This article has been

cited by other articles in ScienceCentral.

Abstract

PURPOSE

Pre-surface treatments of coping materials have been recommended to enhance the bonding to the veneering ceramic. Little is known on the effect on shear bond strength, particularly with new coping material. The aim of this study was to investigate the shear bond strength of veneering ceramic to three coping materials: i) metal alloy (MA), ii) zirconia oxide (ZO), and iii) lithium disilicate (LD) after various pre-surface treatments.

MATERIALS AND METHODS

Thirty-two (n = 32) discs were prepared for each coping material. Four pre-surface treatments were prepared for each sub-group (n = 8); a) no treatment or control (C), b) sandblast (SB), c) acid etch (AE), and d) sandblast and acid etch (SBAE). Veneering ceramics were applied to all discs. Shear bond strength was measured with a universal testing machine. Data were analyzed with two-way ANOVA and Tukey's multiple comparisons tests.

RESULTS

Mean shear bond strengths were obtained for MA (19.00 ± 6.39 MPa), ZO (24.45 ± 5.14 MPa) and LD (13.62 ± 5.12 MPa). There were statistically significant differences in types of coping material and various pre-surface treatments (P<.05). There was a significant correlation between coping materials and pre-surface treatment to the shear bond strength (P<.05).

CONCLUSION

Shear bond strength of veneering ceramic to zirconia oxide was higher than metal alloy and lithium disilicate. The highest shear bond strengths were obtained in sandblast and acid etch treatment for zirconia oxide and lithium disilicate groups, and in acid etch treatment for metal alloy group.

Go to :

Keywords: Shear bond strength, Pre-surface treatment, Metal alloy, Zirconia, Lithium disilicate

INTRODUCTION

For more than 40 years, metal ceramic restorations (MCRs) have been widely used in the fabrication of fixed partial dentures (FPDs) and still represent the gold standard nowadays.

1 The success of these MCRs depends on the effective bonding between the veneering ceramic and metal substructure, which is believed to develop from chemical bond of the metal oxides.

2 However, although the conventional MCRs have demonstrated superior fracture resistance, metal-free restorations have gained importance and their development has been accelerated by increasing interest in aesthetic dentistry.

3

The introduction of zirconium dioxide as a framework structure or coping for ceramic restorations has initiated lengthy discussions on the design and limitations of these restorations. Furthermore, the bonding mechanism between zirconia framework and veneering ceramic is not yet well understood since no documented evidence of the bonding mechanism between these materials is available.

4 However, a few studies have looked into methods to increase the surface roughness of the zirconia.

56 As the surface roughness increases, the bonding between zirconia coping and veneering ceramic increases, thus leading to success of the restorations.

Various surface treatments (e.g. sandblasting, acid etching, glazing, heat treatment, and application of liner onto coping materials) have been recommended to enhance the bonding efficiency between veneering ceramic and coping material. However, none of these treatments have been determined to produce the highest bond strength. Airborne-particle abrasion or sandblasting, an important treatment procedure for achieving strong adhesion of veneering ceramics, works by increasing surface roughness and providing undercuts.

7 For ceramic surface treatment, acid reacts with the glassy matrix that contains silica and forms hexafluorosilicates.

8 As a result, the surface of the ceramic becomes rough, which is advantageous for micromechanical retention on the ceramic surface. Combination of surface treatments, such as sandblasting with alumina oxide-particle and acid etching may substantially increase the surface area for micromechanical retention.

9 This will subsequently increase the bond strength.

Therefore, the purpose of this study is to investigate shear bond strength (SBS) of veneering ceramic to different types of coping material (metal alloy, zirconia oxide, and lithium disilicate) after various pre-surface treatments such as sandblast and acid etch. The null hypothesis is that the shear bond strength of these veneering ceramic will not be different after various pre-surface treatments.

Go to :

MATERIALS AND METHODS

Ninety-six disc specimens measured 14 × 4 ± 0.2 mm were prepared from three different type of coping materials (n = 32): i) metal alloy (MA), ii) zirconia oxide (ZO), and iii) lithium disilicate (LD). Specimens for MA and LD groups were fabricated using lost-wax technique. Pre-cast wax patterns were prepared using silicone mold (Metrosil, Metrodent, Huddersfield, England) and were invested with investment materials. The waxes were eliminated in a burnout furnace (Bifatherm, Bifa Ltd., Ramat-gan, Israel) pre-heated to 850℃ with alumina plunger for 90 minutes. For MA group, the mold was filled with molten Ni-Cr alloy (4all, Ivoclar Vivadent AG, Schaan, Liechtenstein) using a casting machine (Fornax, Bego GmbH, Bremen, Germany). For LD group, IPS e.max® Press (Ivoclar Vivadent AG, Liechtenstein) ingots were softened at 920℃ and were automatically pressed into the mold in a furnace (EP 600, Ivoclar-Vivadent, Liechtenstein). After pressing and cooling to room temperature, the investments were divested from the specimens with polishing glass beads. Finally, the specimens were cleaned in an ultrasonic bath with distilled water for 15 minutes and air-dried for 10 seconds.

For ZO group, the specimens were machined out of a block of pre-sintered zirconia (Cercon, DeguDent GmbH, Hanau-Wolfgang, Germany). The specimens were milled using Cercon Brain Expert (DeguDent GmbH, Germany) machine in an enlarged proportion according to the data installed from manufacturer's software. The milled specimens were then sintered in the Cercon Heat Plus furnace (DeguDent GmbH, Germany) at 1,350℃ for six hours, producing final specimens sized 14 × 4 mm.

The specimens from each coping material group were randomly divided into 4 subgroups with 8 specimens in each subgroup (n = 8). Four pre-surface treatments were prepared for each subgroup; a) no treatment or control (C), b) sandblasted (SB), c) acid etched (AE), and d) combination of sandblasted and acid etched (SBAE). The specimens in subgroup C were grounded with diamond disc with no further treatment applied to the surface. The specimens in subgroup SB were treated with 50 µm alumina (Al2O3) particles at 0.2 MPa for 10 seconds and at the 10 mm distance from the nozzle to the specimen. The specimens in subgroup AE were etched with 5% hydrofluoric acid (HF) (IPS Ceramic Etching Gel, Ivoclar Vivadent AG, Liechtenstein) for 20 seconds. The specimens in subgroup SBAE were sandblasted with 50 µm alumina (Al2O3) particles at 0.2 MPa for 10 seconds and at the 10 mm distance from the nozzle to the specimen. The specimens then etched with 5% hydrofluoric acid for 20 seconds.

All specimens were cleaned in an ultrasonic bath containing acetone, alcohol, and distilled water for 10 minutes. Two thin layers of opaque veneering ceramic in paste-liquid form were applied to the prepared surfaces of the specimens from group MA (IPS Inline, Ivoclar Vivadent AG, Liechtenstein) and ZO (Ceram Kiss, DeguDent GmbH, Germany). The specimens were fired in the furnace (Programart P500, Ivoclar Vivadent AG, Liechtenstein) according to the recommendations of the manufacturers. A silicone mold (Duplicone, Shofu Inc., Kyoto, Japan) was fabricated with a slit measured 4 × 4 mm for the placement of veneering ceramic. The silicone mold was placed on top of the specimen disc. Veneering ceramic for specimens MA (IPS Inline, Ivoclar Vivadent AG, Liechtenstein), ZO (Ceram Kiss, DeguDent GmbH, Germany) and LD (IPS emax Ceram, Ivoclar Vivadent AG, Liechtenstein) in the study were manipulated as recommended by the manufacturer. Liquid was added to veneering ceramic powder until paste consistency was obtained and condensed in the mold. After condensation was completed and excess moisture was removed with absorbent paper, the silicone was carefully removed.

The specimens were fired in the furnace for the first dentin firing. After the first firing cycle, another layer of dentin ceramic was applied and excess water was removed using absorbent paper. The specimens were fired for the second time to compensate for the shrinkage generated during the first cycle. At the end of these firing cycles, the veneering ceramic surface was ground flat and parallel to the coping surface using Diagen Turbo Grinder (Bredent GmbH, Senden, Germany).

A universal testing machine (UTM) (Autograph AG-X, Shimadzu, Kyoto, Japan) was used for the SBS test at a crosshead speed 0.5 mm/min. A shear load was applied until failure occurred and failures fractures were determined from the chart recorder. The data were compiled and analyzed using the Statistical Package for Social Science (SPSS) software version 20.0 (IBM Inc., Armonk, NY, USA). Statistical analyses using two-way ANOVA and Tukey's multiple comparisons tests were used. The significance level was set at P < .05.

Go to :

RESULTS

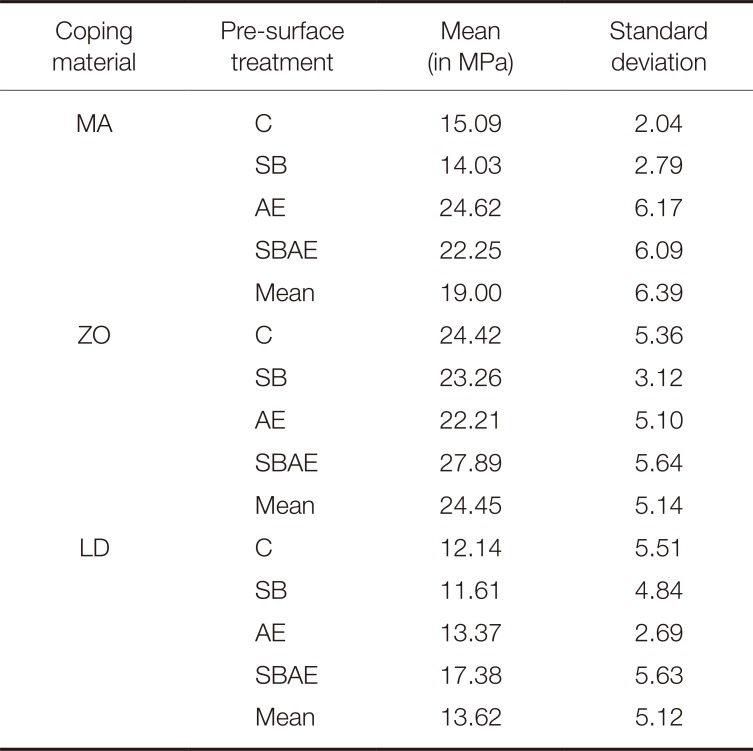

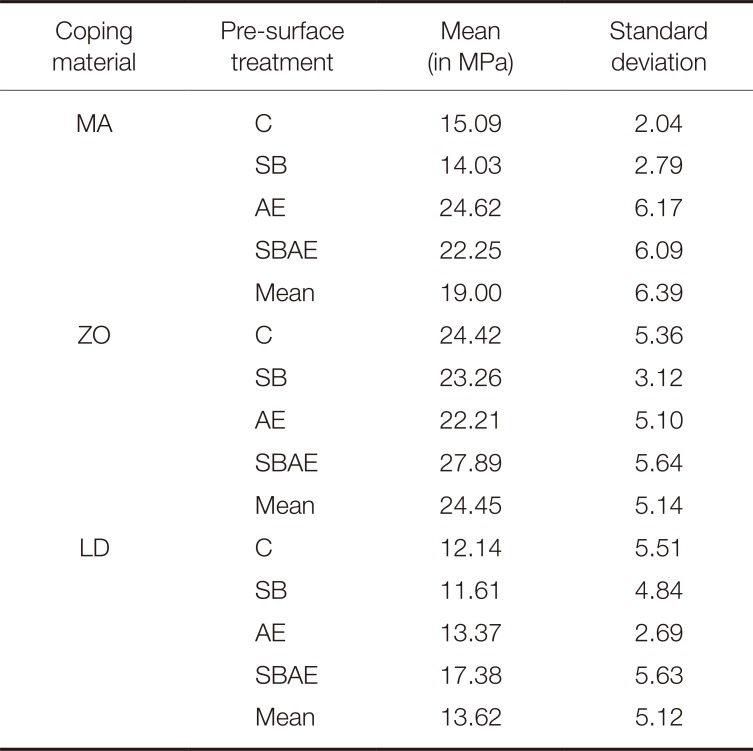

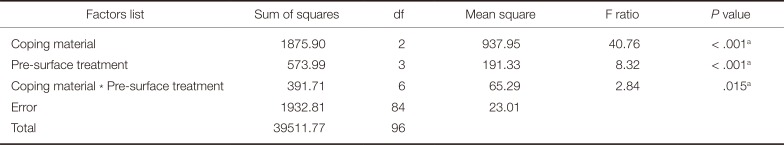

The mean SBS values for all groups of coping materials ranged from 11.61 ± 4.84 MPa to 27.89 ± 5.64 MPa (

Table 1). Shapiro-Wilk normality test showed that the data had a normal distribution (

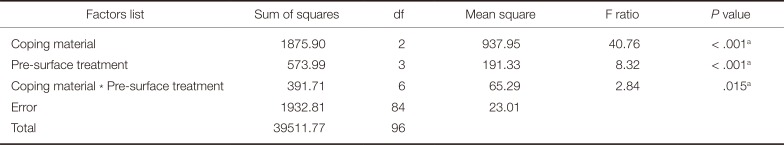

P > .05). Two-way ANOVA revealed that there were statistically significant interactions for the types of coping material groups, pre-surface treatment groups, and among the groups (

P < .05) (

Table 2).

Table 1

Mean shear bond strength values for all coping material groups

|

Coping material |

Pre-surface treatment |

Mean (in MPa) |

Standard deviation |

|

MA |

C |

15.09 |

2.04 |

|

SB |

14.03 |

2.79 |

|

AE |

24.62 |

6.17 |

|

SBAE |

22.25 |

6.09 |

|

Mean |

19.00 |

6.39 |

|

ZO |

C |

24.42 |

5.36 |

|

SB |

23.26 |

3.12 |

|

AE |

22.21 |

5.10 |

|

SBAE |

27.89 |

5.64 |

|

Mean |

24.45 |

5.14 |

|

LD |

C |

12.14 |

5.51 |

|

SB |

11.61 |

4.84 |

|

AE |

13.37 |

2.69 |

|

SBAE |

17.38 |

5.63 |

|

Mean |

13.62 |

5.12 |

Table 2

Two-way ANOVA statistical results

|

Factors list |

Sum of squares |

df |

Mean square |

F ratio |

P value |

|

Coping material |

1875.90 |

2 |

937.95 |

40.76 |

< .001a

|

|

Pre-surface treatment |

573.99 |

3 |

191.33 |

8.32 |

< .001a

|

|

Coping material * Pre-surface treatment |

391.71 |

6 |

65.29 |

2.84 |

.015a

|

|

Error |

1932.81 |

84 |

23.01 |

|

|

|

Total |

39511.77 |

96 |

|

|

|

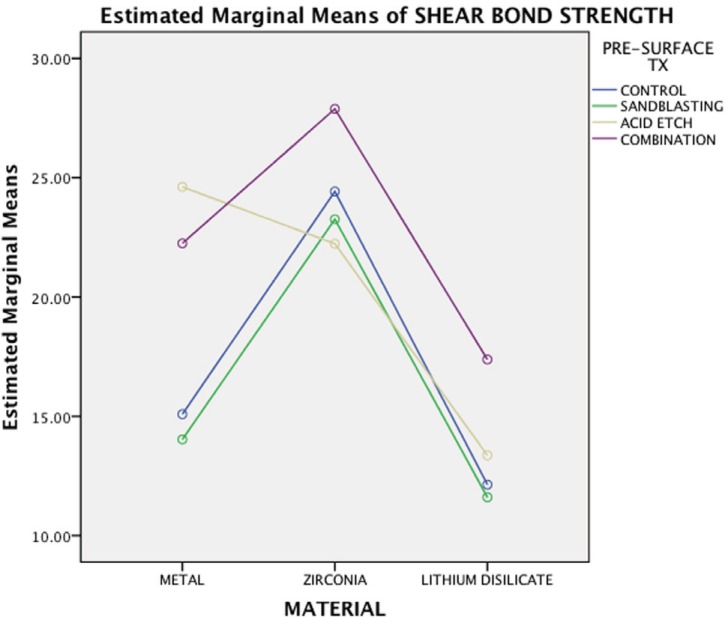

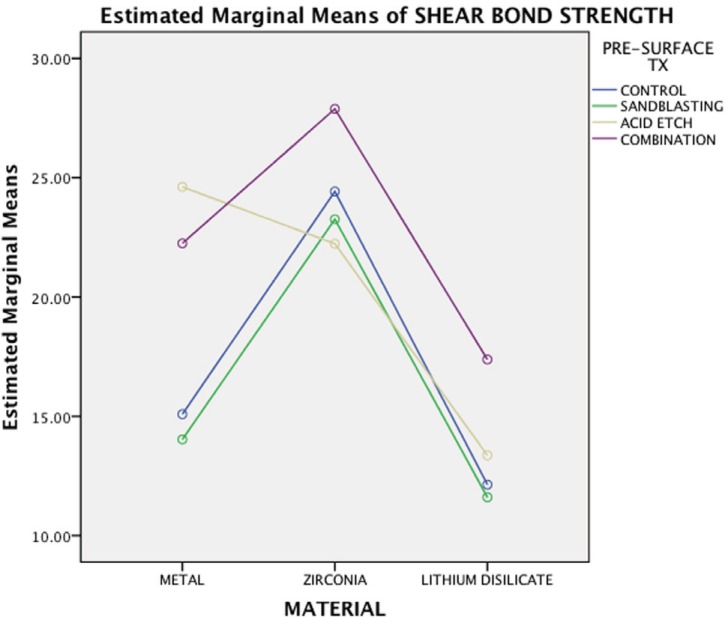

Furthermore, there was a statistically significant interaction between the effect of coping materials and pre-surface treatments on shear bond strength, as shown by non-parallel lines within the graph (

P < .05) (

Fig. 1).

| Fig. 1The effects of pre-surface treatments and coping material on shear bond strength of veneering ceramic.

|

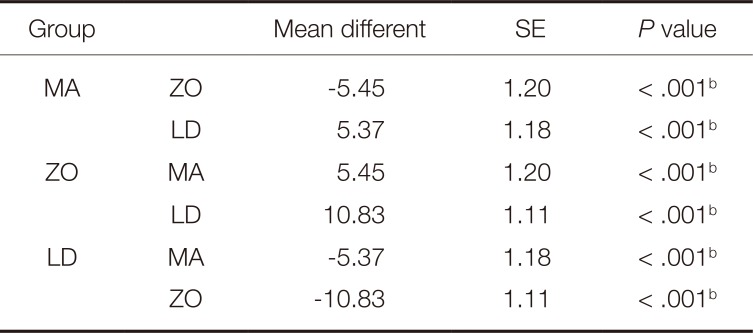

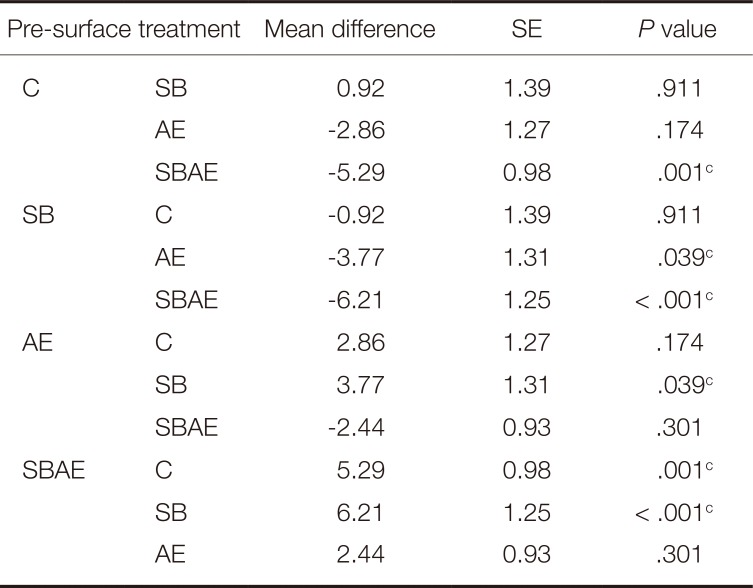

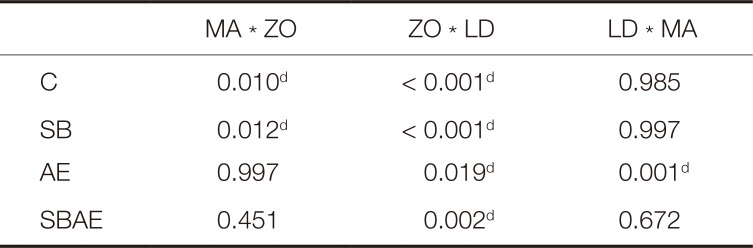

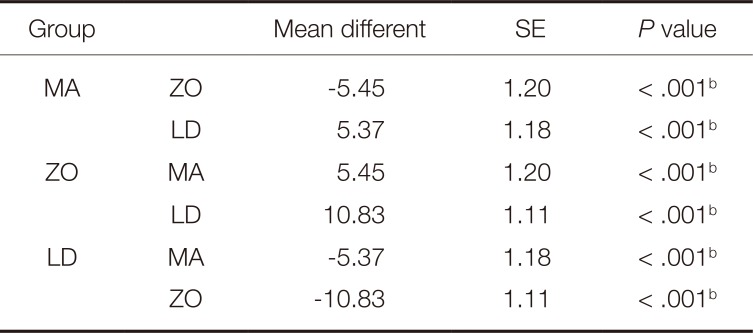

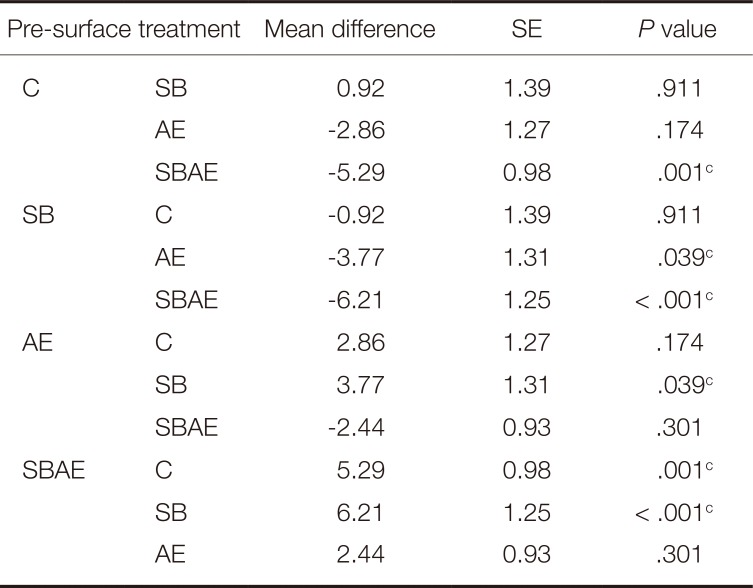

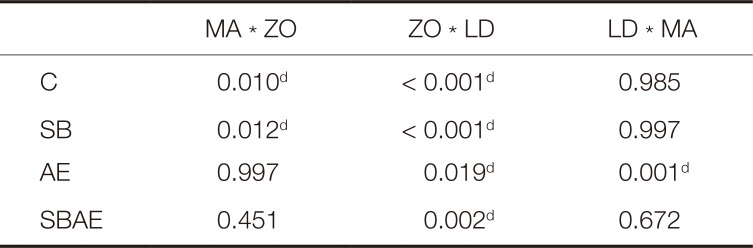

Tukey's multiple comparisons showed a statistically significant difference in SBS of veneering ceramic within the coping material groups and the pre-surface treatment groups as shown in

Table 3 and

Table 4 (

P < .05). Among various types of coping materials tested, group ZO produced significantly higher SBS than group MA, while group MA produced significantly higher SBS than group LD. On the other hand, the specimens treated with SBAE showed significantly higher SBS than the specimens treated with SB alone or with no treatment. The specimens treated with AE were also showed significantly higher shear bond strength than the specimens treated with SB. For relationship between coping material and pre-surface treatment, Tukey's comparisons test showed a statistical significant interaction between the groups with

P < .05 (

Table 5). In group MA, the specimens treated with AE showed significantly higher shear bond strength than other pre-surface treatments, while, in group ZO and LD, the specimens treated with SBAE showed significantly higher shear bond strength than other pre-surface treatments.

Table 3

Tukey's multiple comparisons test for shear bond strength of veneering ceramic for three different coping materials

|

Group |

Mean different |

SE |

P value |

|

MA |

ZO |

−5.45 |

1.20 |

< .001b

|

|

LD |

5.37 |

1.18 |

< .001b

|

|

ZO |

MA |

5.45 |

1.20 |

< .001b

|

|

LD |

10.83 |

1.11 |

< .001b

|

|

LD |

MA |

−5.37 |

1.18 |

< .001b

|

|

ZO |

−10.83 |

1.11 |

< .001b

|

Table 4

Tukey's multiple comparisons test for shear bond strength of veneering ceramic to various pre-surface treatments

|

Pre-surface treatment |

Mean different |

SE |

P value |

|

C |

SB |

0.92 |

1.39 |

.911 |

|

AE |

−2.86 |

1.27 |

.174 |

|

SBAE |

−5.29 |

0.98 |

.001c

|

|

SB |

C |

−0.92 |

1.39 |

.911 |

|

AE |

−3.77 |

1.31 |

.039c

|

|

SBAE |

−6.21 |

1.25 |

< .001c

|

|

AE |

C |

2.86 |

1.27 |

.174 |

|

SB |

3.77 |

1.31 |

.039c

|

|

SBAE |

−2.44 |

0.93 |

.301 |

|

SBAE |

C |

5.29 |

0.98 |

.001c

|

|

SB |

6.21 |

1.25 |

< .001c

|

|

AE |

2.44 |

0.93 |

.301 |

Table 5

Tukey's multiple comparisons test for shear bond strength of veneering ceramic to various coping materials with same pre-surface treatments

|

MA * ZO |

ZO * LD |

LD * MA |

|

C |

0.010d

|

< 0.001d

|

0.985 |

|

SB |

0.012d

|

< 0.001d

|

0.997 |

|

AE |

0.997 |

0.019d

|

0.001d

|

|

SBAE |

0.451 |

0.002d

|

0.672 |

Go to :

DISCUSSION

International Standard of Organization (ISO) has standardized the bond strength measurement of metal ceramic system through the Schiwickerath crack initiation test; the mean debonding strength should be greater than 25 MPa. However, due to the brittleness of all-ceramic coping materials, this test cannot be applied to all-ceramic multilayered system.

10 To date, there is no standardized test or minimum bond strength requirement for all-ceramic system.

11 According to some authors, SBS values of 10 MPa is the minimum value for clinical flaw to happen between metal and ceramic.

1213 Therefore, SBS values more than 10 MPa indicate excellent bonding clinically. Assuming that shear stresses are generally responsible for the clinical failure of the coping-ceramic interface, SBS test was adopted in this present study. In addition, this test required simple preparation of specimens and the testing could be performed easily. Important aspects should be considered, including storage condition, type of substrate, specimen preparations, rate of load application, cross-sectional surface area, and experience of the researcher.

11

In the present study, when the ceramic was veneered to MA, SBS values ranged from 14 to 24 MPa with mean value of 19.00 ± 6.39 MPa. This finding was lower than SBS of base metal group recorded by Al-Dohan et al..

11 The specimen's size could be accounted for the differences. They used smaller diameter of veneering ceramic, which could have given higher bond strength value as the formula was calculated by dividing the maximum applied force by the bonded cross-sectional area. In other studies, SBS between nickel-chromium or cobalt-chromium metal alloy were reported higher than the SBS finding in the present study.

141516 However, it is difficult to compare the results of the present study with those obtained in other studies because different methods were used to evaluate the SBS. Furthermore, some authors suggested that the failure of the bonded interface occurred when a crack propagated from a flaw of a considerable size found in an area subjected to high tensile stresses.

10

The SBS values reported for ZO group in this study ranged from 22 to 27 MPa with mean value of 24.45 ± 5.14 MPa. This finding was slightly lower than the SBS values obtained from other similar studies.

1718 The other studies used the circular interface test, which was different from the SBS test in the present study. Guess et al.

19 found the mean SBSs of veneering ceramic to Zr to be ranged from 9.4 to 12.5 MPa, which were lower than the values in the present study. The different findings were attributed to different testing method, particularly related to the size and form of the specimens tested.

The mean SBS value for LD group was 13.62 ± 5.12 MPa, which the lowest SBS value obtained among all coping materials. The present study is in agreement with study done by Umer et al.

20 The finding of the current study showed that application of veneering ceramic onto the coping material lowered the strength of the bilayer specimens. However, several authors have reported that the mean SBS value for LD group was higher than zirconia and base metal groups in their studies, which contradicted the current finding.

1121

There are several methods used for surface grinding, which include grinding using an abrasive paper or wheels (SiC or Al

2O

3), particle air-abrasion using Al

2O

3 or other abrasive particles ranging in size from 50 to 250 µm, and grinding using a diamond bur.

22 The highest mean SBS value for sandblasting treatment was obtained from group ZO, followed by MA and LD groups. This finding is in agreement with other studies.

2324 The other studies reported that SBS value for sandblasting group was higher than the other groups and concluded that SBS of veneering ceramic on zirconia treated with sandblasting was significantly higher than that subjected to other pre-surface treatments.

Contrary to the current finding above, some researches have shown that surface grinding techniques have no significant effect on increasing the bond strength of zirconia to veneering ceramic.

25 Another possible problem with sandblasting is that it can create surface microcracks that can initiates bigger crack. These cracks later can decrease strength and cause fracture toughness of the material.

26

Since acid etching was first suggested as a ceramic presurface treatment for resin bonding, many different etching periods have been advocated and used. The most profound ceramic surface roughness and the highest bond strength data at the ceramic–resin interface have been obtained by 2-minute acid etching, as reported by Chen and Suh in 1998.

27

The present study found that the mean of SBS value for acid etching treatment was highest in MA group, followed by ZO and LD group. The application of HF acid to metal was capable of roughening the surfaces, therefore increasing mechanical retention. The HF acid can also cause diminishing of oxide layer to the degree that would not affect the bonding.

28 The statement might explain why the SBS value of MA group was still the highest after acid etching treatment was done. On the contrary, Smielak and Klimek found that etching zirconia copings with 5% HF showed no significant difference to the surface roughness, as the nature of the material was not glass-like.

5

The present study found that the mean of SBS value for the combined treatment of sandblasting and acid etching produced the highest SBS value in MA and LD group compared with other pre-surface treatment. Sandblasting with 50 µm alumina particles changed the surface by increasing the number of pits per unit area.

Application of HF acid following acid etch was able to remove the glass matrix and the second crystalline phase, thus creating irregularities within the LD crystals.

29

Go to :

CONCLUSION

Zirconia had the highest shear bond strength value, while lithium disilicate had the lowest shear bond strength value among the coping materials tested. Combination of sandblasting and acid etching produced the highest SBS value in zirconia and lithium disilicate. Meanwhile, metal alloy etched with acid had the highest SBS value.

Go to :

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download