Abstract

Objectives

This study aimed to evaluate the stability of prosthetic screws from three types of craniofacial prostheses retention systems (bar-clip, ball/O-ring, and magnet) when submitted to mechanical cycling.

Materials and Methods

Twelve models of acrylic resin were used with implants placed 20 mm from each other and separated into three groups: (1) bar-clip (Sistema INP, São Paulo, Brazil), (2) ball/O-ring (Sistema INP), and (3) magnet (Metalmag, São Paulo, Brazil), with four samples in each group. Each sample underwent a mechanical cycling removal and insertion test (f=0.5 Hz) to determine the torque and the detorque values of the retention screws. A servo-hydraulic MTS machine (810-Flextest 40; MTS Systems, Eden Prairie, MN, USA) was used to perform the cycling with 2.5 mm and a displacement of 10 mm/s. The screws of the retention systems received an initial torque of 30 Ncm and the torque values required for loosening the screw values were obtained in three cycles (1,080, 2,160, and 3,240). The screws were retorqued to 30 Ncm before each new cycle.

Results

The sample was composed of 24 screws grouped as follows: bar-clip (n=8), ball/O-ring (n=8), and magnet (n=8). There were significant differences between the groups, with greater detorque values observed in the ball/O-ring group when compared to the bar-clip and magnet groups for the first cycle. However, the detorque value was greater in the bar-clip group for the second cycle.

Prostheses utilizing screws are largely utilized for multiple and single units because the screws can be easily accessed without damage to the prostheses1. This is important because although we have historical clinical success of implantsupported rehabilitations, some adverse outcomes still occur, such as loosening or fracture of the prosthetic screws2.

The stability of the retention screw is related to several factors, including the geometrical shape, thread format, fit of the prosthetic component, frictional coefficient of the screw, amount and properties of lubricant, speed of tightening, tightening force used, and occlusal loads applied3.

When torque is applied to screws that retain a non-passive framework, the screws can be overloaded, thus increasing the chances of loosening and fracture. After the initial torque is applied, a compressive force is generated on the screw. The tension created at the thread surfaces of the retention screw, the so-called preload, is responsible for keeping the components together. The stability is directly related to the stretching of the screw and the maintenance of the retaining screws. In such cases, if the preload decreases below a critical level, the stability of the screw joint will be compromised4.

The aim of the study was to evaluate the stability of prosthetic screws used within three types of craniofacial prostheses retention systems (bar-clip, ball/O-ring, and magnet) when submitted to mechanical cycling.

To conduct the present study, twenty-four craniofacial implants of dimensions 4×6 mm (HABE Implants-facie line; INP System, São Paulo, Brazil) utilized for facial prosthesis were used. Three retained auricular prosthesis implant-supported systems, the bar-clip system, magnet system, and ball/O-ring system, were considered as study factors.

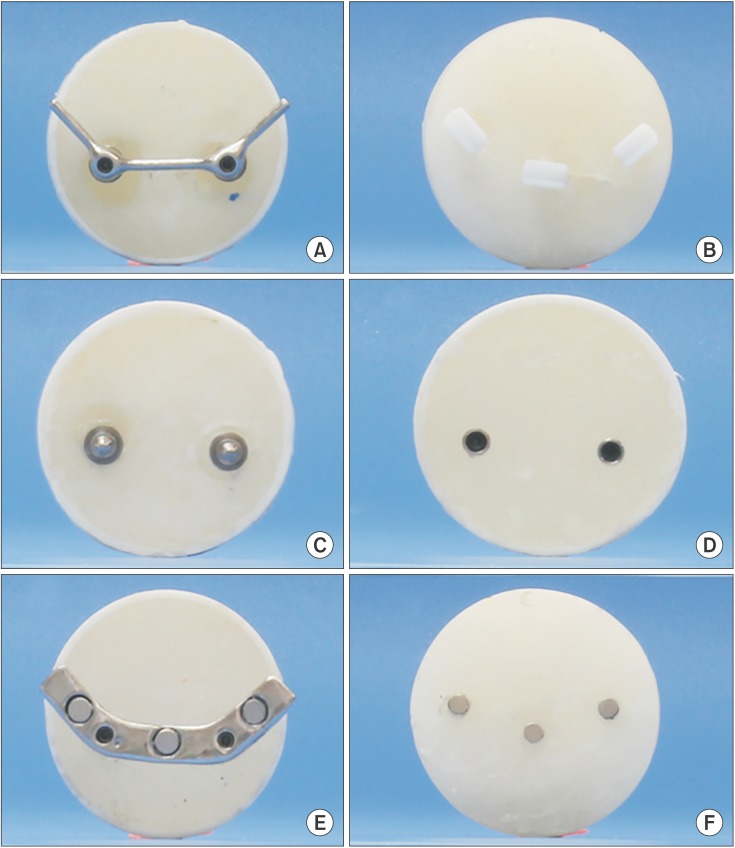

Twelve cylinders 2.0×3.8 cm (height×diameter) filled with self-polymerized colorless acrylic resin (Vipi Flash; Dental Vipi, São Paulo, Brazil) were used to replicate the fixation of two craniofacial implants (HABE Implants-facie line) and its connection components. The craniofacial implants were positioned parallel at 20 mm apart in a polyvinyl chloride cylinder. To capture the retained auricular prosthesis systems, twelve cylinders with similar characteristics were filled with self-polymerized acrylic resin, and then the respective retention system was positioned. Three groups were present based upon the retention systems tested (4 devices with 8 implants in each group).(Fig. 1)

Two craniofacial implants and a bar-clip retention system were used with a bar of 20 mm for the overdenture and three straight plastics clips (INP System). The custom bars were fixed to the implants via UCLA (INP System) and cast in nickel-chromium alloy. The clips were placed on the metal bars and fixed to the holders with self-polymerized acrylic resin.

Two craniofacial implants and an O-ring retention system with two retaining balls, two spacers rings, and two rubber rings retained in a metal capsule (INP System) were required. The retaining balls were screwed to the implants with a torque of 30 Ncm using a torque wrench (INP System). The spacers were placed over the balls. The O-rings were placed over the spacers, and then captured with self-polymerized acrylic resin.

The magnet system contained craniofacial implants and a magnet retention system with three 4.0×2.0 mm neodymium-ironboron magnets coated with nickel (Metalmag, São Paulo, Brazil). A plastic structure containing three apertures was fixed to the implants via UCLA (INP System), and then sent to the lab for casting of nickel-chromium alloy. Three magnets were glued to the metallic structure and another three magnets where positioned over the glued magnets in order to capture the holders.

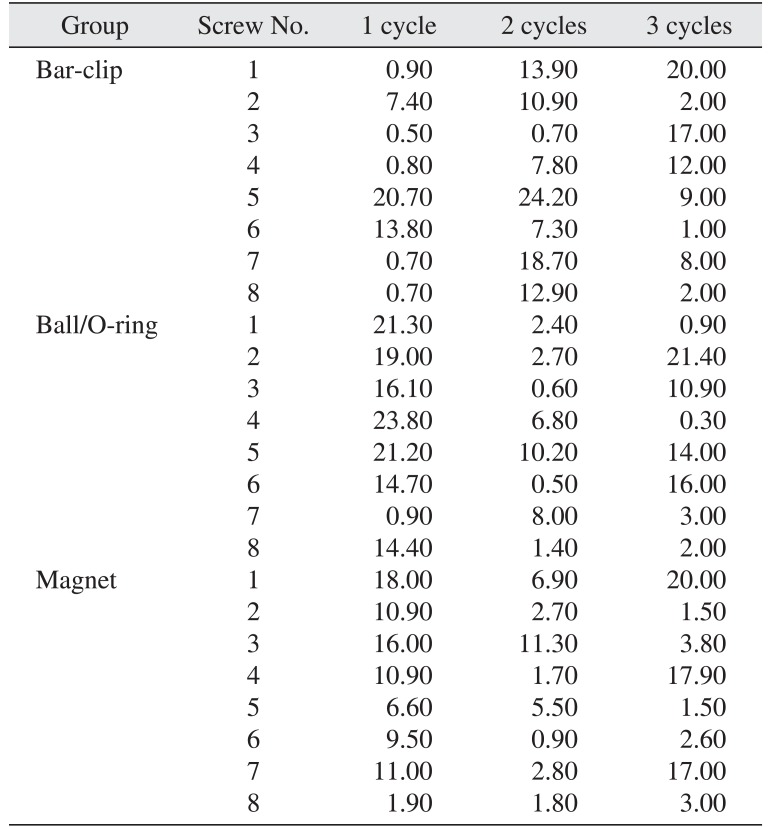

For torque and detorque readings, all retention systems were screwed onto their respective implants using a digital torque meter with 0.1 N/cm precision (Torque Meter TQ-8800; Lutron, Taipei, Taiwan) to 30 Ncm (torque recommended by the manufacturer INP System) for each screw. (Fig. 2) The retention systems were submitted to cyclical mechanical loading using the servo-hydaulic machine MTS 810-Flex Test 40 (MTS Systems, Eden Prairie, MN, USA), which was calibrated to operate with a 1.5 kN load cell at 0.5 Hz and performed movement along the long axis of the implants. To adapt the samples to the servo-hydraulic machine, a two-piece metal device was prepared. Each part has a cylindrical portion, where the samples were positioned and secured by four screws located around the cylinder. In the lower portion of these devices, a cylindrical metal bracket allowed for attaching the samples to the MTS machine. In the device located at the bottom of the machine, the samples were adapted to the systems according to each of the test groups.

After this procedure, the samples were first inserted into the lower cylinder component, and then the load cell was slowly lowered to the upper cylinder locking position, thus guaranteeing adaptation between the prosthetic components. Therefore, both cylinders containing the samples were fixed in their respective devices. Each replica was subjected to the pull-out test to determine the tensile strength corresponding to three years of prosthesis usage, which assumes that an auricular prosthesis is removed three times a day and the change of prosthesis should be performed after two to three years of use due to progressive change in texture and color567. The lifetime of a prosthesis was based on results from Hooper et al.8 that reported a mean lifetime of 14 months for implant-retained extraoral prostheses. Another study demonstrated a mean time of 17 months for implant-retained auricular prosthesis9 and a recent study indicated that a new prosthesis should be made every 1.5 to 2 years6. The test samples underwent 1,080 cycles, after which the detorque value was measured and a 30 Ncm re-torque was applied to the connector screw. This procedure was repeated after the corresponding cycles representing two years (2,160 cycles) and three years (3,240 cycles).

Data analysis was performed using the computer programs Biostat 5.0 (Belém, Brazil) and PASW Statistics 18.0 (IBM Co., Armonk, NY, USA). The detorque values were submitted to the Shapiro-Wilk and Levene method; despite having homogeneity of variances P>0.05, the sample did not show a normal distribution (P<0.05). Thus, the data were evaluated via comparative analysis in relation to the number of cycles (one year, two years, and three years) within each type of retention system (bar-clip, ball/O-ring, and magnets) by the Kruskal-Wallis test and post hoc Duncan test. Comparisons of the type of retention were performed for each evaluation period. The results were considered statistically significant if P<0.05.

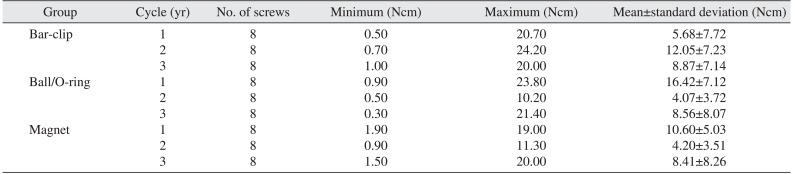

The mean and standard deviation of the detorque value according to the type of retention system and the number of cycles are shown in Table 1. It was observed that some screws showed total loosening after completion of the first year cycling test, with a higher number in the bar-clip group (n=5). Other instances of loosening screws are presented in Table 2.

There were no statistically significant differences when comparing the detorque values in relation to the number of cycles (one, two, and three years) with bar-clip (Kruskal-Wallis, P=0.66) and magnet retention systems (Kruskal-Wallis, P=0.20). However, for the ball/O-ring retention system, a statistically significant difference was observed between the first year and second year, while the highest detorque was observed in the first year (z=–2.72; P<0.05).

When comparing the torque values to the type of retention system, a statistical difference was observed for the first cycle (Kruskal-Wallis, P=0.02); the detorque value was greater in the ball/O-ring retention system when compared to the bar-clip retention system (z=2.81; P<0.05). For the second cycle, a statistically significant difference was noted between the three groups, with higher values in the bar-clip group as compared with ball/O-ring (P<0.05) and magnets groups (P<0.05). There was no difference between groups for the third year of cycles (Kruskal-Wallis, P=0.102); results are presented in Table 2.

This study evaluated the loosening of screws and the influence of three different retention systems. The hypothesis of the study was that the different prosthesis retention systems did not influence the loosening of prosthetic screw. There were no statistically significant differences when detorque values were compared between the bar-clip and magnet retention systems, but statistical difference was found when comparing the first and second cycles of the ball/O-ring retention system.

The detorque value refers to the force required to remove the screw, so when this force is greater, it means that the screw has lost only part of the initial retention torque applied (30 N). In the first year of cycles, we observed a greater loss of the initial screw torque for the group retained by a bar-clip compared to a ball/O-ring. However, in the second year of cycling, we observed that the group retained by a bar-clip did not lose retention as noted in the first years. This result could be due to the plastic deformation of the clip and consequent loss of retention. For the group retained by a ball/O-ring, the contrary effect was noted with an increase of retention between the first and second years. Despite these results, we did not find the same tendency in the third year of cycles, which could be due to possible wear on the internal threads of the implant.

The results demonstrate that the more times a screw is removed and reinserted, the less torque that is required to remove it again. These results are similar to those obtained by Weiss et al.10 in 2000 and Cardoso et al.11 in 2012, who also found an inverse relationship between the tightening/loosening force and the number of cycles. However, this relationship is not true for the ball/O-ring group, which showed an increase of retention between the first and second year cycles. These results could be due to degradation of the plastic parts, which tend to suffer deformation due to forces generated during the test. These changes may have caused an increase in the retaining force and screw loosening concomitantly, a phenomenon already observed in another study using electron microscopy12. Another probable cause of increased retention is the thermal expansion of plastic during the test13.

In this study, all retention systems had a smaller detorque value than the initial tightening torque (30 Ncm). Cho et al.14 confirmed that screw loosening is caused by an inadequate tightening torque, settling of implant components, inappropriate implant position, inadequate occlusal scheme or a crown anatomy, poorly fitting frameworks, improper screw design/material, and heavy occlusal forces.

The resistance to opening torque is a direct function of the tension in the screw and the frictional resistance of the components, and is inversely related to the vertical force vector that results from the thread's radial and tangential slopes. Because the vertical force vectors resulting from the threads' radial and tangential slopes tend to open the screw, maintaining the preload relies mainly on the component of friction10.

During this study, the removal and insertion axis were always perpendicular to the base of the retention system. This condition is not necessarily true during clinical use, because the retention system may undergo small dislocations and lead to deformations of the retention system, faster loss of retention, and hence a decrease in clinical longevity1516.

When the prosthetic screw is tightened, a preload is produced, causing tension in components that create friction. In cases where the adaptation is tolerable, the abutment-implant interface makes only partial contact. Thus, the screw ultimately receives all of the load and its fatigue resistance becomes low. When an external load is applied to the components that are joined, the tension on the screw increases further. According to the same authors, in cases where the precision of the prosthesis is adequate, the screws provide a fatigue resistance of at least twenty years. In cases where the adaptation of the prosthesis is deficient, this time is reduced dramatically17.

As presented by Weiss, all of the screws showed a progressive decrease in opening torque. To minimize screw loosening, Weiss also recommends that the number of closing/opening cycles in clinical and laboratory procedures before final prosthetic closure should be minimized.

No other study has assessed the effect of replacing a screw with a new screw. In 2012, Cardoso et al.11 found no evidences that the replacing of a prosthetic screw procedure alone increases the resistance to loosening, perhaps because a modification had already occurred, possibly due to wear of the internal threads of the implant. Apparently, it is more important to restrict the number of removals than to replace the screw when inserting the definitive restoration.

A previous study evaluated the effect of retightening sometime after the initial tightening torque on the stability of the prosthetic screws, and concluded that retightening represents an easy and fast method to increase stability. However, it has been observed that holding the torque meter for a period of time during the tightening of the screws could provide an elongation of the screw and increased pre-load1819.

Modifications in the screw surface have been proposed to promote greater preload stability. The coating of the screw surface with diamond-like carbon film is one of the methods employed and already commercially available. Being better than non-coated screws due to its capacity to reduce stresses during tightening and offering a higher preload, it may equally reduce the frictional resistance of the screw to removal. However, there is no consensus in the literature regarding the benefits of coated screws for prosthetic fixation1.

This study concluded that as follows: (1) All prosthetic screws will have a loosening trend after initial tightening torque. (2) The bar-clip retention system yields more loosening of the screws when compared with ball/O-ring and magnet retention systems during the first year of prosthesis usage. (3) The ball/O-ring system seems to have a better retention of prosthesis over the time, which means a lower detorque. However, it was not possible to establish whether this trend is stable over the long-term, as it was not present in third year of cycles.

References

1. Bacchi A, Regalin A, Bhering CL, Alessandretti R, Spazzin AO. Loosening torque of Universal Abutment screws after cyclic loading: influence of tightening technique and screw coating. J Adv Prosthodont. 2015; 7:375–379. PMID: 26576253.

2. Jemt T, Lekholm U, Gröndahl K. 3-year followup study of early single implant restorations ad modum Brånemark. Int J Periodontics Restorative Dent. 1990; 10:340–349. PMID: 2098358.

3. Binon PP. Evaluation of the effectiveness of a technique to prevent screw loosening. J Prosthet Dent. 1998; 79:430–432. PMID: 9576318.

4. Cibirka RM, Nelson SK, Lang BR, Rueggeberg FA. Examination of the implant-abutment interface after fatigue testing. J Prosthet Dent. 2001; 85:268–275. PMID: 11264934.

5. Karakoca S, Aydin C, Yilmaz H, Bal BT. Retrospective study of treatment outcomes with implant-retained extraoral prostheses: survival rates and prosthetic complications. J Prosthet Dent. 2010; 103:118–126. PMID: 20141816.

6. Visser A, Raghoebar GM, van Oort RP, Vissink A. Fate of implant-retained craniofacial prostheses: life span and aftercare. Int J Oral Maxillofac Implants. 2008; 23:89–98. PMID: 18416416.

7. Sencimen M, Bal HE, Demiroğullari M, Kocaoglu M, Dogan N. Auricular episthesis retained by an attachment system (2 case reports). Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2008; 105:e28–e34.

8. Hooper SM, Westcott T, Evans PL, Bocca AP, Jagger DC. Implant-supported facial prostheses provided by a maxillofacial unit in a U.K. regional hospital: longevity and patient opinions. J Prosthodont. 2005; 14:32–38. PMID: 15733133.

9. Aydin C, Karakoca S, Yilmaz H, Yilmaz C. Implant-retained auricular prostheses: an assessment of implant success and prosthetic complications. Int J Prosthodont. 2008; 21:241–244. PMID: 18548964.

10. Weiss EI, Kozak D, Gross MD. Effect of repeated closures on opening torque values in seven abutment-implant systems. J Prosthet Dent. 2000; 84:194–199. PMID: 10946337.

11. Cardoso M, Torres MF, Lourenço EJ, de Moraes Telles D, Rodrigues RC, Ribeiro RF. Torque removal evaluation of prosthetic screws after tightening and loosening cycles: an in vitro study. Clin Oral Implants Res. 2012; 23:475–480. PMID: 21457352.

12. Fromentin O, Picard B, Tavernier B. In vitro study of the retention and mechanical fatigue behavior of four implant overdenture stud-type attachments. Pract Periodontics Aesthet Dent. 1999; 11:391–397. quiz 398. PMID: 10379298.

13. Wichmann MG, Kuntze W. Wear behavior of precision attachments. Int J Prosthodont. 1999; 12:409–414. PMID: 10709521.

14. Cho WR, Huh YH, Park CJ, Cho LR. Effect of cyclic loading and retightening on reverse torque value in external and internal implants. J Adv Prosthodont. 2015; 7:288–293. PMID: 26330975.

15. de Sousa AA, Mattos BS. Magnetic retention and bar-clip attachment for implant-retained auricular prostheses: a comparative analysis. Int J Prosthodont. 2008; 21:233–236. PMID: 18548962.

16. Moura e Costa AJ, Lasserre FS, Westphalen VP, Deonizio MD, da Silva Neto UX, de Sousa MH. Delayed tooth replantation: case report. Rev Clin Pesq Odontol. 2004; 1:41–43.

17. Patterson EA, Johns RB. Theoretical analysis of the fatigue life of fixture screws in osseointegrated dental implants. Int J Oral Maxillofac Implants. 1992; 7:26–33. PMID: 1398820.

18. Siamos G, Winkler S, Boberick KG. Relationship between implant preload and screw loosening on implant-supported prostheses. J Oral Implantol. 2002; 28:67–73. PMID: 12498448.

19. Spazzin AO, Henrique GE, Nóbilo MA, Consani RL, Correr-Sobrinho L, Mesquita MF. Effect of retorque on loosening torque of prosthetic screws under two levels of fit of implant-supported dentures. Braz Dent J. 2010; 21:12–17. PMID: 20464315.

Fig. 1

Prostheses retention systems. A, B. Bar-clip retention system. C, D. Ball/O-ring retention system. E, F. Magnets retention system.

Table 1

Detorque results for the cycle number corresponding to one year and three years depending on retention system type

Table 2

Detorque values (Ncm) of the different retention types after cycling

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download