There are many advantages in using 36-mm femoral head mated with highly cross linked polyethylene (HXLPE) as bearing surface of total hip arthroplasty. A larger femoral head has many potential advantages such as stability and increased range of motion, which reduces the risk of impingement and dislocation1). But, the larger metal head size against polyethylene hip arthroplasty has historically been limited due to concerns regarding increased volumetric wear rates2). This issue could be addressed with the advent of HXLPE. It has been shown that HXLPE wear rates decreased by 58% to 74% over the ultra high molecular weight polyethylene (UHMWPE) in various in vitro studies3). The improvements in stability and observations of lower wear rates with large heads on HXLPE compared to a 28-mm head on standard polyethylene have led to the increased acceptance of 36-mm femoral head mated with HXLPE4). But, there are also some trade-offs in using 36-mm femoral head mated with HXLPE. This highly cross linking is made by exposures of gamma radiation. Unfortunately, the increase in gamma dose is associated with the degradations of other mechanical properties including a decrease in tensile yield strength and fatigue strength and resultant liner breakage5).

There are few reports of 1st generation HXLPE breakage6). Majority of these reports pointed out high body mass index (BMI), improper acetabular cup position, thin liner thickness and impingement between femoral stem and liner, etc. as causes of liner breakge. This case of liner breakage happened although patient belonged to normal BMI and proper acetabular cup position so called "safe zone" on radiographs.

This paper's aim is to report HXLPE breakage case of patient operated with 36-mm femoral head coupled with HXLPE and discuss about causes of breakage.

CASE REPORT

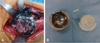

A male patient aged 58 years visited our hospital because of right hip joint pain. In the past, he underwent bipolar hemiarthroplasty on the right hip due to osteonecrosis of femoral head 11 years ago and total hip arthroplasty on left hip due to same disease 3 years ago. The patient weighted 52 kg and had BMI of 19.6 kg/m2. On plain film, there was stem loosening at right bipolar hemiarthroplasty. So, we decided to revise the right hip. In 2005, we revised with 54-mm acetabular cup (Trilogy; Zimmer, Warsaw, IN, USA) and 36-mm metal head mated against HXLPE (Longevity; Zimmer) as bearing surface. As to a femoral stem, we revised with 11 mm beaded full coating, non-cemented revision femoral stem (Versys; Zimmer). Post-operative radiograph showed a cup abduction angle of 50° and 23.4° anteversion respectively (Fig. 1). After 10 days since index operation, patient took a weight-bearing within the limits of tolerance, and discharged without any event. After 6 years since 1st revision, the patient visited our center complaining an abrupt right hip pain developed without recent trauma history. Radiographs demonstrated eccentric femoral head position within acetabular cup and radiopacity suggesting tines of the locking mechanism on the infero-medial side of right hip joint (Fig. 2). On the basis of this finding, we suspected a liner breakage. In the 2nd revision, we identified metallosis (Fig. 3A). Also, we found a fragmentation of the Longevity liner at the superior quadrant (Fig. 3B), severe scratch damages in just below the neck portion of femoral stem and superior quadrant area of liner. After checking stable fixation status of femoral stem, and no damages in Morse taper of femoral stem, we conducted 2nd revision with 56-mm acetabular cup (Trilogy) and 36-mm metal head mated with HXLPE (Longevity) as bearing surface remaining femoral stem. Since leaving the hospital, there have not been special events.

DISCUSSION

There are some risk factors as known as making a HXLPE fracture. Thin liner thickness, impingement between femoral stem and liner, inadequate acetabular cup position, excessive patient's BMI, and excessive patient's motions are being suspected as risk factors of liner breakage678). In this case, 1st revision radiographs showed acetabular cup position was in the adequate position so called "safe zone". Also, patient's BMI belonged to normal area.

Possible hypothesis contributing liner breakage in our case were thin liner thickness, the increased brittleness of HXLPE due to remelting process, and impingement between liner rim and femoral stem. It is important to note that modular liner thickness is often specified on the basis of the nominal material thickness at the specific degree angle of the liner. First revision was conducted with 54-mm acetabular cup. Liner thickness when using 36-mm metal head coupled with HXLPE (Longevity) as bearing surface with 54-mm acetabular cup are 5.8 mm at 45° angle direction and 6.7 mm at pole respectively (Fig. 4). This thickness is the thinnest thing we can use when using 36-mm metal head. But the dimension of edge of liner is less than 5.8 mm. US Food and Drug Administration is approving of at least 3-mm HXLPE application. But, many hip simulator study demonstrated thinner polyethylene components showed that higher contact stress and wear rates2). In a study of Berry et al.9), 10 cases of catastrophic acetabular liner failure were described. All failures occurred in patients who had acetabular liners implanted with thicknesses of less than 5 mm. So, we conducted 2nd revision with 56-mm acetabular cup to use thicker liner. Liner thickness when using 36-mm metal head coupled with HXLPE (Longevity) as bearing surface with 56-mm acetabular cup are 6.9 mm at 45° angle direction and 7.8 mm at pole respectively.

This manufacture adopts a remelting method to remove remaining free radial. This method degraded mechanical properties, particularly the fatigue strength10). So, this liner may be vulnerable to crack formation due to impingement. In our case, we found superior quadrant liner rim fracture, and severe scratch damage in just below femoral neck portion as the counter-part of impingement.

On the basis of this findings, we speculate multiple factors including thin liner thickness, impingement between liner rim and femoral stem, and re-melting method to remove remaining free radial involved in HXLPE breakage of this case.

In conclusion, surgeon had better use thicker liner when it is possible and should avoid impingement between liner rim and femoral stem.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download