Abstract

PURPOSE

Temperature increase of 5.5 ℃ can cause damage or necrosis of the pulp. Increasing temperature can be caused not only by mechanical factors, e.g. grinding, but also by exothermic polymerization reactions of resin materials. The aim of this study was to evaluate influences of the form material on the intrapulpal temperature during the polymerization of different self-curing resin materials for temporary restorations.

MATERIALS AND METHODS

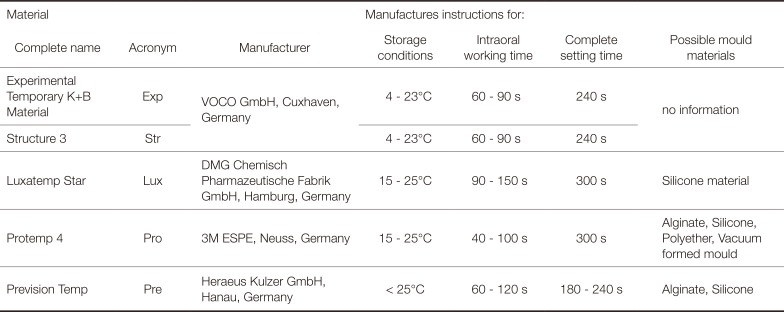

30 provisonal bridges were made of 5 resin materials: Prevision Temp (Pre), Protemp 4 (Pro), Luxatemp Star (Lux), Structure 3 (Str) and an experimental material (Exp). Moulds made of alginate (A) and of silicone (S) and vacuum formed moulds (V) were used to build 10 bridges each on a special experimental setup. The intrapulpal temperatures of three abutment teeth (a canine, a premolar, and a molar,) were measured during the polymerization every second under isothermal conditions. Comparisons of the maximum temperature (TMax) and the time until the maximum temperature (tTMax) were performed using ANOVA and Tukey Test.

RESULTS

Using alginate as the mould material resulted in a cooling effect for every resin material. Using the vacuum formed mould, TMax increased significantly compared to alginate (P<.001) and silicone (P<.001). In groups Lux, Pro, and Pre, tTMax increased when the vacuum formed moulds were used. In groups Exp and Str, there was no influence of the mould material on tTMax.

Temporary restorations (TRs) are needed during treatment with crowns and bridges. TRs restore the function and aesthetics of the prepared teeth, besides forming the marginal gingiva until the new restoration can be cemented. Furthermore, TRs protect the pulp against chemical or thermal damage, which may be their most important function. In most cases, TRs are produced intraorally after tooth preparation using self-polymerizing resin materials. Chemical polymerization of these materials is an exothermic reaction, which may increase the temperature of the pulp1 and therefore can lead to tissue or cell damage.2 As early as 1965, Zach and Cohen3 published a frequently cited in vivo study on the influence of thermal irritation on the pulp in monkeys. Pulpitis or necrosis of the pulp was found in 15% of the examined teeth after an increase in temperature of 5.5℃.3 In contrast, an in vivo study of human teeth was published by Baldissara et al.4 in 1997. They found no irritation of the pulp after a temperature increase of 8.9 - 14.7℃. In 2006, Amano et al.5 found that HSP70 protein might play a role in the recovery of pulp after thermal stress in a rat model. The combination of these findings suggests that thermal stress might cause irritation of the pulp, which can be self-cured in some situations. However, it is unclear which temperature is tolerated by the pulp and which temperature leads to irreversible damage. In their 2013 literature review, Kwon et al.6 commented that “Previous in vivo studies about the range of safe temperatures have reported varied results, indicating that the range of safe temperatures is not accurately known”. The great variation within the literature can be explained by different study designs and the large number of relevant variables.6 There seems to be a consensus that a temperature increase of less than 5.5℃ is harmless.37 It may then well be asked whether the increase of the pulp temperature can be caused by polymerization of materials for TRs. In their in vitro studies, Castelnuovo and Tjan7 and Chiodera et al.8 found that the temperature increase in dental pulp during polymerization of temporary restorations varied between 3℃ and 12℃.

Depending on the number and size of the TRs, different fabrication techniques can be used. In clinical practice, previously taken alginate or silicone over-impressions are often used as moulds for TRs, especially for single crowns or small FPDs. For larger restorations or full-arch restorations, it is very convenient for the clinician to construct TRs using lab-side prefabricated vacuum-formed moulds (V) (Fig. 1).

Several studies have described the temperature conductivity of these materials. Alginate has a cooling effect.9 Putty silicone can reduce the increase in temperature, although an increase of up to 5.5℃ was found.7 It might be desirable to precool the putty silicone form to avoid increasing the temperature, although this is time-consuming.6 There appears to be no published information on the conductivity of vacuum formed moulds. It can be assumed that they have no cooling effect and are poor insulators.

Aside from technical strategies, newly developed materials for TRs might reduce the risk of irritating or damaging the dental pulp. One possible approach might be to develop materials that reach their temperature maximum slowly. This would make it possible to remove the polymerized TR out of the patient's mouth securely before the maximum temperature has been reached. Another approach might be to change the chemical composition of the resin material to reduce the maximum temperature during polymerization. The type of the mould material might also influence the temperature.

The aim of the current study was to evaluate the influence of different mould materials on the maximal intrapulpal temperature (TMax) and the time until TMax (tTMax). Therefore two-span five-unit temporary FPDs, made from different materials for TRs, were produced in vitro and the temperature in the abutment teeth was measured. One of the tested materials was a new experimental material. To evaluate the new material, three hypotheses were postulated: 1) the new experimental material leads to a lesser increase in TMax in the pulp than do other materials; 2) tTMax of the experimental material is longer than tTMax of the other materials; 3) the mould material has a significant influence on TMax and tTMax.

A special experimental setup to measure the temperature in the pulp chamber of extracted teeth has been developed at Hannover Medical School (Fig. 2). This setup includes three extracted human teeth, a canine (C), a premolar (P), and a molar (M), which had to be extracted for periodontal reasons. The pulps of these teeth were removed via an apical access cavity and temperature sensors were placed in the cleaned pulp chambers. Depending on their positions, the sensors are designated as C (canine), P (premolar), Mo (molar oral), or Mb (molar buccal). The teeth were embedded into an acrylic block and prepared with a diamond bur to have a circumferential chamfer preparation with 0.8 mm depth. The acrylic block was placed in an acrylic chamber with a lid on the top. The chamber and the acrylic block were tempered by a heating pipe, which was connected to a temperature water bath (ministat 125, Peter Huber Kältemaschinen GmbH, Offenburg, Germany) to establish a constant temperature of 36.0 +/- 0.1℃ of the entire experimental setup (Fig. 2). A silicone impression (Silagum Putty & Silagum light, DMG, Hamburg, Germany) of the prepared teeth was taken and a plaster model was cast (SHERA maximum, SHERA Werkstoff-Technologie GmbH & Co. KG, Lemförde, Germany). A wax-up of a 5-unit FPD was modelled and transferred to metal (Phantommetall NF, Degudent GmbH, Hanau, Germany). This metal bridge was adjusted to fit into the prepared teeth. A silicone over-impression (Silagum Putty & Silagum light, DMG, Hamburg, Germany) was taken over the bridge and a resin model (Diemet, Erkodent, Pfalzgrafenweiler, Germany) was cast of the acrylic block with the adapted bridge. This model was used as a master model for production of the TR's moulds for five different resin materials (Table 1) with three different techniques. Figure 3 shows the wax-up, the metal bridge, and the acrylic resin model (Fig. 3). The TRs were produced of five different resin materials (Table 1) directly on the prepared teeth, using moulds made of alginate (A) (ALGINoplast fast, Heraeus, Hanau, Germany) or putty silicone (S) (Silagum Putty, DMG, Hamburg, Germany), or using a lab-side prefabricated vacuum formed mould (V) (Erkodur 1.5 mm, Erkodent, Pfalzgrafenweiler, Germany). All materials, composites as well as mould materials, were stored in a climate cabinet at 22.5℃ to comply with their manufacturer's instructions, which ensured that all of the materials had the same starting temperature at the beginning of the experiment. In dental practice, materials for temporary restorations are normally stored at room temperature, which is in line with the chosen temperature. The ambient room temperature in the laboratory did not exceed 23℃. The resin materials were applied following the manufacturer's instructions. The temperature inside the teeth was measured and recorded automatically by a computer every second. Before the beginning of each measurement, the temperature inside the prepared teeth had to be constant at 36.0 +/- 0.1℃ for 30 seconds, in order to ensure the same starting conditions for each experiment. During the polymerization, the temperature in the pulp champers was recorded. The measurements were stopped after 420 seconds, at a time where the polymerization of all materials was completed. For statistical evaluation, the maximum temperature “TMax” was measured and the time until the maximum temperature - “tTMax”- was identified for each specimen.

Statistical analysis using the Kolmogorov Smirnov test, Levene analysis, two-way ANOVA, and the Post-Hoc Tukey Test was performed using SPSS (IBM SPSS Statistics V23.0.0.0, IBM Corp., Armonk, NY, USA). The level of significance was set to P = .05.

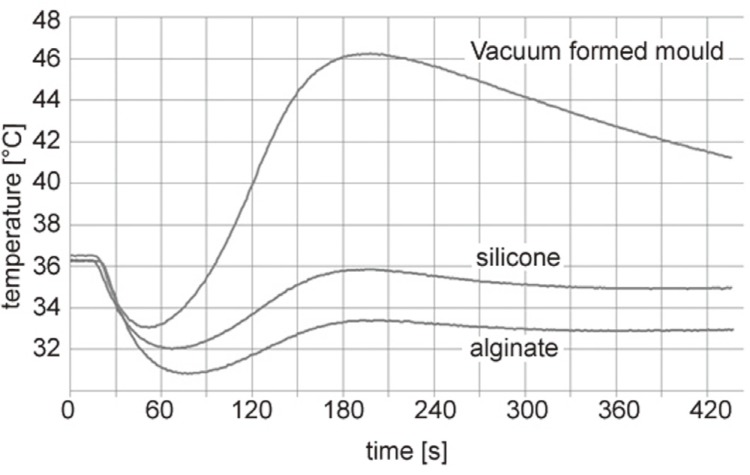

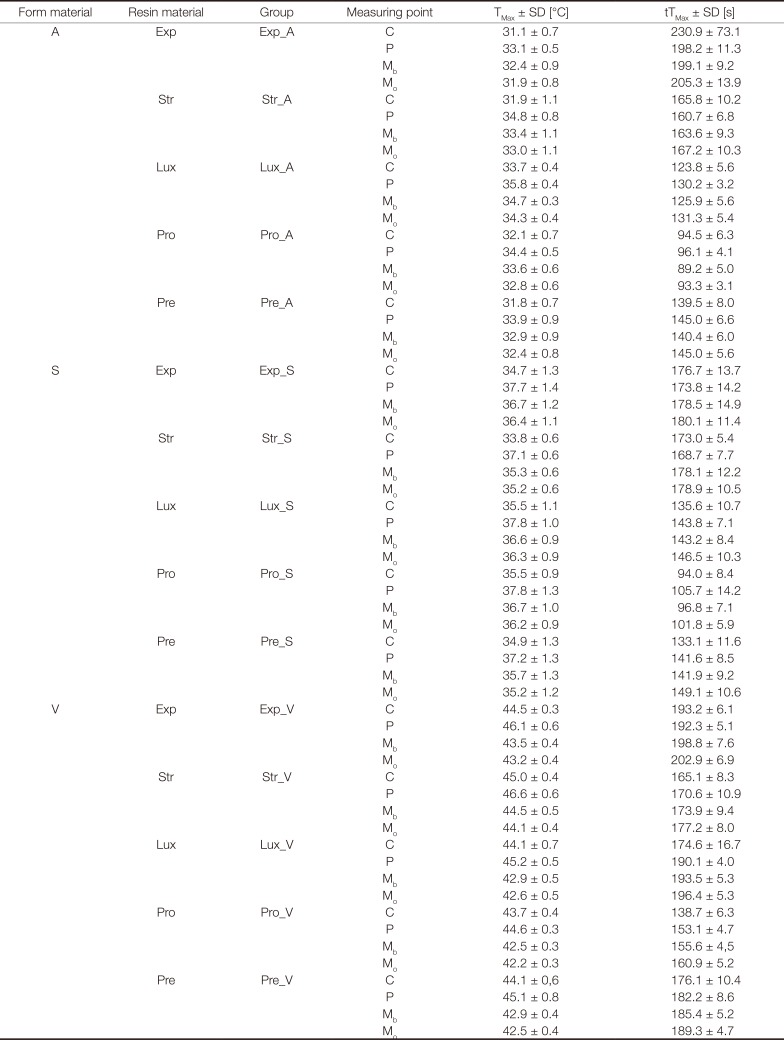

The data for TMax and tTMax are given in Table 2 for the three mould materials and the five resin materials for the four measuring points in the prepared teeth. Figure 4 shows the temperature profiles of measuring point “P” during polymerization of the experimental material with different mould materials. These profiles are typical of all the measurements performed. All curves showed a decrease in temperature, which was caused when the acrylic climate chamber was opened to place the form with the resin material onto the prepared teeth. A further decrease in the temperature in the pulp chamber was then observed, as the resin material was cooler than the temperature of the climate chamber. Because of the exothermic polymerization reaction, the temperature increased again until a maximum temperature was reached. The further progression of the curves varied and depended on the cooling effects of the mould materials: The alginate curve showed the smallest inclination and a maximum temperature below the base line temperature. The silicone curve had a higher inclination than the alginate curve and exhibited a maximum temperature nearly as great as the baseline temperature. The vacuum-formed mould curve showed the highest inclination and a maximum temperature greatly above the baseline temperature (Fig. 4).

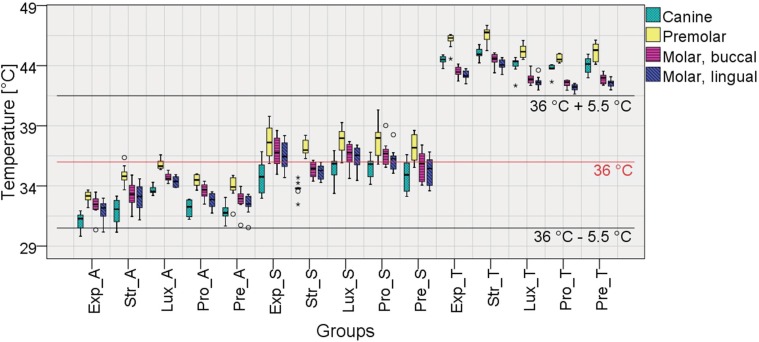

Figure 5 shows the temperature for each measuring point for each group. Three lines are highlighted in the diagram. The red line shows the baseline temperature of 36℃. The lines at 30.5℃ and 41.5℃ mark the temperature variation of ± 5.5℃ from the baseline temperature. According to Zach and Cohen, a temperature increase of 5.5℃ does not cause irreversible damage of the pulp.3 In the groups where alginate was used as the mould material, a decrease in temperature was seen. All of the mean values in these groups were between 30.5℃ and 36.0℃. The lowest mean TMax for all alginate groups was found in group Exp_A on the canine teeth (31.1 +/- 0.7℃). In the silicone groups, the mean TMax varied between 33.0℃ and 39.0℃. The highest mean TMax was found in group Lux_S at the premolar (37.8 +/- 1.0℃). In the groups where the vacuum-formed mould was used, an increase in the temperature to more than 41.5 ℃ was observed for all resin materials and all measuring points. The highest mean temperature was recorded on the premolar in group Str_V (46.6 +/- 0.6℃).

In the groups where alginate or silicone moulds were used, the lowest mean TMax were found in the canines. In the vacuum form groups, mean TMax in the molar was lower than at the other measuring points. In all groups, the highest mean TMax was found in the premolar.

Normal distribution and equality of variances were proved using the Kolmogorov-Smirnov test and Levene analysis. Multivariate factorial analysis revealed significant differences for the mould material (P < .001) and the type of the resin material (P < .001).

For further analysis, only mean TMax of position “P” was used, as the highest mean temperatures were measured in the premolar for all resin materials and all mould materials (Fig. 3).

ANOVA showed significant differences amonng the mould material groups in TMax on position P (P < .001). Single comparisons revealed that the difference in TMax between the alginate groups and the silicone groups, as well as between the alginate groups and the vacuum-formed mould groups, were statistically significant for all resin materials (P < .034). Alginate gave the lowest temperatures for every composite. Single comparisons between silicone moulds and vacuum-formed moulds were statistically significant (P < .001); the temperatures in the vacuum-formed moulds were higher. Pairwise comparisons within the groups using the same mould material found significant differences in only a few cases; within the alginate groups, the new experimental material showed significantly lower mean values for TMax than did the other materials (P < .033). Furthermore, the mean temperature in group Lux_A was significantly higher than in group Pro_A (P = .031) and in group Pre_A (P < .001). Pairwise comparisons within the silicone groups did not show any significant differences between the mean maximum polymerization temperatures (P > .879). With the vacuum-formed mould for production of the TRs, the temperature in group Str_V was significantly higher than in groups Lux_V (P = .017), Pro_V (P < .001), and Pre_V (P = .011). Furthermore, group Exp_V showed significantly higher temperatures than group Pro_V (P = .010).

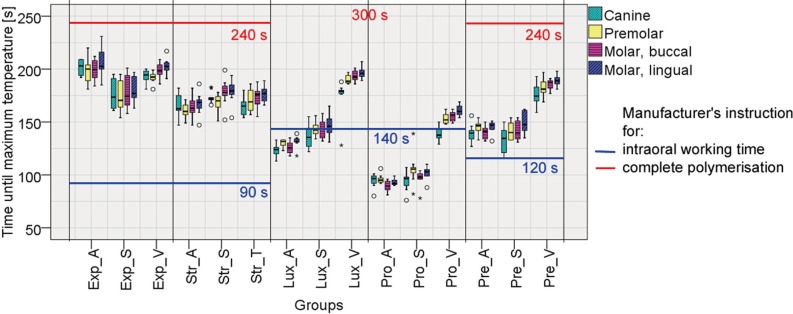

Besides TMax, the time until maximum temperature (tTMax) is an important parameter to characterize the temperature increase during polymerization and the potential risk for the pulp. This time span was identified for each TR and the mean tTMax was calculated for each group for the measuring points C, P, Mb, and Mo (Table 2). Figure 6 shows a box-plot with tTMax for each group. Beside the boxes for each material, the manufacturer's information about the intraoral working time and about the complete setting time of the materials are given (Fig. 6). All materials reached TMax after 80 – 240 seconds. The manufacturer's instructions for the experimental material and for Structure 3 recommend removing the material from the patient's mouth after 60 – 90 seconds. The material Prevision has to be removed after 120 seconds. Luxatemp and Protemp have an intraoral working time of 140 seconds. Furthermore, the temperatures at the individual specified times of removal from the patient's mouth (Table 1) were identified. In alginate or silicone groups, these temperatures did not exceed 38℃.

In the groups where vacuum formed-moulds were used, the mean temperature exceeded 41.5℃ after the recommended removal time, except for the experimental material, where the mean temperature did not exceed 38℃ during the intraoral working time.

Normal distribution and equality of the variances were proved using the Kolmogorov Smirnov test and Levene analysis. Multivariate analysis revealed a significant influence on tTMax of the mould material (P < .001) and of the resin type (P < .001). Similar to the statistical analysis of TMax, further statistics for pairwise comparisons of tTMax with the Tukey test were only calculated for the measuring point “P” in the premolar. The pairwise comparisons among the groups Exp_A, Exp_S, and Exp_V showed a significantly faster temperature increase in group Exp_S than in groups Exp_A (P < .001) and Exp_V (P < .001). There was no significant difference between groups Exp_A and Exp_V (P = .966). In the groups where Luxatemp Star, Provision 4, and Prevision Temp were used, the longest tTMax was seen when the vacuum-formed mould was used. Thereby, all of the pairwise comparisons of the groups using the same composite were statistically significantly different (P < .001). The other within-composite comparisons showed no statistically significant differences. In addition, a significant difference (P = .038) could be observed between groups Lux_A and Lux_S.

When alginate was used as the mould material, pairwise comparisons of tTMax between the experimental material and the other materials showed significantly longer tTMax in group Exp_A than in the other groups (P < .001). With silicone as the mould material, tTMax in group Str_S was significantly longer than in groups Exp_S, Lux_S, Pro_S, and Pre_S (P < .001). For the vacuum formed mould tTMax in group Exp_V, there was no significant difference from groups Lux_V (P > .999) and Pre_V (P = .345), but there were significant differences from groups Str_V (P < .001) and Pro_V (P < .001).

The risk of pulp damage or pulp irritation during dental treatment increases with increasing temperature on the tooth surface.6 This might be caused by frictional heat during tooth preparation,10 by laser treatment,1011 or by polymerization heat of direct temporary restorations.78 In the current study, the maximum temperatures in the pulp chamber during polymerization differed significantly within each group and between the measuring points C, P, and Mo/Mb. This may originate from the different chemistry of the resin materials12 and from the different thickness of the residual hard tissues after tooth preparation.12 In 2016, Piplani et al.13 compared temperature increase in the pulp chamber of human teeth during the production of temporary restorations in the direct technique with regard to the width of the finish lines after preparation. They found similar data for the different widths: 40.3℃ for a width of 1.0 mm and 40.2℃ for a width of 1.2 mm. It can be deduced that the temperature increase in the pulp is greater when the residual hard tissue is thinner. Seelbach et al.14 found that the temperature increase was critical when the temporary materials were 4 mm thick. In the current study, the highest temperature peaks could be seen on measuring point P, which is the middle tooth between the two temporary pontics.

The data of the current study showed different temperature effects during the exothermic polymerization reaction of the resin materials - depending on the mould materials. The cooling effect of alginate seen in the current study for all materials is in line with the literature.9 Besides the benefit of the cooling effect, alginate has a disadvantage that the impression cannot be stored to be reused at successive appointments because of the changes in dimensionsdepending on storage conditions and humidity.15

With silicone, storage conditions and dimensional accuracy are not a problem16 and the silicone moulds can be used for more than one TR. Castelnuovo and Tjan7 found a cooling effect of putty silicone moulds when they had been previously cooled in a fridge for 30 minutes but not when the mould was at room temperature. A temperature increase in the pulp between 3℃ and 12℃ has been reported in their study.78 This also is in line with the current study. TMax in groups Exp_S, Str_S, Lux_S, Pro_S, and Pre_S varied between 34 and 38℃.

The temperature increase in the pulp chamber during the use of vacuum-formed moulds has not been studied in the recent literature. A disadvantage is that an additional appointment is necessary to take an impression because these moulds have to be prepared in the dental laboratory. However, these moulds are very convenient for the clinician, especially for large or for full-arch restorations. In 1990, Moulding and Teplitsky17 found that the temperature increase in the pulp was greater when temporary restorations were produced using vacuum-formed matrixes than with other matrixes. This is in line with the current study. More recent information about temperature increase using vacuum formed moulds could not be identified. In the current study, TMax increased to more than 42.2℃ for all tested resin materials in combination with vacuum-formed moulds (Table 2). The highest mean temperature of 46.1℃ was detected in group Str_V on point P (Fig. 5). Interestingly, the time until TMax was significantly greater (P < .001) when vacuum-formed moulds were used with resin materials Luxatemp Star, Protemp 4, or Prevision Temp. These three resin materials all exceeded 41℃ at their individual specified time of removal from the patient's mouth, irrespective of the mould material. When the experimental material or Structure 3 was used (groups Exp_V and Str_V), there was no increase in the time (Fig. 6). Furthermore in these two groups, the temperature did not exceed 38℃ after the manufacturer's recommended removal time from the patient's mouth.

Within the limitations of this study, the following conclusions can be drawn.

In combination with the experimental resin material or with Structure 3, the use of vacuum-formed moulds for the production of temporary restorations is an established technique, as long as the intraoral working time of 90 seconds is not exceeded, as recommended in the manufacturer's instructions. Therefore, vacuum formed moulds can be recommended for clinical use. Further research might be warranted to study subsequent deformation of temporary restorations depending on polymerization time and the type of different mould materials.

The risk of pulp damage does not increase at prolonged intraoral working time if alginate or silicone is used as a mould material.

For the experimental material and for Structure 3, the use of silicone mould and vacuum-formed moulds has no influence on tTMax. If alginate is used as the mould material, tTMax for the experimental material is longer than for Structure 3.

References

1. Kim SH, Watts DC. Exotherm behavior of the polymer-based provisional crown and fixed partial denture materials. Dent Mater. 2004; 20:383–387. PMID: 15019454.

2. Barlattani A, Cardelli P, Cioccolanti F, Gallio M. Polymerization exothermal reaction of dental prosthetic resin for temporary crowns. A comparative evaluation. Minerva Stomatol. 2002; 51:11–20. PMID: 11845116.

3. Zach l, Cohen G. Pulp response to externally applied heat. Oral Surg Oral Med Oral Pathol. 1965; 19:515–530. PMID: 14263662.

4. Baldissara P, Catapano S, Scotti R. Clinical and histological evaluation of thermal injury thresholds in human teeth: a preliminary study. J Oral Rehabil. 1997; 24:791–801. PMID: 9426160.

5. Amano T, Muramatsu T, Amemiya K, Kubo K, Shimono M. Responses of rat pulp cells to heat stress in vitro. J Dent Res. 2006; 85:432–435. PMID: 16632756.

6. Kwon SJ, Park YJ, Jun SH, Ahn JS, Lee IB, Cho BH, Son HH, Seo DG. Thermal irritation of teeth during dental treatment procedures. Restor Dent Endod. 2013; 38:105–112. PMID: 24010075.

7. Castelnuovo J, Tjan AH. Temperature rise in pulpal chamber during fabrication of provisional resinous crowns. J Prosthet Dent. 1997; 78:441–446. PMID: 9399184.

8. Chiodera G, Gastaldi G, Millar BJ. Temperature change in pulp cavity in vitro during the polymerization of provisional resins. Dent Mater. 2009; 25:321–325. PMID: 18817967.

9. Lenz E, Lang V. Comparative study on the biological properties of plastics for temporary crowns and bridges. Stomatol DDR. 1990; 40:100–102. PMID: 2284649.

10. Firoozmand L, Faria R, Araujo MA, di Nicoló R, Huthala MF. Temperature rise in cavities prepared by high and low torque handpieces and Er:YAG laser. Br Dent J. 2008; 205:E1. discussion 28-9. PMID: 18535534.

11. Srimaneepong V, Palamara JE, Wilson PR. Pulpal space pressure and temperature changes from Nd:YAG laser irradiation of dentin. J Dent. 2002; 30:291–296. PMID: 12554109.

12. Bevilacqua L, Biasotto M, Cadenaro M, Di Lenarda R, Dorigo E. Reaction exothermia of 2 relining resins for temporary crowns. Minerva Stomatol. 2005; 54:35–41. PMID: 15902061.

13. Piplani A, Suresh Sajjan MC, Ramaraju AV, Tanwani T, Sushma G, Ganathipathi G, Jagdish K, Agrawal A. An in-vitro study to compare the temperature rise in the pulp chamber by direct method using three different provisional restorative materials. J Indian Prosthodont Soc. 2016; 16:36–41. PMID: 27134426.

14. Seelbach P, Finger WJ, Ferger P, Balkenhol M. Temperature rise on dentin caused by temporary crown and fixed partial denture materials: influencing factors. J Dent. 2010; 38:964–973. PMID: 20728504.

15. Kulkarni MM, Thombare RU. Dimensional changes of alginate dental impression materials-An invitro study. J Clin Diagn Res. 2015; 9:ZC98–ZC102.

16. Al-Zarea BK, Sughaireen MG. Comparative analysis of dimensional precision of different silicone impression materials. J Contemp Dent Pract. 2011; 12:208–215. PMID: 22186818.

17. Moulding MB, Teplitsky PE. Intrapulpal temperature during direct fabrication of provisional restorations. Int J Prosthodont. 1990; 3:299–304. PMID: 2083018.

Fig. 2

Experimental setup, overview (A), prepared teeth (B) and radiograph of the temperature sensors in the teeth (C).

Fig. 3

Wax-up (A), metal bridge (B) and resin model of the bridge positioned onto the measurement arrangement (C).

Fig. 4

An example of temperature profiles on measuring point “P” during one measurement each of the experimental material (Exp) in combination with alginate, silicone, and the vacuum formed mould.

Fig. 5

Boxplot of the intra-pulpal temperature at the measuring points C, P, Mb, and Mo for all groups. The baseline temperature and the temperature interval of +/- 5.5℃ are also given.

Fig. 6

Boxplot of the time until the maximum temperature during polymerization is reached. The manufacturer's instructions for intraoral working time (blue lines) and the time until complete polymerization (red lines) are also given.

Table 1

Materials for temporary restorations

Table 2

Measurements for all groups. Mean and SD are given for TMax, tTMax

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download