Abstract

PURPOSE

Although several surface treatments have been recently investigated both under in vitro and in vivo conditions, controversy still exists regarding the selection of the most appropriate zirconia surface pre-treatment. The purpose of this study was to evaluate the effect of alumina (Al) and aluminium nitride (AlN) coating on the shear bond strength of adhesive resin cement to zirconia core.

MATERIALS AND METHODS

Fifty zirconia core discs were divided into 5 groups; air particle abrasion with 50 µm aluminum oxide particles (Al2O3), polishing + Al coating, polishing + AlN coating, air particle abrasion with 50 µm Al2O3 + Al coating and air particle abrasion with 50 µm Al2O3 + AlN coating. Composite resin discs were cemented to each of specimens. Shear bond strength (MPa) was measured using a universal testing machine. The effects of the surface preparations on each specimen were examined with scanning electron microscope (SEM). Data were statistically analyzed by one-way ANOVA (α=.05).

Developments in the ceramic materials science for dental applications has increased the popularity of high strength core-veneered all-ceramic restorations (alumina and zirconia based ceramics) in the last few years. One of the high strength material is yttria stabilized tetragonal zirconia polycrystals (Y-TZP, zirconia).1

High flexural strength and fracture toughness, white color, chemical and structural stability and combined with CAD/CAM technology afford its application as framework material for fixed partial dentures (FPDs) without any limitation regarding the size even in loaded reconstructions in the posterior region.2 Due to their high fracture resistance, zirconia crowns and FPDs can be cemented using conventional luting methods recommended by the manufacturers.3 However, adhesive luting techniques can provide significant clinical advantages over conventional cementation of dental restorations. Adhesive luting is advocated for improving the retention, marginal adaptation, fracture resistance of restorations and inhibition of secondary caries.1,3,4 Although superior in terms of mechanical performance (strength, toughness, fatigue resistance), bonding of resins to zirconia core materials is more difficult than it is for conventional silica-based dental ceramics.5-7

Chemo-mechanical and mechanical surface treatments affect surface topography and roughness of zirconia core material. Some of these surface treatments were grinding with diamond burs, air abrasion with aluminum oxide (Al2O3), tribochemical silica-coating (CoJet, Rocatec), acid etching with hydrofluoric acid, coupling with silane, plasma spraying with hexamethyldisiloxane, internal coating with low fusing porcelain pearl layer, selective infiltration etching and combinations of any of these methods.1,3,4,8-15 Although etching the inner surfaces of conventional Silica based dental ceramics with hydrofluoric acid or the application of most often used silane coupling agent, 3-methacryloxypropyltrimethoxysilane (3-MPS), was an effective conditioning method for bonding resin composite,1,16-18 these methods showed unsatisfactory resin bond to oxide based dental ceramics.1,6,16,19,20

Airborne particle abrasion with 50-110 µm alumina particles at 0.25 MPa has been found to be effective in cleaning and roughening the surface of various dental oxide ceramics.1,13,21-23 However, currently there is a controversy whether airborne particle abrasion alters the strength of oxide ceramic restorations on a clinically relevant level.1 Some studies showed even a strengthening effect of airborne particle abrasion on oxide ceramics,24,25 others reported a strength reducing effect.26,27 However, particle abrasion and adjusting with burs of zirconia results in creation of sharp cracks and structural defects that render the zirconia framework susceptible to radial cracking during function.3,15

Some studies have shown that tribochemical silica coating increased the bond strength to oxide ceramics.13,22 However it has also been reported that tribochemical silica coating might be less effective for densely sintered ceramics than for glass-infiltrated ceramics.28 Although several surface treatments have been recently investigated both under in vitro and in vivo conditions, concerns still exist regarding the selection of the most appropriate zirconia surface pretreatment.

Magnetron sputtering is one of the most commonly used methods for the deposition of thin film materials. Its popularity is derived from the simplicity of the process, versatility of the technique, and flexibility with regard to system alteration and configuration.29 Sputtering techniques have shown that with various thin-film materials, a uniform coat and a dense crystal surface structure with the substrate material can be achieved, even at a low temperature.30 Coating by the sputtering technique has often been applied to dental alloys in order to improve the properties of the metallic dental alloy, giving the alloy a high degree of hardness, high wear and corrosion resistance and good biocompatibility.30-32

Recently, coating of dental ceramic surface was developed to improve mechanical properties and to obtain strong and durable resin bond strength to ceramic. The use of the magnetron sputtering technique to deposit yttria-stabilized zirconia (YSZ) thin films on dental porcelain shows promising results. This technique could be applied to all ceramic materials in principal, to modify inherent surface flaws, suppress crack propagation, thereby improving fatigue behavior and fracture resistance, and potentially having a broader application than developing new materials and material systems.33

The purpose of this study was to evaluate the effect of alumina (Al) and aluminium nitride (AlN) coating by reactive magnetron sputtering technique on shear bond strength of a composite resin luting cement to a zirconia core. The research hypothesis tested was that alumina and aluminium nitride coating would improve the shear bond strength of resin cement to zirconia core.

Fifty zirconia core specimens (10 mm diameter and 2 mm height) were produced by a copy-milling system (Zirconzahn, Bruneck, Italy) using prefabricated blanks of zirconia (ICE Zircon Translucent; Zirconzahn, Bruneck, Italy) and then sintered according to manufacturer instructions.

Subsequently, all specimens were divided into 5 groups, each containing 10 specimens for surface treatments. The groups include; air particle abrasion with 50 µm Al2O3 (Group A), polishing + Al coating (Group PAl), polishing + AlN coating (Group PAlN), air particle abrasion with 50 µm Al2O3 + Al coating (Group AAl) and air particle abrasion with 50 µm Al2O3 + AlN coating (Group AAlN). Polishing procedure was started with a 600-grit silicon carbide abrasive paper (3M ESPE, St. Paul, USA) and finished with 1200 grit each for 10 seconds on a 300 rpm grinding machine (Buehler Metaserv, Buehler, Germany) under running water. Air particle abrasion procedure was performed using an intraoral air abrasion device (Microetcher, Danville Engineering Inc., San Ramon, CA, USA) at an air pressure of 2.5 bars for 10 seconds at a distance of approximately 10 mm.

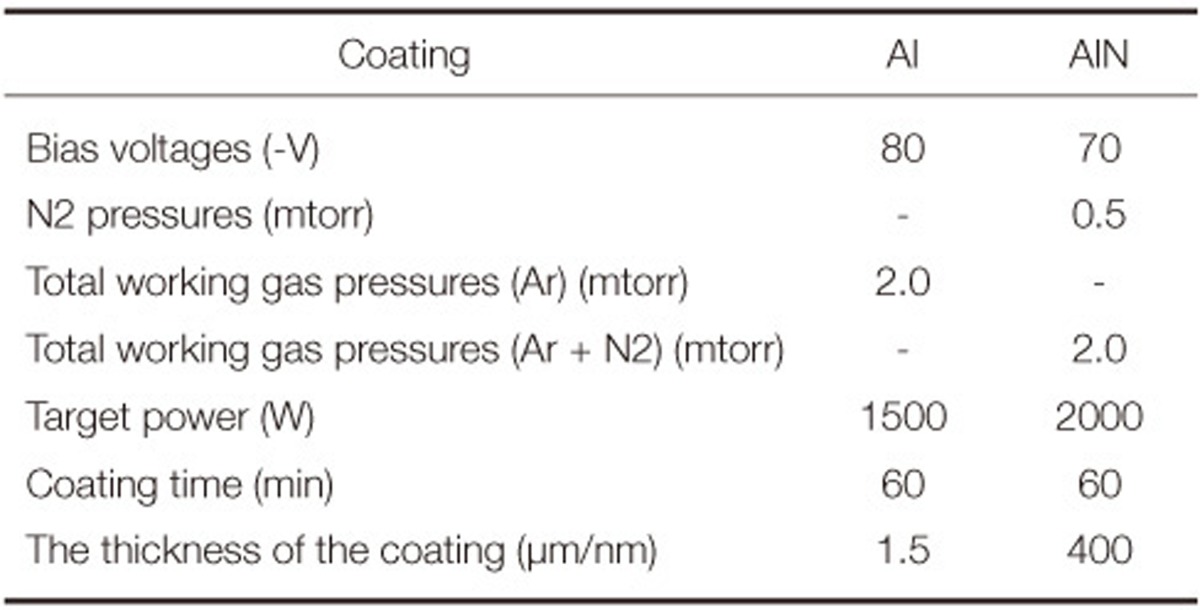

Al and AlN coatings were deposited by a dual magnetron sputtering system and deposition conditions are summarized in Table 1. Surface morphology of zirconia specimens after coating procedure and thickness of the coatings deposited on the specimens were evaluated by scanning electron microscope (SEM-Leo 440, Cambridge, England).

Fifty composite resin discs (Filtek Z250, 3M ESPE, Seefeld, Germany) were fabricated by compact the material into a polytetrafluoroethylene mold (Isoflon, Diemoz, France) with a hole in center (6 mm diameter and 2 mm thickness). Composite resin was incrementally condensed into the mold to fill up the mold and each layer was light polymerized for 40 seconds at a distance of 1 mm using a light-polymerizing unit (Astralis 3, Ivoclar Vivadent, Schaan, Liechtenstein) with an output power of 600 mW/cm2. One composite resin block was fabricated for each specimen.

Composite resin discs were cemented to the specimen surfaces with a dualpolymerized adhesive resin cement (Panavia F 2.0, Kuraray, Osaka, Japan). For cementation, equal amounts of a dual-polymerized resin luting agent paste base and catalyst were mixed and applied to the composite resin block with a plastic spatula. Each composite disc was bonded to a zirconia core specimen under the load of 500 g. The excess resin cement was removed by means of a brush. The resin cement was then light polymerized for 20 seconds with a curing light (Astralis 3). A glycerin gel (Oxyguard II, Kuraray, Osaka, Japan) was applied for 10 minutes.

Specimens were embedded in the centers of autopolymerizing acrylic resin blocks (Meliodent, Heraeus Kulzer, Armonk, NY, USA) then were stored in distilled water at 37℃ for 24 hours and thermocycled for 6000 cycles between 5 ± 2℃ and 55 ± 2℃ with a dwell time of 30 seconds.

A universal test machine (Lloyd LRX, Lloyd Instruments PIC., Fareham, Hampshire, England) was used for shear bond strength test at a crosshead speed 0.5 mm/min. The shear bond strength values were calculated in megapascal (MPa) by dividing the failure load (N) to the area of the composite resin discs (N/πr2). Data were statistically analyzed.

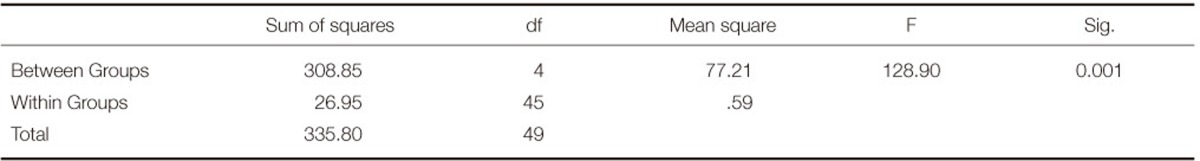

The Kolmogorov-Simirnov test showed that the data was of a normal distribution (P>.05). A homogenity of variance test was done using Levene's test (F: 0.301, P>.05). Means and standard deviations of bond strengths were calculated and mean values were compared by one-way analysis of variance (ANOVA) (SPSS 12,0; SPSS Inc., Chicago, IL, USA), followed by a multiple comparisons' test performed using a Post Hoc Tukey test (α=.05).

To assess the mode of failure, the specimen surfaces were examined with a stereomicroscope (Stemi 2000-C; Carl Zeiss, Gottingen, Germany) at a magnification of ×10. The failure modes were classified into one of the following: adhesive failure at the coated zirconia core surface; or cohesive failure in the resin cement.

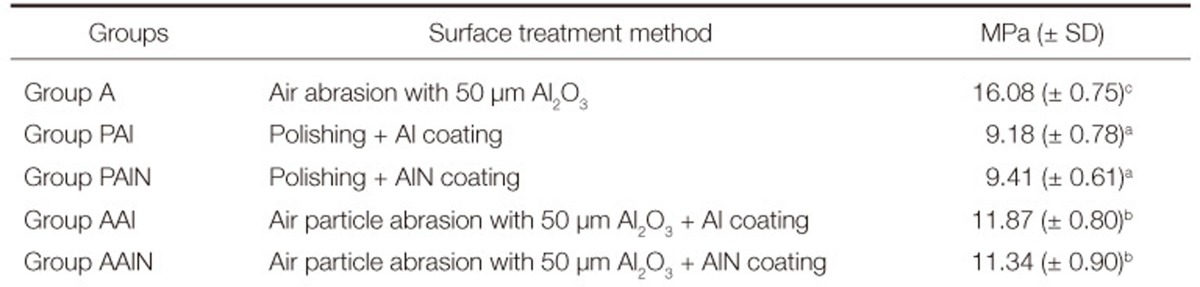

The mean values and standard deviations of shear bond strength values of all tested groups are presented in Table 2. One-way ANOVA analysis revealed significant differences between the groups (Table 3). Air abrasion with 50 µm Al2O3 particles showed higher bond strength of the resin cement to zirconia core and significant differences were found when compared with Al and AlN coated groups.

Coating of zirconia core surfaces after air particle abrasion with 50 µm Al2O3 particles or polishing did not affect the shear bond strength of resin cement. The lowest shear bond strength value was obtained in group PAl and no significant difference was found between group PAlN.

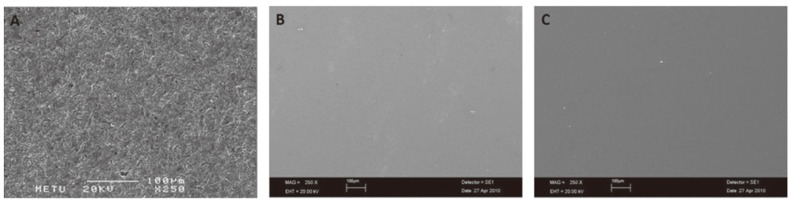

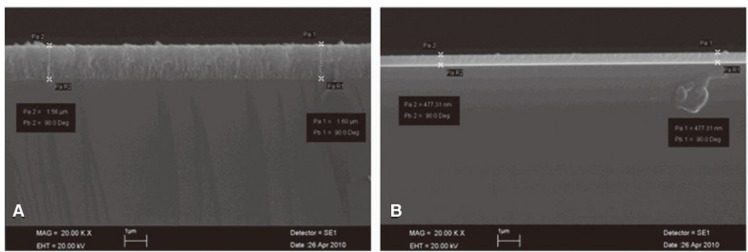

SEM photomicrographs of air abraded or Al and AlN coated zirconia surfaces are presented in Fig. 1. Air abrasion with 50 µm Al2O3 (Fig. 1A) created more irregular and rough surface when compared with Al (Fig. 1B) or AlN coated (Fig. 1C) specimens. Al and AlN coated specimens represented similar smooth surfaces. Fig. 2A represents lateral view of Al coating whereas Fig. 2B represents AlN coating. SEM analysis showed the coating thickness to be 1.5 µm for Al and 0.4 µm for AlN.

For group A with high shear bond strengths, failure mode was adhesive (60%) and cohesive in the resin cement (40%), leaving a small amount of residual resin cement on the debonded surface. The failure mode in Group PAl, PAlN, AAl and AAlN was adhesive at the coated zirconia core surface (100%).

The data support rejection of the hypothesis that Al and AlN coating would improve the shear bond strength of resin cement to zirconia core. Al and AlN coating with air abrasion or polishing, showed lower bond strength values then air abrasion with 50 µm Al2O3 particles. SEM images (Fig. 1B, 1C, 2A and 2B) revealed dense, uniform and smooth coating structure on the zirconia core surface. The result of the present study showed that Al and AlN coating with reactive magnetron sputtering technique did not provide a bonding surface yielding strong bond strength of resin cement.

In previous studies, various surface coatings including tin oxide, alumina (Al), gold (Au), calcium phosphates, glass composites, bioactive phosphosilicate glasses, glass-ceramics and hydroxyapatite have been reported on ceramic surfaces.23,29,34,35 They were also designed for mechanical reason to increase mechanical strength of ceramic used for fixed partial denture and for biological reasons, mainly to promote cell ingrowths and osseointegration of implanted ceramics.35

In earlier studies, aluminous porcelain was coated with tin oxide by a reactive ion plating technique and tensile bond strength of phosphate methacrylate based dental cement to coated and uncoated aluminous porcelain was evaluated.36 The result of the study indicated that reactive ion plating technique was effective technique to increase bond strength of dental cements to aluminous porcelain. In another study, aluminous porcelain was coated with tin oxide by magnetron sputtering technique and resin cement bond strength was evaluated. Similar to the previous study, coating procedure improved the bond strength.37

Ruddell et al.29 reported that mechanical properties of machinable feldspathic porcelain can be improved by the deposition of a thin film of Au, Al an AlN using radio frequency magnetron sputtering technique. The authors stated that magnetron sputtering has the ability to produce coherent thin films on a dental ceramic. Although coating of ceramic surface improved the mechanical properties, it did not interfere with the optical properties of the all ceramic restoration.29 In the present study Al and AlN coating was chosen, in part, because of its translucency to visible light.

When leucite reinforced feldspathic porcelain was modified through the deposition of a sputtered YSZ thin film, the flexural strength of porcelain increased.33,38 It is presumed that the strengthening mechanism is due to modification of surface flaws and/or surface residual stress by the applied thin film.

Teixeira et al.38 evaluated the different YSZ thin film thicknesses (1, 3, 5 and 7 µm) on the flexural strength of a dental ceramic. The authors reported that a slight increase in strength is shown for specimens coated with a 1 µm thick thin film, but this was not statistically different than the uncoated control group. The highest mean strength value was observed for the group coated with 3 µm YSZ thin film. An increase in the thin film thickness did not result in an increase in the flexural strength of the substrate.

The clinical fit of zirconia restorations depends on the manufacturing process. Marginal and internal gaps have been reported ranging from 29 to 119 µm.34,39 In the present study, the coating thickness was only 1.5 µm in Al coating, 0.4 µm in AlN coating which are too lower to cause a problem in marginal and internal adaptation.

Previous studies showed that nano-structured alumina coating seems to be effective in creating microretention, providing favorable resin bonding.23,34 Jevnikar et al.34 evaluated the effect of nano-structured alumina coating on resin bond strength to zirconia ceramics before and after thermocycling. The authors reported that alumina coating to Y-TZP ceramics created a highly retentive surface for resin penetration. The resin bond strength to coated groups was significantly higher than non-coated groups. Despite of morphological differences, the bond strength did not differ between coated groups (as-sintered, polished and air-borne particle abraded). In a recent study, Zhang et al.23 evaluated the influence of contamination and subsequent cleaning on the bond strength and durability of adhesive resin cement to nano-structured alumina-coated zirconia ceramic. They stated that nano-structured alumina coating improves resin bonding to zirconia ceramic and eliminates the need for air abrasion before bonding.23

Coating of materials often involve thin film processes like physical vapor deposition (PVD), chemical vapor deposition (CVD), thermal spray coating, dip/spin coating, electroplating, sol-gel deposition or laser-based processes. These processes lead to coatings with very good mechanical and physical properties.40 In the present study zirconia core surfaces were coated by reactive magnetron sputtering technique. This technique is one of the PVD process and is often used for coating of dental materials. It has been shown that reactive magnetron sputtering has the ability to produce coherent thin films on a dental ceramic at low substrate temperatures. Furthermore these films have a significant effect on the flexural strength and flexural modulus of a dental ceramic, depending on the coating.41

In contrast to previous studies,23,34 in the present study, lower shear bond strength values were obtained in coated groups when compared to air abraded group. SEM images revealed a dense, uniform and smooth coating surface on zirconia core surface after reactive magnetron sputtering. Failure modes of the PAl, PAlN, AAl and AAlN groups were predominantly adhesive and this is in agreement with shear bond strength results where low bond strength values were found for coated surface. Zhang et al.23 and Jevnikar et al.34 used suspension plasma spraying (SPS) technique to coat the specimen surfaces. SPS is a new promising processing method which employs suspensions of submicrometer particles as feedstock. Therefore, much finer grain and pore sizes as well as dense and also thin ceramic coatings can be achieved. The researchers obtained microporous and nano-structured lamellar surface on the zirconia specimen. In this way a large micro-retentive area was created on the specimen surfaces, with the potential for promoting resin bonding.23,34 In the present study flexural strength of zirconia core after Al or AlN coating was not investigated. Also different coating parameters, materials and thickness can be considered in further studies. In vitro studies that replicate clinical conditions are fundamental, especially for the development of new techniques, and should be performed prior to clinical studies.

References

1. Kern M. Resin bonding to oxide ceramics for dental restorations. J Adhes Sci Techno. 2009; 23:1097–1111.

2. Ozcan M, Kerkdijk S, Valandro LF. Comparison of resin cement adhesion to Y-TZP ceramic following manufacturers' instructions of the cements only. Clin Oral Investig. 2008; 12:279–282.

3. Kitayama S, Nikaido T, Maruoka R, Zhu L, Ikeda M, Watanabe A, Foxton RM, Miura H, Tagami J. Effect of an internal coating technique on tensile bond strengths of resin cements to zirconia ceramics. Dent Mater J. 2009; 28:446–453. PMID: 19721282.

4. Casucci A, Mazzitelli C, Monticelli F, Toledano M, Osorio R, Osorio E, Papacchini F, Ferrari M. Morphological analysis of three zirconium oxide ceramics: Effect of surface treatments. Dent Mater. 2010; 26:751–760. PMID: 20471073.

5. Ozcan M, Nijhuis H, Valandro LF. Effect of various surface conditioning methods on the adhesion of dual-cure resin cement with MDP functional monomer to zirconia after thermal aging. Dent Mater J. 2008; 27:99–104. PMID: 18309618.

6. Piascik JR, Swift EJ, Thompson JY, Grego S, Stoner BR. Surface modification for enhanced silanation of zirconia ceramics. Dent Mater. 2009; 25:1116–1121. PMID: 19376572.

7. Blatz MB, Sadan A, Kern M. Resin-ceramic bonding: a review of the literature. J Prosthet Dent. 2003; 89:268–274. PMID: 12644802.

8. Atsu SS, Kilicarslan MA, Kucukesmen HC, Aka PS. Effect of zirconium-oxide ceramic surface treatments on the bond strength to adhesive resin. J Prosthet Dent. 2006; 95:430–436. PMID: 16765155.

9. Matinlinna JP, Lassila LV, Vallittu PK. Pilot evaluation of resin composite cement adhesion to zirconia using a novel silane system. Acta Odontol Scand. 2007; 65:44–51. PMID: 17354094.

10. Tsukakoshi M, Shinya A, Gomi H, Lassila LV, Vallittu PK, Shinya A. Effects of dental adhesive cement and surface treatment on bond strength and leakage of zirconium oxide ceramics. Dent Mater J. 2008; 27:159–171. PMID: 18540388.

11. Tsuo Y, Yoshida K, Atsuta M. Effects of alumina-blasting and adhesive primers on bonding between resin luting agent and zirconia ceramics. Dent Mater J. 2006; 25:669–674. PMID: 17338299.

12. Nagayassu MP, Shintome LK, Uemura ES, Araújo JE. Effect of surface treatment on the shear bond strength of a resin-based cement to porcelain. Braz Dent J. 2006; 17:290–295. PMID: 17262141.

13. Kern M, Thompson VP. Bonding to glass infiltrated alumina ceramic: adhesive methods and their durability. J Prosthet Dent. 1995; 73:240–249. PMID: 7760272.

14. Derand T, Molin M, Kvam K. Bond strength of composite luting cement to zirconia ceramic surfaces. Dent Mater. 2005; 21:1158–1162. PMID: 16005508.

15. Aboushelib MN, Feilzer AJ, Kleverlaan CJ. Bonding to zirconia using a new surface treatment. J Prosthodont. 2010; 19:340–346. PMID: 20202104.

16. Nothdurft FP, Motter PJ, Pospiech PR. Effect of surface treatment on the initial bond strength of different luting cements to zirconium oxide ceramic. Clin Oral Investig. 2009; 13:229–235.

17. Ozcan M, Vallittu PK. Effect of surface conditioning methods on the bond strength of luting cement to ceramics. Dent Mater. 2003; 19:725–731. PMID: 14511730.

18. Della Bona A, Anusavice KJ, Hood JA. Effect of ceramic surface treatment on tensile bond strength to a resin cement. Int J Prosthodont. 2002; 15:248–253. PMID: 12066487.

19. de Oyagüe RC, Monticelli F, Toledano M, Osorio E, Ferrari M, Osorio R. Influence of surface treatments and resin cement selection on bonding to densely-sintered zirconium-oxide ceramic. Dent Mater. 2009; 25:172–179. PMID: 18620746.

20. Amaral R, Ozcan M, Bottino MA, Valandro LF. Microtensile bond strength of a resin cement to glass infiltrated zirconia-reinforced ceramic: the effect of surface conditioning. Dent Mater. 2006; 22:283–290. PMID: 16039705.

21. Wolfart M, Lehmann F, Wolfart S, Kern M. Durability of the resin bond strength to zirconia ceramic after using different surface conditioning methods. Dent Mater. 2007; 23:45–50. PMID: 16427692.

22. Blatz MB, Chiche G, Holst S, Sadan A. Influence of surface treatment and simulated aging on bond strengths of luting agents to zirconia. Quintessence Int. 2007; 38:745–753. PMID: 17873981.

23. Zhang S, Kocjan A, Lehmann F, Kosmac T, Kern M. Influence of contamination on resin bond strength to nano-structured alumina-coated zirconia ceramic. Eur J Oral Sci. 2010; 118:396–403. PMID: 20662914.

24. Guazzato M, Quach L, Albakry M, Swain MV. Influence of surface and heat treatments on the flexural strength of Y-TZP dental ceramic. J Dent. 2005; 33:9–18. PMID: 15652163.

25. Oblak C, Jevnikar P, Kosmac T, Funduk N, Marion L. Fracture resistance and reliability of new zirconia posts. J Prosthet Dent. 2004; 91:342–348. PMID: 15116035.

26. Guazzato M, Proos K, Quach L, Swain MV. Strength, reliability and mode of fracture of bilayered porcelain/zirconia (Y-TZP) dental ceramics. Biomaterials. 2004; 25:5045–5052. PMID: 15109867.

27. Zhang Y, Lawn BR, Malament KA, Van Thompson P, Rekow ED. Damage accumulation and fatigue life of particle-abraded ceramics. Int J Prosthodont. 2006; 19:442–448. PMID: 17323721.

28. Amaral R, Ozcan M, Valandro LF, Balducci I, Bottino MA. Effect of conditioning methods on the microtensile bond strength of phosphate monomer-based cement on zirconia ceramic in dry and aged conditions. J Biomed Mater Res B Appl Biomater. 2008; 85:1–9. PMID: 17680669.

29. Ruddell DE, Thompson JY, Stoner BR. Mechanical properties of a dental ceramic coated by RF magnetron sputtering. J Biomed Mater Res. 2000; 51:316–320. PMID: 10880072.

30. Tanaka K, Kimoto K, Sawada T, Toyoda M. Shear bond strength of veneering composite resin to titanium nitride coating alloy deposited by radiofrequency sputtering. J Dent. 2006; 34:277–282. PMID: 16153766.

31. Liu GT, Duh JG, Chung KH, Wang JH. Mechanical characteristics and corrosion behavior of (Ti,Al)N coatings on dental alloys. Surf Coat Technol. 2005; 200:2100–2105.

32. Tek Z, Gügör MA, Çal E, Sonugelen M, Artunç C, Oztarhan A. A study of the mechanical properties of TiN coating of Cr-Ni alloy. Surf Coat Technol. 2005; 196:317–320.

33. Teixeira EC, Piascik JR, Stoner BR, Thompson JY. Dynamic fatigue behavior of dental porcelain modified by surface deposition of a YSZ thin film. J Prosthodont. 2008; 17:527–531. PMID: 18761578.

34. Jevnikar P, Krnel K, Kocjan A, Funduk N, Kosmac T. The effect of nano-structured alumina coating on resin-bond strength to zirconia ceramics. Dent Mater. 2010; 26:688–696. PMID: 20381854.

35. Ferraris M, Verné E, Appendino P, Moisescu C, Krajewski A, Ravaglioli A, Piancastelli A. Coatings on zirconia for medical applications. Biomaterials. 2000; 21:765–773. PMID: 10721745.

36. McCrory PV, Tinston S, Piddock V, Kelly P, Combe EC, Arnell RD. Tin oxide coating of aluminous porcelain by reactive ion plating. J Dent. 1991; 19:171–175. PMID: 1939818.

37. McCrory PV, Piddock V, Combe EC, Tinston S, Arnell RD, Weglicki P, Owen J. Evaluation of a potential dental application of vapour deposition techniques for coating alumina with tin oxide. J Mater Sci. 1994; 5:543–550.

38. Teixeira EC, Piascik JR, Stoner BR, Thompson JY. Effect of YSZ thin film coating thickness on the strength of a ceramic substrate. J Biomed Mater Res B Appl Biomater. 2007; 83:459–463. PMID: 17471523.

39. Beuer F, Aggstaller H, Edelhoff D, Gernet W, Sorensen J. Marginal and internal fits of fixed dental prostheses zirconia retainers. Dent Mater. 2009; 25:94–102. PMID: 18620749.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download