This article has been

cited by other articles in ScienceCentral.

Abstract

PURPOSE

The purpose of this study was to achieve more retention and stability and to delay or prevent screw loosening.

MATERIALS AND METHODS

Twenty implants (Implantium 3.4 mm, Dentium, Seoul, Korea) were divided into 2 groups (n = 20). In the first group, an adhesive material was applied around the screw of the abutments (test group). In the second group, the screws are soaked in saliva (control group). All the screws were torqued under 30 N/cm, Then, the samples were gone through a cyclic fatigue loading process. After cyclic loading, we detorqued screws and calculated detorque value.

RESULTS

In comparison with the control group, all the implant screws in the test group were smeared with the adhesive material, showing significant higher detorque value.

CONCLUSION

There are significantly higher detorque values in the group with adhesive. It is recommended to make biocompatible adhesive to reduce screw loosening.

Go to :

Keywords: Dental implants, Dental implant-abutment design, Dental implant-abutment interface, Adhesives

INTRODUCTION

Nowadays implant-supported prosthesis is the best treatment plan for replacement of missing teeth to restore patients' esthetics and function. However, there are still complications, such as mechanical failures of prosthetic components and implants, increased marginal openings, and abutment screw loosening.

12

On a recent systematic review, screw loosening was known as the most frequent technical complication of implant-supported single crowns.

3

Screw loosening has two mechanisms, which are excessive bending on the screw joint and settling effect. If the bending force on restoration is more than yield strength of the screw, it leads to permanent deformation of the screw and subsequently loss of tensile force in the screw stem. Eventually, contact forces between the implant and the abutment decreases and the screw joint loosens more easily. Slight micro roughness of the two surfaces, which is inevitable in manufacturing of implants, leads to the second complication. In this situation, two surfaces don't contact completely with each other, and the incomplete contact leads to micro movements under external loads.

4

Inadequate tightening torque, settling of implant components, inappropriate implant position, inadequate occlusal scheme or crown anatomy, poorly fitting frameworks, presence of microleakage at the abutment-implant interface, improper screw design/material, and heavy occlusal forces can cause implant screw loosening.

5678

Abutment screw loosening may result in mobility of prosthesis, which necessitates removing the prosthesis in order to tighten the abutment. The most usual complications of abutment screw loosening include inflammation of the gingival, failure of implant, and fracture of the screws.

9

To minimize these problems, various solutions are recommended, such as using diamond-like carbon coating over abutment screws, retightening screws after initial tightening, and increasing the torque value.

14

Although the design and the screw material have advanced recently, the screw loosening is still the issue that sometimes occurs.

5

This study aimed to investigate whether using specific adhesive material used in industry was favorable for decreasing torque loss in implant-abutment screws.

The purpose of this study was to achieve the method to attain more retention and stability, and delay or prevention of implant screw loosening.

Go to :

MATERIALS AND METHODS

20 fixtures (Superline, Dentium, Seoul, Korea) measuring 4 mm in platform diameter and 12 mm in length, 20 straight abutments (Dual abutment, Dentium, Seoul, Korea) measuring 4.5 mm in diameter, 5.5 mm in length, and 3.5 mm in gingival height were used. The samples were randomly divided into 2 groups. Each group included 10 fixtures and 10 straight abutments (n = 10).

The implants were wrapped in thin layers of lead of radiographic films in order to prevent acrylic resin from remaining in the implant threads and to effortlessly remove acryl from implants after cyclic loading procedure. In this situation, autopolymerized acrylic resin (Luxatemp; DGM, Hamburg, Germany) was poured inside mold at 1 mm below the interface of implant-abutment level.

In the first group, an adhesive material (Loctite, Henkel Adhesives Technologies, Rocky Hill, United States) was applied only around the abutment screws (test group). In the second group, the screws were soaked in saliva (control group). In order to better simulate masticatory loads, designing of a crown for the abutment was needed; crowns at an angle of 45 degrees were fabricated from base metal alloy (Wirobond C, Bego, Bremen, Germany). Crowns had a horizontal process to be easily removed after cyclic loading.

10 When the load is applied at an angle of 45 degrees, it is subdivided into horizontal and vertical components so the load is applied along both horizontal and vertical axis, similar to load during mastication. There was no need to temporarily cement the crowns because they were stable enough and they could be easily removed after cyclic loading. Direct contact of beating arm with abutments during the cycling loading may bring about crack or fracture of the abutments. The samples were placed in cyclic loading jig using a surveyor to make sure that the force was applied parallel to long axis of the implant abutments.

In order to achieve accurate and reliable measurements, the electronic torque meter (Proto Electronic Torque Meter, Nebraska, USA) was calibrated first. They were all torqued 30 N/cm and, 15 minutes later, retorqued to 30 N/cm as recommended by the manufacturer for final prosthesis insertion appointment. Embedment relaxation occurs due to microroughness existed on the mating surfaces when the initial tightening torque is applied to the screw, and only the prominent spots contact; by embedment relaxation that flatten the prominent spots under load, 2% to 10% of initial preload is lost.

11 To limit this process, retightening after 10 - 15 minutes is recommended (

Fig. 1).

4 Five screws in each group were maintained for a month in a stable state and the rest of them underwent cyclic loading (Chewing simulator, S-D mechatronic, Germany) for 500,000 cycles with frequency of 2 Hz and force of 75 N/cm (which is equal to the occlusion loads for a natural tooth in one year) (

Fig. 2 and

Fig. 3). The end point of the force applying lever was round and it was adjusted on a slope of 45 degree on the crown. All the specimens were maintained at 37℃.

| Fig. 1Digital torque meter is used to reach reproducible and accurate forces.

|

| Fig. 2The forces are applied in 45-degree angle over the crowns.

|

| Fig. 3Cyclic loading was applied to imitate the oral condition.

|

After one month, all the screws were detorqued by use of the same digital torque meter that was used for tightening the screws. Finally, the removal torque values were recorded.

Quantitative variable of the results in both groups was calculated as mean and standard deviation with SPSS for Windows (Version 16.0, SPSS Inc., Chicago, IL, USA). To analyze the effect of applying cyclic loading on specimens and using adhesive material on detorque value, 2-way analysis of variance (2-way ANOVA) was used. The value less than 0.05 was considered statistically significant difference (P < .05).

Go to :

RESULTS

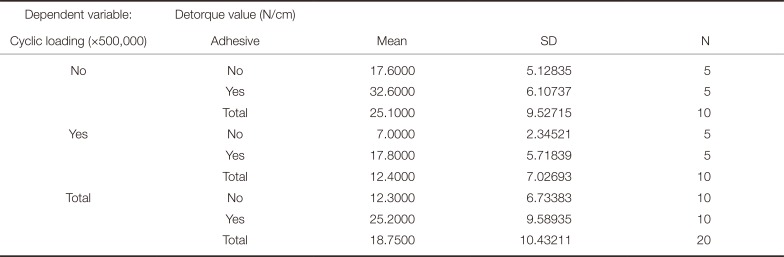

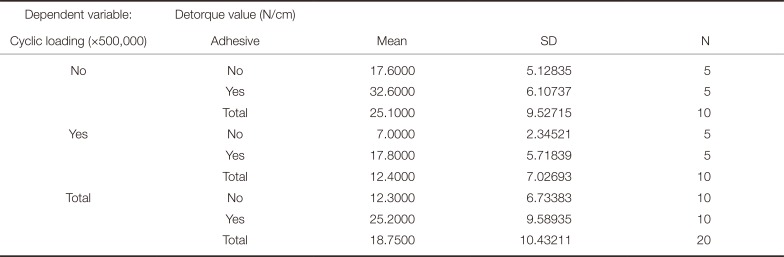

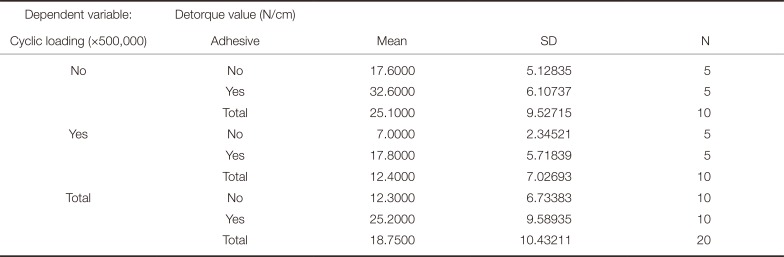

The value less than 0.05 was considered statistically significant difference (

P < .05). Two-way ANOVA determined that there was a statistically significant difference between two major groups of samples regarding applying the cyclic load. Using an adhesive material in the test group caused a considerable increase in detorque value which was 25.2000 N/cm. The detorque value of implants without adhesive was 12.3000 (

Table 1). It was also determined that the average of detorque value of all groups was significantly decreased after cyclic loading (All implants not under cyclic loading showed the average of 25.1000 N/cm regardless of using the adhesive material, and all implants under cyclic loading showed the average of 12.4000 N/cm regardless of using the adhesive material) (

Table 1).

Table 1

Descriptive statistics

|

Dependent variable: Cyclic loading (×500,000) |

Detorque value (N/cm)

Adhesive |

Mean |

SD |

N |

|

No |

No |

17.6000 |

5.12835 |

5 |

|

Yes |

32.6000 |

6.10737 |

5 |

|

Total |

25.1000 |

9.52715 |

10 |

|

Yes |

No |

7.0000 |

2.34521 |

5 |

|

Yes |

17.8000 |

5.71839 |

5 |

|

Total |

12.4000 |

7.02693 |

10 |

|

Total |

No |

12.3000 |

6.73383 |

10 |

|

Yes |

25.2000 |

9.58935 |

10 |

|

Total |

18.7500 |

10.43211 |

20 |

The mean and standard deviation values in the two groups are shown in

Table 1 (

P ≤ .05).

Go to :

DISCUSSION

Abutment screw loosening is the most frequent complication in implant-supported prostheses, and it faces the patients and physicians with an inconvenient situation.

3

Finding an approach to increase the retention and stability of the abutment screws was the main purpose of this study. To achieve this goal, we carried out this study to find out whether utilization of an adhesive material on abutment screws can increase removal torque value of screws.

The results found in this study indicated that the abutment screws that were tightened by the adhesive material showed a significant increase in removal torque value. In other words, removal torque value average of the group with the adhesive material was considerably greater than that of the other group.

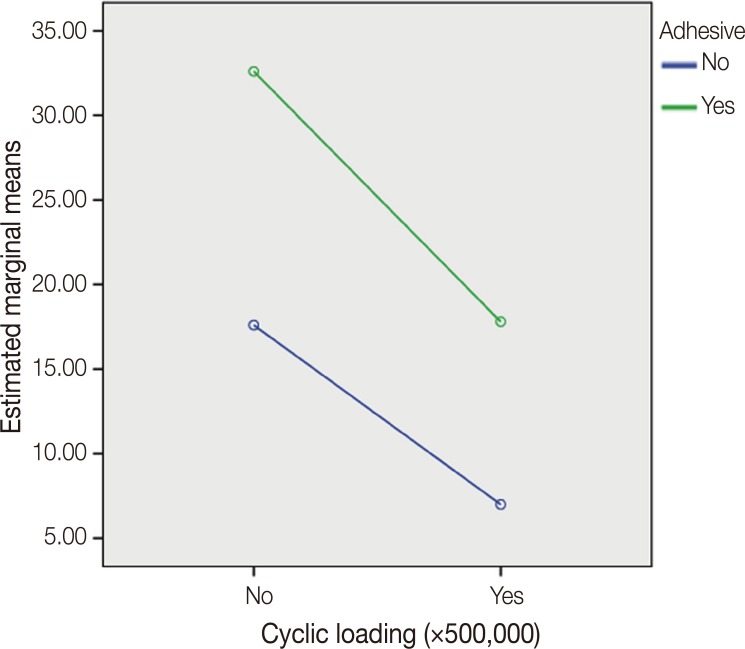

We used a digital torque meter (which was strongly recommended by the manufacturer) to deliver an accurate and reproducible forces. The number of five screws from each group was gone under cycling loading to imitate the oral condition. By applying cyclic loading, the detorque value in both groups (with and without adhesive material) decreased, which was predictable according to the results from the study of Khraisat et al.

12 Although, by applying cyclic load, the discrepancy between two main groups detorque value averages decreased, it was statistically significant. In fact, this shows that taking advantage of an adhesive material to reach more retention in abutment screws can be helpful even under cyclic loading (

Fig. 4).

| Fig. 4Estimated marginal means of detorque value (N/cm).

|

Furthermore, we can also consider another role for the adhesive material as a filler material. The adhesive material can fill the space that exists in abutment-implant junction surface in all of commercial screw retained implant systems. Based on the study of Gross et al.,

13 this space can provide a path for fluids and macromolecules generated from saliva or gingival cervicular fluid (GCF). It is suggested the fluids that seep in this space may contain molecules that is vital for bacterial population growth or bacterial byproducts, which are related to clinically observable peri-implantitis and malodor.

11 According to previous studies, the occurrence of microleakage can bring about screw loosening, followed by decrease in detorque value.

1213 Moreover, screw loosening increases the chance of microleakage.

13 Thus, by using an adhesive material, the microleakage in abutment-implant interface can be reduced not only by filling the gap exist in that interface, but also by improving the retention of screw retained abutments.

Adhesive material that we used in our study is used for prevention from screw loosening in industrial appliances. Since it showed excellent results in our study, our next step is to achieve an adhesive material that is biocompatible with more longevity and easy removal. Moreover, we can expect it to release antibacterial agents, which can delay and inhibit microbial growth. Therefore, it will decrease gingival and periodontal inflammation and crestal bone resorption. No study was found to use adhesive material in this condition.

There were some constraints to complete this study, which are inherent in any kind of in vitro study. Finding an appropriate adhesive material that preserves its adhesion characteristics was the most important one. One should be cautious in interpreting the results, while simulating the complex biomechanics of oral cavity cannot be accurately accomplished. So, the results have to be validated in a clinical condition.

Go to :

CONCLUSION

Within the limitation of this study, it was found that the application of an adhesive material on the abutment screws is recommended to prevent or decrease screw loosening.

Go to :

ACKNOWLEDGEMENTS

The authors kindly thank Dentium Company (Seoul, Republic of Korea) for supplying implant components for evaluation.

Go to :

References

1. Diez JS, Brigagão VC, Cunha L, Neves AC, da Silva-Concilio LR. Influence of diamondlike carbon-coated screws on the implant-abutment interface. Int J Oral Maxillofac Implants. 2012; 27:1055–1060. PMID:

23057017.

2. Cho SC, Small PN, Elian N, Tarnow D. Screw loosening for standard and wide diameter implants in partially edentulous cases: 3- to 7-year longitudinal data. Implant Dent. 2004; 13:245–250. PMID:

15359161.

3. Jung RE, Pjetursson BE, Glauser R, Zembic A, Zwahlen M, Lang NP. A systematic review of the 5-year survival and complication rates of implant-supported single crowns. Clin Oral Implants Res. 2008; 19:119–130. PMID:

18067597.

4. Siamos G, Winkler S, Boberick KG. Relationship between implant preload and screw loosening on implant-supported prostheses. J Oral Implantol. 2002; 28:67–73. PMID:

12498448.

5. Cho WR, Huh YH, Park CJ, Cho LR. Effect of cyclic loading and retightening on reverse torque value in external and internal implants. J Adv Prosthodont. 2015; 7:288–293. PMID:

26330975.

6. Sahin C, Ayyildiz S. Correlation between microleakage and screw loosening at implant-abutment connection. J Adv Prosthodont. 2014; 6:35–38. PMID:

24605204.

7. Tsumita M, Kokubo Y, Kano T, Sasaki K. Effect of fatigue loading on the screw joint stability of zirconium abutment. J Prosthodont Res. 2013; 57:219–223. PMID:

23796911.

8. Binon PP. The effect of implant/abutment hexagonal misfit on screw joint stability. Int J Prosthodont. 1996; 9:149–160. PMID:

8639238.

9. Zeno HA, Buitrago RL, Sternberger SS, Patt ME, Tovar N, Coelho P, Kurtz KS, Tuminelli FJ. The effect of tissue entrapment on screw loosening at the implant/abutment interface of external- and internal-connection implants: An in vitro study. J Prosthodont. 2016; 25:216–223. PMID:

26422295.

10. Ha CY, Lim YJ, Kim MJ, Choi JH. The influence of abutment angulation on screw loosening of implants in the anterior maxilla. Int J Oral Maxillofac Implants. 2011; 26:45–55. PMID:

21365037.

11. Shigley JE, Mischke CR. Standard handbook of machine design. New York: McGraw-Hill;1986. p. 23–26.

12. Khraisat A, Hashimoto A, Nomura S, Miyakawa O. Effect of lateral cyclic loading on abutment screw loosening of an external hexagon implant system. J Prosthet Dent. 2004; 91:326–334. PMID:

15116033.

13. Gross M, Abramovich I, Weiss EI. Microleakage at the abutment-implant interface of osseointegrated implants: a comparative study. Int J Oral Maxillofac Implants. 1999; 14:94–100. PMID:

10074758.

Go to :