Abstract

PURPOSE

Considering the importance of metal-ceramic bond, the present study aimed to compare the bond strength of ceramics to cobalt-chrome (Co-Cr) alloys made by casting and selective laser melting (SLM).

MATERIALS AND METHODS

In this in-vitro experimental study, two sample groups were prepared, with one group comprising of 10 Co-Cr metal frameworks fabricated by SLM method and the other of 10 Co-Cr metal frameworks fabricated by lost wax cast method with the dimensions of 0.5 × 3 × 25 mm (following ISO standard 9693). Porcelain with the thickness of 1.1 mm was applied on a 3 × 8-mm central rectangular area of each sample. Afterwards, bond strengths of the samples were assessed with a Universal Testing Machine. Statistical analysis was performed with Kolmogorov-Smirnov test and T-test.

The major challenges related to the use of porcelain-fusedto-metal (PFM) restorations include their durability and fracture resistance.1 Fracture rate of these restorations has been reported to be 2.3 - 8%.2 During the recent years, PFM restorations have been increasingly used due to their high fracture resistance and esthetics.3 One of the fundamental prerequisites of metal-ceramic systems is proper metal-ceramic bond strength that can provide suitable strength for the restoration.4 Numerous studies have evaluated the bond strength between porcelain and noble and base metal alloys and different results have been reported. Despite the availability of various tests, no reliable results have been achieved regarding the factual bond strength in metal-ceramic systems.5678 PFM bond strength depends on different factors including the fabrication process. The common fabrication method for the metal framework of PFM restorations is the lost wax technique, which is comprised of wax pattern buildup, investment, wax elimination, and casting. One of the reasons for restoration failure is the problems encountered during the firing and cooling steps in lost wax technique, which can adversely affect the porcelain bonding.910

Selective laser melting (SLM) is a novel technique for construction of metal framework. In this technique, a high-power laser beam melts the layers of metal powder based on the scanned data, with an extremely accurate microscopic structure. Therefore, it is recommended to use SLM technique to decrease the number of fabrication steps and consequently increase the bond strength of the metal framework.11 Nevertheless, SLM technique is not commonly used.

Various methods are available for measuring the bond strength between materials such as metal-porcelain. One of the most common methods is the 3-point bend test.12

SLM technique has many advantages. However, it is an innovative technique with controversial results as indicated by researches in valid journals. Therefore, comparing the bond strength of ceramic to Co-Cr alloys made by SLM and lost wax casting methods seems necessary. The present research aimed to determine the effect of SLM and lost wax techniques on the bond strength between ceramic and Co-Cr alloys of PFM restorations.

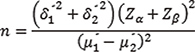

In this experimental study, sample size was determined according to similar studies and based on the following formula n1 = n2 = 10.

Rectangular molds of 0.5 mm height × 3 mm width × 25 mm length were fabricated with Duralay acrylic resin (GC, Alsip, IL, USA) and were randomly assigned to two groups: 1-Control group: Lost wax technique 2-Case group: SLM.

Co-Cr base metal alloy (star CL, Dentaurum, Germany) in SLM group and Co-Cr alloy (Wirobond, BEGO, Germany) in cast group with different compositions were used in the present study. The components of both alloys are summarized in Table 1.

In the control group, conventional lost wax technique was used. Casting wax was cut to 0.5 × 3 × 25-mm rectangular strip, which served as the jig for fabrication of the rectangular acrylic model. Ten acrylic samples were made using Duralay acrylic resin (GC, America). Afterwards, acrylic models were sprued and were invested with a phosphate-bonded investment. Then, 910℃ heat was provided and the alloy was melted at 1450℃. Centrifugal casting machine (model T.I.M500 Plus; Dentalfarm, Italy) was used to fabricate the samples.

In the SLM group, Arcam system (Molndal, Sweden) was used to fabricate the samples. First, the fabricated acrylic mold was scanned. Arcam machine was equipped with two Co-Cr powder containers and an indexing table. These containers uniformly placed 20 - 50 µm thickness of metal powders on to a substrate plate attached to the indexing table. The device also divided the scanned data to 20 - 50 µm elements. Metal powders were melted by the laser beam and formed the desired layer. The high-power laser fully melted and fused the metal powders by producing 750℃ heat in the area.

Samples of both groups were first sandblasted with 250 µm aluminum oxide particles and ultrasonically cleaned for 10 minutes before the application of porcelain. To ensure a flat surface without any concavity or convexity, all samples were visually inspected before application of porcelain and the diameter of each sample was carefully measured.

Bonding agent (GC, Alsip, IL, USA) was applied on all samples. A thin layer of opaque porcelain and a layer of body porcelain (VMK, Master, Vita, Germany) were applied on the center of a 3 × 8-mm rectangular area of the metal mold with the total thickness of 1.1 mm (in accordance with ISO standard 9693) (Fig. 1). Afterwards, dimensions of the samples were carefully assessed.

Ten molds of each group were tested inside a Universal Testing Machine (model z040, Zwick/Roell, Germany) following ISO standard 9693. The span between the two supporting columns was 20 mm and piston bending radius equaled 1mm. Samples were symmetrically placed in the Universal Testing Machine with the crosshead speed of 1.5 mm/min. The load was applied at the center of each specimen at 90 degrees angle (Fig. 2). The load of the crosshead extension curves was documented for each sample. The fracture point or the point of crack-initiation in the specimens was measured in 3-point bend test.

The Fracture patterns presented in 3-point bend test were divided to three groups as follows:13

Six samples from each group were assessed under a stereomicroscope (Nikon, z800, Melville, NY, USA) (10×) to determine the fracture mode. The strength required for the fracture at the interface between the veneer porcelain and substrate metal is called the bond strength.

Finally, the data were entered into SPSS software (version 20, IBM, San Francisco, CA, USA) and were statistically analyzed with Kolmogorov-Smirnov test and T-test.

The present study was conducted on metal-ceramic samples fabricated by lost wax and SLM methods.

The results of Kolmogorov-Smirnov test are summarized in Table 2, which shows that the bond strengths in both groups follow normal distribution. The results of T-test are summarized in Table 3, which shows that the bond strength in the control group (lost wax method) equaled 74.94 ± 16.06 MPa and that in the case group (SLM) equaled 69.02 ± 5.77 MPa, while no statistically significant differences between the groups were detected. Mixed fracture mode was observed in 5 samples from each assessed group.

One of the fundamental prerequisites of metal-ceramic systems is strong enough bonding between porcelain and metal to provide proper strength for the restoration. PFM bond strength depends on different factors including the fabrication process. The common fabrication method for the metal framework of these restorations is the lost wax technique, which is comprised of wax pattern buildup, investment, burn out, and casting. SLM is a novel technique for fabrication of metal framework. In this technique, a high-power laser beam melts the layers of metal powders according to the scanned data and builds the restoration.

Considering the importance of metal-ceramic bond strength in treatment success, the present study investigated whether the fabrication method of the metal framework (lost wax or SLM) can affect metal-ceramic bond strength in PFM restorations.

There was no significant bond strength difference between lost wax group and SLM group.

Akova et al.14 in 2008 performed a study to compare bond strength between two groups of Co-Cr alloys fabricated by casting and SLM methods. The results showed that the casting group showed higher bond strength than the SLM group, while the difference was not statistically significant. This result concurs with the results of our study. One of the advantages of the mentioned study was assessment of Ni-Cr alloy as the control group. Fracture modes were assessed by stereomicroscope similar to our study and all ten samples of the casting group showed mixed fracture mode, while five of the samples of the SLM group revealed mixed fracture and the other five presented adhesion fracture.

Xiang et al.13 in 2012 assessed the bond strength of casting and SLM Co-Cr alloys and declared that the bond strengths of these two groups were not significantly different. Samples in the mentioned study were fabricated in compliance with ISO standard 9693 and fracture modes were also assessed, which was shown to be the mixed fracture modes in both groups, similar to the findings of our study.

Moreover, Wu et al.15 in 2013 stated that bond strengths of casting and SLM Co-Cr alloys were not significantly different, which concurs with our results. The above study evaluated all the mechanical properties of these two groups, although they neglected the assessment of fracture modes.

Dental prostheses and restorations may fracture even if high quality materials have been used. These fractures result from application of a heavy load at a certain point of the restoration even if the average force applied on the entire restoration was low.16 Therefore, evaluation of fracture modes can help identify the weak points in a restoration.

In the present study, fracture modes were classified as follows:13

Five samples were selected from each group and were observed under stereomicroscope. All samples showed mixed fracture. More casting specimens showed fractures entirely within porcelain (in comparison with the SLM samples). This is the most desirable type of fracture and indicates high metal-ceramic bond strength. Similar to previous studies, the present study also showed that fracture mode was not correlated with the fracture load.13

Chemical bond and mechanical bond between the metal and porcelain are among the factors that determine the bond strength.

One of the factors that decrease the bond strength is the difference between coefficient of thermal expansion (CTE) of metal and porcelain.17 Nevertheless, in the present study, materials with similar CTE were used. (CTE of porcelain: 13.2 × 10-6 and CTE of metal: 14.1 × 10 k)

Chemical bond depends on the primary components of alloy and porcelain and consequently the oxide layer.18 Nevertheless, by selecting almost similar alloy and porcelain components in both groups, this factor cannot affect the bond strength.

The second factor that influences the bond strength is mechanical retention. Sandblasting with aluminum oxide particles is usually used to increase hardness and also to increase the contact surface between porcelain and metal. Moreover, studies have shown that increased hardness can increase the bond strength.19

In SLM technique, components have natural surface roughness after fabrication, which is completely different from that of the components fabricated by casting.20 Previous studies have shown that sandblasting of casting specimens by aluminum oxide increases surface roughness and consequently increases mechanical retention.20 In contrast, sandblasting of SLM samples decreases primary surface roughness and mechanical retention of porcelain to metal and also decreases Balling phenomenon, which can decrease the bond strength of SLM below the expected levels. 21

The bond strengths recorded in the present study significantly exceeded the minimum bond strength declared by ISO standard 9693 (25 MPa) and also the minimum bond strength documented by in-vitro studies (51 MPa). Therefore, both fabrication methods described in the present research are suitable for clinical use.

Figures and Tables

Table 1

The components of Co-Cr alloys

| Casting group's Mass (%) | SLM group's Mass (%) | Component |

|---|---|---|

| 60.2 | 60.5 | Co |

| 26 | 27 | Cr |

| 7.2 | 8 | W |

| 0.5 | 1.5 | Si |

| 4.2 | 2.1 | Mo |

Table 2

Kolmogorov-Smirnov test results of the bond strength of the two groups

References

1. Ferrari M, Giovannetti A, Carrabba M, Bonadeo G, Rengo C, Monticelli F, Vichi A. Fracture resistance of three porcelain-layered CAD/CAM zirconia frame designs. Dent Mater. 2014; 30:e163–e168.

2. Anusavice KJ. Standardizing failure, success, and survival decisions in clinical studies of ceramic and metal-ceramic fixed dental prostheses. Dent Mater. 2012; 28:102–111.

3. Gupta A, Musani S, Dugal R, Jain N, Railkar B, Mootha A. A comparison of fracture resistance of endodontically treated teeth restored with bonded partial restorations and full-coverage porcelain-fused-to-metal crowns. Int J Periodontics Restorative Dent. 2014; 34:405–411.

4. Reitemeier B, Hänsel K, Kastner C, Walter MH. Metal-ceramic failure in noble metal crowns: 7-year results of a prospective clinical trial in private practices. Int J Prosthodont. 2006; 19:397–399.

5. Atluri KR, Vallabhaneni TT, Tadi DP, Vadapalli SB, Tripuraneni SC, Averneni P. Comparative evaluation of metal-ceramic bond strengths of nickel chromium and cobalt chromium alloys on repeated castings: An in vitro study. J Int Oral Health. 2014; 6:99–103.

6. Patel KA, Mathur S, Upadhyay S. A comparative evaluation of bond strength of feldspathic porcelain to nickel-chromium alloy, when subjected to various surface treatments: An in vitro study. J Indian Prosthodont Soc. 2015; 15:53–57.

7. Lee BA, Kim OS, Vang MS, Park YJ. Effect of surface treatment on bond strength of Ti-10Ta-10Nb to low-fusing porcelain. J Prosthet Dent. 2013; 109:95–105.

8. Girish PV, Dinesh U, Bhat CS, Shetty PC. Comparison of shear bond strength of metal brackets bonded to porcelain surface using different surface conditioning methods: an in vitro study. J Contemp Dent Pract. 2012; 13:487–493.

9. Sadeq A, Cai Z, Woody RD, Miller AW. Effects of interfacial variables on ceramic adherence to cast and machined commercially pure titanium. J Prosthet Dent. 2003; 90:10–17.

10. Tholey MJ, Swain MV, Thiel N. SEM observations of porcelain Y-TZP interface. Dent Mater. 2009; 25:857–862.

11. Benetti P, Della Bona A, Kelly JR. Evaluation of thermal compatibility between core and veneer dental ceramics using shear bond strength test and contact angle measurement. Dent Mater. 2010; 26:743–750.

12. Hammad IA, Talic YF. Designs of bond strength tests for metal-ceramic complexes: review of the literature. J Prosthet Dent. 1996; 75:602–608.

13. Xiang N, Xin XZ, Chen J, Wei B. Metal-ceramic bond strength of Co-Cr alloy fabricated by selective laser melting. J Dent. 2012; 40:453–457.

14. Akova T, Ucar Y, Tukay A, Balkaya MC, Brantley WA. Comparison of the bond strength of laser-sintered and cast base metal dental alloys to porcelain. Dent Mater. 2008; 24:1400–1404.

15. Wu L, Zhu H, Gai X, Wang Y. Evaluation of the mechanical properties and porcelain bond strength of cobalt-chromium dental alloy fabricated by selective laser melting. J Prosthet Dent. 2014; 111:51–55.

16. Taufall S, Eichberger M, Schmidlin PR, Stawarczyk B. Fracture load and failure types of different veneered polyetheretherketone fixed dental prostheses. Clin Oral Investig. 2016; 03. 15.

17. Tan JP, Sederstrom D, Polansky JR, McLaren EA, White SN. The use of slow heating and slow cooling regimens to strengthen porcelain fused to zirconia. J Prosthet Dent. 2012; 107:163–169.

18. Kannari Y, Endo K, Ida Y, Ochi M, Ohno H. Analysis of fracture surface of titanium-porcelain bonding by electron spectroscopy for chemical analysis. Dent Mater J. 2014; 33:689–695.

19. Cai Z, Bunce N, Nunn ME, Okabe T. Porcelain adherence to dental cast CP titanium: effects of surface modifications. Biomaterials. 2001; 22:979–986.

20. Kajima Y, Takaichi A, Nakamoto T, Kimura T, Yogo Y, Ashida M, Doi H, Nomura N, Takahashi H, Hanawa T, Wakabayashi N. Fatigue strength of Co-Cr-Mo alloy clasps prepared by selective laser melting. J Mech Behav Biomed Mater. 2016; 59:446–458.

21. Bae EJ, Kim JH, Kim WC, Kim HY. Bond and fracture strength of metal-ceramic restorations formed by selective laser sintering. J Adv Prosthodont. 2014; 6:266–271.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download