Abstract

Purpose

This retrospective study was performed to evaluate the clinical results and measure polyethylene liner wear in total hip arthroplasty (THA) with highly cross-linked polyethylene.

Materials and Methods

Except for patients who had died or were unable to have follow-up at least 2 years, 60 of 78 hips that underwent THA were included this study. The mean age was 64.5 years (range, 25-81 years) and the mean body mass index (BMI) was 23.0 kg/m2 (18.1-32.3 kg/m2). Diagnosis at the time of the operation was osteonecrois of the femoral head in 28 hips, primary osteoarthritis in 14, hip fracture in 13, and other diseases in 5. The mean follow-up period was 3.8 years (2.1-7.1 years). Harris hip score (HHS) was reviewed before THA and at the last follow-up. On the anteroposterior pelvic radiographs, acetabular cup inclination and ante-version were also measured. The annual linear wear rate was measured using Livermore's method on the radiographs.

Results

The mean HHS was 60.1 (28-94) before operation and 90.4 (47-100) at the last follow-up. In the immediate post-operation, the average inclination and anteversion angles of the acetabular cups were 46.3° (standard deviation, ±6.7°) and, 21.4°(±10.1°) respectively. The mean of the annual linear polyethylene wear was 0.079 mm/year (0.001-0.291 mm/year). Age, gender and BMI were not statistically related to linear polyethylene wear but the period of follow-up and the acetabular cup's inclination showed significant negative and positive correlation respectively.

The use of a metal head with polyethylene in total hip arthroplasty (THA) is the oldest articular surface combination and is in wide use nowadays1). However, wear particles of polyethylene were produced from the articular surface when metal to polyethylene was used in THA and seen in long-term follow-up. The osteolysis due to the wear particles is the main cause of revision because it causes aseptic loosening of the prosthesis23456). In order to increase the survival rate of the prosthesis in long-term follow-up, several bearing surfaces were attempted using ceramic to ceramic or metal to metal articular surfaces instead of a metal to polyethylene articular surface. Even though these articular surfaces showed good results with respect to wear, there were the complications of ceramic breakage, increased serum metal ions, and hypersensitivity to metal ions7). At the same time work continued to reduce the wear in polyethylene. Highly cross-linked polyethylene improves its wear resistance by increasing cross-linking and reducing free radicals and inhibiting its oxidation. This bearing surface has excellent wear durability in comparison with conventional polyethylene8). In particular, highly cross-linked polyethylene was not significantly influenced by the activity level of the patient, body mass index (BMI), age, or gender. So it is possible to use a large diameter head in THA to prevent dislocation and increase the range of motion910). The purpose of this study is to analyze the wear rate in THA with highly cross-linked polyethylene and validate the factors that affect the wear rate.

From January 2006 to May 2010, 60 cases in 55 patients from 78 cases in 71 patients with primary THA using highly cross-linked polyethylene and a 28 mm metal head (Zimmer, Warsaw, IN, USA) were studied after at least 2 years of follow-up. Five patients underwent arthroplasty on their both hips. This excludes patients who died (11 cases) and those who were unable to follow-up (7 cases). The mean age at the time of surgery was 64.5 years (25-81 years). There were 36 males and 24 females. The average BMI was 23.0 kg/m2 (range, 18.1-32.3 kg/m2). There were 28 cases of avascular necrosis (46.7%), 14 cases of osteoarthritis (23.3%), 13 cases of hip fractures (21.7%), and 5 cases of other diseases such as ankylosing spondylitis (8.3%) as the causes leading to THA. Follow-up period was an average of 3.8 years (2.1-7.1 years). Surgery in all cases was performed with a posterolateral approach by one surgeon (C.Y.Y), used cementless acetabular cups (Zimmer), and the diameter ranged from 48 mm to 62 mm. For press-fit fixation, the acetabular cups were inserted 1-2 mm bigger than the last reaming diameter. From one to three metal screws were added to fix the acetabular cups. The polyethylene used was Longevity® (Zimmer) which is the first generation for highly cross-linked cross-linked polyethylene and its average thickness was 7.7 mm (6.2-11.3 mm). Metal femoral heads of cobalt-chrome with a diameter of 28 mm and cementless femoral stems for proximal fixation were used in all cases.

After the removal of wound drainage, patients practiced walking with crutches for up to two months after surgery. Clinical follow-up was done every 3 months for the first year. For every follow-up, patients were evaluated using anteroposterior and lateral views of pelvic radiographs. During the follow-up period, the anteversion and inclination angles of the acetabular cups were compared with the immediate post-operation results. Osteolysis and stress shielding around the acetabular cup or the femoral stem were analyzed on the follow-up radiographs. Loosening of acetabular cup was defined as change of cup angle more than 5° or displacement more than 2 mm in the follow-up radiographs compared to that of immediate postoperation11).

Liner wear rate of the polyethylene was measured using the Livermore's method on the anteroposterior views of the pelvic radiographs 3 months after surgery and at the last follow-up12). Enlargement or reduction of the measured radiologic parameters, except the anteversion and inclination angles, were corrected through the ratio between measured diameter on radiograph and actual diameter of femoral head 28 mm in diameter. The annual wear rates of polyethylene were calculated on the basis of this method. Three orthopedic surgeons measured the radiologic parameters and calculated the annual wear rates of polyethylene by the same technique in order to increase the accuracy of the measurement. Average values of the calculated wear rates were defined as the final wear rate of the polyethylene. And we found that moderate reliability was confirmed (P<0.05) with 0.695 reliability in measured values between the observers using this method. For clinical outcome evaluation, Harris hip scores (HSS) of the pre-operation and last follow-up were assessed and grouped as excellent for > 90 out of 100 points, good for > 80, average for > 70, and poor for <70.

Statistical analysis was done using SPSS version 18.0 for Windows (SPSS, Chicago, Illinois) program. The Pearson correlation test was used to analyze correlation of multiple continuous variables with the annual wear rate of polyethylene. Based on the results of the Pearson correlation test, we used the Univariate linear regression test between each continuous variable and the annual wear rate of polyethylene. Intra class correlation analysis was done to determine the inter-observer reliability of the calculated wear rate.

This study was approved by the institutional ethics committee of our hospital and informed consent was obtained from each patient. There was no external funding source for this study.

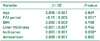

The annual wear rate of polyethylene was 0.079 mm/year (0.001-0.291 mm/year) measured using the Livermore's method. From the correlation analysis, the annual wear rate of polyethylene did not have a significant correlation with age, gender, BMI, acetabular cup size, thickness of polyethylene and anteversion angles. But there was a negative correlation between the annual wear rate of polyethylene and the follow-up period (P=0.001), and a positive correlation between the inclination angles of the acetabular cups and the annual wear rate of polyethylene (P=0.030) (Table 1). Significantly, above two factors were shown the linear relationship with the annual wear rate of polyethylene from univariate linear regression analysis (Table 2, Fig. 1). Divided into several groups of the above two factors, the more the period of follow up increase, the more annual wear rate of polyethylene decrease. In contrast, the more the inclination angles of the acetabular cups, the more annual wear rate of polyethylene increase (Fig. 2).

Harris hip score (HHS) significantly increased from an average of 50.1 points (28-64 points) before surgery to 90.4 points (77-100 points) at the last follow-up. Satisfactory clinical results were obtained in 56 cases (93.3%) with more than a good grade in HHS. There were no cases of osteolysis at the last follow-up in pelvic radiographs and there were no cases of revision surgery during the follow-up period. However there were 4 cases of dislocation so those were treated with abduction orthosis.

Polyethylene is the most commonly used articular surface in THA. However, in conventional polyethylene, free radicals remain through the production and packaging process, so oxidative reactions which cause wear in polyethylene occur due to the oxygen in its environment13). Wear in the polyethylene eventually causes osteolysis around the implants and is a major cause of revision arthroplasty141516). Therefore, what was needed was a more durable polyethylene for increasing the survival of the implant in the long-term follow-up. In order to increase the durability, polyethylene was irradiated with gamma radiation to increase crosslinking; moreover, other procedures have been introduced to eliminate the remaining free radicals17). The methods to eliminate the remaining free radicals after polyethylene processing were the remelting method by heating the polyethylene to its melting point and the annealing method by heating it to a temperature a little lower than the melting point18). In this study, we used Longevity® which is highly cross-linked by irradiation with an electron beam of 10 Mega rad. And the polyethylene was processed using the remelt-annealing method for elimination of any remaining free radicals and finally the implant was packaged with the gas-plasma method in order to minimize the wear of the polyethylene918).

McCalden et al.19) used highly cross-linked polyethylene to carry out THA and reported the average annual wear rate to be 0.003 mm/year from an average 6.8 year follow-up. It was reported that wear rates were reduced more than 95% compared to the wear rate of conventional polyethylene and osteolysis was not observed during the follow-ups. Lee et al.20) carried out the retrospective study of THA with the same polyethylene which used our study for follow-ups of more than 7 years. They reported that the average annual wear rate was 0.006 mm/year and 10.6% of all patients had osteolysis. The average HHS was 90.4 points at the last follow-up and the annual wear rate of the polyethylene was 0.079 mm/year in this study. Osteolytic lesions could not be observed in this study, it was considered that the average follow-up period was a little short at 3.8 years. But the annual wear rate of polyethylene did not increase in cases with follow up more than 5 years. Therefore it is estimated that good clinical and radiologic results could be obtained from mid-term follow-ups after several years.

Sychterz et al.2122) described two processes where the femoral head penetrates the polyethylene liner. The bedding-in state lasts for 1-2 years after surgery and the true-wear state continues thereafter. The bedding-in state is a setting in process where the polyethylene liner moves slightly in the acetabular cup. The true-wear state was reported to be a process of production of wear particles. In the study of Lee et al.20), the annual wear rate of polyethylene increased up to 2 years after surgery and was drastically reduced thereafter. In our study, there was a negative correlation of the annual wear rate of polyethylene with the follow-up period, in other words, the longer the follow-up period, the more the annual wear rate of polyethylene is reduced. Therefore we considered that our annual wear rate for polyethylene includes more of the period of the bedding-in state rather than the true-wear state as Sychterz et al.22) described. So the wear rate of highly cross-linked polyethylene is actually thought to be much smaller than what has been calculated as the wear rates of polyethylene are drastically reduced in cases after 2 years of surgery. Also, the annual wear rate of polyethylene is thought to reduce as the overall followup period increases (Fig. 2A).

It is known that a patient's activity, the modular cementless acetabular cup, higher inclination angles of the acetabular cup, a larger metallic femoral head, and a thinner thickness of polyethylene are negative factors which affect the wear of polyethylene2324). But the wear of polyethylene is not affected in THA with highly cross-linked polyethylene by these factors. Manning et al.25) reported that the wear rate of highly cross-linked polyethylene does not have significant relations with gender, age, BMI, or a patient's activity. Hermida et al.26) reported no significant difference in wear rate between using a 28 mm-diameter femoral head and a 32 mmdiameter femoral head. Lee et al.20) reported that there were no significant correlations of other factors including the thickness of the polyethylene liner, only a significant correlation with the inclination angle of the acetabular cups. Our study also showed a positive correlation between the wear rates of polyethylene and the inclination angle of the acetabular cups. The wear rates of polyethylene were significantly higher for angles greater than 45° than for those less than 45° of inclination in the acetabular cups on radiographs after surgery (Fig. 2B). Therefore, it is very important to correctly insert the acetabular cups so they have a stable position, in order to reduce the wear in highly cross-linked polyethylene and increase the survival rate for long-term follow-up.

A limitation of our study was that the follow-up period was short. So the wear rates of polyethylene were calculated to be higher than the actual wear rate of polyethylene because it was measured on radiographs which had taken at three months after surgery that is in bedding-in period. But it is indirectly confirmed that the actual period of the bedding-in state is longer than three months from a negative correlation between the annual wear rate of polyethylene and follow-up period. It is necessary to study the clinical results of the wear in polyethylene with long-term follow-ups in the future. follow-up. It also shows excellent clinical results for the overall period of follow-up. However, our study was based on a short-term follow-up, so a long-term followup study is necessary in the future.

The wear rate of a highly cross-linked polyethylene was shown to correlate negatively with duration of follow-up. It also shows excellent clinical results for the overall period of follow-up. However, our study was based on a short-term follow-up, so a long-term followup study is necessary in the future.

Figures and Tables

| Fig. 1A scatter plots show linear correlation the annual wear rate of polyethylene versus the period of follow-up (A) and inclination angles of the acetabular cups (B). The y-axis is the annual wear rate of polyethylene (mm/year), x-axis are the period of follow-up (years) and inclination angles of the acetabular cups (°). The dash lines show the regression lines of linear correlation the annual wear rate of polyethylene versus the period of follow-up and inclination angles of the acetabular cups. |

| Fig. 2Each divided into groups of the period of follow-up (A) and inclination angles of the acetabular cups (B), a flow plots show the means of annual wear rate of polyethylene and the total wear during follow up. The y-axis is the means of annual wear rate of polyethylene (mm/year), x-axis are different groups by the period of follow-up (years) and inclination angles of the acetabular cups (°). The dash lines represent the regression lines of linear correlation. |

References

1. Laupacis A, Bourne R, Rorabeck C, et al. The effect of elective total hip replacement on health-related quality of life. J Bone Joint Surg Am. 1993; 75:1619–1626.

3. Clohisy JC, Calvert G, Tull F, McDonald D, Maloney WJ. Reasons for revision hip surgery: a retrospective review. Clin Orthop Relat Res. 2004; (429):188–192.

4. Harris WH. Conquest of a worldwide human disease: particle-induced periprosthetic osteolysis. Clin Orthop Relat Res. 2004; (429):39–42.

6. Böhler M, Kanz F, Schwarz B, et al. Adverse tissue reactions to wear particles from Co-alloy articulations, increased by alumina-blasting particle contamination from cementless Ti-based total hip implants. A report of seven revisions with early failure. J Bone Joint Surg Br. 2002; 84:128–136.

7. van der Weegen W, Sijbesma T, Hoekstra HJ, Brakel K, Pilot P, Nelissen RG. Treatment of pseudotumors after metal-on-metal hip resurfacing based on magnetic resonance imaging, metal ion levels and symptoms. J Arthroplasty. 2014; 29:416–421.

8. Kurtz SM, Gawel HA, Patel JD. History and systematic review of wear and osteolysis outcomes for first-generation highly crosslinked polyethylene. Clin Orthop Relat Res. 2011; 469:2262–2277.

9. Jacobs CA, Christensen CP, Greenwald AS, McKellop H. Clinical performance of highly cross-linked polyethylenes in total hip arthroplasty. J Bone Joint Surg Am. 2007; 89:2779–2786.

10. García-Rey E, García-Cimbrelo E. Polyethylene in total hip arthroplasty: half a century in the limelight. J Orthop Traumatol. 2010; 11:67–72.

11. Onsten I, Carlsson AS, Ohlin A, Nilsson JA. Migration of acetabular components, inserted with and without cement, in one-stage bilateral hip arthroplasty. A controlled, randomized study using roentgenstereophotogrammetric analysis. J Bone Joint Surg Am. 1994; 76:185–194.

12. Livermore J, Ilstrup D, Morrey B. Effect of femoral head size on wear of the polyethylene acetabular component. J Bone Joint Surg Am. 1990; 72:518–528.

13. Schmalzried TP, Kwong LM, Jasty M, et al. The mechanism of loosening of cemented acetabular components in total hip arthroplasty. Analysis of specimens retrieved at autopsy. Clin Orthop Relat Res. 1992; (274):60–78.

14. Maloney WJ, Galante JO, Anderson M, et al. Fixation, polyethylene wear, and pelvic osteolysis in primary total hip replacement. Clin Orthop Relat Res. 1999; (369):157–164.

15. Sochart DH. Relationship of acetabular wear to osteolysis and loosening in total hip arthroplasty. Clin Orthop Relat Res. 1999; (363):135–150.

16. Oparaugo PC, Clarke IC, Malchau H, Herberts P. Correlation of wear debris-induced osteolysis and revision with volumetric wear-rates of polyethylene: a survey of 8 reports in the literature. Acta Orthop Scand. 2001; 72:22–28.

17. McKellop H, Shen FW, Lu B, Campbell P, Salovey R. Development of an extremely wear-resistant ultra high molecular weight polyethylene for total hip replacements. J Orthop Res. 1999; 17:157–167.

18. Kang JS, Kim RS. Metal on polyethylene in total hip arthroplasty. J Korean Hip Soc. 2010; 22:241–246.

19. McCalden RW, MacDonald SJ, Rorabeck CH, Bourne RB, Chess DG, Charron KD. Wear rate of highly cross-linked polyethylene in total hip arthroplasty. A randomized controlled trial. J Bone Joint Surg Am. 2009; 91:773–782.

20. Lee JH, Lee BW, Lee BJ, Kim SY. Midterm results of primary total hip arthroplasty using highly cross-linked polyethylene: minimum 7-year follow-up study. J Arthroplasty. 2011; 26:1014–1019.

21. Sychterz CJ, Engh CA Jr, Shah N, Engh CA Sr. Radiographic evaluation of penetration by the femoral head into the polyethylene liner over time. J Bone Joint Surg Am. 1997; 79:1040–1046.

22. Sychterz CJ, Engh CA Jr, Yang A, Engh CA. Analysis of temporal wear patterns of porous-coated acetabular components: distinguishing between true wear and socalled bedding-in. J Bone Joint Surg Am. 1999; 81:821–830.

23. Devane PA, Horne JG, Martin K, Coldham G, Krause B. Three-dimensional polyethylene wear of a press-fit titanium prosthesis. Factors influencing generation of polyethylene debris. J Arthroplasty. 1997; 12:256–266.

24. Young AM, Sychterz CJ, Hopper RH Jr, Engh CA. Effect of acetabular modularity on polyethylene wear and osteolysis in total hip arthroplasty. J Bone Joint Surg Am. 2002; 84-A:58–63.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download