of application methods. Dent Mater. 2010; 26:545–552. PMID: 20223513.

3. Pereira GKR, Guilardi LF, Dapieve KS, Kleverlaan CJ, Rippe MP, Valandro LF. Mechanical reliability, fatigue strength and survival analysis of new polycrystalline translucent zirconia ceramics for monolithic restorations. J Mech Behav Biomed Mater. 2018; 85:57–65. PMID: 29857261.

4. Aboushelib MN, de Jager N, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Dent Mater. 2005; 21:984–991. PMID: 16085302.

5. Juntavee N, Dangsuwan C. Role of coefficient of thermal expansion on bond strength of ceramic veneered yttrium-stabilized zirconia. J Clin Exp Dent. 2018; 10:e279–e286. PMID: 29721230.

6. Saito A, Komine F, Blatz MB, Matsumura H. A comparison of bond strength of layered veneering porcelains to zirconia and metal. J Prosthet Dent. 2010; 104:247–257. PMID: 20875529.

7. Ozkurt-Kayahan Z. Monolithic zirconia: A review of the literature. Biomed Res. 2016; 27:1427–1436.

8. Kim HK, Kim SH, Lee JB, Ha SR. Effects of surface treatments on the translucency, opalescence, and surface texture of dental monolithic zirconia ceramics. J Prosthet Dent. 2016; 115:773–779. PMID: 26809221.

9. Orhun E. The effect of coloring liquid dipping time on the fracture load and color of zirconia ceramics. J Adv Prosthodont. 2017; 9:67–73. PMID: 28243394.

10. Carrabba M, Keeling AJ, Aziz A, Vichi A, Fabian Fonzar R, Wood D, Ferrari M. Translucent zirconia in the ceramic scenario for monolithic restorations: A flexural strength and translucency comparison test. J Dent. 2017; 60:70–76. PMID: 28274651.

11. Church TD, Jessup JP, Guillory VL, Vandewalle KS. Translucency and strength of high-translucency monolithic zirconium oxide materials. Gen Dent. 2017; 65:48–52.

12. Ueda K, Güth JF, Erdelt K, Stimmelmayr M, Kappert H, Beuer F. Light transmittance by a multi-coloured zirconia material. Dent Mater J. 2015; 34:310–314. PMID: 25904173.

13. Kim HK, Kim SH. Optical properties of pre-colored dental monolithic zirconia ceramics. J Dent. 2016; 55:75–81. PMID: 27717755.

14. Erdelt K, Pinheiro Dias Engler ML, Beuer F, Güth JF, Liebermann A, Schweiger J. Computable translucency as a function of thickness in a multilayered zirconia. J Prosthet Dent. 2019; 121:683–689. PMID: 30527568.

15. Vichi A, Louca C, Corciolani G, Ferrari M. Color related to ceramic and zirconia restorations: a review. Dent Mater. 2011; 27:97–108. PMID: 21122905.

16. Tuncel İ, Özat P, Eroğlu E. Effects of coloring procedures on zirconia/veneer ceramics bond strength. J Adv Prosthodont. 2014; 6:451–455. PMID: 25551004.

17. Sulaiman TA, Abdulmajeed AA, Donovan TE, Vallittu PK, Närhi TO, Lassila LV. The effect of staining and vacuum sintering on optical and mechanical properties of partially and fully stabilized monolithic zirconia. Dent Mater J. 2015; 34:605–610. PMID: 26438983.

18. Zhang Y. Making yttria-stabilized tetragonal zirconia translucent. Dent Mater. 2014; 30:1195–1203. PMID: 25193781.

19. Nassary Zadeh P, Lümkemann N, Sener B, Eichberger M, Stawarczyk B. Flexural strength, fracture toughness, and translucency of cubic/tetragonal zirconia materials. J Prosthet Dent. 2018; 120:948–954. PMID: 29807742.

20. Tabatabaian F. Color Aspect of Monolithic Zirconia Restorations: A Review of the Literature. J Prosthodont. 2019; 28:276–287. PMID: 29801196.

21. KH Ko. KH Ko. Method of manufacturing zirconia prosthesis for teeth using coloring liquid with adjustable brightness/saturation. Korea patent. KR 101756370. 2017. 7. 04.

22. TS Park. TS Park. Method for manufacturing zirconia block for dental prosthesis having layed color gradient by water absorption rate. World Intellectual Property Organization patent. WO 2018/225934 A1. 2018. 12. 13.

23. JD KimSB Park. DENTAL MAX, Co. Method of manufacturing multilayer zirconia block for artificial teeth. United States patent. US 20160354186 A1. 2016. 12. 08.

24. TS ParkIK Chun. DMAX, Co. Method of manufacturing zirconia block for artificial tooth having color gradient. United States patent. US 9687325 B2. 2017. 6. 27.

25. YS Kim. HASS, Co. Dental zirconia block having strength, translucency, and color gradient, and method for manufacturing same. World Intellectual Property Organization patent. WO 2016/043378 A1. 2016. 3. 24.

26. DJ KimJS HanIB LeeHH JeongJM KimSW Kim. ECUCERA, Co. Multi-shaded and translucent zirconia blank. Korea patent. KR 101324467 B1. 2013. 11. 06.

27. Hjerppe J, Närhi T, Fröberg K, Vallittu PK, Lassila LV. Effect of shading the zirconia framework on biaxial strength and surface microhardness. Acta Odontol Scand. 2008; 66:262–267. PMID: 18645687.

28. Ban S, Suzuki T, Yoshihara K, Sasaki K, Kawai T, Kono H. Effect of coloring on mechanical properties of dental zirconia. J Med Bio Eng. 2014; 34:24–29.

29. Nam JY, Park MG. Effects of aqueous and acid-based coloring liquids on the hardness of zirconia restorations. J Prosthet Dent. 2017; 117:662–668. PMID: 27881316.

30. Sedda M, Vichi A, Carrabba M, Capperucci A, Louca C, Ferrari M. Influence of coloring procedure on flexural resistance of zirconia blocks. J Prosthet Dent. 2015; 114:98–102. PMID: 25858219.

31. Kong MC, Kim KJ, Kown TY, Hong MH. The effects of the number of times dipped in coloring liquid and final sintering temperature on flexural strength of zirconia ceramics : Zirconia ceramics having improved transparency. J Dent Mater. 2017; 44:171–178.

32. Park JW. A Comparative Study on the fracture strength of the multi coloured monolithic zirconia restoration. [dissertation]. Daegu: Kyungpook National University;2016.

33. Muñoz EM, Longhini D, Antonio SG, Adabo GL. The effects of mechanical and hydrothermal aging on microstructure and biaxial flexural strength of an anterior and a posterior monolithic zirconia. J Dent. 2017; 63:94–102. PMID: 28591620.

34. ISO 6872. Dentistry-ceramic materials. Geneva; Switzerland: International Standards Organization (ISO);2015. Available at https://www.iso.org/standard/59936.html.

35. Christel P, Meunier A, Heller M, Torre JP, Peille CN. Mechanical properties and short-term in-vivo evaluation of yttrium-oxide-partially-stabilized zirconia. J Biomed Mater Res. 1989; 23:45–61. PMID: 2708404.

Fig. 2

Field emission scanning election micrograph images of multilayered zirconia specimens (3M Lava Esthetic). (A) ZU, non-shaded, upper; (B) ZL, non-shaded, lower; (C) KU, acid-based coloring liquid, upper; (D) KL, acid-based coloring liquid, lower; (E) AU, aqueous coloring liquid, upper; (F) AL, aqueous coloring liquid, lower. (Orignal magnification, × 20,000)

Table 1

Materials used (n = 10)

| Materials | Coloring liquid | Zirconia position | Group code | |

|---|---|---|---|---|

| 3M Lava Esthetic | - | Upper | ZU | Z |

| Lower | ZL | |||

| Acid-based | Upper | KU | K | |

| Lower | KL | |||

| Aqueous | Upper | AU | A | |

| Lower | AL | |||

Table 2

Mean and standard deviation of flexural strength of zirconia specimens (n = 10)

| Group | Mean ± SD (MPa) |

|---|---|

| ZU | 433.38 ± 59.30a |

| ZL | 443.03 ± 38.33a |

| KU | 424.12 ± 42.76a |

| KL | 433.94 ± 37.60a |

| AU | 444.81 ± 40.59a |

| AL | 461.62 ± 59.57a |

ZU, non-shaded, upper (control); ZL, non-shaded, lower (control); KU, acid-based coloring liquid, upper; KL, acid-based coloring liquid, lower; AU, aqueous coloring liquid, upper; AL, aqueous coloring liquid, lower. The same superscript letters in the same column show not significant differences (P > .05).

Table 3

Flexural strength test of specimens, as analyzed by two-way ANOVA (± SD)

Table 4

Clinical recommendation proposed by ISO 6872:2015 dental ceramics

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download