Abstract

Objective

Methods

Results

Figures and Tables

Figure 1

A, Thermoforming machine (Biostar®; Scheu Dental, Iserlohn, Germany) and fabrication of specimens for evaluation of the effects of thermoforming on the mechanical and physical properties of different thermoplastic materials with varying thicknesses. B, Surface X was cut from the models and used as a specimen for analysis.

Figure 2

Comparison of water absorption (A) and solubility (B) before thermoforming (BT) and after thermoforming (AT) and among different thermoplastic materials. All tests were performed for 1.0-mm-thick Duran, Essix A+, Essix ACE, and 0.75-mm-thick eCligner. The same capital letters indicate no difference between materials at the 1% significance level. The same lower case letters indicate no difference between BT and AT at the 1% significance level.

Figure 3

Comparison of Knoop hardness values before thermoforming (BT) and after thermoforming (AT) and among different thermoplastic materials. All tests were performed for 1.0-mm-thick Duran, Essix A+, Essix ACE, and 0.75-mm-thick eCligner. The same capital letter indicates no difference between materials at the 1% significance level. The same lower case letters indicate no difference between BT and AT at the 1% significance level.

Table 1

Properties of thermoplastic materials used for the fabrication of transparent orthodontic aligners and the thermoforming conditions used in the present study

Table 2

Comparison of the transparency of different thermoplastic materials before thermoforming (BT) and after thermoforming (AT)

Values are presented as mean ± standard deviation.

A,B,CThe same capital letters in the vertical columns indicate no difference between materials at the 1% significance level. a,bThe same lower case letters in the horizontal rows indicate no difference between BT and AT at the 1% significance level.

See Table 1 for the manufacturer of each product.

Table 3

Comparison of the flexural forces and flexure moduli for different thermoplastic materials before thermoforming (BT) and after thermoforming (AT)

Values are presented as mean ± standard deviation.

A,B,CThe same capital letters in the vertical columns indicate no difference between materials at the 1% significance level. a,bThe same lower case letters in the horizontal rows indicate no difference between BT and AT at the 1% significance level.

See Table 1 for the manufacturer of each product.

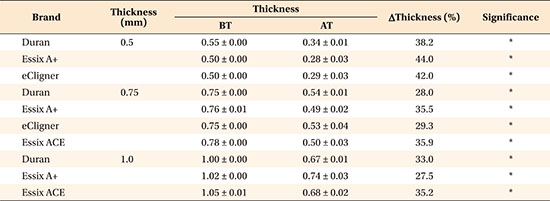

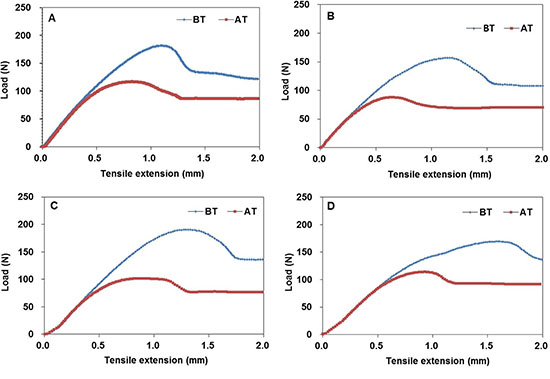

Table 4

Comparison of the tensile forces and elastic moduli for different thermoplastic materials before thermoforming (BT) and after thermoforming (AT)

Values are presented as mean ± standard deviation.

A,BThe same capital letters in the vertical columns indicate no difference between materials at the 1% significance level. a,bThe same lower case letters in the horizontal rows indicate no difference between BT and AT at the 1% significance level.

See Table 1 for the manufacturer of each product.

ACKNOWLEDGEMENTS

Notes

Appendices

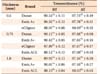

Appendix 1

Thickness variations for different thermoplastic materials used for the fabrication of transparent orthodontic aligners

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download