Abstract

PURPOSE

To determine whether the fracture strengths and failure types differed between metal and zirconia frameworks veneered with pressable or layering ceramics.

MATERIALS AND METHODS

A phantom molar tooth was prepared and duplicated in 40 cobalt-chromium abutments. Twenty metal (IPS d.SIGN 15, Ivoclar, Vivadent, Schaan, Liechtenstein) and 20 zirconia (IPS e.max ZirCAD, Ivoclar) frameworks were fabricated on the abutments. Each framework group was randomly divided into 2 subgroups according to the veneering material: pressable and layering ceramics (n=10). Forty molar crowns were fabricated, cemented onto the corresponding abutments and then thermocycled (5-55℃, 10,000 cycles). A load was applied in a universal testing machine until a fracture occurred on the crowns. In addition, failure types were examined using a stereomicroscope. Fracture load data were analyzed using one-way ANOVA and Tukey HSD post-hoc tests at a significance level of 0.05.

RESULTS

The highest strength value was seen in metal-pressable (MP) group, whereas zirconia-pressable (ZP) group exhibited the lowest one. Moreover, group MP showed significantly higher fracture loads than group ZP (P=.015) and zirconia-layering (ZL) (P=.038) group. No significant difference in fracture strength was detected between groups MP and ML, and groups ZP and ZL (P>.05). Predominant fracture types were cohesive for metal groups and adhesive for zirconia groups.

During the past 40 years, the porcelain fused to metal technique has proven to be a reliable treatment option for fixed partial dentures and still represents the gold standard.1 However, due to the rising interest in esthetic dentistry, zirconia which is a computer-aided design/computer aided manufacturing (CAD/CAM) bilayer restoration have gained popularity with its superior mechanical properties such as high flexural strength (700 - 1,200 MPa), fracture toughness (7 - 10 MPa·m1/2), hardness, translucency,2 chemical stability,345 biocompatibility, and favorable optical properties.6

Metal or zirconia core materials must be covered with a feldspathic veneering ceramics to establish an optimum esthetic outcome especially color and translucency.78 Different techniques, including layering and pressing techniques, can be performed for veneering ceramic on core materials.9 In the layering technique, the porcelain powder is mixed with modeling liquid, and the mixture is brush-applied on the core (metal or fully-sintered zirconia) larger than the final dimensions to compensate for the shrinkage of the veneering ceramic.8 Furthermore, multiple applications and firings (minimal three firing cycles, namely dentin, enamel and glaze firings), which are carried out by the skillful dental technician, are required.10 On the other hand, in the pressing technique, prior to investing, a final contour anatomical waxing is prepared on a core. After elimination of the wax in an oven, ceramics are heat-pressed into the mold and to the core.8 This technique has some advantages on the layering technique with its speed, accuracy and stability. Moreover, the core and wax pattern complex can be tried in the mouth before final laboratory processes of the pressing ceramic.911 Additionally, the shrinkage related problems as well as consequences of possible sintering procedures are eliminated.8

For the zirconia-based ceramic restorations, delamination of the veneering porcelain from the core structure (chipping of the veneering ceramic) is a major failure mode.412 Ceramic structures tend to fail because of surface tension, where cracks and flaws propagate by slow crack growth leading to the failure. The flaw size, number and distribution can be related to the material, or be affected by the fabrication process.13 Chipping can be attributed to potential flaws and artifacts generated during the veneering technique.14 As the pressing technique is a more controlled procedure, fewer flaws and better strength properties are expected than the layering technique.15 In literature, very limited data has been reported about evaluating pressable ceramics on metal and zirconia core materials and comparing them with layering ones.81617 Thus, the aim of this in vitro study was to investigate the load bearing capacities of pressable and layering ceramics to the corresponding metal and zirconia frameworks. The hypothesis was that the fracture strength of metal or zirconia based ceramic restoration is independent of the veneering techniques.

In this in vitro study, base metal alloy and zirconia were used as core materials; pressing and layering techniques were performed as veneering materials to produce posterior crowns. A phantom mandibular molar tooth (Frasaco GmbH, Tettnang, Germany) was prepared with a 1 mm circumferential chamfer preparation and tapered angle of 8°, using a surveyor (F1, DeguDent, Hanau, Germany). Forty impressions (Affinis Precious, Coltene/Whaledent, Altstätten, Switzerland) were taken and the prepared tooth was duplicated in 40 cobalt-chromium alloy dies (Remanium 2000, Dentaurum, Ispringen, Germany) in order to standardize the frameworks. Metal dies were randomly divided into 2 groups according to the framework types: metal and zirconia (n = 20).

Twenty wax patterns were built on dies and 20 metal frameworks (IPS d.SIGN 15, Ivoclar Vivadent, Schaan, Liechtenstein) with a thickness of 0.5 mm were fabricated with lost-wax technique. The metal frameworks were randomly divided into 2 subgroups and coded by veneering process, layering (ML) and pressing (MP) groups (n = 10).

In the ML group, two layers of opaque (IPS InLine Opaquer, Ivoclar Vivadent) was applied to the metal surface and fired under vacuum in a calibrated porcelain oven (Programat 500, Ivoclar Vivadent) to 930℃. Then, leucite based body porcelain (IPS InLine, Ivoclar Vivadent) was vibrated and condensed to produce minimal shrinkage during processing. The crown was completed with a buccolingual width of 8 mm, a mesiodistal width of 10 mm, and an occlusal thickness of 2 mm after 3 firing cycles under vacuum at 910℃, including glaze firing. A silicone index was made from the outer surface of the first finished crown. This index was then used by the dental technician to fabricate all crowns.

In the MP group, two layers of opaque (IPS InLine Opaquer, Ivoclar Vivadent) was applied and fired. Subsequently, a pressable ceramic wax-up was applied using an ash-free wax (XP Dent Corp., Miami, FL, USA) with the silicone index. The metal-opaque-wax specimen was sprued and invested (IPS PressVEST Speed Investment, Ivoclar Vivadent). Wax elimination was performed according to the manufacturer's instructions. Ingots (IPS InLine PoM, Ivoclar Vivadent) were placed in the pressing furnace (EP600 Combi, Ivoclar Vivadent) and pressed at 940℃. The hot investment ring was left to cool to room temperature. Then the specimens were divested, finished, and glazed at 800℃ (Fig. 1).

The metal dies (n = 20) were scanned and 20 zirconia copings with a thickness of 0.5 mm were produced by a CAD/CAM system (InLab, Sirona Dental Company, Bensheim, Germany) using pre-sintered zirconia (IPS e.max ZirCAD, Ivoclar Vivadent), then sintered in a furnace (Sintramat, Ivoclar Vivadent). A liner (ZirLiner, Ivoclar Vivadent) was applied on the zirconia frameworks and fired at 960℃ according to the manufacturer suggestion. The frameworks were divided into 2 groups: 10 were veneered with layering technique (ZL) and 10 were veneered with pressing technique (ZP).

In the ZL, a glass-ceramic material (IPS e.max Ceram, Ivoclar Vivadent) was used to build up zirconia frameworks with the previously taken silicone index. The final shapes of the crowns were performed with 2 firing processes (dentin and enamel firing) at 750℃ and for a final firing, the crowns were glazed at 725℃ according to the manufacturer's instructions.

In the ZP, the silicone index was used to duplicate the wax-up veneering part of the zirconia frameworks. A sprue was attached to the wax-framework complex and invested. The wax was eliminated in the oven and the pressable fluorapatite glass ceramic ingots (IPS e.max ZirPress, Ivoclar Vivadent) were pressed into the pressing ring (EP 600, Ivoclar, Vivadent) at 910℃ then glazed at 770℃. All veneer build-up and firing procedures were performed according to the manufacturer's instructions by the same dental technician (Fig. 1).

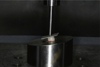

The crowns were cemented (Panavia F 2.0, Kuraray Medical, Okayama, Japan) onto the corresponding metal dies according to the manufacturer's instructions. The cemented crowns were then underwent thermocycling (5-55℃, 10,000 cycles) to simulate aging. Afterwards, they were placed in a universal testing machine (Shimadzu Corperation, Tokyo, Japan) (Fig. 2). The load was applied with a 6 mm diameter stainless steel ball at a crosshead speed of 0.5 mm/min until fracture of the crown occured. To avoid high stress concentration on the veneering material, a 1 mm thin piece of ethylenvinylacetat foil (Bioplast, Scheu Dental, Iserlohn, Germany) was placed on the occlusal surfaces. The load at fracture was determined by the first discontinuity in the load, whether it was an early crack or a catastrophic failure. After testing, all fractured specimens were examined under a stereomicroscope (Leica DFC295, Leica, Bensheim, Germany) at ×10 magnification by one operator to detemine the failure types.

The loads at fracture were registered and the SPSS program (version 13.0, SPSS Inc., Chicago, IL, USA) was used for statistical analysis. Independent samples t-test was used for analysis of the effects of framework material and veneering technique, then followed by one-way ANOVA and Tukey HSD post hoc test to make comparisons among the groups. P was set as 0.05 in all analyses.

The mean fracture loads were presented in Table 1. One-way ANOVA showed statistically significant difference between the groups (P = .01). The highest fracture load was detected in group MP and the lower one seen in group ZP. In addition, analysis of data revealed that the mean fracture load of group MP was significantly higher than group ZL (P = .038) and group ZP (P = .015). There were no significant differences between other groups: MP and ML, ZP and ZL, ML and ZP, ML and ZL (P > .05) (Table 1).

In metal groups, the fracture types were predominantly cohesive within frameworks (Fig. 3) (except one adhesive fracture for the pressing group) but there was no total fracture of the framework. In zirconia groups, the fractures were adhesive or cohesive within the veneering ceramics (Fig. 4) (7 adhesive, 3 cohesive for the layering group; 8 adhesive, 2 cohesive for the pressing group) (Table 2).

Based on the results of the present study, fracture strength of the metal based ceramics was improved by pressing technique. However, this was not statistically significant. In addition, similar values were measured in both layering and pressable ceramics for zirconia framework. Moreover, it was found that pressable ceramics on metal frameworks display significant higher fracture resistance than on the zirconia frameworks. Thus, the hypothesis was rejected. Christensen and Ploeger16 compared the failure rate of porcelain fused to metal restorations with zirconia based ceramics both pressed and layered. According to their report, pressed ceramics had a lower failure rate than layered restorations. Furthermore, it was detected that metal frameworks had the best performance with no framework fractures after 3 years. The results of this in-vivo study are in agreement with that of the present study.

The majority of the published data have compared the fracture resistance of the pressed and layered ceramics on zirconia frameworks.101518 Stawarczyk et al.10 investigated four different ceramic systems (Wieland Dental, GC Europe, Vita Zahnfabrik, and Ivoclar Vivadent) on zirconia framework and pressed technique of Ivoclar Vivadent exhibited significantly higher fracture strength values than layered one, whereas veneering techniques did not show any improvement in fracture strength values for all other ceramic systems. However, Kanat-Ertürk et al.19 demonstrated that layered ceramics of Ivoclar Vivadent on zirconia frameworks had significantly higher fracture strength values than pressed ceramics of Ivoclar Vivadent on zirconia frameworks. Contrary to the results of Stawarczyk et al.10 and Kanat-Ertürk et al.,19 similar fracture strength values were seen for both layered and pressed ceramic systems on zirconia framework in the present study. Consistent with the results of the present study, Beuer et al.,15 Eisenburger et al.,18 and Choi et al.20 found that there was no significant difference between veneering techniques on zirconia framework. These results could be explained that when zirconia ceramics are used for dental applications that require veneering ceramic, the material is repeatedly heated from room temperature up to around 900℃ for the veneering process. During these heating and cooling cycles, zirconia ceramics will pass through different regions of phase stabilities that may influence both the strength and the long-term behaviour of the material.21 Relative lower fracture resistance of ZP could be explained by higher pressing temperature of 910℃ than that of ZL (750℃).21 Furthermore, the present study findings were also consistent with those of Fahmy and Salah.22 They compared pressing and layering ceramics on metal frameworks and found that the fracture loads were not significantly different.

On the other hand, the effect of veneering techniques on the bond strength between ceramic and metal or zirconia frameworks were also evaluated by some researchers.823 They stated that no significant difference was detected between veneering techniques on both metal and zirconia frameworks. In addition, bonding between framework and ceramic material is effective on fracture strength of the framework-ceramic complex and there is a direct proportion between them.823 Therefore, the present study results were in accordance with those of Ishibe et al.8 and Schweitzer et al.23.

Metal-ceramic restorations are considered the standard treatment in dentistry due to their high success rate. Technical complications such as porcelain chipping/fractures are rarely described.2425 Nevertheless, zirconia-based ceramic restorations, which has been considered as a potential replacement for metal-ceramic restorations, have shown veneer or core failures.26 The exact reason for veneer chipping seen in zirconia restorations is unknown, but may have several different causes, such as defects in the veneering material, incorrect cooling rates during veneering, a weak chemical bond between the core and the veneer, and traumatic occlusion.26 In the present study, metal groups showed higher fracture loads and the fracture patterns were predominantly cohesive within metal whereas, zirconia groups showed lower fracture loads and adhesive fractures were common. On the other hand, it was exhibited that the pressing ceramics with leucite have better adhesion than non-leucite ceramics to zirconia.916 Fluorapatite ceramics were used over zirconia frameworks in the present study. Thus, lower fracture loads and more adhesive fractures can be explained by non-leucite content and above mentioned framework-veneer compatibility factors. Leucite containing ceramics for veneering zirconia framework will be further evaluated.

In addition, the maximum posterior chewing forces for a single tooth vary from 200 to 540 N.2728 It becomes as high as 965 N on occasions such as trauma or an accidental bite of hard foreign bodies. As a result, a fracture resistance above 1000 N is required to ensure good clinical performance.29 Therefore, all tested crowns can be used in the posterior region. Moreover, metal framework with pressing veneering technique can be preferred especially in patients with bruxism.

In order to mimic in vivo condition of dental restorations, aging procedures such as pre-load and thermocyling should be performed prior to the in vitro studies. In the present study, thermocycling was used as an artificial aging method for all crowns. Although some authors have not found any effect of artificial aging, it might be prudent to perform these pre-testing procedures to avoid creating unrealistically high fracture loads.30 Loading condition is as important as aging procedures to simulate in vivo environment. Although cyclic loading could be an option of chewing simulation, static loading was used in the present study, which could result in higher fracture loads than chewing forces. In addition, it is stated that increasing elastic modulus of the supporting dies results in increased fracture loads.3132 One of the limitations of this study was that metal dies were used instead of a composite resin or epoxy resin material that resembles the natural tooth's elastic modulus and would simulate the clinical situation.

Figures and Tables

| Fig. 3Stereomicroscope images of fractured metal group, (A) lingual view of MP specimen and (B) fractured segment (cohesive within metal), (C) lingual view of ML specimen and (D) fractured part (cohesive within metal). |

| Fig. 4Stereomicroscope images of fractured zirconia group, (A) lingual view of ZP specimen and (B) fractured segments (cohesive within ceramic), (C) lingual view of ZL specimen and (D) fractured parts (adhesive). |

References

1. Guess PC, Kulis A, Witkowski S, Wolkewitz M, Zhang Y, Strub JR. Shear bond strengths between different zirconia cores and veneering ceramics and their susceptibility to thermocycling. Dent Mater. 2008; 24:1556–1567.

2. Akin GE, Kaval ME, Turk T, Akin H. Surface roughness and bond strength of zirconia posts to a resin cement after various surface pretreatments. Photomed Laser Surg. 2015; 33:246–251.

3. Akın H, Ozkurt Z, Kırmalı O, Kazazoglu E, Ozdemir AK. Shear bond strength of resin cement to zirconia ceramic after aluminum oxide sandblasting and various laser treatments. Photomed Laser Surg. 2011; 29:797–802.

4. Kirmali O, Akin H, Ozdemir AK. Shear bond strength of veneering ceramic to zirconia core after different surface treatments. Photomed Laser Surg. 2013; 31:261–268.

5. Zhang Y, Kim JW. Graded structures for damage resistant and aesthetic all-ceramic restorations. Dent Mater. 2009; 25:781–790.

6. Goracci C, Ferrari M. Current perspectives on post systems: a literature review. Aust Dent J. 2011; 56:77–83.

7. Macedo VC, Anami LC, de Melo RM, Bottino MA, Valandro LF. Effect of the layering technique on bond strength and cohesive resistance of a porcelain-zirconia system. J Adhes Dent. 2014; 16:57–62.

8. Ishibe M, Raigrodski AJ, Flinn BD, Chung KH, Spiekerman C, Winter RR. Shear bond strengths of pressed and layered veneering ceramics to high-noble alloy and zirconia cores. J Prosthet Dent. 2011; 106:29–37.

9. Choi JE, Waddell JN, Torr B, Swain MV. Pressed ceramics onto zirconia. Part 1: Comparison of crystalline phases present, adhesion to a zirconia system and flexural strength. Dent Mater. 2011; 27:1204–1212.

10. Stawarczyk B, Ozcan M, Roos M, Trottmann A, Sailer I, Hämmerle CH. Load-bearing capacity and failure types of anterior zirconia crowns veneered with overpressing and layering techniques. Dent Mater. 2011; 27:1045–1053.

11. Bonfante EA, Coelho PG, Guess PC, Thompson VP, Silva NR. Fatigue and damage accumulation of veneer porcelain pressed on Y-TZP. J Dent. 2010; 38:318–324.

12. Aboushelib MN, de Jager N, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Dent Mater. 2005; 21:984–991.

13. Ritter JE. Predicting lifetimes of materials and material structures. Dent Mater. 1995; 11:142–146.

14. Baldassarri M, Zhang Y, Thompson VP, Rekow ED, Stappert CF. Reliability and failure modes of implant-supported zirconium-oxide fixed dental prostheses related to veneering techniques. J Dent. 2011; 39:489–498.

15. Beuer F, Schweiger J, Eichberger M, Kappert HF, Gernet W, Edelhoff D. High-strength CAD/CAM-fabricated veneering material sintered to zirconia copings-a new fabrication mode for all-ceramic restorations. Dent Mater. 2009; 25:121–128.

16. Christensen RP, Ploeger BJ. A clinical comparison of zirconia, metal and alumina fixed-prosthesis frameworks veneered with layered or pressed ceramic: a three-year report. J Am Dent Assoc. 2010; 141:1317–1329.

17. Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Part II: Zirconia veneering ceramics. Dent Mater. 2006; 22:857–863.

18. Eisenburger M, Mache T, Borchers L, Stiesch M. Fracture stability of anterior zirconia crowns with different core designs and veneered using the layering or the press-over technique. Eur J Oral Sci. 2011; 119:253–257.

19. Kanat-Ertürk B, Cömlekoğlu EM, Dündar-Çömlekoğlu M, Ozcan M, Güngör MA. Effect of veneering methods on zirconia framework-veneer ceramic adhesion and fracture resistance of single crowns. J Prosthodont. 2014; 10. 15.

20. Choi YS, Kim SH, Lee JB, Han JS, Yeo IS. In vitro evaluation of fracture strength of zirconia restoration veneered with various ceramic materials. J Adv Prosthodont. 2012; 4:162–169.

21. Nakamura K, Adolfsson E, Milleding P, Kanno T, Örtengren U. Influence of grain size and veneer firing process on the flexural strength of zirconia ceramics. Eur J Oral Sci. 2012; 120:249–254.

22. Fahmy NZ, Salah E. An in vitro assessment of a ceramicpressed-to-metal system as an alternative to conventional metal ceramic systems. J Prosthodont. 2011; 20:621–627.

23. Schweitzer DM, Goldstein GR, Ricci JL, Silva NR, Hittelman EL. Comparison of bond strength of a pressed ceramic fused to metal versus feldspathic porcelain fused to metal. J Prosthodont. 2005; 14:239–247.

24. Ortorp A, Kihl ML, Carlsson GE. A 3-year retrospective and clinical follow-up study of zirconia single crowns performed in a private practice. J Dent. 2009; 37:731–736.

25. Näpänkangas R, Raustia A. Twenty-year follow-up of metal-ceramic single crowns: a retrospective study. Int J Prosthodont. 2008; 21:307–311.

26. Oilo M, Kvam K, Gjerdet NR. Simulation of clinical fractures for three different all-ceramic crowns. Eur J Oral Sci. 2014; 122:245–250.

27. Attia A, Kern M. Influence of cyclic loading and luting agents on the fracture load of two all-ceramic crown systems. J Prosthet Dent. 2004; 92:551–556.

28. Joda T, Huber S, Bürki A, Zysset P, Brägger U. Influence of Abutment Design on Stiffness, Strength, and Failure of Implant-Supported Monolithic Resin Nano Ceramic (RNC) Crowns. Clin Implant Dent Relat Res. 2014; 03. 14.

29. Chen C, Trindade FZ, de Jager N, Kleverlaan CJ, Feilzer AJ. The fracture resistance of a CAD/CAM Resin Nano Ceramic (RNC) and a CAD ceramic at different thicknesses. Dent Mater. 2014; 30:954–962.

30. Sundh A, Molin M, Sjögren G. Fracture resistance of yttrium oxide partially-stabilized zirconia all-ceramic bridges after veneering and mechanical fatigue testing. Dent Mater. 2005; 21:476–482.

31. Scherrer SS, de Rijk WG. The fracture resistance of all-ceramic crowns on supporting structures with different elastic moduli. Int J Prosthodont. 1993; 6:462–467.

32. Rosentritt M, Plein T, Kolbeck C, Behr M, Handel G. In vitro fracture force and marginal adaptation of ceramic crowns fixed on natural and artificial teeth. Int J Prosthodont. 2000; 13:387–391.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download