Abstract

Xanthii Fructus has been traditionally used for the treatment of rhinitis, rheumatoid arthritis, and eczema. In this study, a high-performance liquid chromatography-photodiode array (HPLC-PDA) method was developed and then used for the simultaneous analysis of eight phenylpropanoids in Xanthii Fructus. The analytical column used for this separation was a SunFire™ C18 column, maintained at 40℃. The mobile phase used was 1.0% acetic acid in distilled water and 1.0% acetic acid in acetonitrile with gradient elution. For identify of each component, the mass spectrometer (MS) was used a Waters triple quadrupole mass spectrometer requipped with electrospray ionization (ESI) source. The HPLC-PDA method showed good linearity: correlation coefficients were ≥ 0.9996. The limits of detection and quantification of the eight compounds were 0.02 – 0.04 and 0.06 – 0.14 µg/mL, respectively. The extraction recoveries ranged from 97.51 to 108.67%. The relative standard deviation values of intra- and inter-day precision were 0.06 – 1.55 and 0.09 – 1.68%, respectively. The validated HPLC-PDA method was applied to simultaneously analyse the amounts of eight phenlypropanoids in Xanthii Fructus.

Xanthii Fructus (XF; Fam. Compositae) is derived from the fruit of Xanthium strumarium (L.). Itis widely distributed in several regions of Korea, Japan, and China.1 It has long been used as traditional medicine in these countries for the treatment of various diseases, including headache, toothache, pruritus, rheumatoid arthritis, empyema, and rhinitis.123 In addition, XF has been re- ported to have various pharmacological effects, including antioxidant, anti-nociceptive, anti-inflammatory, anti-arthritic, anti-allergic rhinitis, and anti-melanogenisis activities.4567 Phytochemical investigations of XF have identified thiazinedione (e.g., xanthiazone),8 sesquiterpenoids (e.g., xanthatin and 8-epi-xanthatin),910 steroids (e.g., stigmasterol and b-sitosterol-O-glucoside),10and phenolic compounds (e.g., ferulic acid, caffeic acid and chlorogenic acid, and caffeoylquinic acids).81112 Recently, the quantitative analysis of the major components in XF using highperformance liquid chromatography (HPLC) coupled with photodiode array (PDA) detector (HPLC-PDA) was reported.13 However, this method focuses on the quantitation of active components for quality assessment of raw and processed XF. The aim of this research was to develop a method, and then validate it, for the simultaneous determination of eight phenylpropanoids for quality assessment of XF using HPLC-PDA. The phenyl- propanoids were 3-caffeoylquinic acid (3-CQA);caffeic acid (CA); 4,5-dicaffeoylquinic acid (4,5-DCQA); ferulic acid (FA); 3,5-dicaffeoylquinic acid (3,5-DCQA); 1,3-dicaffeoylquinic acid (1,3-DCQA); 1,4-dicaffeoylquinic acid (1,4-DCQA); and 1,5-dicaffeoylquinic acid (1,5-DCQA).

The XF used in this study was purchased from HMAX Inc. (Jecheon, Korea) in October 2008.The botanical origin of this sample was taxonomically confirmed by Prof. Je-Hyun Lee, Dongguk University, Gyeongju, Republic of Korea. A voucher specimen (2008-ST-25) has been deposited at the K-herb Research Center, Korea Institute of Oriental Medicine.

3-CQA and CA were purchased from Acros Organics (Pittsburgh, PA, USA). 4,5-DCQA; 3,5-DCQA; 1,3-DCQA; and 1,5-DCQA were obtained from Chengdu Biopurify Phytochemicals Ltd. (Chengdu, China). FA and 1,4-DCQA were obtained from Wako Chemicals Industries (Osaka, Japan) and Chem Faces Biochemical Co. (Wuhan, China), respectively. The purity of all reference standards was ≥98.0% by HPLC analysis. The chemical structures of these components are shown in Fig. 1. HPLC-grade solvents, methanol, acetonitrile, and water were obtained from J.T. Baker (Phillipsburg, NJ, USA). Glacial acetic acid (for analytical grade) was purchased from Merck KGaA (Darmstadt, Germany).

Dried XF(200 g) was extracted three times with 70% (v/v) ethanol (2 L) by sonication for 60 min. The extracted solution was filtered through filter paper, evaporated to dryness under vacuum at 40 ℃ using a R-210 rotary evaporator (Büchi; Flawil, Switzerland) and then freeze-dried using a FD-5525L freeze dryer (IlShin-BioBase; Dongducheon, Korea). The amount of the lyophilized 70% ethanol extract obtained was 11.72 g (yield, 5.86%). For the quantitative analysis of the XF, the 70% ethanol extract (200 mg) was dissolved in 20 mL of 70% methanol and extracted by sonication for 20 min. Prior to injection into the HPLC column, the solution was filtered through a 0.2 µm syringe filter (Woongki Science; Seoul, Korea).

XF samples were analyzed using a Shimadzu Prominence LC-20A series HPLC system (Shimadzu Co., Kyoto, Japan), comprising a LC-20AT pump, CTO-20A column oven, SIL-20AC autosampler, and SPD-M20A PDA detector. Acquired all chromatographic data were converted and processed by LC solution software (Version 1.24, SP1; Shimadzu). The stationary phase used for the separation of the eight marker compounds was a reversed-phase SunFireTM C18 analytical column (150 × 4.6 mm, 5 µm; Waters Corp., Milford, MA, USA), maintained at 40 ℃. The mobile phase used was distilled water (A) and acetonitrile (B), both of which contained 1.0% (v/v) acetic acid. The gradient elution of the two-solvent system was as follows: 5 – 5% B (3 min), 5 – 40% B (15 min), 40% B (20 min), and 40 – 5% B (25 min). The re-equilibration time was 10 min. The flow rate and injection volume were 1.0 mL/min and 10 µL, respectively. The PDA detection wavelength for the simultaneous determination was set over the range 190 – 400 nm and data were recorded at 325 nm. The mass spectrometer (MS) was operated using a Waters triple quadrupole mass spectrometer (Waters Corp., Milford, MA, USA) equipped with electrospray ionization (ESI) source. MS conditions for confirmation of each analyte were as follows: capillary voltage, 3.3 kV; extractor voltage, 3 V; RF lens voltage, 0.3 V; source temperature, 120 ℃; desolvation temperature, 300 ℃; desolvation gas, 600 L/h; cone gas, 50 L/h; collision gas, 0.14 mL/min. The acquisition and process of MS data was conducted using Waters MassLynx4.1 software (Waters Corp.).

The established HPLC-PDA method was validated for linearity, precision, and recovery according to the guidelines prescribed at the International Conference on Harmonisation.14 The regression equation of each compound was measured in triplicate and calculated by plotting the peak area response (y) versus the corresponding concentrations (x, µg/mL), using standard solutions. The limit of detection (LOD) and limit of quantification (LOQ) were calculated using the following equations: LOD = 3.3 × SD / S and LOQ = 10 × SD / S (where SD is the standard deviation of the blanks and S is the slope of the calibration curve).Intra- and inter-day precisions were evaluated using standard solutions prepared to produce solutions of three different levels (low, medium, and high) of each compound. The RSD was used for the assessment of precision [RSD (%) = (SD / mean measured concentration) × 100]. To verify the repeatability of the method, the solutions containing the eight standard compounds were each measured six times and repeatability was evaluated by the RSD value. The accuracy was assessed using a recovery test, which was performed by adding three different, known, concentration levels (low, medium, and high) of standard solutions to the XF extract. The mixtures were extracted as described in Section 3.3. Recovery was calculated as follows: recovery (%) = (detected concentration - original concentration) / spiked concentration × 100.

In an effort to obtain the most suitable chromatographic conditions, various column types, temperatures, and solvents were tested; column types: Waters SunFireC18 (150 × 4.6 mm, 5 µm), Waters SunFireC18 (250 × 4.6 mm, 5 µm), Phenomenex Gemini C18 (250 × 4.6 mm, 5 µm), and OptimaPakC18 (250 × 4.6 mm, 5 µm); column temperatures: 30, 35, and 40 ℃; mobile phase: acetic acid, formic acid, trifluoroacetic acid, and organic solvents, including methanol and acetonitrile. Resulting from these test, and after considering the baselines, resolution, and peak shapes of the eight components under the various conditions, we determined that the most suitable separation conditions were obtained with a Waters SunFireC18 (150 × 4.6 mm, 5 µm), and a gradient system of distilled water and acetonitrile, both containing 1.0% (v/v) acetic acid, at 40 ℃. Having established this HPLC-PDA analytical method, the eight phenlypropanoids in the XF extract were separated within 20 min, at 325 nm, and showed good specificity (≥1.02). The retention times of 3-CQA; CA; 1,4-DCQA; 1,3-DCQA; FA; 1,5-DCQA; 3,5-DCQA; and 4,5-DCQA were 6.51, 11.45, 11.80, 12.16, 13.22, 14.67, 15.63, 15.89, and 16.55 min, respectively (Fig. 2).

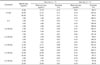

The linearity of the established HPLC method was assessed by the values of the correlation coefficients (r2), using calibration curves of each compound. The linearity of the eight compounds had good r2 values (≥0.9996) in the eight concentration ranges tested: 1.56 – 200.00 µg/mL (3-CQA), 0.16 – 20.00 µg/mL (CA and FA), 0.39 – 50.00 µg/mL (1,4-DCQA and 1,3-DCQA), and 0.78 – 100.00 µg/mL (1,5-DCQA, 3,5-DCQA, and 4,5-DCQA). The LOD and limit of quantification LOQ for the eight marker compounds were 0.02 – 0.04 and 0.06 – 0.14 µg/mL, respectively. Linearity, range, LOD, and LOQ data are summarized in Table 1. To evaluate the recovery, three different concentrations (low, medium, and high) of standard solutions were added to the XF sample. The recovery data are shown in Table 2. Briefly, the average recovery of the tested marker compounds ranged from 97.51 to 108.67% and the relative standard deviation (RSD) values were ≤2.22%. Repeatability of this method was evaluated by the RSD value of peak area responses and retention times. It was found that the RSD values of peak area responses and retention times for repeatability assessment were <0.29 and <0.03%, respectively (Table 3). The RSD values of intra- and inter-day precision, for method, were 0.06 – 1.55 and 0.09 – 1.68%, respectively (Table 4). These results indicate that the developed analytical method was suitable for simultaneous analysis of marker components in XF extract.

The developed HPLC analytical method was used to simultaneously analyses eight components in an XF extract. The amounts of 3-CQA; CA; 1,4-DCQA; 1,3-DCQA; 1,5-DCQA; 3,5-DCQA; and 4,5-DCQA were 33.63, 0.12, 0.97, 0.63, 10.35, 2.81, and 2.40 mg/g, respectively. FA was not detected in this sample (Table 5).

The full scan spectra of eight components were shown in Fig. 3. CA and FA were detected in the positive ion mode [M+H]+ at m/z180.9 and 195.0. 3-CQA and five dicaffeoylquinic acids were detected using the negative ion mode [M-H]− with m/z 353.3 and 515.0 (Table 6).

In conclusion, in this study, a simple, accurate, and convenient HPLC-PDA method was successfully applied for the simultaneous determination of eight marker compounds in an XF extract: 3-CQA; CA; 1,4-DCQA; 1,3-DCQA; FA; 1,5-DCQA; 3,5-DCQA; and 4,5-DCQA. Of these, 3-CQA and 1,5-DCQA are the main compounds, in amounts of 33.56 and 10.12 mg/g. Method validation showed suitable linearity, repeat ability, intra- and interday precision, and recovery. These components were identified by LC-ESI-MS/MS. Results therefore indicate that the developed HPLC-PDA method could be valuable for the quality assessment of XF.

Figures and Tables

| Fig. 2HPLC chromatograms of the standard solutions (A) and XF extract (B) at 325 nm. Identified compounds are (1) 3-CQA; (2) CA; (3) 1,4-DCQA; (4) 1,3-DCQA; (5) FA; (6) 1,5-DCQA; (7) 3,5-DCQA; and (8) 4,5-DCQA. |

| Fig. 3Mass spectra of eight reference standard compounds. (A) 3-CQA; (B) CA; (C) 1,4-DCQA; (D) 1,3-DCQA; (E) FA; (F) 1,5-DCQA; (G) 3,5-DCQA; and (H) 4,5-DCQA. |

Table 3

Repeatability of retention times and peak area responses for the eight analytes in XF (n = 6)

Acknowledgement

This research was supported by the Korea Institute of Oriental Medicine (KIOM; project no. K15251).

References

1. Bae KH. The medicinal plants of Korea. Seoul: Kyo-Hak Publishing;2000. p. 514.

2. Shin SW, Lee JH, Bang KS. Korean J Plant Resour. 2012; 25:372–378.

3. Lee YM, Kang DG, Kim MG, Choi DH, Lee HS. Korean J Orient Physiol Pathol. 2004; 18:792–796.

4. Huang MH, Wang BS, Chiu CS, Amagaya S, Hsieh WT, Huang SS, Shie PH, Huang GJ. J Ethnopharmacol. 2011; 135:545–552.

5. Lin B, Zhao Y, Han P, Yue W, Ma XQ, Rahman K, Zheng CJ, Qin LP, Han T. J Ethnopharmacol. 2014; 155:248–255.

6. Peng W, Ming QL, Han P, Zhang QY, Jiang YP, Zheng CJ, Han T, Qin LP. Phytomedicine. 2014; 21:824–829.

7. Li H, Min YS, Park KC, Kim DS. Biosci Biotechnol Biochem. 2012; 76:767–771.

8. Ma YT, Huang MC, Hsu FL, Chang HF. Phytochemistry. 1998; 48:1083–1085.

9. Chen F, Hao F, Li C, Gou J, Lu D, Gong F, Tang H, Zhang Y. PLoS One. 2013; 8:e76621.

10. Nibret E, Youns M, Krauth-Siegel RL, Wink M. Phytother Res. 2011; 25:1883–1890.

11. Cheng Z, Wang L, Chen B, Li F, Wang M. Chin J Appl Environ Biol. 2011; 3:350–352.

12. Yang L, Su ZJ, Xu SJ, Wu JX, Chen LL, Zhou RL, Li X, Zeng X. Yao Xue Xue Bao. 2010; 45:1537–1540.

13. Jiang H, Yang L, Xing X, Yan M, Guo X, Yang B, Wang Q, Kuang H. Molecules. 2018; 23:243.

14. International Conference on Harmonisation. Guidance for industry, Q2B validation of analytical procedures: methodology. 1996.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download