Abstract

Objectives

In this study we evaluated heat generation during the low-speed drilling procedure without irrigation.

Materials and Methods

Ten artificial bone blocks that were similar to human D1 bone were used in this study. The baseline temperature was 37.0℃. We drilled into 5 artificial bone blocks 60 times at the speed of 50 rpm without irrigation. As a control group, we drilled into an additional 5 artificial bone blocks 60 times at the speed of 1,500 rpm with irrigation. The temperature changes during diameter 2 mm drilling were measured using thermocouples.

Preparation of hard tissues for the insertion of dental implants is usually performed by drilling at high-speed with irrigation. Recently, a new concept of low-speed drilling (50 rpm) without irrigation was suggested as an alternative to the conventional procedure123. The low-speed drilling has several advantages over the high-speed drilling with irrigation. First, the difficulty of irrigation can be solved through drill guides during drilling45. Another advantage is the possibility to collect the bone cut by the drills without contamination by saliva, which can be used for an autograft6. The low-speed drilling can also provide the operator with more precise information on the path of the drill so that corrections can be made if necessary. Consequently, osteotomy can be better controlled by low-speed drilling. Kim et al.1 measured the temperature change in pig rib bone during implant site preparation by drilling at 50 rpm without irrigation and reported that drilling at 50 rpm without irrigation did not produce overheating. In the study, the animal bone without a uniform cortical layer was used. In an attempt to provide more rigorous data, in this study we evaluated heat generation during the low-speed drilling procedure without irrigation.

This in vitro study was designed to simulate the clinical conditions involved in implant site preparation. A total of 10 artificial bone blocks (solid rigid polyurethane foam; Sawbones, Vashon Island, WA, USA) similar to human D1 bone were used in this study.(Fig. 1) The artificial block bone D1 was based on The American Society for Testing and Materials. The blocks consisted of both the cortical layer (thickness, 3 mm; density, 0.8 g/mL) and the cancellous layer (thickness, 15 mm; density, 0.48 g/mL). Drill guides, which could accurately guide drills into their predetermined locations and orientations were designed and fabricated to be placed on the blocks.

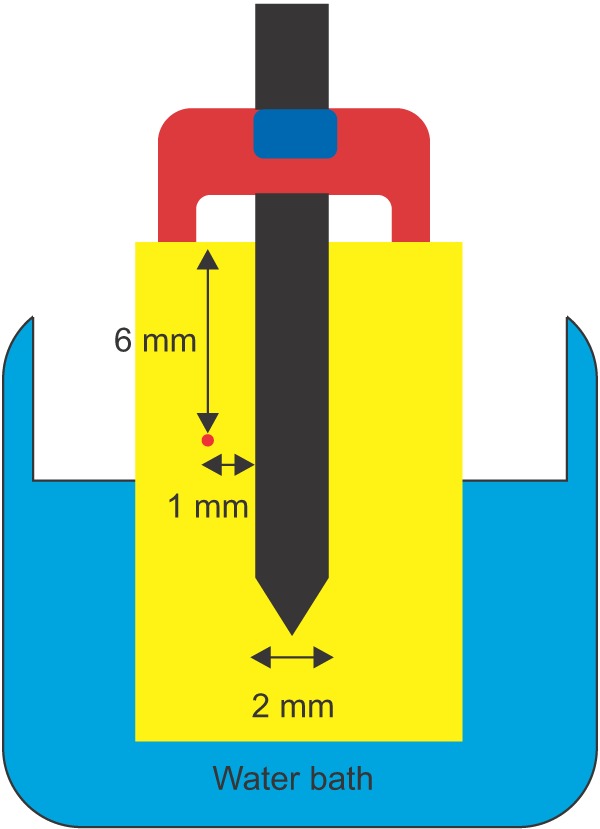

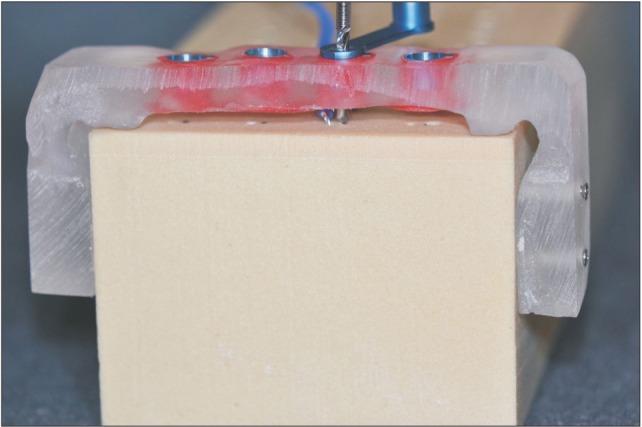

Type K thermocouples (Yokogawa, Tokyo, Japan) were used to measure temperature changes during drilling. A 4-channel handheld data logger thermometer that could measure temperature at 4 sites simultaneously (Yokogawa) and allowed constant, real-time temperature readings was used to read the thermocouples. Temperature measurements were made during site preparation with the diameter 2 mm twist drill (Dio Inc., Busan, Korea). The canal for the thermocouple was drilled to a predetermined depth with a 1 mm bur using the surgical drill guide. One thermocouple was inserted vertically into the 1-mm holes prepared to a depth of 6 mm. The thermocouple was placed 1 mm away from the anticipated periphery of the osteotomy to measure the temperature without damaging the cable while drilling.(Fig. 2) After fixing the thermocouple, the drill guide was placed in the block and fixed using fixation screws.(Fig. 3)

To duplicate clinical operating conditions, the bone blocks with the thermocouple were immersed in a 37℃ water bath (Fig. 2) to set the baseline temperature of 37℃ similar to the human body. Ten blocks were divided into the test and control groups (5 blocks each). In the test group, drilling was performed with the drill guide to a 10-mm depth at a rotation speed of 50 rpm without irrigation. In the control group, drilling was performed with the drill guide to a 10-mm depth at a rotation speed of 1,500 rpm with irrigation. An automated cooling system was used to deliver continuously normal saline to the external wall of the drill throughout drilling at a rate of 40 mL/min. To eliminate the effect of the drill guide on the external irrigation, additional irrigation was performed manually with a simple syringe to deliver the saline solution directly to the drill bone interface. The drilling was performed 12 times on each block. The total time of drilling from start to finish was measured. Apart from the drill speed and the irrigation, the procedures were the same for both groups. After drilling, accuracy and precision in maintaining the 1 mm distance between the thermocouple canal and the drill preparation was determined using a standard dental radiograph. The thickness of the bone substitute wall between the drill preparations and the thermocouple canals was measured. Once the 1 mm wall between them was confirmed, data were included in the study. Temperature values were stored in a personal computer and then analyzed using the SPSS version 15.0 for Windows (SPSS Inc., Chicago, IL, USA). Student's t-test was used to calculate significant differences between the two groups. A P-value <0.05 was considered statistically significant.

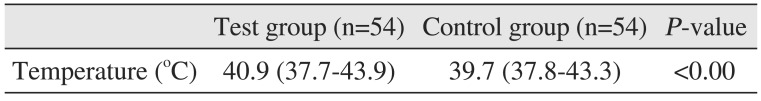

Sixty drilling procedures using drill guides were performed in each group. The average drilling times were 25 and 10 seconds for the test and control groups, respectively.(Fig. 4) The low-speed drilling required approximately 15 seconds longer than the high-speed drilling. Data from 6 drilling sites in each group were excluded from this study, as the wall between the drill preparations and the thermocouple canals did not remain intact. The mean maximum temperatures at the drilling sites were 40.9℃ (range, 37.7℃-43.9℃) in the test group and 39.7℃ (range, 37.8℃-43.3℃) in the control group.(Table 1) Although statistically significant differences existed between the two groups, the low-speed drilling did not produce overheating.

Bone cell survival is susceptible to heat. Eriksson and Albrektsson7 reported that a bone temperature of 47℃ for 1 minute can cause bone cell necrosis. In the present study, overheating was considered when the bone temperature was higher than 47℃. In terms of the heat generated during drilling, in the present study we measured temperature changes during low-speed drilling without irrigation. The measured temperature increase was very low in this experiment, compared to the critical temperature of 47℃7. Apparently, the low-speed drilling did not produce overheating. The results of this study indicated that the low-speed drilling without irrigation might be useful for implant surgery. These findings are in agreement with previously published reports. Kim et al.1 measured the temperature change during implant site preparation by drilling at 50 rpm without irrigation with three different drill systems and reported that drilling at 50 rpm without irrigation did not produce overheating. Giro et al.2 evaluated the effect of the surgical technique on implant integration by performing osteotomies at 50 rpm without irrigation and 900 rpm with irrigation. The authors concluded that both techniques showed similar results and did not affect the integration of implants. Gaspar et al.3 evaluated immediate histological alterations in rabbit tibias produced by low-speed drilling (50 rpm) without irrigation and conventional drilling (800 rpm) under profuse irrigation and concluded that the effects of implant site preparation on bone by the low-speed drilling without irrigation and the conventional drilling under abundant irrigation are similar.

When drilling in bone, the recorded temperatures change exponentially with the distance to the heat sensitive element, and reproducing the position of the thermocouple in relation to the source of heat is necessary. A distance of 1 mm between the heat-producing area and the recording device is standard in most studies on heat production during drilling8910 and was accomplished using a drill guide that could accurately guide drills into their predetermined locations and orientations, the accuracy of which was tested by a standard dental radiograph. To fabricate well-tailored drill guides in the present study, diagnostic casts were created, a resin template was made using clear acrylic resin and then metal sleeves were placed in the resin template.

Arguably, a slower rotational speed requires more drilling time, thus producing more frictional heat and likely overheating during drilling11. In the present study, low-speed drilling required approximately 15 seconds longer in the artificial bone block that was similar to human D1 bone, compared to high-speed drilling. The drilling time was considered clinically acceptable. Drill wear caused by repeated use may result in increased heat production and further damage to the bone tissue10, thus affecting the process of osseointegration of implants12. In our previous study, after 40 uses, the implant drills used in the present study were determined to generate more heat. Therefore, the drills in the present study were used only 10 times to drill into the bone effectively.

References

1. Kim SJ, Yoo J, Kim YS, Shin SW. Temperature change in pig rib bone during implant site preparation by low-speed drilling. J Appl Oral Sci. 2010; 18:522–527. PMID: 21085811.

2. Giro G, Marin C, Granato R, Bonfante EA, Suzuki M, Janal MN, et al. Effect of drilling technique on the early integration of plateau root form endosteal implants: an experimental study in dogs. J Oral Maxillofac Surg. 2011; 69:2158–2163. PMID: 21530048.

3. Gaspar J, Borrecho G, Oliveira P, Salvado F, Martins dos Santos J. Osteotomy at low-speed drilling without irrigation versus highspeed drilling with irrigation: an experimental study. Acta Med Port. 2013; 26:231–236. PMID: 23815837.

4. Misir AF, Sumer M, Yenisey M, Ergioglu E. Effect of surgical drill guide on heat generated from implant drilling. J Oral Maxillofac Surg. 2009; 67:2663–2668. PMID: 19925988.

5. Jeong SM, Yoo JH, Fang Y, Choi BH, Son JS, Oh JH. The effect of guided flapless implant procedure on heat generation from implant drilling. J Craniomaxillofac Surg. 2014; 42:725–729. PMID: 24332815.

6. Anitua E, Carda C, Andia I. A novel drilling procedure and subsequent bone autograft preparation: a technical note. Int J Oral Maxillofac Implants. 2007; 22:138–145. PMID: 17340908.

7. Eriksson RA, Albrektsson T. The effect of heat on bone regeneration: an experimental study in the rabbit using the bone growth chamber. J Oral Maxillofac Surg. 1984; 42:705–711. PMID: 6593442.

8. Eriksson RA, Adell R. Temperatures during drilling for the placement of implants using the osseointegration technique. J Oral Maxillofac Surg. 1986; 44:4–7. PMID: 3455722.

9. Harris BH, Kohles SS. Effects of mechanical and thermal fatigue on dental drill performance. Int J Oral Maxillofac Implants. 2001; 16:819–826. PMID: 11769832.

10. Chacon GE, Bower DL, Larsen PE, McGlumphy EA, Beck FM. Heat production by 3 implant drill systems after repeated drilling and sterilization. J Oral Maxillofac Surg. 2006; 64:265–269. PMID: 16413899.

11. Sharawy M, Misch CE, Weller N, Tehemar S. Heat generation during implant drilling: the significance of motor speed. J Oral Maxillofac Surg. 2002; 60:1160–1169. PMID: 12378492.

12. Carvalho AC, Queiroz TP, Okamoto R, Margonar R, Garcia IR Jr, Magro Filho O. Evaluation of bone heating, immediate bone cell viability, and wear of high-resistance drills after the creation of implant osteotomies in rabbit tibias. Int J Oral Maxillofac Implants. 2011; 26:1193–1201. PMID: 22167423.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download