Abstract

Three-dimensional (3D) computed tomography image models are helpful in reproducing the maxillofacial area; however, they do not necessarily provide an accurate representation of dental occlusion and the state of the teeth. Recent efforts have focused on improvement of dental imaging by replacement of computed tomography with other detailed digital images. Unfortunately, despite the advantages of medical simulation software in dentofacial analysis, diagnosis, and surgical simulation, it lacks adequate registration tools. Following up on our previous report on orthognathic simulation surgery using computer-aided design/computer-aided manufacturing (CAD/CAM) software, we recently used the registration functions of a CAD/CAM platform in conjunction with surgical simulation software. Therefore, we would like to introduce a new technique, which involves use of the registration functions of CAD/CAM software followed by transfer of the images into medical simulation software. This technique may be applicable when using various registration function tools from different software platforms.

This technique describes the superimposition of three-dimensional (3D) images of dental cast models on computed tomography (CT) images using the surface-based registration (SBR) function of industrial computer-aided design/computer-aided manufacturing (CAD/CAM) software for use in surgical simulation medical software that lacks a defined tool for SBR.

First, a facial CT image, stored as a digital imaging and com munications in medicine (DICOM) file, is imported into the simulation software (e.g., Mimics version 14.0 software; Materialise, Leuven, Belgium) to convert the DICOM format to the stereolithography (STL) format. Any simulation software that has the DICOM-to-STL conversion function can be used.

Impressions of the patient's teeth are used to create a dental model with dental stone. Each dental cast model is scanned with a 3D-light scanner (e.g., Rexcan DS2; Solutionix, Seoul, Korea) to obtain the STL data. Then, both the CT and the dental cast STL files are imported into commercial CAD/CAM software (e.g., Rapidform XOV2; INUS Technology, Seoul, Korea), which has a SBR function for overlapping images in a user-defined surface.

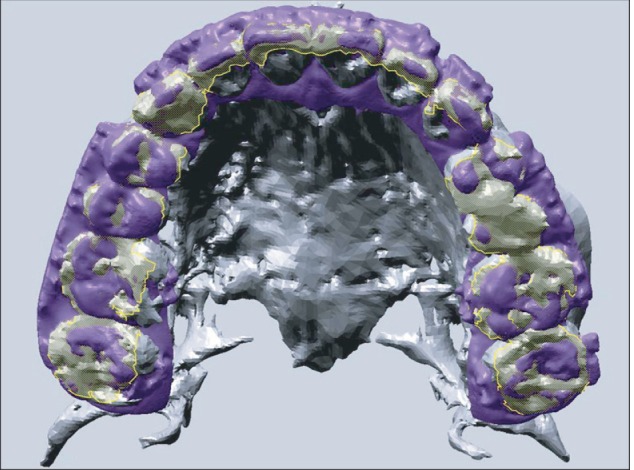

Next, the occlusal surface area is defined. The STLs of the maxillary and mandibular scans of the dental cast are superimposed onto the STL of the CT with the SBR function.(Fig. 1) Deciding which image to move is an important step. Here, the dental cast image must be moved to match the CT image, as the surgical simulation software uses the CT data. Thus, the STL of the dental casts will have positional information relative to the CT image, and every point on the STL has 3D coordinates. The displaced STL of the dental casts is then exported from the CAD software and imported into the surgical simulation software without any other registration procedure.

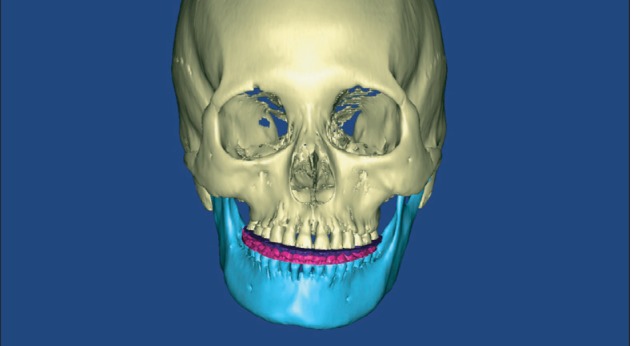

Finally, although the medical simulation software lacks a SBR function tool, the digital dental casts can be superimposed onto the CT images based on the SBR information.(Fig. 2)

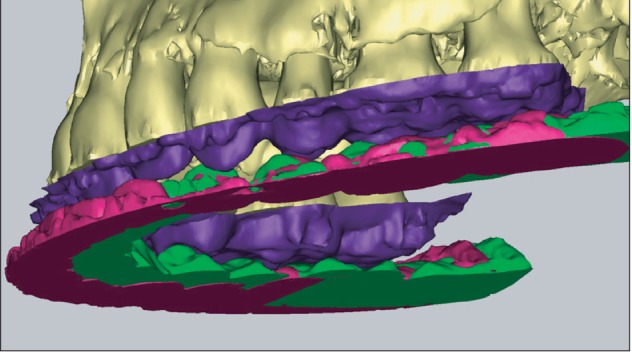

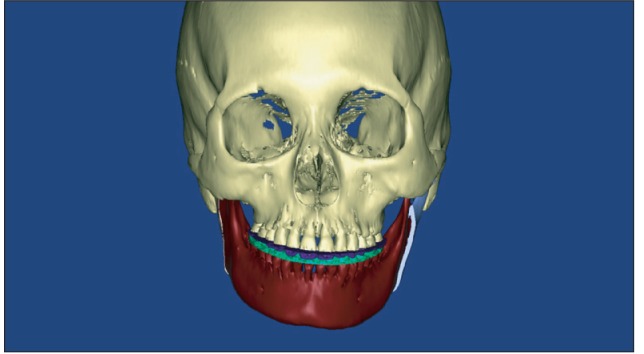

Additionally, to obtain necessary positional information on the mandible with respect to the position of the maxilla during the surgical simulation, the cast model can be fixed in the planned postoperative occlusion state and scanned with the 3D-scanner. Then, the STL of the dental cast must be registered to the coordinates of the CT maxillary occlusal surface with SBR.(Fig. 3) After that, the CT image of the mandible can be superimposed onto the scanned mandible cast image in the planned occlusion state1-3. The displaced STL of the mandible is exported from the CAD/CAM software and imported into the surgical simulation software without any other registration procedure.(Fig. 4) This simulation is used only for mandibular surgery, according to a planned postoperative occlusion in orthognathic surgery.

For a simulation of bimaxillary orthognathic surgery, the surgeon can move both the maxilla and mandible simultaneously, in the planned occlusion state, with the surgical simulation software.(Fig. 5) After the surgical simulation, a stereolithographic surgical guide can also be manufactured with the simulated dental cast data.

This technique has the merits of using the various registra-tion functions of industrial CAD/CAM software in addition to the analysis, diagnosis, and surgical simulation functions of medical software. Furthermore, this technique may be helpful in imaging research using STL and radiologic images.

References

1. Kang SH, Kim MK, Park WS, Lee SH. Accurate computerised mandibular simulation in orthognathic surgery: a new method for integrating the planned postoperative occlusion model. Br J Oral Maxillofac Surg. 2010; 48:305–307. PMID: 19616350.

2. Kim BC, Lee CE, Park WS, Kang JW, Yi CK, Lee SH. Image fusion accuracy for the integration of digital dental model and 3D CT images by the point-based surface best fit algorithm. J Korean Assoc Oral Maxillofac Surg. 2008; 34:555–561.

3. Kim BC, Lee CE, Park W, Kang SH, Zhengguo P, Yi CK, et al. Integration accuracy of digital dental models and 3-dimensional computerized tomography images by sequential point- and surface-based markerless registration. Oral Surg Oral Med Oral Pathol Oral Radiol Endod. 2010; 110:370–378. PMID: 20591700.

Fig. 1

Stereolithography (STL) (purple) of the three-dimensional light-scanned dental cast was superimposed onto the STL (grey) of the computed tomography image converted from the digital imaging and communications in medicine file with surface-based registration, based on the defined occlusal surface (yellow mesh).

Fig. 2

Digital dental cast (purple and pink) was imported and integrated onto the computed tomography image in the surgical simulation software.

Fig. 3

Digital dental cast of the current occlusion (purple and pink) and the planned postoperative occlusion of the mandible (green) were integrated onto the computed tomography image in the surgical simulation software after using the registration function of the computer-aided design/computer-aided manufacturing (CAD/CAM) software.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download