Abstract

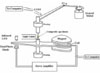

The aim of this study was to measure the initial dynamic modulus changes of light cured composites using a custom made rheometer. The custom made rheometer consisted of 3 parts: (1) a measurement unit of parallel plates made of glass rods, (2) an oscillating shear strain generator with a DC motor and a crank mechanism, (3) a stress measurement device using an electromagnetic torque sensor. This instrument could measure a maximum torque of 2Ncm, and the switch of the light-curing unit was synchronized with the rheometer.

Six commercial composite resins [Z-100 (Z1), Z-250 (Z2), Z-350 (Z3), DenFil (DF), Tetric Ceram (TC), and Clearfil AP-X (CF)] were investigated. A dynamic oscillating shear test was undertaken with the rheometer. A certain volume (14.2 mm3) of composite was loaded between the parallel plates, which were made of glass rods (3 mm in diameter). An oscillating shear strain with a frequency of 6 Hz and amplitude of 0.00579 rad was applied to the specimen and the resultant stress was measured. Data acquisition started simultaneously with light curing, and the changes in visco-elasticity of composites were recorded for 10 seconds. The measurements were repeated 5 times for each composite at 25±0.5℃. Complex shear modulus G*, storage shear modulus G', loss shear modulus G" were calculated from the measured strain-stress curves. Time to reach the complex modulus G* of 10 MPa was determined. The G* and time to reach the G* of 10 MPa of composites were analyzed with One-way ANOVA and Tukey's test (α= 0.05).

The results were as follows.

1. The custom made rheometer in this study reliably measured the initial visco-elastic modulus changes of composites during 10 seconds of light curing.

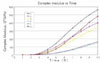

2. In all composites, the development of complex shear modulus G* had a latent period for 1~2 seconds immediately after the start of light curing, and then increased rapidly during 10 seconds.

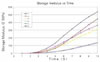

3. In all composites, the storage shear modulus G' increased steeper than the loss shear modulus G" during 10 seconds of light curing.

4. The complex shear modulus of Z1 was the highest, followed by CF, Z2, Z3, TC and DF the lowest.

5. Z1 was the fastest and DF was the slowest in the time to reach the complex shear modulus of 10 MPa.

Figures and Tables

| Figure 3The relationship among shear strain γ(t), stress τ(t), and phase angle δ in a dynamic oscillatory test. |

| Figure 4The relationship among storage (real) modulus G', loss (imaginary) modulus G", and phase angle δ in a complex plane. |

References

1. Dauvillier BS, Feilzer AJ, De Gee AJ, Davison CL. Visco-elastic parameters of dental restorative materials during setting. J Dent Res. 2000. 79(3):818–823.

2. Guggenberger R, Weinmann W. Exploring beyond methacrylates. Am J Dent. 2000. 13:82D–84D.

3. Ellakwa A, Cho N, Lee IB. The effect of resin matrix composition on the polymerization shrinkage and rheological properties of experimental dental composites. Dent Mater. 2007. 23:1229–1235.

4. Labella R, Lambrechts P, Van Meerbeek B, Vanherle G. Polymerization shrinkage and elasticity of flowable composites and filled adhesives. Dent Mater. 1999. 15:128–137.

5. Braga RR, Ferracane JL. Contraction stress related to degree of conversion and reaction kinetics. J Dent Res. 2002. 81:114–118.

6. Kleverlaan CJ, Feilzer AJ. Polymerization shrinkage and contraction stress of dental resin composites. Dent Mater. 2005. 21:1150–1157.

7. Feilzer AJ, De Gee AJ, Davison CL. Setting stress in composite resin in relation to configuration of the restoration. J Dent Res. 1987. 66:1636–1369.

8. Charton C, Colon P, Pla F. Shrinkage stress in light-cured composite resins:Influence of material and photoactivation mode. Dent Mater. 2007. 23:911–920.

9. Odian G. Principles of polymerization. 1991. 3rd Ed. New York: John Wiley & Sons, Inc.;216–226.

10. Sakaguchi RL, Shah NC, Lim BS, Ferracane JL, Borgersen SE. Dynamic mechanical analysis of storage modulus development in light-activated polymer matrix composites. Dent Mater. 2002. 18:197–202.

11. Mesquita RV, Axmann D, Geis-Gerstorfer J. Dynamic visco-elastic properties of dental composite resins. Dent Mater. 2006. 22:258–267.

12. Helvatjoglu-Antoniades M, Papadogiannis Y, Lakes RS, Dionysopoulos P, Papadogiannis D. Dynamic and static elastic moduli of packable and flowable composite resins and their development after initial photo curing. Dent Mater. 2006. 22:450–459.

13. Nakayama WT, Hall DR, Grenoble DE, Katz JL. Elastic properties of dental resin restorative materials. J Dent Res. 1974. 53:1121–1126.

14. Braem M, Lambrechts P, Van Doren V, Vanherle G. The impact of composite structure on its elastic response. J Dent Res. 1986. 65:648–653.

15. Lee IB, Son HH, Um CM. Rheologic properties of flowable, conventional hybrid, and condensable composite resins. Dent Mater. 2003. 19:298–307.

16. Lee IB, Cho BH, Son HH, Um CM. Rheological characterization of composites using a vertical oscillation rheometer. Dent Mater. 2007. 23:425–432.

17. Suh HY, Lee IB. Slumping resistance and viscoelasticity of resin composite pastes. J Korean Acad Conserv Dent. 2008. 33:235–245.

18. Braem M, Lambrechts P, Vanherle G, Davidson CL. Stiffness increase during the setting of dental composite resins. J Dent Res. 1987. 66(12):1713–1716.

19. Sakaguchi RL, Wiltbank BD, Murchison CF. Prediction of composite elastic modulus and polymerization shrinkage by computational micromechanics. Dent Mater. 2004. 20:397–401.

20. Lee JH, Um CM, Lee IB. Rheological properties of resin composites according to variations in monomer and filler composition. Dent Mater. 2006. 22:515–526.

21. Tanimoto Y, Nishiwaki T, Nemoto K. Dynamic viscoelastic behavior of dental composites measured by split Hopkinson pressure bar. Dent Mater J. 2006. 25(2):234–240.

22. Ferracane JL. Developing a more complete understanding of stresses produced in dental composites during polymerization. Dent Mater. 2005. 21:36–42.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download