Abstract

Objectives

Materials and Methods

Results

Conclusions

Figures and Tables

Table 1

Materials investigated and their compositions

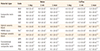

Table 2

ΔE after immersion in deionized water and coffee solution for 1 day, 1 week, and 1 month and after polishing 1 month immersion in coffee

| Material type | Code | Water | Coffee | After polishing | ||||

|---|---|---|---|---|---|---|---|---|

| 1 day | 1 wk | 1 mon | 1 day | 1 wk | 1 mon | |||

| Composite resin block | BLO | 0.2 (0.1)a | 0.3 (0.2)a | 0.3 (0.1)a,3 | 1.3 (0.5)b | 2.2 (0.5)c | 3.7 (0.7)d,5 | 1.8 (0.5) |

| CER | 0.3 (0.3)e | 0.4 (0.2)e | 0.7 (0.2)e,g,1,2,3 | 1.2 (0.4)f,g | 1.9 (0.7)f | 2.7 (0.6)h,5,6,7 | 0.9 (0.4) | |

| GRA | 0.3 (0.2)i | 0.3 (0.2)i | 0.4 (0.2)i,2,3 | 0.5 (0.3)i | 0.9 (0.2)j | 1.6 (0.4)k,$,6,7 | 1.6 (0.5)$ | |

| KZR | 0.2 (0.1)l | 0.3 (0.2)l | 0.3 (0.1)l,3 | 1.0 (0.3)m | 1.6 (0.3)n | 2.9 (0.3)o,5,6 | 0.9 (0.2) | |

| ULT | 0.7 (0.4)p | 0.6 (0.3)p | 0.5 (0.3)p,2,3 | 1.7 (0.3)q | 2.7 (0.4)r | 3.6 (0.6)s,5 | 1.2 (0.4) | |

| Hybrid ceramic block | ENA | 0.3 (0.2)t | 0.4 (0.2)t | 0.5 (0.4)t,2,3 | 0.5 (0.3)t | 0.8 (0.4)t | 1.4 (0.4)u,7 | 0.5 (0.2) |

| PMMA block | TEL# | 0.9 (0.6) | 0.9 (0.8) | 1.0 (0.8)1,2 | 0.9 (0.7) | 1.6 (1.2) | 2.0 (1.1)6,7 | 1.2 (0.9) |

| Feldspar ceramic block | VIT | 0.3 (0.2)v | 0.3 (0.1)v | 0.3 (0.2)v,3 | 0.4 (0.2)v | 1.1 (0.2)w | 1.8 (0.3)x,6,7 | 0.3 (0.1) |

| Conventional restorative composite resin | APX | 0.9 (0.4)y,z | 0.8 (0.4)y | 0.8 (0.7)y,1,2,3 | 1.4 (0.2)z | 2.1 (0.3)A | 2.1 (0.2)A,6,7 | 0.5 (0.2) |

| DUR | 0.5 (0.2)B | 0.7 (0.2)B,C | 0.9 (0.3)B,C,1,2,3 | 1.6 (0.6)B,C | 4.1 (1.2)D | 7.9 (1.5)E,4 | 5.7 (1.4) | |

| ESQ | 0.3 (0.2)F | 0.2 (0.1)F | 0.9 (0.1)G,1,2,3 | 0.8 (0.3)G | 1.6 (0.4)H | 2.4 (0.5)I,5,6,7 | 0.7 (0.3) | |

| FSU | 0.3 (0.1)J | 0.6 (0.2)J | 1.3 (0.1)J,K,1 | 2.3 (0.7)K | 3.7 (1.0)L | 6.6 (1.0)M,4 | 4.4 (0.9) | |

Standard deviations are in parentheses and the same superscript letter denotes homogenous subsets in each material (p > 0.05). The same superscript number denotes homogenous subsets after 1 month immersion (p > 0.05).

BLO, Block HC (Shofu, Kyoto, Japan); CER, Cerasmart (GC, Tokyo, Japan); GRA, Gradia Block (GC); KZR, KZR-CAD Hybrid Resin Block (Yamamota Precious Metal, Osaka, Japan); ULT, Lava Ultimate (3M/ESPE, St. Paul, MN, USA); ENA, Vita Enamic (Vita Zahnfabrik GMbH, Bad Säckingen, Germany); TEL, Telio CAD (Ivoclar Vivadent, Schaan, Liechtenstein); VIT, Vitablocs Mark II (Vita Zahnfabrik GMbH); APX, Clearfil AP-X (Kuraray, Okayama, Japan); DUR, Durafill VS (Heraeus Kulzer, Hanau, Germany); ESQ, Estelite Sigma Quick (Tokuyama Dental, Tokyo, Japan); FSU, Filtek Supreme Ultra (3M/ESPE).

#Not significantly different in spite of immersion condition.

$The difference between ΔE of 1 month coffee and after polishing 1 month coffee by paired t test was significant in all groups except for GRA denotes.

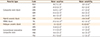

Table 3

ΔTP after immersion in deionized water and coffee solution for 1 day, 1 week, and 1 month

| Material type | Code | Water | Coffee | ||||

|---|---|---|---|---|---|---|---|

| 1 day | 1 wk | 1 mon | 1 day | 1 wk | 1 mon | ||

| Composite resin block | BLO | 0.0 (0.1)a | 0.0 (0.2)a | 0.0 (0.1)a,3 | −0.3 (0.3)b | −0.6 (0.2)c | −1.0 (0.2)d,5 |

| CER | 0.1 (0.2)e,f | 0.2 (0.3)e | 0.6 (0.3)e,1,2 | −0.2 (0.1)e | −0.3 (0.2)f | −0.4 (0.2)f,4 | |

| GRA | 0.0 (0.1)g | 0.1 (0.2)g | 0.6 (0.2)h,1 | −0.3 (0.1)i | −0.5 (0.2)i | −0.7 (0.2)j,4,5 | |

| KZR | 0.0 (0.1)k | −0.3 (0.2)l | −0.2 (0.2)k,l,3 | −0.8 (0.2)m | −1.4 (0.1)n | −1.8 (0.2)o,6 | |

| ULT | 0.1 (0.5)p | 0.0 (0.1)p | −0.1 (0.2)p,3 | −0.4 (0.3)p,q | −0.7 (0.3)q | −1.2 (0.4)r,2,3 | |

| Hybrid ceramic block | ENA | 0.1 (0.2)s | 0.1 (0.2)s | 0.0 (0.2)s,t,3 | −0.1 (0.2)s,u | −0.3 (0.2)t,u | −0.7 (0.1)v,4,5 |

| PMMA block | TEL# | 0.0 (0.4)w | −0.1 (0.4)w | 0.1 (0.3)w,3 | −0.4 (0.2)w | −0.4 (0.3)w | −0.4 (0.2)w,4 |

| Feldspar ceramic block | VIT | 0.0 (0.1)x | −0.1 (0.1)x,y | −0.1 (0.1)x,3 | −0.4 (0.1)y | −1.2 (0.2)z | −2.1 (0.3)A,6 |

| Conventional restorative composite resin | APX | −0.1 (0.4)B | −0.3 (0.4)B,D | 0.0 (0.4)B,3 | −0.3 (0.4)B,C | −0.8 (0.2)C | −0.7 (0.3)C,D,4,5 |

| DUR | −0.3 (0.2)E,F | −0.1 (0.3)E | −0.1 (0.1)E,3 | −0.6 (0.2)F | −1.1 (0.2)G | −2.3 (0.4)H,6,7 | |

| ESQ | −0.1 (0.2)I,J | 0.2 (0.2)I | 0.1 (0.2)I,2,3 | −0.3 (0.2)J,K | −0.4 (0.2)K | −0.9 (0.3)L,4,5 | |

| FSU | 0.1 (0.2)M | 0.1 (0.3)M | 0.1 (0.1)3 | −0.6 (0.2)N | −1.4 (0.2)O | −2.7 (0.2)P,7 | |

Standard deviations are in parentheses and the same superscript letter denotes homogenous subsets in each material (p > 0.05). The same superscript number denotes homogenous subsets after 1 month immersion (p > 0.05).

BLO, Block HC (Shofu, Kyoto, Japan); CER, Cerasmart (GC, Tokyo, Japan); GRA, Gradia Block (GC); KZR, KZR-CAD Hybrid Resin Block (Yamamota Precious Metal, Osaka, Japan); ULT, Lava Ultimate (3M/ESPE, St. Paul, MN, USA); ENA, Vita Enamic (Vita Zahnfabrik GMbH, Bad Säckingen, Germany); TEL, Telio CAD (Ivoclar Vivadent, Schaan, Liechtenstein); VIT, Vitablocs Mark II (Vita Zahnfabrik GMbH); APX, Clearfil AP-X (Kuraray, Okayama, Japan); DUR, Durafill VS (Heraeus Kulzer, Hanau, Germany); ESQ, Estelite Sigma Quick (Tokuyama Dental, Tokyo, Japan); FSU, Filtek Supreme Ultra (3M/ESPE).

Table 4

Water sorption and solubility after water immersion for 1 week (µg/mm3)

Standard deviations are in parentheses and the same superscript letters are not significantly different (p > 0.05).

BLO, Block HC (Shofu, Kyoto, Japan); CER, Cerasmart (GC, Tokyo, Japan); GRA, Gradia Block (GC); KZR, KZR-CAD Hybrid Resin Block (Yamamota Precious Metal, Osaka, Japan); ULT, Lava Ultimate (3M/ESPE, St. Paul, MN, USA); ENA, Vita Enamic (Vita Zahnfabrik GMbH, Bad Säckingen, Germany); TEL, Telio CAD (Ivoclar Vivadent, Schaan, Liechtenstein); VIT, Vitablocs Mark II (Vita Zahnfabrik GMbH); APX, Clearfil AP-X (Kuraray, Okayama, Japan); DUR, Durafill VS (Heraeus Kulzer, Hanau, Germany); ESQ, Estelite Sigma Quick (Tokuyama Dental, Tokyo, Japan); FSU, Filtek Supreme Ultra (3M/ESPE).

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download