This article has been

cited by other articles in ScienceCentral.

Abstract

PURPOSE

The aim of this study was to compare the surface roughness of zirconia when using Zircos E etching system (ZSAT), applying a nitric acid-hydrofluoric acid compound as a pretreatment agent, and also to compare the shear bonding strength according to different resin cements.

MATERIALS AND METHODS

ZSAT, air abrasion, and tribochemical silicacoating were applied on prepared 120 zirconia specimens (10 mm in diameter, 7 mm in height) using CAD/CAM. Each 12 specimens with 4 different resin cements (Panavia F 2.0, Rely X Unicem, Superbond C&B, and Hot bond) were applied to test interfacial bond strength. The statistical analysis was performed using SAS 9.1 (SAS Institute Inc., Cary, NC, USA). The results are as follows: after application of the ZSAT on the zirconia specimens, surface roughness value after 2-hour etching was higher than those after 1- and 3-hour etching on SEM images.

RESULTS

For Superbond C&B and Rely X Unicem, the specimens treated with ZSAT showed higher shear bond strength values than those treated with air abrasion and tribochemical silicacoating system. Regarding the failure mode of interface over cement and zirconia surface, Rely X Unicem and Hot bond showed cohesive failures and Panavia F 2.0 and Superbond C&B showed mixed failures.

CONCLUSION

Zircos E etching system in zirconia restoration could increase its shear bond strength. However, its long term success rate and clinical application should be further evaluated.

Go to :

Keywords: Zirconia, Surface treatment, Hydrofluoric acid-Nitric acid compound, Resin cements, Cohesive, Adhesive, Shear bond strength

INTRODUCTION

Due to its excellence in esthetics, biocompatibility, and mechanical properties, zirconia has been gaining popularity as a single crown core material, or in its usage in fixed prosthetics.

1 Volumetric changes during sintering, cutting, and manufacturing processes of zirconia could exert an influence on the adaptability of the material and the processed abutment.

2 Thus, special considerations for surface treatment and the selection of resin cements are essential for efficient bonding of zirconia.

3

In order to enhance the bond strength, two methods can be used: one increasing the surface area used in adhesion, and the other increasing the surface energy.

4 Handling zirconia, with larger crystalline structures and lower glass contents, calls for different surface treatment methods from glass ceramic treatments.

5

The surface treatment methods for all ceramic crowns can be divided into mechanical and chemical methods. Air abrasion (aluminum oxide particle roughen), laser treatment, selective infiltration technique (SIT), hot etching solution, nano structured alumina coating, and tribochemical silicacoating are used as mechanical methods, whereas silane coupling agents are used as a chemical method.

6789 The coarse surface created by hydrofluoric acid enables efficient infiltration of resin tags, which increases the bond strength between the ceramic and the resin cement. Unfortunately, such hydrofluoric acid cannot adequately increase the surface area of zirconia since it does not contain glass contents but has polycrystalline structures, which exhibit strong resistance to acids. It has been reported that mechanical interlocking created by methods, such as air abrasion (with aluminum oxide particle), creates strong bond strength. However, to date, little has been known concerning the bond strength related to chemical pretreatment methods. A recent study by Sriamporn revealed micro-morphologic changes on the surface topography of zirconia after applying 9.5% hydrofluoric acid (HF) in 25℃ for 24 hours, 9.5% HF in 80℃, and 48% HF in 25℃ and concluded that concentration and temperature of acid could affect the reaction rate.

10

Recently, Zircos E etching system (ZSAT: Zirconia Surface Architecturing Technique, M&C Dental Co., Eunjin Chemical Co., Seoul, Korea), a mixture of nitric acid and hydrofluoric acid that could be applied in room temperature, has been introduced. An increase in surface area through preconditioning could enhance interfacial adhesion and eventually increase the bond strength between the core material and the abutment.

The aim of this study was to compare the surface roughness of zirconia using Zircos E etching system, a nitric acid - hydrofluoric acid compound, in different application times and thermal conditions, and to compare the shear bond strength according to different resin cements. The null hypothesis was that Zircos E etching system has no influence on the condition of zirconia surface and hence exhibits no difference in the bond strengths of various resin cements.

Go to :

MATERIALS AND METHODS

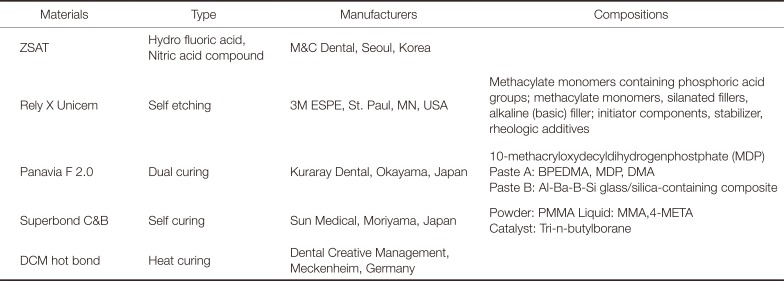

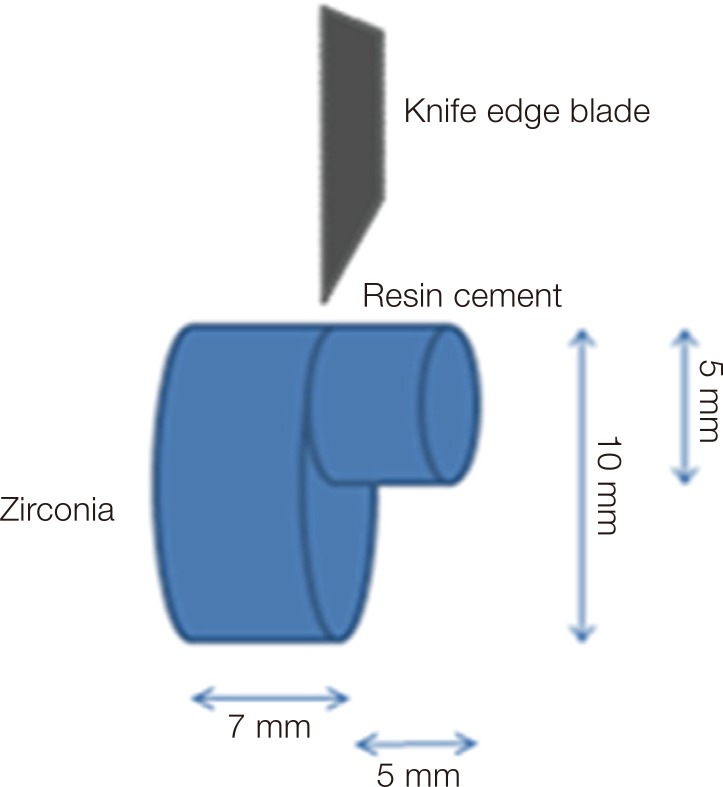

Partially sintered zirconia blocks (D max Natura Z-B2018, DMAX Co., Daegu, Korea) were prepared into 120 cylindrical specimens (10 mm in diameter and 7 mm in height) using Trios CAD/CAM milling machine (Trion Z, Dio, Busan, Korea) (

Fig. 1). Diamond cutting burs were used to polish the connecting part of the blocks. The prepared specimens were sintered in 1500℃ for 2 hours and the surfaces were cleaned in ethanol with ultrasonic application for 20 minutes to remove the lipid components and then washed with distilled water. Each 12 specimens with 4 different resin cements (Panavia F 2.0, Rely X Unicem, Superbond C&B, and Hot bond) were prepared for 3 different surface treatment groups (

Table 1).

| Fig. 1Zirconia specimen with resin cement attachment.

|

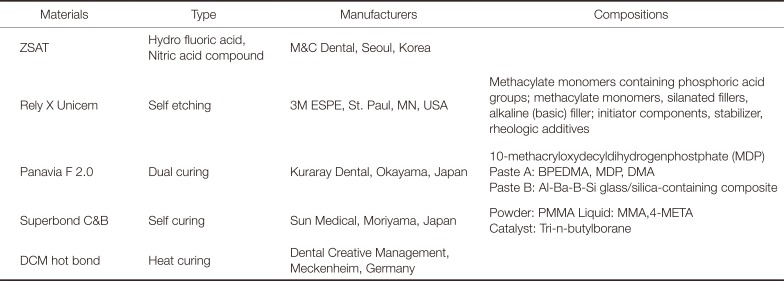

Table 1

Materials used in this study

|

Materials |

Type |

Manufacturers |

Compositions |

|

ZSAT |

Hydro fluoric acid, Nitric acid compound |

M&C Dental, Seoul, Korea |

|

|

Rely X Unicem |

Self etching |

3M ESPE, St. Paul, MN, USA |

Methacylate monomers containing phosphoric acid groups; methacylate monomers, silanated fillers, alkaline (basic) filler; initiator components, stabilizer, rheologic additives |

|

Panavia F 2.0 |

Dual curing |

Kuraray Dental, Okayama, Japan |

10-methacryloxydecyldihydrogenphostphate (MDP) |

|

Paste A: BPEDMA, MDP, DMA |

|

Paste B: Al-Ba-B-Si glass/silica-containing composite |

|

Superbond C&B |

Self curing |

Sun Medical, Moriyama, Japan |

Powder: PMMA Liquid: MMA,4-META |

|

Catalyst: Tri-n-butylborane |

|

DCM hot bond |

Heat curing |

Dental Creative Management, Meckenheim, Germany |

|

Zircos E etching system (ZSAT: Zirconia Surface Architecturing Technique, M&C Dental Co., Eunjin Chemical Co., Seoul, Korea), a nitric acid - hydrofluoric acid compound, was mixed in equal ratio, buffered, and used as a surface treatment agent for the prepared zirconia specimens to test the time required for surface conditioning and the effect of annealing. The control group used 9.5% hydrofluoric acid (Ultradent products, South Jordan, UT, USA) as a surface treatment agent in 25℃ for 3 hours. The test groups were divided into 6 groups in total, 3 groups using ZSAT for 1, 2 and 3 hours respectively, and 3 groups that used ZSAT for 1, 2 and 3 hours likewise, and followed by an annealing process. 3 specimens were used in each group. The preconditioned surfaces of the specimens were evaluated under a scanning electron microscope (SEM) (YOSHIDA, Tokyo, Japan) under ×200 and ×1000 magnification. The surface roughness was analyzed using a 3D optical analyzer (Bruker, Daltonik, Germany). Confirmation of residual substances on the specimen surfaces were evaluated under EMAX (HORIBA, Kyoto, Japan). The specimens underwent thermal annealing in 1150℃ for 1 hour, as a method to relieve residual stress and remove residual substances.

The specimens treated using air abrasion were sprayed with 50 µm KavoRONDOflex plus (Kavo, Biberach, Germany) from 10 mm distance under 3 bar pressure for 15 seconds. The specimens treated with tribochemical silicacoating/silane coupling system were sprayed with 110 µm silica coated aluminum oxide (Rocatec Plus, 3M ESPE, St. Paul, MN, USA) from 10 mm distance under 3 bar pressure for 10 seconds. In order to fabricate identical cementation surface, Aquasil putty (Dentsply, York, PA, USA) indexes were made to create cylindrical negative impressions (5 mm in diameter, 5 mm in height). Three types of resin cements were used. Two types of dual-cured resin cements Rely X Unicem U200 (3M ESPE, St. Paul, MN, USA) and Panavia F 2.0 (Kuraray dental, Okayama, Japan) and one type of self-cured resin cement; Superbond C&B (Sun medical, Moriyama, Japan), were used together with a heat-cured cement, Hot bond (Dental Creativ Management GmBH, Meckenheim, Germany). The cements were uniformly injected into the putty index. Then 5.0 kg weights were placed over the cements in order to standardize the applied vertical pressure.

Interfacial shear bond strength was measured with the universal testing machine (Instron3366, Instron Co., Seoul, Korea) at a crosshead speed of 1 mm/min as shown in

Fig. 1. The prepared zirconia specimens were placed on a metal with a hole sized 10 mm in diameter and 5 mm in height. The knife edge was placed at the adhesion point between the zirconia and the resin cement to test the maximum shear bond strength at the point at which the zirconia and the resin cement separate. The metal housing that holds the zirconia specimens were fixed on the test base clamp using 1000 N load cell. The specimens with gaps between the zirconia and the resin cement or within the cement were excluded from the study.

Comparison of failure modes between bonding surfaces were made using the universal testing machine (Instron3366, Instron Co., Seoul, Korea) to evaluate modes of fracture that include adhesive failure, cohesive failure, and adhesive-cohesive failure. The specimen surfaces were examined in a scanning electron microscopy (SEM) (YOSHIDA, Tokyo, Japan) under × 500 magnification.

Levene's test were first made to evaluate the homogeneity among the groups (P < .05). Welch's ANOVA was used to test the significance among 4 different cement groups when P values were lower than 0.05. A statistical analysis between the groups using the same cements but subjected to different surface conditioning methods was evaluated by one way ANOVA. Significance levels were adjusted with Bonferroni correction (P < .05 /n, n: comparison number) for multiple testing. The statistical analysis was performed using SAS 9.1 (SAS Institute Inc., Cary, NC, USA).

Go to :

RESULTS

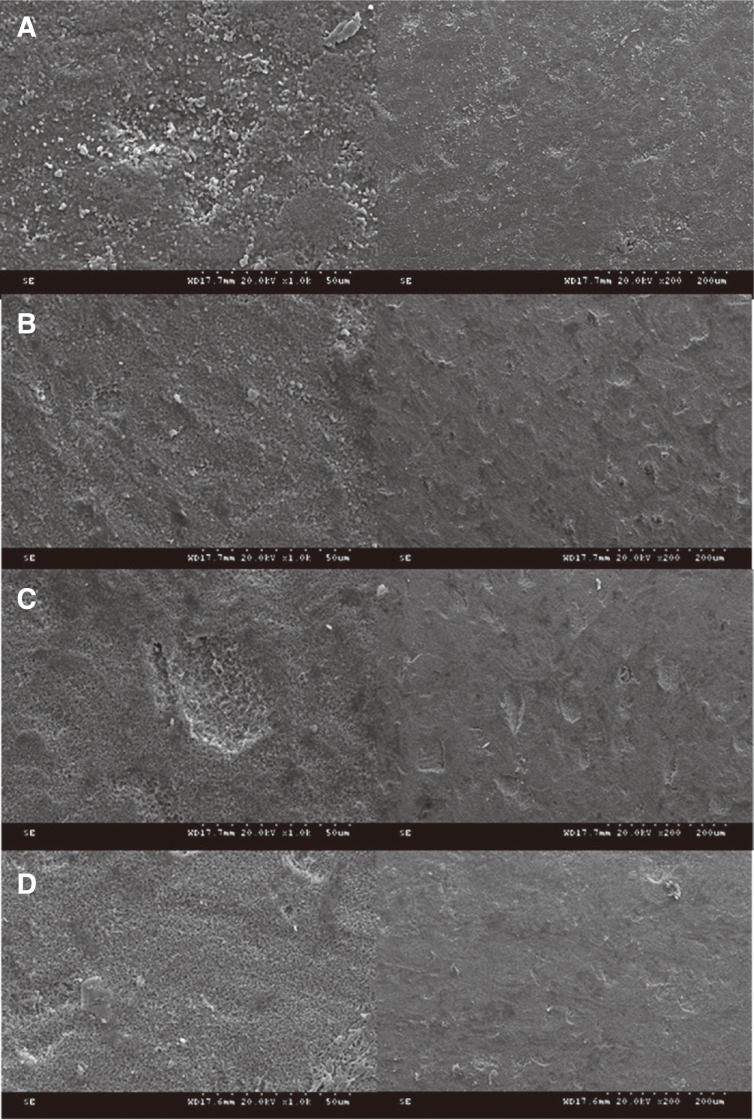

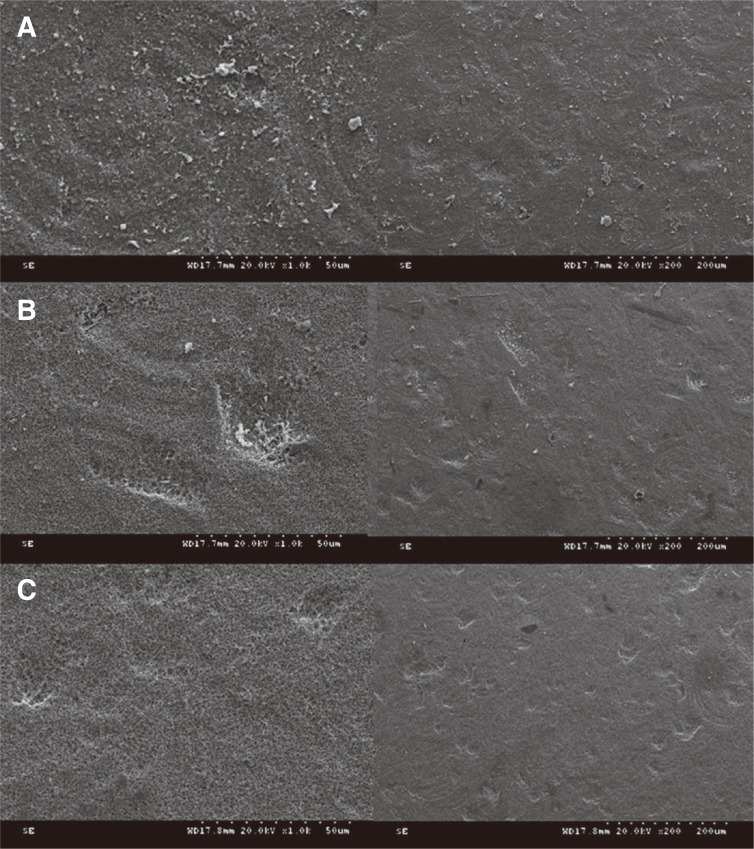

The following SEM images are specimen surfaces after conditioning with 9.5% hydrofluoric acid in 925℃ and Zircos E etching system for 1, 2, and 3 hours, respectively (

Fig. 2).

| Fig. 2(A) SEM image of zirconia surface after HF etching (×1000, ×200), (B) Zircos E 1-hour etching (×1000, ×200), (C) 2-hour etching (×1000, ×200), (D) 3-hour etching (×1000, ×200). Zirconia specimens with 2-hour application of zircos E etching system showed most rough surface.

|

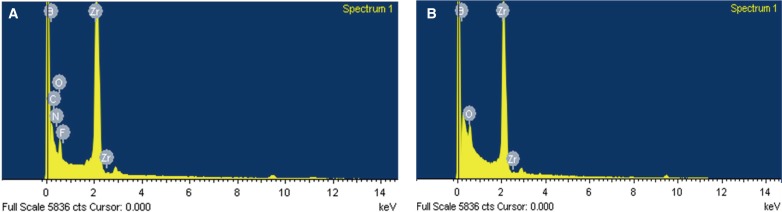

Surface roughness observed by 3D optical analyzer showed the average of 0.562, 0.683, and 0.532 when conditioned with zircos E etching system for 1, 2, and 3 hours group, respectively. With these results combined with SEM images, the test group that used Zircos E etching system for 2 hours appeared to be most effective for resin tag infiltration, and thus was used in zirconia-resin cement bond strength evaluation. Considering the clinical conditions, an annealing process was added to remove residual surface remnants and relieve remaining stress produced during sintering. EMAX (HORIBA, Tokyo, Japan) images of the surface remnants were taken after acid etching. The results are seen as follows (

Fig. 3).

| Fig. 3EMAX spectrum before annealing (A) and after annealing (B). Flourine, Nitrogen, and Carbon removed by heating process.

|

Percentage differences in elements were observed among the groups with different conditioning times. Elements such as fluorine, carbon, nitrogen, and oxygen were observed in the test groups that used distilled water as a rinsing agent after surface conditioning. Carbon, fluorine, and nitrogen were not observed in the test groups that underwent an annealing process in 1150℃. According to Kosmac et al., the annealing process is known to relieve compressive stress and reduce average flexural strength. However, in clinical usage, thermal cycling is used to eliminate surface impurities and possible factors that can reduce bond strength.

The specimens underwent thermal cycling in the furnace under 1150℃ to observe the changes of surface roughness using SEM and 3D optical analyzer before and after annealing. Surface roughnesses after annealing were 0.539, 0.638, and 0.539 in the groups that used Zircos E etching system for 1, 2, and 3 hours, respectively (

Fig. 4).

| Fig. 4SEM image of zirconia surface after annealing process. (A) 1-hour etching (×1000, ×200), (B) 2-hour etching (×1000, ×200), (C) 3-hour etching (×1000, ×200).

|

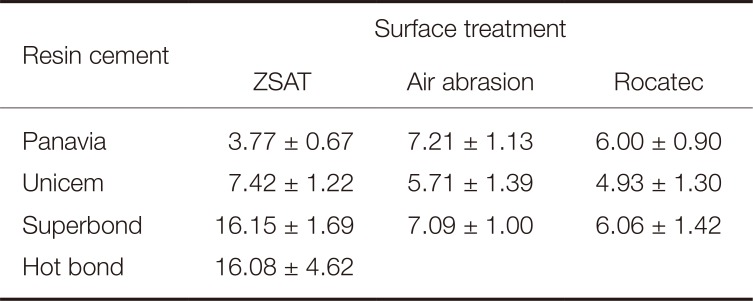

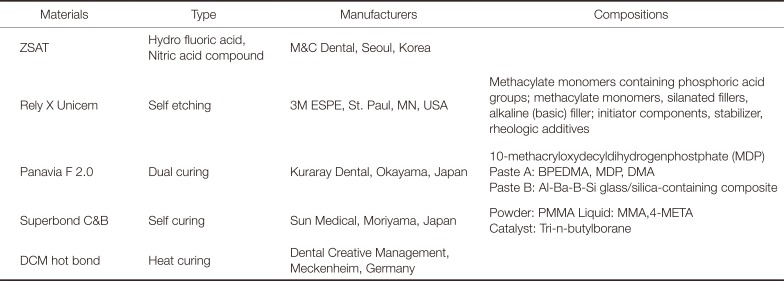

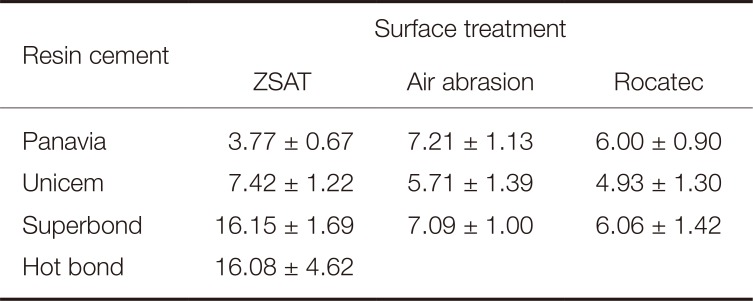

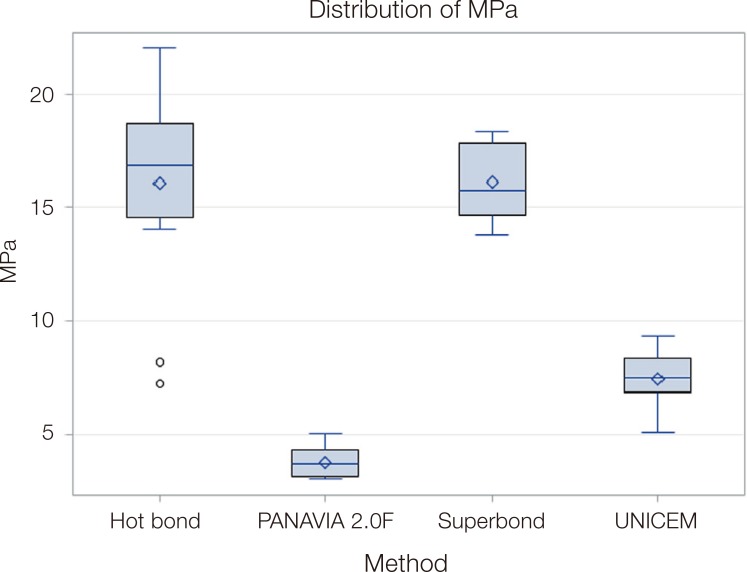

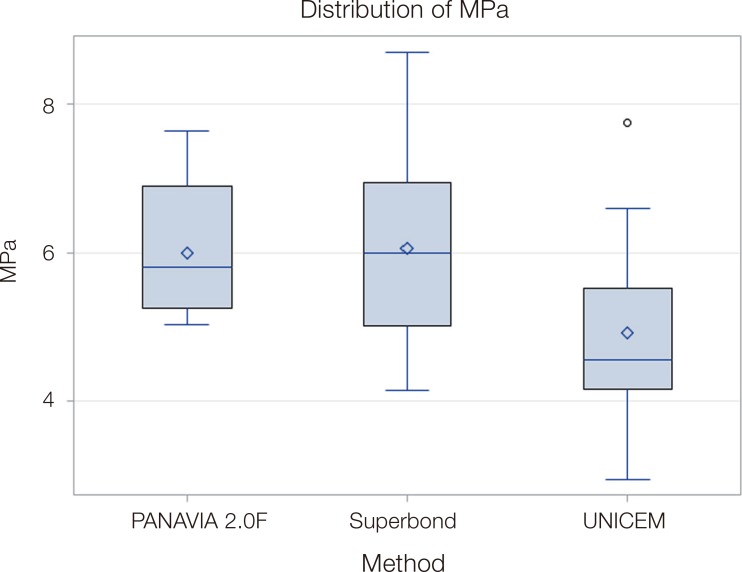

Shear bond strengths after surface conditioning were 3.77 MPa, 7.42 MPa, 16.15 MPa, and 16.08 MPa in the groups that used Panavia F 2.0, Rely X Unicem, Superbond C&B, and Hot bond, respectively (

Table 2). The highest shear bond strength was measured in Superbond C&B, followed by Hot bond, Rely X Unicem, and Panavia F 2.0 in descending order. There was no statistically significant difference between Superbond C&B and Hot bond groups (

P > .05) (

Fig. 5).

| Fig. 5Shear bond strength box plot of ZSAT group.

|

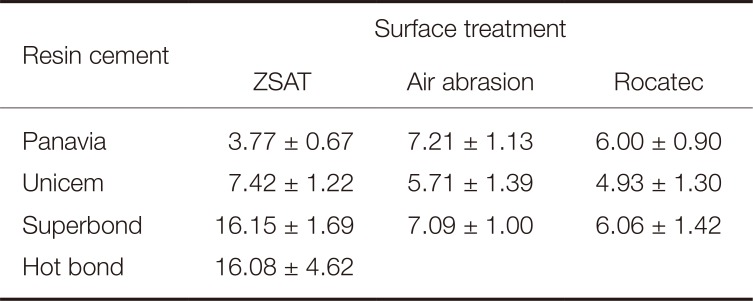

Table 2

Mean average and standard deviation for shear bond strength (in MPa)

|

Resin cement |

Surface treatment Resin cement |

|

ZSAT |

Air abrasion |

Rocatec |

|

Panavia |

3.77 ± 0.67 |

7.21 ± 1.13 |

6.00 ± 0.90 |

|

Unicem |

7.42 ± 1.22 |

5.71 ± 1.39 |

4.93 ± 1.30 |

|

Superbond |

16.15 ± 1.69 |

7.09 ± 1.00 |

6.06 ± 1.42 |

|

Hot bond |

16.08 ± 4.62 |

|

|

Shear bond strengths were evaluated after air abrasion. There was no statistically significant difference between shear bond strengths in the groups that used Superbond C&B and Panavia F 2.0 (

P > .05), but significantly lower shear bond strengths were observed in the groups that used Rely X Unicem (

P < .05) (

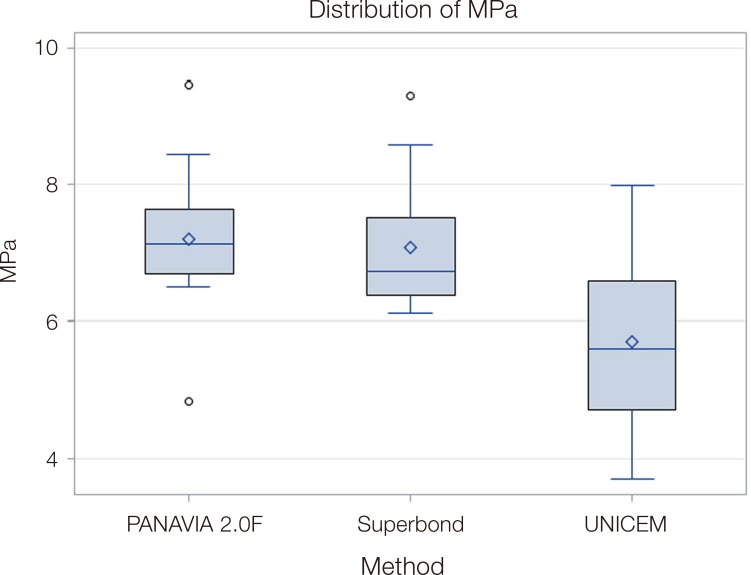

Fig. 6).

| Fig. 6Shear bond strength box plot of air abrasion group.

|

After surface treatent with tribochemical silicacoating, shear bond strengths were 6.06 MPa, 6.00 MPa, and 4.93 MPa in test groups that used Superbond C&B, Panavia F, and Rely X Unicem, respectively. However, through statistical analysis, no statistically significant differences were observed between the resin cement groups (

P > .05) (

Fig. 7).

| Fig. 7Shear bond strength box plot of tribochemical silicacoating group.

|

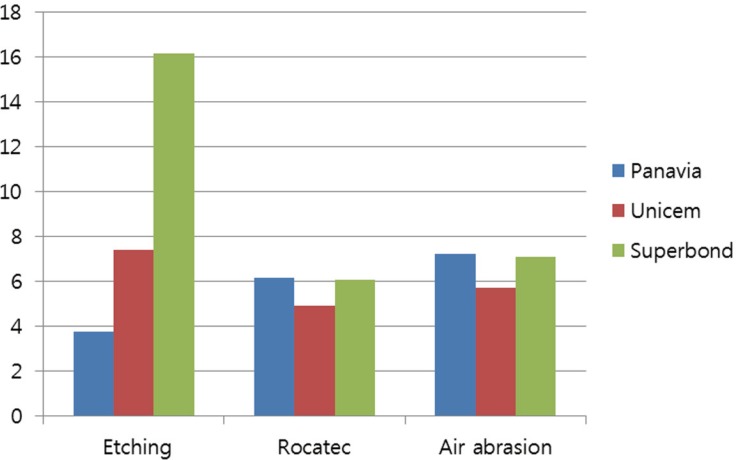

Significantly higher shear bond strengths were observed in the groups that used Rely X Unicem and Superbond after Zircos E etching system. On the other hand, in the groups that used Panavia F 2.0, air abrasion group showed the highest shear bond strength (

Fig. 8).

| Fig. 8Comparison of mean force value in MPa.

|

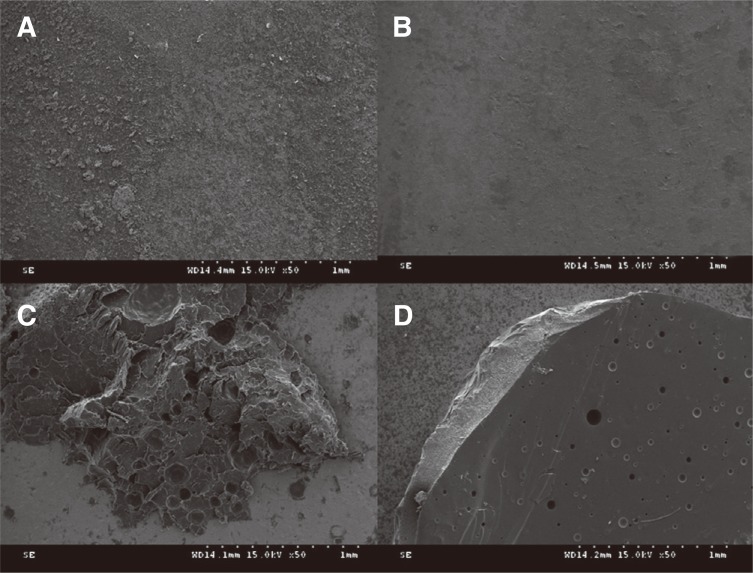

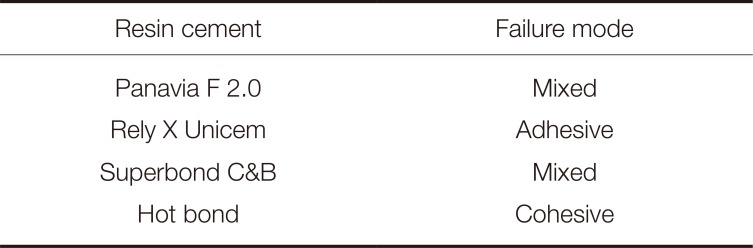

SEM images of failure modes following shear bond strength evaluation are shown as follows (

Fig. 9). In Panavia F 2.0 and Superbond groups, adhesive failure and cohesive failure behaviors were both observed. In the Rely X Unicem group, adhesive failure was predominant. In the Hot bond group, cohesive failure within the resin cement was observed (

Table 3).

| Fig. 9SEM image failure mode of zirconia surface at ×50 magnification. (A) Panavia F 2.0, (B) Unicem, (C) Superbond, (D) Hot bond.

|

Table 3

Failure mode for each group (Zircos E etching system)

|

Resin cement |

Failure mode |

|

Panavia F 2.0 |

Mixed |

|

Rely X Unicem |

Adhesive |

|

Superbond C&B |

Mixed |

|

Hot bond |

Cohesive |

Go to :

DISCUSSION

Among various clinical usage of zirconia, the CAD/CAM system is known to minimize volumetric changes of zirconia and decrease the formation of gaps that reduce the retention with the abutment tooth. According to Voidani et al., the marginal and internal gaps of zirconia crowns fabricated using CAD/CAM system have been reported to be 254.46 ± 25.1 µm, and 110.77 ± 5.92 µm, respectively. These gaps have been reported to be larger when compared to the marginal (88.08 ± 10.67 µm) and internal gaps (76.90 ± 10.17 µm) of metal crowns fabricated using the lost wax technique. Since the cementation space of the restorations made by CAD/CAM system is larger than those using conventional methods, there are higher possibilities of zirconia fracture and reduced cement retention in the marginal areas, especially when the bond strength of the cement is insufficient.

1112 Thus, there have been numerous attempts to improve the fit of zirconia with the abutment tooth. Surface treatment methods and selection of resin cements are key methods that could increase retention of the restorations with the tooth. Although chemical surface conditioning using hydrofluoric acid has been known to be inadequate for zirconia, recent studies have reported that in different concentrations and temperature, hydrofluoric acid could induce change in the zirconia surfaces.

10 Cavitations were found on zirconia surfaces in SEM images taken after surface conditioning using 9.5% hydrofluoric acid at room temperature for 1, 2, 3, and 24 hours, in 80℃ for 1, 3, 5, and 30 minutes, and using 48% hydrofluoric acid for 30 and 60 minutes. Moreover, a mix of tetragonal form and monoclinic form were observed after surface conditioning when compared to the predominant tetragonal form prior to surface conditioning.

Surface roughness (Ra) observed by 3D optical analyzer showed an average of 0.562, 0.683, and 0.532 when treated with zircos E etching system for 1, 2, and 3 hours group, respectively. Annealing process was conducted to remove residual surface remnants and relieve remaining stress during sintering. Surface roughness after annealing was lower, scoring 0.539, 0.638, and 0.539 in groups that used Zircos E etching system for 1, 2, and 3 hours, respectively However, no visible changes were observed in SEM images. Time for etching zirconia surface was much longer than glass ceramics, and zirconia with 2-hour etching had the highest surface roughness value. According Subaşi and Inan

13 average Ra scores were 0.22, 0.74, 0.35, and 0.34 in the control, air abrasion, silica-coating, and laser groups, respectively. The average Ra in the group that underwent air abrasion and laser together was 0.74.

Resin bond strength after zircos E etching system was tested through shear bond strength test and compared with the widely researched results of air abrasion, and tribochemical and silica coating. Shear bond strengths after zircos E etching system were 3.77 MPa, 7.42 MPa, and 16.15 MPa in the groups that used Panavia F 2.0, Rely X Unicem, and Superbond C&B, respectively. All resin cement groups except Panavia showed higher shear bond strengths compared to air abrasion and tribochemical silica coating system. However, Tsukakoshi et al.

14 reported air abrasion as a more effective method to increase micro-mechanical retention, and Xible et al.

15 suggested that surface conditioning with large particle Rocatec resulted in a reinforcement effect. Panavia F 2.0, which demonstrated the lowest shear bond strength after zircos E etching system, showed high bond strength after air abrasion and tribochemical silica coating. Yang et al.

16 have suggested that since Panavia F 2.0 consists of MDP, zirconia primer should be applied after surface conditioning in order to increase bond strength. Lee et al.

17 have reported that anhydride group in 4-META exhibits high bond strength in zirconia treated with tribochemical coating. Rely X Unicem, which contains phosphate monomer, has been reported to have similar bond strength as the resin cements with MDP.

1819 However, the remarkably lower bond strength of Panavia F 2.0 in zircos E etching system group shown in this study could be considered to be a consequence of the chemical bonding process. The MDP contained in Panavia F 2.0 reacts with hydroxyl group on the surface of zirconia. However, previous reports have been made that such reaction cannot be effectively retained when themocycled.

2021 It could be hypothesized that thermocycling of zirconia could have eliminated the hydroxyl group on its surface, and hence reduced the shear bond strength of Panavia F 2.0. On the other hand, the observed interfacial fracture behavior, a mixture of cohesive and adhesive failure, suggests the lower bond strength may be due to micro-mechanical irregular structures of the zirconia surface. According to Reddy et al.,

22 the bond strength increased in the group treated with zirconia primer after surface conditioning with 50 µm aluminum oxide. Conversely, as shown in a report by Kim et al.,

23 the significantly higher bond strength in Superbond C&B could be attributed to its higher micromechanical retention formed due to its excellence in flowability. Thus, it could be drawn that Superbond C&B, which contained no filler contents, had lower viscosity compared to the filler-containing Panavia F 2.0 and hence could exhibit higher shear bond strength with zirconia.

According to Karimipour-Saryazdi et al.,

9 the stress in Panavia F 2.0 and Unicem groups after surface conditioning with silica and aluminum oxide each were recorded as 3.1 ± 0.8 MPa, 3.5 ± 1.6 MPa, 3.5 ± 0.1 MPa, and 3.7 ± 0.1 MPa, respectively, suggesting application of the right cement is more crucial than surface conditioning. Likewise, Subaşi and Inan

13 have reported mixed type of failure modes in Panavia F2.0 and Rely X Unicem, suggesting these resin cements adequate for clinical usage and concluding that cement types were more important than surface conditioning methods.

This study demonstrated that zircos E etching system could induce surface changes on zirconia and increase shear bond strength with resin cements. However, further research is needed to give more detailed understanding about the effect of thermal-cycling and its clinical application.

Go to :

CONCLUSION

Results using Zircos E etching system, which is one of the surface treatment methods in zirconia, showed significant changes compared to the control group. With these results, 4 different cements were applied to test the shear bond strength. The following conclusions were drawn; after the application of the zircos E etching system on the zirconia specimen, surface roughness value after 2-hour etching was higher than those after 1-hour and 3-hour etching on SEM images. Among the zirconia specimens cemented with resin cements, Panavia F 2.0 showed the lowest value followed by Unicem, Hot bond, and Superbond C&B in an increasing order. Superbond C&B, Rely X, and Unicem applied after surface conditioning with zircos E etching system showed higher shear bond strength (P < .05). Regarding the failure mode of interface over cement and zirconia surface, Panavia F 2.0 and Superbond C&B showed mixed failure, and Rely X Unicem and Hot bond showed cohesive failures. Within the limitations of this study, Zircos E etching system in zirconia restoration could increase its shear bond strength. However, its long term success rate and clinical application should be further evaluated.

Go to :