Abstract

PURPOSE

This study inspects the effect of incorporating halloysite nanotubes (HNTs) into polymethyl methacrylate (PMMA) resin on its flexural strength, hardness, and Young's modulus.

MATERIALS AND METHODS

Four groups of acrylic resin powder were prepared. One group without HNTs was used as a control group and the other three groups contained 0.3, 0.6 and 0.9 wt% HNTs. For each one, flexural strength, Young's modulus and hardness values were measured. One-way ANOVA and Tukey's test were used for comparison (P<.05).

RESULTS

At lower concentration (0.3 wt%) of HNT, there was a significant increase of hardness values but no significant increase in both flexural strength and Young's modulus values of PMMA resin. In contrast, at higher concentration (0.6 and 0.9 wt%), there was a significant decrease in hardness values but no significant decrease in flexural strength and Young's modulus values compared to those of the control group.

Polymethyl methacrylate (PMMA) is considered to be the most commonly used material in the field of prosthodontics. It has achieved great success when used for denture base because it is simple in manufacturing, economical, and light in weight. However, one of the drawbacks of PMMA acrylic resin denture base is the low strength, including low impact strength and low fatigue strength.12

Many trials have been done to improve the strength of acrylic denture bases with the use of metal wires and cast metal plates.34 The main drawback with adding metal wire is weak bond between the wire and resin, which leads to insignificant change of mechanical properties. Although metal plates are expected to increase the strength, they are expensive and liable to corrosion.34

Other trials have been also done to strengthen acrylic resin materials with either chemical modification with grafted co-polymers and stronger cross linkage or by introducing various organic and inorganic reinforcing fibers into them. Metal, Kevlar, glass, sapphire, polyester, carbon graphite, and rigid polyethylene are substances used for fiber strengthening.1456

Although the inclusion of the fibers produced encouraging results, this method has various problems including tissue irritation, increased production time, difficulties in handling, the need for precise orientation and placement, and bonding of the fibers within the resin.7 In the case of metal inserts, failure due to stress concentration around the embedded inserts has been reported.8 The incorporation of ceramic particles in various dental materials has been studied and found to be biocompatible and improving mechanical properties.910111213 In addition, due to itswhite color, ceramic powder is not expected to compromise aesthetic appearances. 1415 However, reinforcement methods should not have undesirable effects on the mechanical properties of denture materials. The roughness of acrylic resin surfaces is a critical property because surface irregularities increase the possibility of the retention of microbes on the denture surface after its cleaning.1617 Another property that can have an effect on the surface properties of acrylic resins is the hardness, which is an indication of the simplicity in finishing the material and its resistance to in-service scratching.18

The halloysite (Al2Si2O5(OH)4·2H2O) differs from micron-sized fibers/whiskers as it is formed of nano-sized crystals (tubes). The halloysite nanotube (HNT) has a hollow/tubular structure that is formed of two layers of aluminosilicate. 1920 Halloysite has many advantages over many other nano-sized fillers (such as carbon nanotubes/nanofibers) since it is a naturally occurring mineral and is easy to purify. Accordingly, HNTs are present in plenty amounts and are economical.21 Additionally, halloysite is harmless, biocompatible, and can be simply processed.1921 The diameters of HNTs are approximately in tens of nanometers, and the lengths are in the range from ~200 nm to 1-2 µm.20

The chemical properties of the outer surface of HNTs are close to SiO2, while those of the inner surface are close to Al2O3. Nano-sized crystals of HNTs have a high degree of structural perfection and the related superior mechanical properties; for example, the Young's modulus of HNTs is expected to be in the range of 230-340 GPa, which is very close to that of imogolite nanotubes.2223 Furthermore, halloysite has a unique characteristic as it is quite easy to be split into separate HNTs and to be evenly distributed in dental matrices. This is different from layered silicates (such as montmorillonite), which are difficult to completely peel into nano-sized silicate layers and to uniformly spread in dental matrices. The splitting is due to much larger distance between clustered HNTs in halloysite than that between silicate layers in montmorillonite. Accordingly, the interactions between HNTs is significantly lower than those between silicate layers in montmorillonite.24

Therefore, this study aims to investigate the effect of incorporating HNTs into PMMA resin on the resin's mechanical properties regarding flexural strength, hardness, and Young's modulus. The null hypothesis was that HNTs addition to PMMA resin would not interfere with its mechanical properties.

A conventional heat-cured resin (Acrostone; Acrostone Dental factory, under exclusive license of England, Egypt) was used as a matrix component and the as-received halloysite powder (Sigma-Aldrich Co., St. Louis, MO, USA) as a reinforcing agent. For each test, 40 specimens were prepared. The specimens were categorized into four groups (n = 10) coded A to D. Group A was the control group (unmodified acrylic resin specimens). The specimens of the remaining three groups (B-D) were modified with addition of halloysite powder to attain ratios of 0.3, 0.6 and 0.9 wt%.

In accordance with the studies by Ellakwa et al.,8 and Sehajpal and Sood,25 halloysite powder was mixed with resin powder and liquid monomer in order to obtain an equal distribution of filler within the polymer matrix. The halloysite powder and acrylic powder were thoroughly mixed using a mortar and pestle for initial mixing and blending, followed by hand tumbling in a plastic jar until an even color was obtained. The resin powder was then mixed with monomer in a ratio of 2:1 by volume in a mixing jar with a tightly fitting lid.

Specimens were prepared using stone molds made by investing stainless steel rectangles sized 65 mm × 10 mm × 3 mm and releasing the rectangles after stone setting.8915 The acrylic specimens were prepared by packing the acrylic resin into the stone molds present in denture flasks and curing them for 9 hours at 73.89℃. The cycle was completed by boiling for an extra 30 minutes. The rectangular resin specimens were then removed from the flask. After removing flask and trimming the edges, the specimens were ground with 320-grit silicon carbide paper to obtain polished surfaces. The specimens were stored in water at 37℃ for 7 days before performing the flexural strength test. The flexural strength was measured using a three-point bending test in a universal testing machine (Lloyds, LRX, Lloyds Instruments, Hampshire, UK) at a crosshead speed of 5 mm/min. Specimens were loaded until fracture occurred.

From the stress-strain curve, the flexural strength (FS) and Young's modulus (E) could be calculated. The value of E was the slope of the linear portion of the stress-strain curve, expressed as the ratio of stress/strain. The calculation of FS (in MPa) and E (in GPa) was guided by the formulae: 262728

Where; F is the maximum load at the point of fracture (in N), L is the span (in mm), w is the width of the specimen (in mm), and h its height (in mm), while P/Y is the slope of the linear part of the stress-strain curve within the elastic portion.

For Vickers testing, a separate group of specimens was prepared in molds obtained by investing stainless steel rectangles (12 mm × 12 mm × 3 mm) within flasks.29 The liquid and powder were mixed in a predetermined ratio and modified with halloysite powder as mentioned earlier in the specimen preparation. The mixed resin was then packed into the molds. The specimens were polymerized using a long polymerization cycle followed by 30-minute boiling. After polymerization, the specimens were visually examined for having smooth surfaces without voids or porosities.The specimens were manually wet-polished in a circular motion with a sequence of 600-grit, 800-grit, 1000-grit, and 1200-grit silicon carbide papers. To determine Vickers values, a load of 30 g was applied for 30 seconds on the specimens using a digital hardness tester (Otto Wolpert, Werke, Ludwigshafen, Germany). Each specimen was subjected to three indentations (one at the center and two at the borders), and the average value was calculated for each group from A to D.

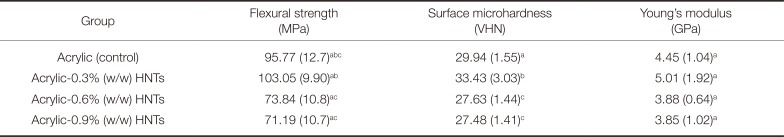

The mean and standard deviation values for flexural strength, surface microhardness, and Young's modulus are presented in Table 1. One-way analysis of variance identified significant differences between the mean values of both flexural strength (P = .018) and surface microhardness (P = .000) of the tested groups, while the Young's modulus mean values showed no significant difference (P = .647). Tukey test showed that there was no statistically significant difference in flexural strength values (P > .05) between the tested groups and the control group (no addition). There was also no significant difference in flexural strength values (P > .05) between the 0.6%(w/w) halloysite nanotubes added acrylic resin group and 0.9% group. The 0.3%(w/w) halloysite nanotubes addition to acrylic resin increased the flexural strength values significantly in comparison to either 0.6% or 0.9% groups. Both 0.6% and 0.9% groups showed significant decrease in microhardness values when compared to either the control group or 0.3% group. The addition of 0.3%(w/w) halloysite nanotubes to acrylic resin significantly increased the resin's microhardness values in comparison to the control group. The Young's modulus values of 0.3% group showed a slight increase in comparison to those of all the other groups. However, this increase was not statistically significant. The Young's modulus values of 0.6% and 0.9% groups did not show a significant decrease when compared to those of the control group.

This study primarily aimed to investigate the probable method for the enhancement in the mechanical properties of PMMA, especially in the flexural strength, surface microhardness, and Young's modulus, through incorporating halloysite nanotubes.

It was shown that incorporating 0.3 wt% of untreated halloysite nanotubes to a conventional heat-cured resin could improve the mechanical properties of PMMA without additional processing steps. Therefore, dentures manufactured this way would not require a lengthy procedure, and the material's regular use in dental laboratories would be encouraged due to its low cost and ease of handling and processing.1

The results illustrated that the addition of small mass fraction (0.3 wt%) of HNTs into PMMA resin could result in a significant improvement of hardness values but neither in flexural strength nor Young's modulus values. The followings were the possible causative factors: (1) the HNTs that were strongly adhered to the resin reinforced the resin and accordingly enhanced the flexural strength, (2) the Young's modulus of HNTs was higher than that of the resin, resulting in an overall increase, and (3) the HNTs that were not strongly adhered to the resin could be scattered or dissociated during the load application; this produced frictional force that permitted stress distribution across the matrix cracks, increasing the material resistance to indentation (i.e., hardness).30

In contrast, PMMA resin modified with either 0.6 or 0.9 wt% of the HNTs had flexural strength, hardness, and Young's modulus values, which were lower than those of the control specimens. These results illustrated that the efficient strengthening would not be obtained at high percentage of HNT incorporation. This may be possibly due to the development of HNT clusters, which could result in mechanical weak points (structural defects). The presence of such clusters would adversely affect the mechanical properties of the dental resin strengthened with HNTs. Other possible explanations for the lower values could be: a reduction in the cross section of the load-bearing polymer matrix; an increase in the amount of filler particles which increases the stress concentration; changes in the modulus of elasticity of the resin and mode of crack propagation through the specimen due to an increased amount of fillers; formation of voids by moisture or entrapment of air; incomplete wetting of the fillers by the resin; and the HNTs; behavior as an intervening factor in the integrity of the polymer matrix.313233

These results are similar to those of Vojdani et al.,34 who investigated the effects of adding 0.5-5 wt% aluminum oxide (Al2O3) powder on the flexural strength and surface hardness of a conventional heat-cured acrylic resin and found that 2.5 wt% Al2O3 powder addition significantly increased its flexural strength and hardness. The results are also similar to those of Chen et al.,30 who found that incorporation of small percentage (1% and 2.5%) of the silanized HNTs in Bis-GMA/TEGDMA dental resins/composites increased the mechanical properties effectively. Nevertheless, large percentage (5%) of incorporation did not further enhance the mechanical properties. Accordingly, the results of this study rejected the null hypothesis since the introduction of small percentage of HNTs into PMMA resin affected its mechanical properties.

Within the limitations of this study, the following results were obtained:

Incorporation of small percentage (0.3 wt%) of HNTs into PMMA resin produced a significant increase in hardness values while the flexural strength and Young's modulus values did not show a significant increase compared to the control group.

High-percentage incorporation of HNTs (0.6 or 0.9 wt%) into PMMA did not show a significant decrease in both flexural strength and Young's modulus values compared to the control group or small-percentage incorporation. However, hardness values significantly decreased in comparison to both groups.

References

1. Jagger DC, Harrison A, Jandt KD. The reinforcement of dentures. J Oral Rehabil. 1999; 26:185–194. PMID: 10194725.

2. Kim SH, Watts DC. The effect of reinforcement with woven E-glass fibers on the impact strength of complete dentures fabricated with high-impact acrylic resin. J Prosthet Dent. 2004; 91:274–280. PMID: 15060499.

3. Vallittu PK, Lassila VP. Effect of metal strengthener's surface roughness on fracture resistance of acrylic denture base material. J Oral Rehabil. 1992; 19:385–391. PMID: 1432353.

4. Vallittu PK. Effect of some properties of metal strengtheners on the fracture resistance of acrylic denture base material construction. J Oral Rehabil. 1993; 20:241–248. PMID: 8496730.

5. John J, Gangadhar SA, Shah I. Flexural strength of heat-polymerized polymethyl methacrylate denture resin reinforced with glass, aramid, or nylon fibers. J Prosthet Dent. 2001; 86:424–427. PMID: 11677538.

6. Chen SY, Liang WM. Effects of fillers on fiber reinforced acrylic denture base resins. Mid Taiwan J Med. 2004; 9:203–210.

7. Zarb GA, Bolender LC. Prosthodontic Treatment for Edentulous Patients. 12th ed. St. Louis: Elsevier;2004. p. 195.

8. Ellakwa AE, Morsy MA, El-Sheikh AM. Effect of aluminum oxide addition on the flexural strength and thermal diffusivity of heat-polymerized acrylic resin. J Prosthodont. 2008; 17:439–444. PMID: 18482365.

9. Ayad NM, Badawi MF, Fatah AA. Effect of Reinforcement of High impact acrylic resin with zirconia on some physical and mechanical properties. Rev Clin Pesq Odontol. 2008; 4:145–151.

10. Panyayong W, Oshida Y, Andres CJ, Barco TM, Brown DT, Hovijitra S. Reinforcement of acrylic resins for provisional fixed restorations. Part III: Effects of addition of titania and zirconia mixtures on some mechanical and physical properties. Biomed Mater Eng. 2002; 12:353–366. PMID: 12652030.

11. Saad-Eldeen MA, AL-Fallal AA, Abouelatta OB. Effect of zirconium oxide reinforcement on epithelial oral mucosa, Immunoglobulin and surface roughness of complete acrylic heat-cured denture. Egypt Dent J. 2007; 53:941–946.

12. Tinschert J, Natt G, Mautsch W, Augthun M, Spiekermann H. Fracture resistance of lithium disilicate-, alumina-, and zirconia-based three-unit fixed partial dentures: a laboratory study. Int J Prosthodont. 2001; 14:231–238. PMID: 11484570.

13. Abdel-Samad A, EL-Fallal A. Evaluation of the effect of zirconium oxide on wear resistance and hardness of acrylic teeth. Egypt Dent J. 2009; 55:639–643.

14. Minamizato T. Slip-cast zirconia dental roots with tunnels drilled by laser process. J Prosthet Dent. 1990; 63:677–684. PMID: 2194027.

15. William D, Callister JR. Materials science and engineering: An introduction. 4th ed. New York: John Wiley & Sons Incorporation;1997. p. 532–533.

16. Radford DR, Sweet SP, Challacombe SJ, Walter JD. Adherence of Candida albicans to denture-base materials with different surface finishes. J Dent. 1998; 26:577–583. PMID: 9754746.

17. Verran J, Maryan CJ. Retention of Candida albicans on acrylic resin and silicone of different surface topography. J Prosthet Dent. 1997; 77:535–539. PMID: 9151275.

18. Powers JM, Sakaguchi RL. Craig's Restorative Dental Materials. 12th ed. St. Louis: Elsevier;2006. p. 79.

19. Joussein E, Petit S, Churchman J. Halloysite clay minerals - a review. Clay Miner. 2005; 40:383–426.

20. Hope E, Kittrick J. Surface tension and the morphology of halloysite. Am Mineral. 1964; 49:859–863.

21. Vergaro V, Abdullayev E, Lvov YM, Zeitoun A, Cingolani R, Rinaldi R, Leporatti S. Cytocompatibility and uptake of halloysite clay nanotubes. Biomacromolecules. 2010; 11:820–826. PMID: 20170093.

22. Guimarães L, Enyashin NA, Seifert G, Duarte AH. Structural, electronic, and mechanical properties of single-walled halloysite nanotube models. J Phys Chem C Nanomater Interfaces. 2010; 114:11358–11363.

23. Guimarães L, Enyashin AN, Frenzel J, Heine T, Duarte HA, Seifert G. Imogolite nanotubes: stability, electronic, and mechanical properties. ACS Nano. 2007; 1:362–368. PMID: 19206688.

24. Ye YP, Chen HB, Chan CM. Interlaminar properties of carbon fiber composites with halloysite nanotube-toughened epoxy matrix. Compos Sci Technol. 2011; 71:717–723.

25. Sehajpal SB, Sood VK. Effect of metal fillers on some physical properties of acrylic resin. J Prosthet Dent. 1989; 61:746–751. PMID: 2724170.

26. International Organization for Standardization. Specification 1567: Denture Base Polymers. ed 2. Geneva: Switzerland;1988. p. 1–9.

27. Takahashi Y, Kawaguchi M, Chai J. Flexural strength at the proportional limit of a denture base material relined with four different denture reline materials. Int J Prosthodont. 1997; 10:508–512. PMID: 9495170.

28. Vallittu PK, Ruyter IE, Ekstrand K. Effect of water storage on the flexural properties of E-glass and silica fiber acrylic resin composite. Int J Prosthodont. 1998; 11:340–350. PMID: 9758998.

29. Machado AL, Breeding LC, Vergani CE, da Cruz Perez LE. Hardness and surface roughness of reline and denture base acrylic resins after repeated disinfection procedures. J Prosthet Dent. 2009; 102:115–122. PMID: 19643225.

30. Chen Q, Zhao Y, Wu W, Xu T, Fong H. Fabrication and evaluation of Bis-GMA/TEGDMA dental resins/composites containing halloysite nanotubes. Dent Mater. 2012; 28:1071–1079. PMID: 22796038.

31. Leinfelder KF, Sluder TB, Santos JFF, Wall JT. Five-year clinical evaluation of anterior and posterior restorations of composite resin. Oper Dent. 1980; 12:52–78.

32. Xu HH. Dental composite resins containing silica-fused ceramic single-crystalline whiskers with various filler levels. J Dent Res. 1999; 78:1304–1311. PMID: 10403457.

33. Xu HH, Schumacher GE, Eichmiller FC, Antonucci JM. Strengthening composite resin restorations with ceramic whisker reinforcement. Pract Periodontics Aesthet Dent. 2000; 12:111–116. PMID: 11404884.

Table 1

Mean (standard deviation in parentheses) of mechanical properties of acrylic resin with halloysite nanotubes incorporation and Tukey's analysis

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download