This article has been

cited by other articles in ScienceCentral.

Abstract

PURPOSE

To evaluate the effect of prolonged sandblasting on the bond durability of dual-cure adhesive resin cement to computer-aided design and computer-aided manufacturing (CAD/CAM) restoratives.

MATERIALS AND METHODS

Nano-ceramic LAVA Ultimate and hybrid-ceramic VITA Enamic CAD/CAM blocks were used for this study. Each CAD/CAM block was sectioned into slabs of 4-mm thickness for the microtensile test (µTBS) test and 2-mm thickness for the surface roughness test. Three groups were created according to the sandblasting protocols; group 1: specimens were sandblasted for 15 seconds, group 2: specimens were sandblasted for 30 seconds, and group 3: specimens were sandblasted for 60 seconds. After sandblasting, all specimens were luted using RelyX Ultimate Clicker. Half the specimens were subjected to µTBS tests at 24 hours, and the other half were subjected to tests after 5000 thermocycles. Additionally, a total of 96 CAD/CAM block sections were prepared for surface roughness tests and scanning electron microscopy (SEM) evaluations. The Mann-Whitney U test, Kruskal-Wallis one-way analysis of variance, and Dunn's post hoc test were used to compare continuous variables among the groups.

RESULTS

At baseline, group 1, group 2, and group 3 exhibited statistically similar µTBS results for LAVA. However, group 3 had significantly lower µTBS values than groups 1 and 2 for VITA. After 5000 thermocycles, µTBS values significantly decreased for each block (P<.05).

CONCLUSION

It is important to perform controlled sandblasting because it may affect bond strength results. Sixty seconds of sandblasting disturbs the initial µTBS values and the stability of adhesion of CAD/CAM restoratives to dual-cure adhesive resin cement for VITA Enamic.

Go to :

Keywords: Computer-aided design and computer-aided manufacturing (CAD/CAM) restoratives, Dual-cure adhesive cement, Surface roughness, Microtensile bond strength

INTRODUCTION

Computer-aided design and computer-aided manufacturing (CAD/CAM) restoratives are increasingly used in dentistry in order to restore severely damaged tooth structures. There are two main types of materials used for CAD/CAM restoratives, glass-ceramics/ceramics and resin-composites.

1 There are some advantages of CAD/CAM resin blocks versus ceramics blocks, such as higher fatigue or fracture resistance, less chips at the restoration margins, and less abrasion for the opposing teeth.

234 Resin-based CAD/CAM materials have the positive features of both ceramics and composites with additional beneficial properties for patients. Some members of this new material group include the polymerinfiltrated-ceramic-network material (Hybrid-ceramic) Vita Enamic, and the nanohybrid-composite with inorganic ceramic fillers (Nano-ceramic) Lava Ultimate CAD/CAM blocks. Hybrid ceramics consist of a ceramic substructure infiltrated with a composite material, whereas nano-ceramic materials contain nano-ceramic particles embedded in a well-polymerized resin matrix.

56

A strong restorative material is not the only criteria for the long-term success of CAD/CAM systems. They also require correct bonding between the restorative material-resin cement and tooth structures. Resin cements bond CAD/CAM blocks chemically and via micromechanical retentions. Therefore, the surface treatment of CAD/CAM restoratives plays an important role in this adhesion.

78 Roughened CAD/CAM surfaces may allow resin cement to penetrate and flow into these micro-retentions, thereby creating a stronger micro-mechanical interlock. However, the most recent literature of Yoshihara et al.

9 reported that sandblasting composite CAD/CAM blocks produced an irregular surface and sub-surface cracks. Therefore, the authors recommended gently sandblasting the surface of CAD/CAM blocks prior to the application of a primer/adhesive.

There are different opinions regarding obtaining optimal bonding/luting between composite CAD/CAM resin blocks and resin cement. Surface treatment prior to cementation can improve bond strengths of CAD/CAM restoratives. These different surface treatment procedures might account for the different bond strength results. One of the most preferred surface treatment procedures is sandblasting. The manufacturers of CAD/CAM systems generally do not give a specific length of time for sandblasting. This time varies throughout the literature, some authors applied 5 seconds,

10 some were 10 seconds,

911 others were 15 seconds,

12 16 seconds,

13 or 20 seconds.

7141516 These different sandblasting procedures could have an effect on creating surface irregularities/micro-cracks on CAD/CAM resin blocks and could cause different degrees of roughness on blocks.

9 Therefore, the aim of this study was to determine the effect of mild or severe sandblasting on the microtensile bond strength (µTBS) of CAD/CAM restoratives to dual-cure adhesive resin cement. The tested hypotheses were: 1) Sandblasting duration does not affect surface roughness values of CAD/CAM restoratives; 2) Sandblasting duration does not affect the µTBS of dual-cure adhesive resin cement to CAD/CAM restoratives; and 3) Accelerating aging does not affect the µTBS of dual-cure adhesive resin cement to CAD/CAM restoratives.

Go to :

MATERIALS AND METHODS

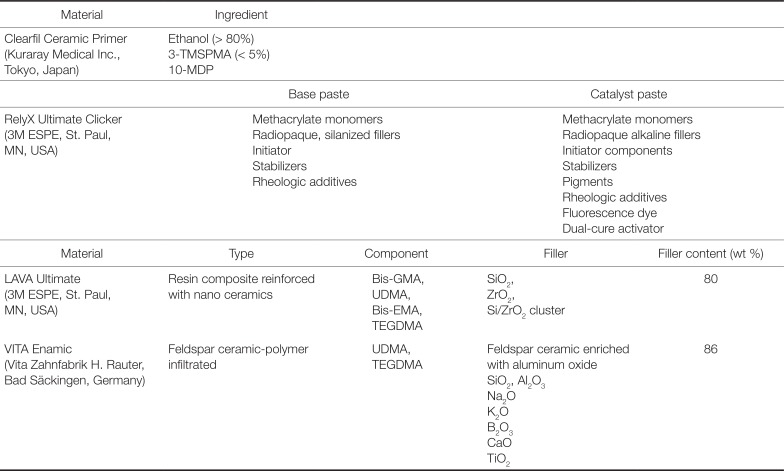

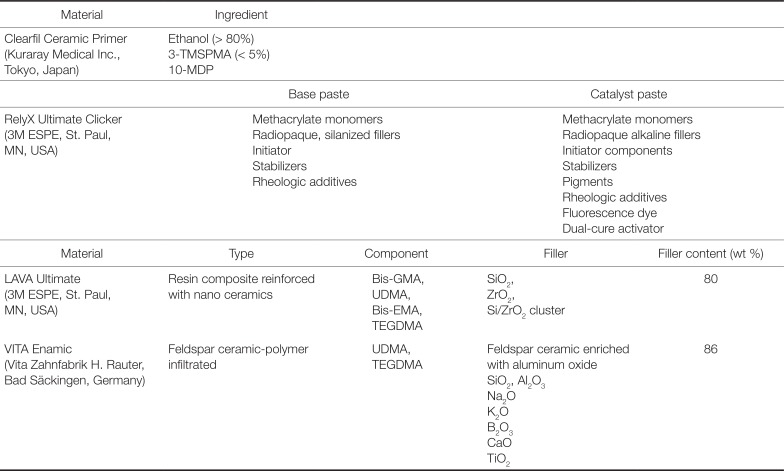

Two CAD/CAM composite blocks; VITA Enamic (Vita Zahnfabrik H. Rauter, Bad Säckingen, Germany) and LAVA Ultimate CAD/CAM restorative (3M ESPE, St. Paul, MN, USA) were used in this study. Details of the manufacturers and compositions are shown in

Table 1.

Table 1

Materials used in this study

|

Material |

Ingredient |

|

Clearfil Ceramic Primer (Kuraray Medical Inc., Tokyo, Japan) |

Ethanol (> 80%) |

|

3-TMSPMA (< 5%) |

|

10-MDP |

|

Base paste |

Catalyst paste |

|

RelyX Ultimate Clicker (3M ESPE, St. Paul, MN, USA |

Methacrylate monomers |

Methacrylate monomers |

|

Radiopaque, silanized fillers |

Radiopaque alkaline fillers |

|

Initiator |

Initiator components |

|

Stabilizers |

Stabilizers |

|

Rheologic additives |

Pigments |

|

Rheologic additives |

|

Fluorescence dye |

|

Dual-cure activator |

|

Material |

Type |

Component |

Filler |

Filler content (wt %) |

|

LAVA Ultimate (3M ESPE, St. Paul, MN, USA) |

Resin composite reinforced with nano ceramics |

Bis-GMA, UDMA, Bis-EMA, TEGDMA |

SiO2, ZrO2, Si/ZrO2 cluster |

80 |

|

VITA Enamic (Vita Zahnfabrik H. Rauter, Bad Säckingen, Germany) |

Feldspar ceramic-polymer infiltrated |

UDMA, TEGDMA |

Feldspar ceramic enriched |

86 |

|

with aluminum oxide |

|

SiO2, Al2O3

|

|

Na2O |

|

K2O |

|

B2O3

|

|

CaO |

|

TiO2

|

For µTBS test, two CAD/CAM blocks were used for each group. Each CAD/CAM block was sectioned into slabs of 4-mm thickness using an Isomet 1000 (Buehler, Lake Bluff, IL, USA). The top surface of the sectioned slices was abraded using 600 SIC papers for 60 seconds under running water. The block sections were then sandblasted using aluminum-oxide (Al2O3, mean particle size 50 µm) (Renfert GmbH, 78247, Hilzingen, Germany). Sandblasting procedures were conducted using a sandblaster (Basic Eco, Renfert GmbH, 78247, Hilzingen, Germany) at 2.5 bar pressure approximately 10 mm from the composite surface. Three groups of specimens were formed for µTBS testing and surface roughness measurements. The following groups were created in terms of their surface treatments: block sections were sandblasted using 50-µm Al2O3 for 15, 30, and 60 seconds (groups 1, 2, and 3, respectively). After sandblasting, all samples were rinsed under running water for 5 minutes and air dried.

After sandblasting, the specimens were silanized using Clearfil Ceramic Primer (Kuraray, Tokyo, Japan; lot number: 930004) for 30 seconds and air dried. Two pairs of 4-mm CAD/CAM slabs from the same CAD/CAM block material and the same group were luted together using dual-cure adhesive cement [RelyX Ultimate Clicker (3M ESPE)] in line with the manufacturer's recommendations. A standardized constant pressure of 1 kg was applied to lute CAD/CAM blocks. The compressive force was applied for the first 2 min, leaving the material to set in the self-curing modality. The specimens were light cured for 40 s from each side using an Elipar S10 curing unit (1200 mW/cm

2, 3M ESPE). The bonded specimens were stored in distilled water for 24 hours at 37℃ prior to µTBS testing. The specimens were then sectioned into serial slabs, and beams with cross-sectional areas of approximately 1 ± 0.2 mm

2 using an Isomet 1000 (Buehler Ltd., Lake Bluff, IL, USA) with a low-speed cutting saw. Sixty sticks were obtained from each group and half of the specimens were subjected to µTBS tests at 24 hours, and the remainder was subjected to the tests after 5000 thermocycles (n = 30). The specimens were thermocycled for 5000 cycles between 5 – 55℃ with 30 seconds dwell time. The beams were subjected to a tensile force in a Micro Tensile Tester Machine (Bisco Inc., Schaumburg, IL, USA) at a crosshead speed of 0.5 mm/min until specimen failure. The failure load was recorded for each specimen. The failure modes were evaluated at ×40 magnification using a stereomicroscope (Olympus SZ61, Munster, Germany). The failure modes were classified as cohesive failure within the resin block and adhesive failure at the interface (

Table 2). Pretest failures were excluded from statistical analyses.

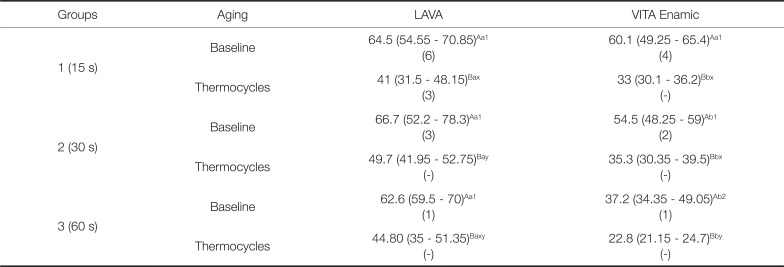

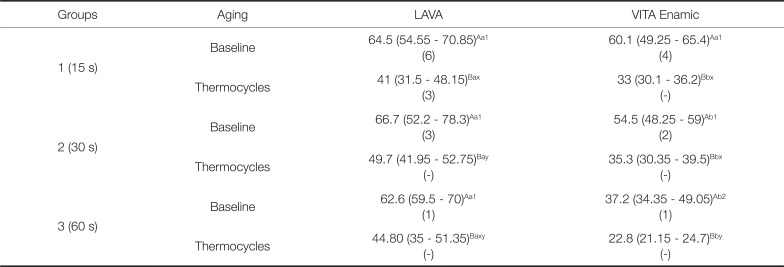

Table 2

Microtensile bond strength (MPa) (median (25th–75th percentile) of the groups and the number of cohesive failures from blocks (n = 30)

|

Groups |

Aging |

LAVA |

VITA Enamic |

|

1 (15 s) |

Baseline |

64.5 (54.55 – 70.85)Aa1

|

60.1 (49.25 – 65.4)Aa1

|

|

(6) |

(4) |

|

Thermocycles |

41 (31.5 – 48.15)Bax

|

33 (30.1 – 36.2)Bbx

|

|

(3) |

(−) |

|

2 (30 s) |

Baseline |

66.7 (52.2 – 78.3)Aa1

|

54.5 (48.25 – 59)Ab1

|

|

(3) |

(2) |

|

Thermocycles |

49.7 (41.95 – 52.75)Bay

|

35.3 (30.35 – 39.5)Bbx

|

|

(−) |

(−) |

|

3 (60 s) |

Baseline |

62.6 (59.5 – 70)Aa1

|

37.2 (34.35 – 49.05)Ab2

|

|

(1) |

(1) |

|

Thermocycles |

44.80 (35 – 51.35)Baxy

|

22.8 (21.15 – 24.7)Bby

|

|

(−) |

(−) |

For the surface roughness test, 2-mm thickness specimens were created for each group. Fifteen specimens were included in each group, thus a total of 90 CAD/CAM block sections were prepared. The surface roughness of the specimens was measured using a 2-dimensional profilometer (Surtronic S128, Taylor Habson Ltd., Leicester, England) with a 5-µm diamond stylus angled at 90°. Starting from the midpoint of each specimen, 5 measurements were taken in different directions, with a cut-off length of 0.25 mm, and the average roughness values were then calculated and recorded (Ra, in µm).

17

For SEM observations, one specimen was prepared for each group. The specimens were sputter-coated with gold (Emitech K-550X Sputter Coater, Emitech, Ashford, UK). The CAD/CAM specimens were examined under a scanning electron microscope (SEM) (LEO 440, LEO Electron Microscopy, Oxford, England) at an acceleration voltage of 20 kV and ×2000 magnification.

17 Two different SEM images were obtained from each specimen after sandblasting. One was obtained from upper surface of CAD/CAM block and the other was taken from the cross-section for each material.

IBM SPSS for Windows version 20.0 (SPSS, Chicago, IL, USA) was used for all statistical analyses. The Kolmogorov-Smirnov test was used to test for normal data distribution. Continuous variables are expressed as median (25th – 75th percentiles). The Mann-Whitney U test, Kruskal-Wallis oneway analysis of variance, and Dunn's post hoc test were used to compare continuous variables between the groups. Two-sided P values < .05 were accepted as statistically significant.

Go to :

RESULTS

The results of the µTBS test (MPa) and surface roughness test (Ra, in µm) are presented in

Table 2 and

Table 3. At baseline, LAVA (64.5 MPa) and VITA (60.1 MPa) exhibited statistically similar µTBS values in group 1 (

P = .077). However, the µTBS of LAVA CAD/CAM restoratives to dual-cure adhesive resin cement was found significantly higher than the µTBS of VITA CAD/CAM restoratives to dual-cure adhesive resin cement in group 2 (

P = .014) and group 3 (

P < .001). After 5000 thermocycles, the µTBS of LAVA CAD/CAM restoratives to dual-cure adhesive resin cement was found significantly higher than the µTBS of VITA CAD/CAM restoratives to dual-cure adhesive resin cement in each group (

P < .05).

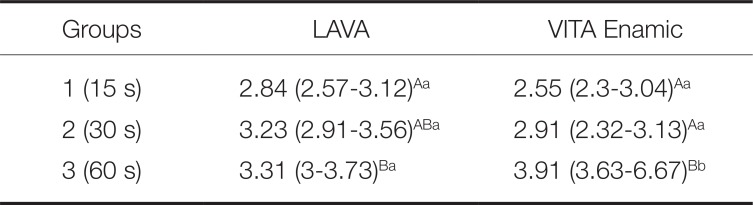

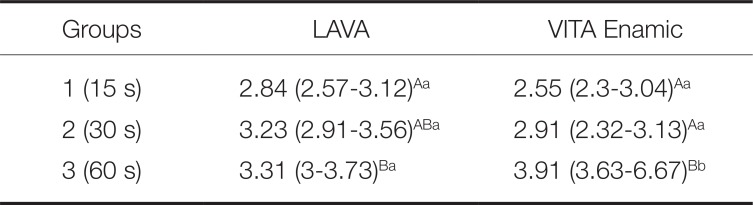

Table 3

Surface roughness values (Ra, µm) (median (25th–75th percentile) of the groups (n = 15)

|

Groups |

LAVA |

VITA Enamic |

|

1 (15 s) |

2.84 (2.57–3.12)Aa

|

2.55 (2.3–3.04)Aa

|

|

2 (30 s) |

3.23 (2.91–3.56)ABa

|

2.91 (2.32–3.13)Aa

|

|

3 (60 s) |

3.31 (3–3.73)Ba

|

3.91 (3.63–6.67)Bb

|

For LAVA, group 1, group 2, and group 3 exhibited statistically similar µTBS values at baseline (P = .875). For VITA, group 3 exhibited significantly lower µTBS values than group 1 and group 2 (P < .001). After 5000 thermocycles, group 2 (49.7 MPa) exhibited significantly higher µTBS values than group 1 (41 MPa) (P = .039) for LAVA. Group 1 and group 3 (44.8 MPa) were found statistically similar (P > .05). For VITA, group 1 (33 MPa) and group 2 (35.3 MPa) displayed significantly higher µTBS values than group 3 (22.8 MPa) (P < .001).

After 5000 thermocycles, the µTBS values of each group and each material decreased significantly compared with baseline (P = .018). For LAVA, the values decreased from 64.5 MPa to 41 MPa in group 1, 66.7 MPa to 49.7 MPa in group 2, and 62.6 MPa to 44.8 MPa in group 3 (P < .001). For VITA, µTBS values declined from 60.1 MPa to 33 MPa in group 1, 54.5 MPa to 35.3 MPa in group 2, and 37.2 MPa to 22.8 MPa in group 3 (P < .001).

In this study, failure modes are classified as adhesive failure from the adhesive layer or cohesive failure from the block. At baseline or after thermocycles, adhesive failure types were generally observed in the specimens. However, a significant difference was not found among the groups in terms of account of adhesive failures (P > .05).

Surface roughness values of LAVA in group 1 (2.84 µm) were significantly lower than group 3 (3.31 µm) (P = .003). For VITA, group 3 (3.91 µm) exhibited significantly higher Ra values than group 1 (2.55 µm) and group 2 (2.91 µm) (P < .001). LAVA and VITA CAD/CAM restoratives exhibited statistically similar Ra values in group 1 and group 2 (P > .05). However, VITA displayed significantly higher surface roughness values than LAVA in group 3 (P < .001).

According to the SEM evaluation, all CAD/CAM surfaces exhibited irregular and rough appearance with sandblasting. For LAVA, 15-s sandblasted specimens included micro-craters near the sandblasted surface. Surface irregularity was more evident in CAD/CAM specimens that were sandblasted for 30 seconds and 60 seconds (

Fig. 1). The specimens that were sandblasted for 30 seconds and 60 seconds showed large surface defects including deep scratches, micro-craters, pitting, and grain pull-out caused by sandblasting particles (

Fig. 1). In addition, many sand grains were observed embedded in the material surface of specimens that were sandblasted for 60 seconds. In cross-section, SEM images of LAVA CAD/CAM specimens sandblasted for 30 seconds showed a large crack near the sandblasted surface that had propagated along the material (

Fig. 1).

| Fig. 1Observation of LAVA surfaces: (A, C, E): top surfaces of sandblasted CAD/CAM blocks; (B, D, F): cross-sectional view; the specimens were sandblasted for 15 seconds, 30 seconds, and 60 seconds. The top surface figures show a rough surface for LAVA CAD/CAM blocks after sandblasting. However, a small crack is observed on the surface of the LAVA sample that was sandblasted for 30 seconds.

|

For VITA, the specimens that were sandblasted for 15 seconds exhibited micro-craters and pitting (

Fig. 2). However, the specimens that had 30-s and 60-s sandblasting demonstrated larger pitting and deep scratches, and larger micro-craters. Also, some grains or particles were observed near the sandblasted surface (

Fig. 2). Cross-section SEM images of 15-s, 30-s, and 60-s sandblasted VITA CAD/CAM specimens showed surface roughness. VITA specimens that were sandblasted for 30 seconds were damaged and cracked within the filler particles and resin matrix (

Fig. 2).

| Fig. 2Observation of VITA surfaces: (A, C, E): top surfaces of sandblasted CAD/CAM blocks; (B, D, F): cross-sectional view; the specimens were sandblasted for 15 seconds, 30 seconds, and 60 seconds. The top surface figures show a rough surface for VITA CAD/CAM blocks after sandblasting. Irregularities and deep holes are present on the surface of VITA samples that were sandblasted for 30 seconds and 60 seconds.

|

Go to :

DISCUSSION

The first hypothesis, “Sandblasting duration does not affect surface roughness values of CAD/CAM restoratives;” is rejected. In this study, for LAVA, group 1, group 2, and group 3 exhibited statistically similar µTBS values at baseline. However, for VITA, group 3 exhibited significantly lower µTBS values than group 1 and group 2. Therefore, our second hypothesis, “Sandblasting duration does not affect the µTBS of dual-cure adhesive resin cement to CAD/CAM restoratives” is partially rejected. Our last hypothesis, “Accelerating aging does not affect the µTBS of dual-cure adhesive resin cement to CAD/CAM restoratives” is also rejected.

It was reported that sandblasting increases surface roughness values of materials

101415 and promotes micromechanical interlocking for adhesives.

18 Spitznagel et al.

4 reported that increased surface roughness through sandblasting improved bond strength results more than chemical etching with hydrofluoric acid.

4 However, Yoshihara et al.

9 reported sandblasting may damage the surface of composite CAD/CAM blocks; therefore, sandblasting for CAD/CAM resin blocks must be mild. Ersu et al.

10 irradiated surfaces with a laser, rather than using sandblasting, which produced craterlike irregularities in and around glazed patches, which the authors suggested may provide mechanical retention. However, extensive micro-cracks in the ceramic surfaces that were seen after the laser treatment could reduce the fracture resistance of ceramics.

10 Su et al.

19 showed that bond strength between indirect composite resin and zirconia ceramics could be influenced by various types of sandblasting. The authors examined the surface loss of dental zirconia and the short-term bond strength between an indirect composite resin and zirconia after sandblasting for 7, 14, and 21 seconds, and using alumina powder (50 and 110 µm). They recommended sandblasting with alumina particles for 21 seconds with a 110-µm powder for dental applications to improve bonding between zirconia core and composite resin.

19 Different from our study, they emphasized that as powder size and sandblasting time increased, bond strengths between zirconia and indirect composite also increased. The difference between the two studies may be from different structure of zirconia from the materials used in our study (CAD/CAM resin blocks). It is proven that increased surface roughness after sandblasting or hydrofluoric acid etching leads to higher bond strength values compared with no pre-treatment.

71420 However, within the limitations of this study, extensive surface roughness cannot be considered as better microtensile bond strength to CAD/CAM restoratives. On the contrary, forcing the adherent surface may cause deterioration of the interface.

It is important to obtain high bond strength results at baseline; however, long-term results are also very important to predict survival for CAD/CAM restoratives. Resin cement/ceramic bonded interfaces are susceptible to degradation.

21 One of the aims of this study was to evaluate the bond durability of CAD/CAM restoratives to dual-cure adhesive resin cement after 5000 thermal cycles. Cekic-Nagas et al.

22 examined the micro-shear bond strength of different resin cements to ceramic/glass-polymer CAD/CAM block materials after 5000 thermal cycles and found that bond strengths of ceramic/glass-polymer materials with different resin cement systems decreased with thermocycles. Osorio et al.

21 evaluated the bond stability of resin cements when luted to glass-reinforced alumina and zirconia CAD/CAM dental ceramics after immersion in 10% NaOCl aqueous solution for 5 hours. They found that both cements Clearfil Esthetic Cement and RelyX Unicem were prone to degradation; however, RelyX Unicem luted to zirconia or untreated or sandblasted alumina had the most durable interfaces. In this study, µTBS values of each CAD/CAM restorative to dual-cure adhesive resin cement decreased significantly after 5000 thermocycles. After 5000 thermocycles, bond durability of 60-s sandblasted specimens of VITA Enamic was found very low (22.8 MPa) compared with the 15-s and 30-s sandblasted specimens. This may be related with VITA Enamic incorporating an increased feldspar ceramic structure or having a relatively lower polymer structure compared with LAVA. Increasing the ceramic content of materials makes them vulnerable to the formation and progression of cracks into the material and this may disturb the mechanical behavior of restorative materials. Also, the very high inorganic content (86%) of VITA Enamic may make it more brittle. According to our results, bonding with LAVA seems more stable against water/thermal aging than bonding with VITA Enamic. This may be related to the fact that both the luting agent RelyX Ultimate Clicker and LAVA Ultimate are produced by the same manufacturer. Also, Clearfil Ceramic Primer may be effective on enhanced bonding to LAVA, which contains SiO

2and ZrO

2. Clearfil Ceramic Primer contains the phosphate monomer MDP, which bonds very strongly to metal oxides and SiO

2-based materials.

Elsaka

15 examined the bond strength of novel CAD/CAM restorative materials to self-adhesive resin cement at 24 hours and 30 days of water storage. They reported that water aging had a considerable impact on restorative material/luting resin bond degradation. The authors attributed this decrease to the vulnerability of resin cement to hydrolytic degradation because water absorption at the interface could reduce bond strength over time. Smith et al.

23 examined the long-term microtensile bond strength of surface-modified zirconia after sandblasting with Cojet (30-µm SiO

2) for 15 seconds and they measured data at 24 hours, 1, 3, and 6 months of water storage. They bonded composite blocks (Herculite XRV) to zirconia surfaces and found 24 MPa bond strength values at baseline, 25.7 MPa at 1 month, and 22.1 MPa at 6 months. Oyagüe et al.

24 examined the effect of water aging on µTBS of dual-cured resin cements to zirconium-oxide ceramics and reported a statistically significant decline in bond strength when luting Clearfil Esthetic Cement after 6 months of storage, and water aging had a significant effect on the durability of zirconia-to-composite chemical bonds. One of the important results of Oyagüe et al.'s

24 study was that resin-ceramic interface longevity was more dependent on the choice of cement and not on the surface pre-treatment method. Pollington et al.

25 reported that the optimal surface treatment for resin bonding glass-ceramics would vary between systems and that it could not be assumed that any one treatment would be appropriate for all materials. We agree with Pollington et al. that the optimal times for sandblasting can change for different products.

A limitation of this study is that bonding procedure was realized between CAD/CAM sections instead of to the tooth structure. Also, the laboratory environment of our study cannot provide the same conditions as in the oral cavity environment, which incorporates all aging factors together (i.e. aging with enzymes, water, acids, thermal or mechanical aging). In this study, only thermal aging was performed on the specimens. For future studies, using all aging procedures together, using cavity preparation on tooth structures, and luting inlay/onlay restorative material to the tooth cavity would be useful. If CAD/CAM slices lute to tooth structures, bonding between enamel/dentin and luting agent may be more realistic. In addition, using different cavity preparation designs and the effect of cavity configuration factors could provide different aspects. As mentioned, several factors can be effective on bond strength results. However, the type of luting agent is a major determinant on bonding to dental materials or tooth structures; therefore, its effect cannot be ignored. Consequently, pre-treatment procedures and luting cements or restorative materials used are all important as a whole. Therefore, for future studies, each parameter should be evaluated separately.

Go to :

CONCLUSION

To conclude, if sandblasting time increases, surface roughness increases. However, µTBS values decrease with prolonged sandblasting over 30 seconds. Sixty seconds of sandblasting disturbs the initial µTBS values and the stability of adhesion of CAD/CAM restoratives to dual-cure adhesive resin cement for VITA. The microtensile bond strength values of each CAD/CAM restorative to dual-cure adhesive resin cement decreased significantly after 5000 thermocycles. Sixty seconds' sandblasting of specimens increased the degradation rate for VITA, and bond durability was impaired in 60-s sandblasted specimens. A rough surface is required to obtain ideal bond strength; however, excessive sandblasting was deleterious for CAD/CAM resin restoratives. Therefore, it is clinically beneficial to not exceed 30 seconds of sandblasting for CAD/CAM resin restoratives.

Go to :

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download