This article has been

cited by other articles in ScienceCentral.

Abstract

Objectives

The purpose of this study was to examine the effect of glycerin topical application on the surface hardness of composite after curing.

Materials and Methods

A composite (Z-250, 3M ESPE) was packed into a disc-shaped brass mold and light cured according to one of the following protocols. Group 1 (control) was exposed to air and light cured for 40 sec, group 2 was covered with a Mylar strip and light cured for 40 sec, group 3 was surface coated with glycerin and light cured for 40 sec, and group 4 was exposed to air and light cured for 20 sec and then surface coated with glycerin and cured for additional 20 sec. Twenty specimens were prepared for each group. The surface hardnesses of specimens were measured with or without polishing. Five days later, the surface hardness of each specimen was measured again. Data were analyzed by three-way ANOVA and Tukey's post hoc tests.

Results

The surface hardnesses of the unpolished specimens immediately after curing decreased in the following order: group 2 > 3 > 4 > 1. For the polished specimens, there was no significant difference among the groups. Within the same group, the hardness measured after five days was increased compared to that immediately after curing, and the polished specimens showed greater hardness than did the unpolished specimens.

Conclusions

The most effective way to increase the surface hardness of composite is polishing after curing. The uses of a Mylar strip or glycerin topical application before curing is recommended.

Keywords: Composite, Glycerin, Mylar strip, Polishing, Surface hardness

INTRODUCTION

Growing patient demands for esthetics and concerns about environmental contamination by amalgam have led to a large increase in restorations using dental composites. Polymerization of dental composites occurs through a chain reaction that is induced by free radicals. If composite is exposed to air during this process, oxygen in the air decreases the excitability of the photo initiator and stabilizes the free radicals, causing polymerization interference or delay. As a result, oxygen inhibition layer (OIL) is formed on the surfaces of cured composites. Depending on the type of composite used, the thickness of the OIL is between 10 and 200 µm.

1-

3 The OIL adversely affects the prognosis of composite restorations since it reduces surface hardness, wear resistance, and marginal adaptation of composite restorations.

3-

5

The OIL cannot be completely removed by occlusal adjustment, finishing, or polishing procedures after curing, and the partial remnants of the OIL reduce the quality of the final restoration. Therefore, in order to minimize the OIL as much as possible, its formation can be reduced by curing the composite after inhibiting oxygen contact either through the use of a Mylar strip or application of glycerin to the composite surface.

3-

5 A Mylar strip or plastic matrix can be used for proximal and bucco-lingual cavities, but glycerin application is more effective for complicated occlusal cavities and areas with limited access.

The surface hardnesses of composites cured using a Mylar strip were initially lower than those of composites polished after being cured in the air, however, after six days, no differences remained.

4 When ceramic restorations are adhesively luted with resin cements, OIL formation can be prevented by curing the resin cement with a surface application of glycerin.

5 However, there is a lack of studies that quantitatively compare the effects of Mylar strip use, application of glycerin, and surface polishing.

The purpose of this study was to investigate effective procedures for preventing OIL formation or reducing already formed OIL. In this study, composites were cured in different ways and their surface hardnesses were compared, using a Mylar strip; via glycerin application; cured in air, coated with glycerin, then cured again; and finished and polished.

MATERIALS AND METHODS

Materials

A universal hybrid composite, Z-250 (3M ESPE, St. Paul, MN, USA), was used for the measurement of surface hardness under different curing conditions. An LED light-curing unit (Elipar Freelight, 3M ESPE) was used at a light intensity of 700 mW/cm2. The surface hardness was measured with a Vickers micro-hardness measuring instrument (HMV, Shimadzu, Kyoto, Japan).

Measurement of surface hardnesses of composites cured under various conditions

A disc-shaped brass mold (outer diameter 12 mm, inner diameter 6 mm, thickness 3 mm) was fabricated. The brass mold was placed on a clean mixing sheet, and a thin plastic disc (outer diameter 12 mm, inner diameter 6 mm, thickness 0.2 mm) was placed on top of the mold, which was then filled with composite. A Mylar strip and a glass slide were placed on the top of the composite and pressed to remove excess material. The composite specimens were then cured for 40 seconds according to the following protocols (

Figure 1).

Group 1 (control): The specimen was exposed to air and light cured for 40 seconds (OIL was allowed to form).

Group 2: The specimen was covered with a Mylar strip and light cured for 40 seconds (OIL formation was prevented).

Group 3: The specimen was surface coated with glycerin and light cured for 40 seconds (OIL formation was prevented).

Group 4: The specimen was exposed to air and light cured for 20 seconds. A surface coating of glycerin was then applied, and the sample was light-cured for an additional 20 seconds (the already-formed OIL was additionally cured).

In all groups, the distance between the light-curing tip and the specimen was maintained at 1 mm during the 40 seconds curing. Every step of the procedure was performed in a room with yellow light in order to eliminate any unwanted effects from ambient light sources during specimen preparation and curing. Following curing, all specimens were rinsed in running water for 10 seconds and dried naturally.

Twenty specimens were prepared for each group. The surface hardnesses of ten specimens were measured without any further treatment. The other 10 specimens were measured after removing the 0.2 mm plastic disc and polishing the composite projecting above the brass mold using No. 500 and 1,200 SiC paper under water spray. The times from initial curing to hardness measurement were identical for both non-polished and polished specimens.

After curing, each specimen was stored under 100% humidity at a temperature of 25℃ for five days, after which the surface hardness was measured again. Surface hardness was measured with a Vickers micro-hardness measuring instrument using a load of 9.807 N for 10 seconds. To reduce measurement errors among different areas within a specimen, the surface hardness of three points per specimen were measured and averaged to produce the representative value for that specimen.

Statistical analysis

Three-way analysis of variance (ANOVA) and Tukey's post hoc tests were applied to determine the statistical significance among groups based on the curing method, surface polishing, and measurement time. Statistical analysis was performed with SPSS version 14.0 (SPSS Inc., Chicago, IL, USA) at a significance level of α = 0.05.

RESULTS

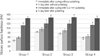

The surface hardnesses of the four groups according to surface polishing and measurement time are presented in

Table 1 and

Figure 2. Results of the statistical analysis which evaluated the effects of groups, surface polishing and measurement time and their interaction on the surface hardnesses are summarized in

Table 2. The surface hardnesses of unpolished specimens immediately after curing decreased in the following order: group 2 > 3 > 4 > 1 (

p < 0.001). Five days after curing, there was no significant difference between groups 2 and 3, whose hardness values were greater than those of groups 1 and 4.

For specimens where 0.2 mm of composite were polished away, there was no significant difference in surface hardness among the four groups either immediately after polishing (p > 0.05) or five days later (p > 0.05). The hardness measured after five days showed increases of 14.9% (group 2) and 26.0% (group 1) for non-polished specimens and 21.7% (group 2) and 28.1% (group 1) for polished specimens compared to the hardness values determined immediately after curing. The surface hardnesses of specimens in which 0.2 mm of composite were polished away increased in specimens both right after curing and five days after polishing. The effect of polishing was significantly different among the groups. The surface hardnesses of the polished specimens right after curing and five days after polishing increased by 143.4% and 147.4% in group 1, 105.7% and 124.3% in group 4, 57.8% and 65.0% in group 3, and 45.4% and 54.0% in group 2 compared to the values from the non-polished specimens. A high degree of interaction was found between surface polishing and experimental groups, but no interaction was seen between measurement time and groups.

DISCUSSION

This study was performed to identify effective procedures that could prevent or reduce OIL formation during curing. The measurement for surface hardness of composites is an indirect method for evaluating the relative degree of polymerization.

6,

7 Oxygen is a powerful inhibitor which retards or even terminates polymerization. Therefore, the measurement for surface hardness of composites was used for evaluating the quantity of OIL formation in this study. The degree of polymerization is affected by many factors such as initiator,

8,

9 filler content and size, color, light intensity, curing time.

10 OIL formation is also affected by these factors.

11,

12 Therefore, this study was carried out at fixed values of the aforementioned conditions.

For the unpolished specimens measured right after curing, the use of a Mylar strip was most effective in preventing OIL formation, and the application of glycerin before curing was the second most effective method. When additional curing with glycerin applied to specimens already cured in air, the surface hardness increased compared to those of specimens solely cured in air. It is speculated that since a Mylar strip blocks any contact with air, only the oxygen already present within the composite contributes to OIL formation, thus minimizing OIL formation. However, when glycerin is used, minute amounts of oxygen in the glycerin in addition to that already existing on the composite surface may support the formation of an OIL, leading to a greater amount of OIL formation than that observed with the Mylar strip method. When glycerin is applied to previously cured composites and additionally cured, initiators remaining in the OIL might be converted into free radicals, supporting the occurrence of additional polymerization in an oxygen-restricted state. However, in this case, the surface hardness was relatively lower than those of groups 2 and 3 in which oxygen was restricted throughout.

In every case, there was a significant increase in surface hardness five days after curing. This indicates that additional polymerization occurred during the five days in which the specimens were stored, in agreement with the results from several previous studies.

4,

13-

15 Non-reacted free radicals remain in composites even after light activation and react with free monomers to produce a continued polymerization chain reaction. This additional polymerization by free radicals occurs considerably during the first hour and has been reported to persist over the course of one month.

13-

15 In the unpolished specimens, the surface hardnesses of the group that used a Mylar strip and the group cured with glycerin were similar five days after curing. These two methods resulted in greater hardness than that achieved through supplemental curing with glycerin after the initial cure.

Removal of 0.2 mm of material from the surface of the composite via polishing led to a large increase in surface hardness compared to that observed with no polishing. This result is due to exposure of the solid surface under the OIL after removal through polishing. The subsurface under the OIL is not influenced by oxygen, and its temperature increases more than that of the surface during polymerization, resulting in a greater degree of conversion.

16 Furthermore, in contrast to unpolished specimens, the hardnesses of the polished specimens showed no differences based on the curing method. Based on these results, it was inferred that the OIL is limited to 0.2 mm in depth, and that curing methods which affect OIL formation do not influence composites that are greater than 0.2 mm thick.

Interactions between surface polishing and curing methods were observed. As explained above, there was a significant difference in hardness depending on the curing method for unpolished specimens. However, when the OIL was removed via polishing, there were no differences in hardness. On the other hand, there was no interaction between measurement time and curing method. In other words, the differences in surface hardness among the groups observed immediately after curing decreased slightly with time but were maintained to some degree.

Among the procedures tested in this study, the most effective method for reducing OIL formation was polishing after light curing. Polishing results in a higher surface hardness than that produced when a matrix is used,

13 is effective in preventing discoloration,

17 and is advantageous in achieving a satisfactory surface and marginal adaptation.

18 Clinically, however, the OIL may not be able to be completely removed and can remain in deep pits and fissures even after polishing. Therefore, in order to reduce the amount of OIL on composites as much as possible, it is recommended that a Mylar strip be used for proximal and bucco-lingual cavities, and that glycerin be applied for occlusal surfaces and hard-to-reach cavities during curing.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download