I. INTRODUCTION

The polymerization shrinkage stress in resin composite restoration has been studied as a function of cavity shape. Feilzer, et al

1) first described the effect of cavity shape on shrinkage stress as the configuration factor (C-factor), which was calculated from the ratio of unbonded to bonded surface area. Because the bond strength of the dentin bonding agent at that time was insufficient to resist the shrinkage stress of the resin composite, polymerization shrinkage of the resin composite lead to separation of the resin-dentin bond at the dentin wall of the cavity. Recently, bond strength has improved to values greater than the suggested shrinkage stress of 20 MPa resulting from the polymerizing resin composite

2). However, the detrimental effect of the inherent shrinkage of polymerizing resin composite on dentin bond strength has still been investigated with respect to the C-factor by comparing the bond strengths of resin composites filled in the cavities with different C-factors, bonding agents, and various filling techniques

3-

5).

It is generally accepted that the direction of shrinkage in a light-curing resin composite restoration depends on the cavity shape and bond quality

6,

7). In an

in vitro study, Asmussen & Peutzfeldt

8) demonstrated that light-curing resin composites filled in a ring-shaped brass mold shrank towards the light source when the thickness of resin composite was less than that being cured in most clinical situations (< 2 mm). However, when an adequate bond quality was obtained at the bottom wall as well as the lateral walls, the light-curing resin composite did not shrink toward the light source during polymerization

7-

9). Because the bulk of the resin composite shrank toward a certain point between the center of the bulk and the cavity floor, the shrinkage of the polymerizing resin composite still exerted stresses on the adhesive layer at the cavity floor

9). Moreover, even if the bonding agent is cured properly following the manufacturer's instruction, the initial strength of the adhesive layer is so poor that it cannot resist the shrinkage stress of the polymerizing resin composite. The shrinkage stress may result in cracks within the bonded complex during an early stage of the filling procedure

10) and may lead to gap formation, marginal discoloration, postoperative sensitivity, and secondary caries

11).

The bond strength at each wall within a cavity may be affected by the bond strength, named here as bond quality, of the bonding agent applied to the other walls within the cavity, as well as the ratio of bonded/unbonded area. This means that when defining the C-factor, the bond quality at each wall should be simultaneously considered with the surface area of cavity walls. In addition to bond quality and surface area, the volume of resin composite may also be included in the concept of C-factor. This is due to that larger amounts of resin composite will show a greater amount of volumetric shrinkage in an absolute dimension and accordingly will result in increased recession of a certain marginal part of the resin composite mass.

In this study, it was hypothesized that when resin composite was filled into a cavity, if the ratio of bonded/unbonded surface area was great, the cavity walls had already been bonded well and the volume of resin composite was large, increased shrinkage stresses would apply to the resin-dentin bond from the polymerizing resin composite and nominal shear bond strength values would decrease. The aim of this study was to evaluate the effect of cavity shape assumed by different wall materials, bond quality of the bonding agent and volume of the resin composite on the shrinkage stress developed at the cavity floor. This was done by measuring the shear bond strength with respect to iris materials (cavity shape), bonding agents (bond quality) and iris hole diameters (volume) using the iris method that simulates a Class I cavity.

II. MATERIALS AND METHODS

Experimental Design

Three variables, cavity shape, bond quality and volume, were selected for measuring the shear bond strength of a resin composite to the dentin at the cavity floor of a Class I restoration. To simulate the variable 'cavity shape', two types of irises were made of dentin and metal. The internal wall of the dentin iris hole was treated with the assigned bonding agent in order to obtain a Class I cavity with a high C-factor, when the iris was put on a flat dentin surface treated with the same bonding agent (

Figure 1). The internal wall of the metal iris hole was coated with Teflon in order to prevent bonding to the lateral walls, thereby achieving bonding on the flat dentin surface with a low C-factor. To observe the variable 'bond quality', because the bond strength of fourth generation bonding systems were generally accepted to be higher than that of sixth generation systems

12), Scotchbond Multi-Purpose (SBMP; 4

th generation total-etch bonding system, 3M ESPE, St. Paul, MN, USA) and Xeno III (6

th generation self-etch bonding system, Detrey/Dentsply, Konstanz, Germany) were treated on the internal wall of the dentin iris hole and flat occlusal dentin surface on which the iris would be placed. In the case of metal iris, since the internal wall of the iris hole was coated with Teflon, the polymerizing resin composite bonded only to the cavity floor. To test the variable 'volume', a hole of 1 mm or 3 mm in diameter was drilled at the center of 1.5 mm thick irises, so that the volume of the resin composites filled into the iris holes varied by nine fold. Thereby, a 2 × 2 × 2 test design was constructed. In order to investigate the effect of these variables on shrinkage stress at the cavity floor, after treating the flat occlusal dentin with the assigned bonding agent, the iris whose internal wall was treated with the same bonding agent was placed on the treated dentin surface and resin composite (Filtek Z-250; 3M ESPE) was filled into the iris hole in a bulk-filling method.

Iris preparation

The dentin iris was made by sectioning teeth into discs with a thickness of 1.50 ± 0.08 mm with a low-speed diamond saw (ISOMET; Buehler Co., IL, USA) from the middle portion of the crown, trimming the lateral surface at a right angle to the sectioned surface, and drilling a hole of 1 mm or 3 mm in diameter. The sections were stored in distilled water at room temperature. Teflon tape, 0.14 mm thick, was punched to form a hole with the same diameter as the dentin iris and attached to the bottom surface of the dentin iris just before the bonding procedure.

The stainless-steel metal iris, 7 mm in diameter and 1.5 mm in thickness, with a hole of either 1 mm or 3 mm in diameter, was sandblasted, heat-treated, and spray-coated with Teflon (average thickness: 20 µm) on all surfaces including the internal surface of the hole, and were used as a mold for packing the resin composite.

Bonding procedure

Ninety-six caries-free human third molars were used in this study. After extraction, the teeth were debrided and refrigerated at 4℃ in 0.5 mass fraction% chloramine-T solutions for 24 hours. They were then stored in distilled water until needed. Within one month of extraction, they were embedded in a self-cure epoxy resin for use.

The teeth were sectioned using a low-speed diamond saw under water irrigation through the mid-crown to expose the superficial occlusal dentin. The exposed dentin surface was polished with 500 grit SiC paper. The prepared specimens were randomly divided into eight experimental groups (2 × 2 × 2 experimental setup). The assigned bonding agent was applied to the polished occlusal dentin surface and light-cured (Hilux ultra plus, Benlioglu Dental inc., Ankara, Turkey; Light intensity: 600 mW/cm

2) according to the manufacturer's instructions (

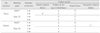

Table 1). In the case of dentin iris, prior to positioning the iris on the occlusal dentin surface, the internal surface of the iris hole was treated with the bonding agent and light-cured. The iris was pressed against the treated dentin surface using a holder. Filtek Z250 Universal Restorative (A2 shade) was filled into the iris hole in a bulk-filling manner and then light-cured for 20 seconds. The assembly was allowed to sit for an additional 4 minutes, and then immersed in distilled water at room temperature for 24 hours prior to testing.

Shear bond strength test and fracture surface analysis

The bonded assembly was loaded in a shear mode until fracture in a universal testing machine (Instron 4400, Instron Corp., Canton, MA, USA) at a crosshead speed of 1.0 mm/min following the chisel-on-iris method

13). The bond strength data was analyzed using three-way ANOVA and the Tukey test to determine the interactions between the variables, i.e., the iris material (cavity shape), the bonding agent (bond quality), and the hole diameter (volume). All statistical analyses were conducted at a 95% confidence level using SigmaStat (Version 2.03; Jandel Scientific, Chicago, IL, USA).

After debonding, the failure mode of each specimen was determined and classified into 'failure at the top of the hybrid layer' or 'mixed failure' that accompanied partially cohesive fracture in the adhesive resin and resin composite under a stereomicroscope (SZ4045TR, Olympus Optical Co., Tokyo, Japan). The failure mode patterns were verified using a scanning electron microscopy (SEM, JSM-840A: JEOL Ltd, Tokyo, Japan). The bond strength values obtained from the specimens that indicated cohesive failure in the dentin or resin composite were excluded from the data.

III. RESULTS

The power analysis revealed that our sample size was adequate. The mean shear bond strength and standard deviations for the three variables (cavity shape, bond quality and volume) are shown in

Table 2. Three-way ANOVA showed that significant differences were observed for each variable (p < 0.001,

Table 2). When shear bond strengths were measured with dentin irises (high C-factor), they were significantly lower than those measured with metal irises (low C-factor). When SBMP was used, shear bond strengths were significantly higher than those bonded with Xeno III. When the volume of resin composite was large (3 mm hole), bond strength decreased significantly. There were statistically significant interactions between the variables of cavity shape (iris material) and bond quality (bonding agent), and between cavity shape and volume (iris hole diameter) (p = 0.003 and p = 0.007, respectively,

Table 2). On the other hand, the interaction between the variables of bond quality and volume was not found (p = 0.336). The two significant interaction terms indicated that although the effect of bond quality on shear bond strength was not dependent upon the volume, the effect of cavity shape on bond strength was dependent upon the bond quality and volume of resin composite.

On the fracture surfaces, there were two main features, the plain detached area, which was parallel with the ground occlusal dentin surface, and the inclined fractured area, in which the failure plane meandered through more than one material (

Figure 2). When most of the fractured surface area was plain detached area, it was classified as 'Failure at the top of the hybrid layer', because most of the surfaces were covered with resinous material. However, if fracture fragments of the adhesive layer or resin composite were left on the dentin side, the fractures were classified as 'Mixed failure'(

Table 3 and

Figure 2). The incidences of 'failure at the top of the hybrid layer' and 'mixed failure' were nearly the same between the metal iris and dentin iris. Xeno III showed a higher incidence of 'failure at the top of the hybrid layer' than SBMP. The irises having a 3 mm hole presented a much higher incidence of 'failure at the top of the hybrid layer' than those having a 1 mm hole (

Figure 3). Only 3 specimens in the group bonded with SBMP using the metal iris with a 3 mm hole demonstrated complete cohesive failure in the dentin and only 1 in the group bonded with SBMP with 3 mm hole dentin irises demonstrated cohesive failure in the resin composite. These specimens were excluded from the bond strength data (

Table 3).

IV. DISCUSSION

The bond strength values were used to compare the quality and efficacy of the dental adhesive products. The microtensile bond strength test has become accepted as the most reliable method. However, due to the relative simplicity in preparing the test specimens and the ease in fabricating the test equipment, shear bond strength tests have been used frequently to evaluate dentin bonding systems. Along with the improvement in bond strength of the current generation dentin bonding agents, cohesive failure in dentin during shear bond strength tests was observed more frequently

14). However, rather than improvement in the material properties, the test mechanics of the shear test set-up, such as loading condition

15-

17) and small changes in the geometric arrangement

18,

19), was suggested to cause the variations in strength values and cohesive fracture in dentin.

Due to such drawbacks, test methods measuring the shear bond strength of bonding agents evolved to improve the test mechanics

13,

20). The chisel-on-iris method was suggested to be simple and to avoid the extraneously introduced failure modes, such as cohesive fracture in dentin

13). In this study, only 3 specimens tested with the iris method showed dentin cohesive failures and only 1 specimen failed within the resin composite. They were excluded from the data (

Table 3), due to being regarded as representing the cohesive strength of the dentin and resin composite themselves, respectively, not the adhesive bond strength. Therefore, the iris method using the metal iris appeared to have advantages in reducing the stress concentration, thereby preventing the deviation of fracture propagation from the adhesive plane, and thus measuring a more approximate 'true shear bond strength' over other shear test methods

13).

The iris method has another unique advantage in reproducing a Class I cavity and might represent clinical situations more similarly than the conventional shear test using a composite cylinder. In this study, the internal surface of the iris hole was either a Teflon-coated metal or an adhesive-treated dentin. The adhesive-treated internal wall of the dentin iris simulated the lateral wall of a Class I cavity, which had a high C-factor. On the other hand, in order to simulate a situation having a low C-factor, the internal wall of the metal iris was coated with Teflon so that the resin composite could bond only to the flat dentinal surface of cavity floor. Under the specific condition of this study, the shear bond strengths measured with dentin irises were lower than those measured with metal irises (p < 0.001,

Table 2). The result was in agreement with previous reports showing that the bond strength of a resin composite filled into a cavity was lower than that bonded to a flat dentin surface

4,

5). Therefore, the shear bond strength must be affected by the variable 'cavity shape' that was reproduced by the different iris materials. The adhesive-treated internal wall of the dentin iris must have induced a higher level of stress at the resin-dentin bonded interface of the cavity floor than the unbonded wall of the Teflon-coated metal iris. The contraction stress from polymerizing resin composite in a cylindrical Class I cavity represented by dentin iris might have affected the shear bond strength. This stress was suggested to induce contraction gaps

9), which influenced the marginal adaptation

6,

11,

21). The lower bond strength values might represent the resin-dentin bond strength at the interface within an actual cavity.

Besides the well-known C-factor that is dependent upon cavity geometry, contraction stress was affected by whether the internal surface of the mold for packing the resin composite was Teflon-coated or roughened

6). The experimental setup used in this study had the same cylindrical configuration with their ring mold. However, rather than the roughened internal surface of the ring mold, two bonding agents were used to evaluate the effect of bond quality on the shrinkage stress of the resin composite filled into the iris. Confirming the general agreement that the bond strength of the fourth generation dentin bonding system is higher than that of the sixth generation

12), the shear bond strength of SBMP was higher than that of Xeno III (p < 0.001,

Table 2). Therefore, the selection of two bonding agents to compare the effect of bond quality on the shrinkage stress was appropriate. The interaction between the variables 'cavity shape' and 'bond quality' was statistically significant (p = 0.003,

Table 2), indicating that the effect of different cavity shapes on bond strength values was dependent upon different types of bonding agents.

Since the C-factor is estimated by definition from the ratio of bonded to unbonded surface area, it can vary with different diameters and heights even in a Class I cavity. In this study, the height of the iris hole was fixed to the dimension of 1.5 mm for ease of preparing the dentin disc. When the diameters of the iris holes increased from 1 mm to 3 mm, the C-factors of the dentin irises decreased from 5.0 to 2.33, but those of the metal irises slightly increased from 0.2 to 0.43 (

Table 2). In addition to the originally defined C-factor, which affected the bond strength as discussed in the previous sections, three-way ANOVA revealed that the bond strengths measured with this irises having a 3 mm hole were significantly lower than those measured with the irises having a 1 mm hole (p < 0.001,

Table 2) and the interaction between the variables 'cavity shape'(iris material) and 'volume'(iris hole diameter) was statistically significant (p = 0.007,

Table 2). Therefore, the variable of 'volume' determined by the diameter of the iris hole must have affected the bond strength measurements. There was no statistically significant interaction between the variables of 'bond quality' and 'volume'(p = 0.336,

Table 2).

In this study, the shear bond strength measured with the irises having a 3 mm hole was lower than that measured with the irises having a 1 mm hole. This could be explained by the general acceptance that a smaller bonded area would obtain higher bond strength. A smaller bonded area contains fewer defects compared to a larger one, thereby increasing the bond strength

22). This interpretation agreed with the results recorded for the dentin iris (

Table 2). However, in the case of the metal iris, the difference in the bond strengths measured with irises of different hole diameters was not so apparent (

Table 2). The comparison suggested that the changes in bond strength according to the diameter couldn't be understood only by considering bonded area. The different iris materials must have affected the result as well. The absolute amount of shrinkage, which resulted from the volume of resin composite affected by the C-factor, could be suggested as a factor influencing the bond strength in the dentin iris. Contrary to the dentin iris, since there were no bonds between the resin composite and the Teflon-coated internal wall of the metal iris, the direction of shrinkage was mainly toward the cavity floor. The volume of resin composite restricted within the bonded lateral wall was so small in the metal iris that it might have a negligible effect on the shrinkage stresses exerted on the resin-dentin bond at the cavity floor. Although the increase in the hole diameter of metal iris resulted in a slight increase in C-factor, the increase in bonded area did not decrease the bond strength not so much as the dentin iris (

Table 2). Therefore, the change in the 'diameter' of the iris hole can be transformed to the 'volume' that was restricted within the bonded wall and thus affected the C-factor.

The transformation of the variable of 'diameter' to 'volume' was confirmed by fracture surface analysis. In order to simplify the classification of failure modes, the observed fracture surfaces were divided into the plain detached area, which was parallel with the ground occlusal dentin surface, and the inclined fractured area, in which the failure plane meandered through more than one material (

Figure 2). When most of the fractured surface was plain detached area, it was classified as 'failure at the top of the hybrid layer', because most of the surfaces were covered with resinous material. However, if fracture fragments of the adhesive layer or resin composite were left on the dentin side, the fractures were classified as 'mixed failure' (

Table 3 and

Figure 2). The term 'mixed' was used in this study for the features, in which, regardless of fracture initiation site, fractures propagated through different materials. Accordingly, in a mixed failure, the fractures at the dentin surface covered with resinous material (hybrid layer), across or within the adhesive resin layer and into the resin composite, could be found simultaneously with various combinations and proportions.

The incidences of 'failure at the top of the hybrid layer' and 'mixed failure' were nearly the same between the metal iris and dentin iris (

Figure 3). The variable of 'cavity shape' failed to show a difference in the incidence between the two failure modes. However, the variables of 'bond quality' and 'volume' showed different incidences of the two failure modes (

Figure 3). The failure analysis suggested that the groups showing low bond strength (Xeno III and 3 mm hole) result in a higher incidence of 'failure at the top of the hybrid layer' than the groups showing high bond strength (SBMP and 1 mm hole,

Table 2 and

Figure 3). Since the 'failure at the top of the hybrid layer' was mainly composed of plain detached area, it could originate from early debonding between the hybrid layer and adhesive layer, which was developed by the contraction stress from the polymerizing resin composite at an early stage of the bonding procedure

10,

23). It is well accepted that increased bonded area increases the inherent defect and as a result, decreases bond strength. However, this describes the situation at the time of load application. The inherent defects may change the path of crack propagation into different material and induce mixed failure. The high incidence of 'failure at the top of the hybrid layer' and low bond strength in the groups using a 3 mm hole in this study may have resulted from early debonding caused by large volumetric shrinkage of the polymerizing resin composite (

Table 2 and

Figure 3). Therefore, the dimension 'diameter' can be designated as the variable 'volume', rather than 'bonded area'.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download