Abstract

PURPOSE

To evaluate the effects of hydrogen peroxide pretreatment and heat activation of silane on the shear bond strength of fiber-reinforced composite posts to resin cement.

MATERIALS AND METHODS

The specimens were prepared to evaluate the bond strength of epoxy resin-based fiber posts (D.T. Light-Post) to dual-curing resin cement (RelyX U200). The specimens were divided into four groups (n=18) according to different surface treatments: group 1, no treatment; group 2, silanization; group 3, silanization after hydrogen peroxide etching; group 4, silanization with warm drying at 80℃ after hydrogen peroxide etching. After storage of the specimens in distilled water at 37℃ for 24 hours, the shear bond strength (in MPa) between the fiber post and resin cement was measured using a universal testing machine. The fractured surface of the fiber post was examined using scanning electron microscopy. Data were analyzed using one-way ANOVA and post-hoc analysis with Tukey's HSD test (α=0.05).

RESULTS

Silanization of the fiber post (Group 2) significantly increased the bond strength in comparison with the non treated control (Group 1) (P<.05). Heat drying after silanization also significantly increased the bond strength (Group 3 and 4) (P<.05). However, no effect was determined for hydrogen peroxide etching before applying silane agent (Group 2 and 3) (P>.05).

Dental treatment with intracanal posts is widely used and considered as a standard treatment option for extensive loss of coronal tooth structure.12 Among the various intracanal post systems available, the fiber-reinforced composite (FRC) post system has gained popularity over several decades because of its definite advantages in restoring coronal structures, such as its color similar to natural tooth and its non-corrosive properties. The most important characteristic is its elastic modulus, which is similar to dentin.3 Because of the similarity in elastic modulus, excessive stress is optimally distributed, and, consequently, the risk of root fracture is significantly reduced.45

However, regarding the long-term treatment success, the tensile bond strength between the fiber posts and adhesive resin composite is critical because bonding failure frequently occurs from tensile force and the posts are dislodged from the teeth.6 Various surface treatments have been suggested as the ways to enhance the adhesion of the fiber posts to the resin cement. Airborne-particle abrasion, such as sandblasting using aluminum oxide particles, and etching using acidic solution have been employed as surface treatments in order to increase surface micro-roughness, expose the post fibers, and increase the available surface area for chemical adhesion. A silane coupling agent has also been widely studied to enhance chemical bonding between fiber posts and resin composite materials.378910111213 This is especially important for fiber posts with resin matrix made of epoxy resin, which is highly cross-linked and does not make chemical bonds with methacrylate-based resin cement. The surface pretreatments described above can increase micromechanical interactions by roughening the superficial layer and exposing a greater surface area of the post fibers, consequently allowing more efficient chemical reactions with the resin cement. Several acidic solutions for etching epoxy resin are available, such as potassium permanganate, sodium ethoxide, and hydrogen peroxide. Among these materials, hydrogen peroxide is considered an acceptable mild etchant for clinical use because it does not affect the integrity of the fiber posts.714 A reliable theory proposes that hydrogen peroxide shows an etching effect by breaking epoxy resin bond by hydrogen peroxide oxidation through a mechanism of substrate oxidation.141516

A combination protocol, which consists of micromechanical surface roughening and subsequent silane application, is commonly used in clinical practice. In particular, in order to treat epoxy resin-based fiber posts, Machado et al.8 recommended using hydrogen peroxide etching followed by silane application. Nonetheless, the studies examining the effects of hydrogen peroxide etching for adhering fiber posts to resin composites remain rare in comparison to other studies on other methods, such as sand blasting and post silanization.81718 For silane applications, related articles have reported conflicting results. Some results reported no significant differences between silanated and untreated posts.3910 On the other hand, in other studies, micro-tensile bond strength significantly improved with post silanization.41112 Heat activation of the silane coupling agent was introduced to completely evaporate the redundant solvent and therefore maximize the chemical effectiveness of the agent. However, previous studies have reported controversial results on its effect.19202122

The objective of our present study was to evaluate the effects of hydrogen peroxide etching and heat activation following silanization on the shear bond strength of FRC post to resin cement. The null hypothesis was that none of these factors would improve the bond strength.

The fiber post system tested in this study was the D.T. Light Post (size 3; BISCO Inc., Schaumburg, IN, USA), with a tapered configuration and a maximum diameter of 2.2 mm. The post is composed of quartz fibers (60%) and an epoxy resin matrix (40%). The fiber post was fixed to unsaturated polyester resin (Formica Polycoat; Aekyung Chemical Co., Seoul, Korea) in a cylindrical plastic mold (internal diameter=32 mm; length=30 mm). The long axis of the post was first made parallel to the axial wall of the mold. Polyester resin was then poured until the top of the post was completely submerged and was left for a while to be polymerized. The top surface of the resin specimen was then made flat using a model trimmer (dual-wheel model trimmer; Wehmer Co., Addison, TX, USA) in order to expose the post surface. The post surface was polished using 220- and 500-grit sand papers (each paper was used 10 times each). The post surface was cleaned using 95% ethanol and 32% phosphoric acid (Uni-etch; BISCO Inc., Schaumburg, IN, USA), thoroughly rinsed with distilled water, and dried in accordance with the manufacturer's instructions (Fig. 1A).

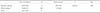

Seventy-two specimens were divided into 4 groups that received different surface treatments (n=18): Group 1 (control group), no surface pretreatment was performed before adhesion to the resin cement; Group 2, the exposed post surfaces were only conditioned using a silane coupling agent; Group 3, additional surface etching with hydrogen peroxide was done before silane application and resin cementation; Group 4, surface pretreatments were the same with Group 3, but applied silane coupling agent was heat activated with warm air drying. Concise explanation of the experimental groups is presented in Table 1.

Hydrogen peroxide was used in Group 3 and 4, and the same concentration, 24%, was applied to each group, which was prepared from 35% original solution (Samchun Pure Chemical Co., Pyeongtaek, Korea). The exposed post surfaces were etched with the solution for 10 minutes using cotton pellets. Following etching, the treated post surfaces in Group 3 and 4 were silanated using a 2-component silane coupling agent (Porcelain Liner M; Sun Medical, Moriyama, Japan). In Group 3, the applied silane agent was dried at room temperature (21℃) for 60 seconds using a gentle air stream provided by an air-syringe. In Group 4, the silanated post surfaces were dried in a preheated burnout oven (Temp Master M; Jelrus, Hicksville, NY, USA) that was maintained at a constant temperature (80℃) for 10 minutes.

Resin bonding procedures were performed for every treated post surface. Metal hexagonal nuts with an identical internal diameter (2 mm) were carefully positioned at the middle of the exposed post surfaces, which had larger diameter (2.2 mm) than that of metal nuts. Through this way, bonding area of every specimen can be controlled to be same. The internal space of the hexagonal nut was then completely filled with dual-polymerizing resin cement (RelyX U200; 3M ESPE, Seefeld, Germany) using an AccuDose syringe and needle tip (Centrix, Shelton, WA, USA). All the materials used in this study are presented in Table 2.

The filled resin was then light polymerized for 40 seconds with a polymerizing light-emitting diode (Mini L.E.D.; Satelec, Paris, France). All specimens were stored in distilled water for 24 hours at 37℃ before they were administered to the shear bond strength test (Fig. 1B). All specimens were prepared by the same investigator for the purpose of standardization.

Each specimen was firmly mounted on a universal testing machine (Instron 3366; Instron Corp., Norwood, MA, USA) with a metal jig and was loaded at a cross-head speed of 1.0 mm/minute (Fig. 2). When the metal hexagonal nut fell off from the specimen, the force applied at that time was measured. The maximum shear bond strength (in MPa) was calculated by dividing the force (in N) by the bonding surface area (in mm2).

After the shear bond strength test, a single specimen was randomly selected from each group for an analysis using a scanning electron microscope (SEM)(Hitachi S-3000N; Hitachi Science Systems, Tokyo, Japan). The fractured surface was coated with platinum and observed under 500× and 1500× magnification.

Statistical analysis was performed using SPSS version 17.0 (SPSS Inc., Chicago, IL, USA). The Levene's test for equality of variances was used to assess the homogeneity of variances. One-way ANOVA and post-hoc comparisons using the Tukey HSD test were also used. The significance level for all statistical tests was set at P ≤ .05.

The mean and standard deviation of the shear bond strength for each group are presented in Table 3. The Levene's test showed that the variances were homogenous (P > .05). The one-way ANOVA test indicated that the differences between groups were significant (F = 29.443; P ≤ .05) (Table 4). Post-hoc comparisons using the Turkey HSD test indicated that the mean value of the control group (Group 1) was significantly different from those of the other groups, implying that every surface treatment method used in this study had an effect on the shear bond strength (P ≤ .05). Moreover, the mean value of Group 3 was significantly different from that of Group 4 (P ≤ .05). However, the mean of Group 2 was not significantly different from those of Group 3 or 4 (P > .05) (Fig. 3).

SEM analysis revealed the presence of residual resin cement attached to the fractured post surface in Group 4. In contrast, the fractured surface of Group 1 specimen was relatively clean, thereby exposing clear circular fiber structures. Specific representations of the SEM analysis are provided in Fig. 4.

According to the results of this study, both silane application and subsequent heat activation of the silane agent effectively increased the shear bond strength between epoxy resin-based fiber posts and resin cement, whereas hydrogen peroxide etching did not significantly increase bonding strength. Thus, the null hypothesis tested in this study could be rejected.

Silane coupling agent as a primer for pretreatment is widely used in dentistry for various purposes, such as repairing ceramic prosthesis, luting all-ceramic crowns, adhering ceramic brackets to tooth surfaces, and bonding fiber posts to endodontically treated teeth. Many authors have studied the effects of silanization on the bonding between fiber posts and resin adhesives, reporting significant improvements in bond strength.41219 On the other hand, Choi et al.3 expected silanization to play only a minor role in increasing bond strength, and similar results were also found by several other investigators.911 In our study, the positive effects of the silane coupling agent on shear bond strength between the fiber post and resin cement were identified by comparing the results of Group 1 (the untreated control group) and Group 2 (the silane-treated group without any additional surface pretreatment), and the difference between the two groups was statistically significant (P < 0.05). This finding is consistent with the previous studies reporting silane agent as an effective factor for fiber post bonding to resin cement. The mean values different from those in the studies by Choi et al.3 and Kim et al.19 are probably due to the different adhesive bonding systems and resin cements used. The other two studies used a dual-polymerizing resin cement (Variolink II; Vivadent AG, Schaan, Liechtenstein) and reported slightly higher bond strengths for the silanated groups than that of this study. When comparing the values of the control groups, considerable difference was observed.

The highest bond strength was recorded in the heat-treated group after hydrogen peroxide etching and silane application. When comparing Group 4 with Group 3, the differences between groups were statistically significant, indicating that heat activation of the silane coupling agent could be used to enhance the bond strength of the resin cement to the fiber post. Based on the SEM analysis performed on the fractured surfaces of the Group 4 specimen, most of the surface area was covered with residual resin cement without exposing the fiber structures, indicating that the bond strength between the fiber post and resin cement was strong enough to prevent adhesive failure at the bonding interface.

It is noteworthy that in the glass industry, heat activation is commonly applied to silanated glass to increase the bond potential.23 By applying heat to the silane agent, the solvent of the agent sufficiently evaporates, increasing the chemical responsiveness of the silane coupling agent.24 For dental applications, several previous studies have already used the heat activation technique and evaluated its effectiveness on the bonding of fiber posts to resin composites. For example, Monticelli et al.21 concluded that drying at a high temperature (38℃) may facilitate the evaporation of solvents in silane agents, eventually improving the bonding strength of the dual-cure composite resin to the fiber post (the study used D.T. Light Post). Papacchini et al.22 also reported similar results concluding that drying using warm air (38℃) can benefit the coupling capacity of the silane agent. These previous results are concordant with our current findings.

Although results similar to our present findings were reported by previous studies, there is a significant difference between these studies and our current analyses in terms of the drying temperatures. Most of the previously mentioned studies reported that the silanated post surfaces were dried at or around 38℃; on the other hand, heat treatment in our study was performed at 80℃. All the previous studies, including the study of Kim et al.19 arguing against the effect of post-silanization heat treatment on bond strength, used a blow dryer on warm air stream mode to heat-activate the silane agent around 38℃. However, this kind of method for heat activation is quite technique-sensitive and the desired temperature cannot be easily controlled and maintained during the process, thereby resulting in a non-homogeneous environment for specimen preparation within the same study and between different studies. Moreover, it was not specified how the drying temperature was controlled in the previous reports. In those studies, the temperature that was actually applied might have been elevated from the originally planned temperature, especially considering the fact that 80℃, although it is a much higher temperature, can be easily achieved by blowing warm air using an ordinary hair dryer for just 1 minute at a distance of 10 cm.

One other study, however, described a specific method for controlling the temperature with a blow dryer and a thermometer and a Type T (copper-constantan) thermocouple. In that study, were a much higher drying temperature (60℃) was applied, but there was no increase in the bond strength between the fiber post and composite core.20

In a our pilot study, several silanated post surfaces were dried in a preheated burnout oven at 40℃, but a noticeable improvement in bond strength was not found. The instructions for the silane product used in our study recommended heating the surface with a warm-air dryer after applying the silane agent in order to enhance the bond strength and specifically suggested a temperature and duration of 80-120℃ and 2-3 minutes, respectively. Accordingly, the temperature of heat activation was decided at a slightly higher temperature (80℃), and a preheated burnout furnace was used as a simple but reliable way to maintain a constant temperature. As previously described, high-temperature silane heat treatments (80℃) can be easily achieved using a conventional hair dryer even at chair-side. However, Monticelli et al.21 mentioned in their study that high temperatures (70-80℃) are not feasible in clinical settings. Thus, in clinical practice, a conventional hair dryer may be advantageous over a burnour furnace to simply dry a silanated fiber post. With a hair dryer, satisfactory results could be accomplished.

The D.T. Light-Post, which was used in this study, is composed of quartz fiber (60%) and epoxy resin matrix (40%). The epoxy resin does not have functional monomers that react with the methacrylate-based resin cement, thereby reducing the bond strength between the resin composite and the fiber post.19 Therefore, the outer layer of the fiber post should be removed, and the exposed inner quartz fiber can enhance adhesion between the fiber post and resin cement from the increased bonding area for the silane coupling agent. For this, various surface treatments have been suggested, such as sand-blasting and etching procedures. Among these techniques, hydrogen peroxide etching is considered as a clinically simple and effective way to dissolve the superficial epoxy layer, while maintaining the integrity of the post fibers.1314 Machado et al. described hydrogen peroxide etching followed by silane application as the most promising protocol among many other combinations of surface treatments. In this regard, several studies have reported the enhanced bond strength of resin materials to hydrogen-peroxide-etched fiber posts.141718

All of the specimens in Group 3 and 4 were pretreated with 24% hydrogen peroxide for 10 minutes prior to silanization, as described in the study of Monticelli et al.14 However, it was found that hydrogen peroxide etching before topical silane application did not effectively enhance bond strength, and an even lower bond strength was found in Group 3. This finding conflicts with those of the previous studies.141718 It can be hypothesized that the presence of oxygen residuals on the roughened post surface after the application of oxidizing agents might have interfered with the chemical reactions between the fiber post and adhesive resin. Use of an antioxidant agent, such as rosmarinic acid, hesperidin, or sodium ascorbate, can invalidate the negative effects of oxygen residuals through scavenging mechanisms. Khoroushi et al.25 evaluated the effects of antioxidant agents on hydrogen-peroxide-etched fiber posts. When cemented using a self-adhesive resin cement rather than conventional resin cement, fiber posts treated with hydrogen peroxide and subsequently with antioxidant agent demonstrated significantly enhanced bond strength.

The coupling capacity of the silane agent was verified again in this investigation. However, bond strength through silanization can be effectively increased only when inner post fibers were sufficiently exposed from epoxy resin matrix. In this context, hydrogen peroxide can be a optimal etchant. However, unfortunately specific effect of the agent was not proved in this study. Further studies are needed to address the issues on hydrogen peroxide applications through the identification of proper scavenging agents or development of new etching protocols that thoroughly sweep away the remnant of hydrogen peroxide.

Figures and Tables

| Fig. 1The schematic drawings of specimens. (A) the specimen before bonding procedure, (B) the specimen after surface treatment and bonding procedure. |

| Fig. 2Shear bond strength test using a universal testing machine. (A) Frontal view, (B) lateral view. |

| Fig. 3Box plot of shear bond strength for each group. Significant differences between mean values were denoted by *(P < .05). |

| Fig. 4The surface topography of the fractured surface using SEM. (A, B) SEM images from group 1 (magnification of ×500 and ×1500, respectively), (C, D) SEM images from group 2, (E, F) SEM images from group 3, (G, H) SEM images from group 4. |

Table 1

Classification of groups depending on surface treatments

| Group | Surface treatment | N |

|---|---|---|

| 1 | No treatment (Control) | 18 |

| 2 | Silane | 18 |

| 3 | H2O2 + Silane | 18 |

| 4 | H2O2 + Silane + Heat (80℃) | 18 |

Table 2

Materials used in this study

Table 3

The mean and standard deviation of shear bond strength

References

1. Morgano SM. Restoration of pulpless teeth: application of traditional principles in present and future contexts. J Prosthet Dent. 1996; 75:375–380.

2. Ayad MF, Bahannan SA, Rosenstiel SF. Influence of irrigant, dowel type, and root-reinforcing material on fracture resistance of thin-walled endodontically treated teeth. J Prosthodont. 2011; 20:180–189.

3. Choi Y, Pae A, Park EJ, Wright RF. The effect of surface treatment of fiber-reinforced posts on adhesion of a resin-based luting agent. J Prosthet Dent. 2010; 103:362–368.

4. Aksornmuang J, Foxton RM, Nakajima M, Tagami J. Microtensile bond strength of a dual-cure resin core material to glass and quartz fibre posts. J Dent. 2004; 32:443–450.

5. Aksornmuang J, Nakajima M, Foxton RM, Panyayong W, Tagami J. Regional bond strengths and failure analysis of fiber posts bonded to root canal dentin. Oper Dent. 2008; 33:636–643.

6. Ferrari M, Cagidiaco MC, Goracci C, Vichi A, Mason PN, Radovic I, Tay F. Long-term retrospective study of the clinical performance of fiber posts. Am J Dent. 2007; 20:287–291.

7. Monticelli F, Osorio R, Sadek FT, Radovic I, Toledano M, Ferrari M. Surface treatments for improving bond strength to prefabricated fiber posts: a literature review. Oper Dent. 2008; 33:346–355.

8. Machado AC, Vilela ALR, Souza PG, Pereira AG, Raposo LHA, Faria-e-Silva AL, de Sousa MENEZES M, Soares PV. Critical analysis of fiber post surface treatment: A review. Biosci J. 2014; 30:914–924.

9. Bitter K, Noetzel J, Neumann K, Kielbassa AM. Effect of silanization on bond strengths of fiber posts to various resin cements. Quintessence Int. 2007; 38:121–128.

10. Mosharraf R, Baghaei Yazdi N. Comparative evaluation of effects of different surface treatment methods on bond strength between fiber post and composite core. J Adv Prosthodont. 2012; 4:103–108.

11. Perdigão J, Gomes G, Lee IK. The effect of silane on the bond strengths of fiber posts. Dent Mater. 2006; 22:752–758.

12. Goracci C, Raffaelli O, Monticelli F, Balleri B, Bertelli E, Ferrari M. The adhesion between prefabricated FRC posts and composite resin cores: microtensile bond strength with and without post-silanization. Dent Mater. 2005; 21:437–444.

13. Goracci C, Ferrari M. Current perspectives on post systems: a literature review. Aust Dent J. 2011; 56:77–83.

14. Monticelli F, Toledano M, Tay FR, Sadek FT, Goracci C, Ferrari M. A simple etching technique for improving the retention of fiber posts to resin composites. J Endod. 2006; 32:44–47.

15. Brorson SH, Hansen AR, Nielsen HZ, Woxen IK. A comparative study of the immunogold labeling on H2O2-treated and heated epoxy sections. Micron. 2001; 32:147–151.

16. Pfeiffer SW. Use of hydrogen peroxide to accelerate staining of ultrathin Spurr sections. Stain Technol. 1982; 57:137–142.

17. de Sousa Menezes M, Queiroz EC, Soares PV, Faria-e-Silva AL, Soares CJ, Martins LR. Fiber post etching with hydrogen peroxide: effect of concentration and application time. J Endod. 2011; 37:398–402.

18. Yenisey M, Kulunk S. Effects of chemical surface treatments of quartz and glass fiber posts on the retention of a composite resin. J Prosthet Dent. 2008; 99:38–45.

19. Kim HD, Lee JH, Ahn KM, Kim HS, Cha HS. Effect of silane activation on shear bond strength of fiber-reinforced composite post to resin cement. J Adv Prosthodont. 2013; 5:104–109.

20. Novais VR, Simamotos Júnior PC, Rontani RM, Correr-Sobrinho L, Soares CJ. Bond strength between fiber posts and composite resin core: influence of temperature on silane coupling agents. Braz Dent J. 2012; 23:8–14.

21. Monticelli F, Toledano M, Osorio R, Ferrari M. Effect of temperature on the silane coupling agents when bonding core resin to quartz fiber posts. Dent Mater. 2006; 22:1024–1028.

22. Papacchini F, Monticelli F, Hasa I, Radovic I, Fabianelli A, Polimeni A, Ferrari M. Effect of air-drying temperature on the effectiveness of silane primers and coupling blends in the repair of a microhybrid resin composite. J Adhes Dent. 2007; 9:391–397.

23. Barghi N, Berry T, Chung K. Effects of timing and heat treatment of silanated porcelain on the bond strength. J Oral Rehabil. 2000; 27:407–412.

24. de la Fuente JL, Madruga EL. Solvent effects on the free-radical copolymerization of butyl acrylate with methyl methacrylate. Macromol Chem Phys. 1999; 200:1639–1643.

25. Khoroushi M, Mazaheri H, Tarighi P, Samimi P, Khalighinejad N. Effect of antioxidants on push-out bond strength of hydrogen peroxide treated glass fiber posts bonded with two types of resin cement. Restor Dent Endod. 2014; 39:303–309.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download