Introduction

Resin composites have improved in terms of the chemical composition and filler reinforcements. Recently, many clinicians have shown the preference for time-saving restorative procedures for posterior resin applications. A new category of resin composites, a bulk-fill resin composite, has been introduced over the past few years. They were developed to speed up the restoration process by enabling up to 4 mm thick increments to be cured in a single step, thereby skipping the time-consuming layering process.

Flowable bulk-fill resin composites (SDR, Smart Dentin Replacement, Dentsply Caulk, Milford, DE, USA; Venus Bulk Fill, Heraeus Kulzer, Hanau, Germany; Filtek Bulk Fill, 3M ESPE, St. Paul, MN, USA) have low-viscosity and easy-handling properties. They have many advantages for use as flowable composites. First, high flowability makes them particularly useful for cavities that are difficult to access. Second, the ability to form layered structures helps reduce air entrapment. Third, the high flexibility makes them useful for liners in the cavity.

1 On the other hand, other resin composites in the same category (Tetric N-Ceram Bulk Fill, Ivoclar vivadent, Schaan, Liechtenstein; x-tra fil, VOCO, Cuxhaven, Germany) have high viscosity and high filler content. The handling properties of these composites are similar to regular hybrid composites. Recently, a sonic-activated bulk-fill resin composite (SonicFill, Kerr, Orange, CA, USA) was introduced, and according to the manufacturer instruction, 5 mm thick increments can be placed in a single step.

In a previous study, the modulus of elasticity and hardness of SDR, Venus Bulk Fill and Filtek Bulk Fill were considerably below the mean values measured in the regular nanohybrid and microhybrid resin composites.

2 In the same study, the modulus of elasticity and hardness of Tetric EvoCeram Bulk Fill (European trade name of Tetric N-Ceram), SonicFill and X-tra Fil were higher.

2 Therefore, flowable bulk-fill resin composites, such as SDR, Venus Bulk Fill and Filtek Bulk Fill require an additional final capping layer made from regular hybrid resin composites, whereas other new resin composites, such as SonicFill, Tetric N-Ceram Bulk Fill and X-tra Fil, can be placed without it.

Although the manufacturers recommend bulk-filling of these materials up to 4 mm, many clinicians suspect that the depth of cure and mechanical properties might not be suitable for clinical use.

3 Hardness measurements of the bottom surface can be used to evaluate the depth of cure for resin composites. Because the composition and filler content play important roles in the optical properties of resin composites, the bulk-fill resin composites exhibit different optical properties including excellent translucency parameter compared with regular resin composites.

1,

4

The manufacturers explain that the higher depth of cure of the bulk-fill resin composites is due to the more potent initiator system or/and higher translucency.

4,

5 However, few studies have examined translucency and depth of cure of bulk-fill resin composites. Also, there are few reports of the microhardness and optical properties according to resin thickness of these composites. Therefore, this study investigated the effects of the resin thickness on the microhardness and optical properties of bulk-fill resin composites.

Materials and Methods

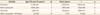

Resin composites used in this study

Four bulk-fill resin composites (Venus Bulk Fill, VB; SDR, SR; Tetric N-Ceram Bulk Fill, TB; SonicFill, SO) and two regular resin composites (Charisma flow, CF; Tetric N-Ceram, TN) were used. CF was used as the control group of flowable bulk-fill resin composites including VB and SR, whereas TN was used as the control group of the non-flowable bulk-fill resin composites including TB and SO.

Table 1 lists the other details of the resin composites used in this study.

Specimens preparation

Sixty acrylic cylindrical molds with a socket, 9 mm in diameter, were prepared for each thickness (2 mm, 3 mm and 4 mm). They were divided into six groups for each resin composite (n = 10). The resin composites were dispensed, manipulated and polymerized on thin glass slides according to the manufacturers' instructions. The top surfaces were then covered with another glass slide to make the surface flat. Polymerization was then carried out using a LED light curing unit (BluePhase, Ivoclar Vivadent Inc., Amherst, NY, USA; light intensity of 1,200 mW/cm2) for 20 seconds in contact with the top surface of the specimens. Subsequently, specimens were stored in water for 24 hours at 37℃ in a dark chamber.

Measurement of microhardness

The microhardness of the top (0 mm) and bottom (2 mm, 3 mm and 4 mm) surfaces were measured using a Vickers hardness tester (MVK-H1, Akashi, Tokyo, Japan). Microindentation was carried out using a 200 gf load with a 10 seconds dwell time.

Measurement of color

The colors of all specimens were measured with a spectrophotometer (CM-3600d, Minolta, Tokyo, Japan) according to the Commission Internationale d'Eclairage (CIE) L*a*b* relative to the standard illuminant D65 against white background (L* = 93.26, a* = -0.61, and b* = 2.09) and black background (L* = 2.93, a* = 0.38, and b* = -0.34). The black standard was a matt black plate covered with black velvet, and the white standard was a white ceramic. Before measuring each group, the spectrophotometer was calibrated with standard calibrating blocks (white and black) according to the manufacturer's recommendation.

Calculation of the color difference and translucency parameter

Color change according to thickness is important when using esthetic materials. Thus the color differences (Δ

E) according to the thickness were obtained. Δ

E23 means Δ

E between the 2 mm and 3 mm specimens, and Δ

E24 means Δ

E between the 2 mm and 4 mm specimens. Δ

E23 and Δ

E24 were calculated using the following formula:

L* represents the degree of gray corresponding to a lightness, a* is the red (for + a* value)-green (for - a* value) axis, and b* is the yellow (for + b* value)-blue (for - b* value) axis.

The translucency parameter (

TP) values were determined by calculating the color difference between readings over the black and white background for the same specimen, using the following formula:

Subscripts 'B' and 'W' refer to the color coordinates over a black and white background, respectively. The differences between

TP2mm and

TP3mm (Δ

TP23) and between

TP2mm and

TP4mm (Δ

TP24) were also calculated.

Statistical analysis

The microhardness was analyzed by one-way and two-way ANOVA and Scheffe's post hoc test, and the color differences were analyzed using a student t-test. TP was analyzed by one-way ANOVA. The software used was SPSS 15.0 (SPSS Inc., Chicago, IL, USA). The level of significance was set to p < 0.05.

Discussion

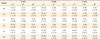

In the present study, the flowable bulk-fill resin composites showed lower microhardness than the non-flowable bulk-fill resin composites as shown in a previous study.

2 This could be attributed to the lower filler content of the flowable bulk-fill resins. SR showed the highest microhardness among the flowable resin composites, and SO exhibited the highest microhardness among the non-flowable resin composites. These results can also be explained by SR and SO containing more inorganic filler than the other composites in the same category (flowable or non-flowable).

The microhardness of resin composites are affected by the resin composite thickness.

6,

7 In the present study, the same tendency of the microhardness decreasing as the resin thickness increased was observed. Regarding the amount of the hardness change, bulk-fill resin composites, such as VB, SR, TB and SO exhibited smaller changes in hardness according to the thickness, whereas regular resin composites, such as CF and TN showed a drastic decrease in the 4 mm specimens. The steep decreases in the microhardness of the 4 mm specimens of regular composites in this study are in agreement with a previous study which reported that the resin hardness at the bottom was significantly different from that at the top when the specimens were 4 or 5 mm thick.

8 This can be explained by the difference in

TP between the bulk-fill and regular composites. With a higher

TP, the bulk-fill resin composites allow more light to penetrate deep inside the resin composites, which possibly results in more polymerized monomers at the bottom surface.

The increased depth of cure in bulk-fill resin composites might be due to not only the increased

TP, but also to the modified monomers and photoinitiator systems. The manufacturer explains that SR has a substance described as a 'polymerization modulator' embedded chemically in the backbone of the polymerizable resin.

9 The polymerization modulator synergistically interacts with the camphorquinone photoinitiator. In the case of TB, the manufacturer states that, besides having a regular camphorquinone/amine initiator system, it has introduced an 'initiator booster' (Ivocerin) that can polymerize the material in depth.

2

Several studies

3,

5,

10,

11 have used hardness measurements performed on the top and bottom surface of a light-cured resin composite specimen to define the depth of cure. The bottom/top hardness ratio above 80% has often been used as a minimum acceptable threshold. The bulk-fill resin composites used in this study showed a bottom/top hardness ratio of almost 80% or more in the 4 mm thick specimens, which means that these materials can be placed and cured properly in the 4 mm bulk in clinical situations.

The color of the resin composites may be affected by altering the resin thickness.

12 According to Inokoshi et al., Δ

E < 1 is considered not appreciable by the human eye.

13 Values 1 < Δ

E < 3.3 are considered appreciable by skilled operators, whereas values of Δ

E > 3.3 are considered appreciable by non-skilled persons. In the present study, 2 mm thick specimens of each group were used as the standard to evaluate Δ

E according to the thickness. From the result of this study, VB showed the largest Δ

E (> 3.3) depending on the resin thickness, which is appreciable by non-skilled persons. In TN, Δ

E24 could also be appreciable by non-skilled persons (Δ

E > 3.3). Other resin composites showed Δ

E values that were only appreciable by skilled operators (1 < Δ

E < 3.3).

TP is a parameter that can indicate the translucency of resin composites. The translucency of resin composites depends on their thickness as well as the scattering and absorption coefficients of the resin, filler particles, pigments and opacifiers.

14,

15,

16 In the present study, VB and TN showed the highest and lowest

TP, respectively (

p < 0.05). Lee reported that

TP decreased with increasing amount of filler.

17 Campbell et al. reported that as the filler size increased, the

TP of the resin composite increased accordingly.

18 A significantly high

TP in VB could be attributed to similar refraction indices between fillers and matrix resin.

1 In another flowable bulk-fill resin composite, SR, the increased

TP might be due to the large filler size.

2 In TB, a lower inorganic filler content might lead to a high

TP. Although TB has the high filler content, it also contains prepolymerized fillers, meaning that the inorganic filler content is consistently lower.

3 In SO, despite the high filler content, a large filler size might increase

TP. A comparison of the same handling category (flowable or non-flowable) revealed the bulk-fill resin composites to have a higher

TP than the regular composites. Regarding the

TP changes depending on the resin thickness, Kim et al., and Lassila et al., reported that the translucency of the resin composites increases with decreasing thickness.

1,

19 In agreement of these studies, the same results were found in all resin composites.

The present study evaluated the correlation between the microhardness and

TP according to the resin thickness. The correlation coefficients (R) between the microhardness and

TP for VB, SR, CF, TB, SO and TN were 0.43, 1.00, 0.89, 0.94, 0.95 and 0.92, respectively. All resin composites used in this study except for VB showed linear correlations between the microhardness and

TP depending on the thickness, meaning that clinicians should be cautious about thickness of resin composites when restoring deep cavities. In VB, the significantly higher

TP than the others may allow more light to penetrate deeper up to 4mm, resulting in the similar microhardness among the 2 mm, 3 mm and 4 mm specimens (

p > 0.05). This can be also explained by the highest percentage (94.2%) of the bottom/top hardness ratio in 4 mm. Therefore, in VB there was no linear correlation between the microhardness and

TP. A comparison of the slopes of the microhardness-

TP correlation graph showed that the regular resin composites exhibited gentler slopes than the bulk-fill resin composites (

Figure 3). This might be because the decrease in microhardness with increasing thickness is larger in regular resin composites. In contrast, the slopes of the bulk-fill resin composites were steep, which means that the microhardness of the bulk-fill resin composites decreased gradually with increasing resin thickness.

For the restorations with bulk-fill resin composites, the manufacturers recommend that 4 mm thick increments can be cured in a single step. Based on the results of this study, up to 4 mm thick increments of bulk-fill resin composites are clinically acceptable.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download