Abstract

Teeth that have short clinical crown, which are not alone enough to support the definitive restoration can be best treated using the post and core system. The advantages of fiber post over conventional metallic post materials have led to its wide acceptance. In addition to that the combination of aesthetic and mechanical benefits of fiber post has provided it with a rise in the field of dentistry. Also the results obtained from some clinical trials have encouraged the clinicians to use the fiber posts confidently. Fiber posts are manufactured from pre-stretched fibers impregnated within a resin matrix. The fibers could that be of carbon, glass/silica, and quartz, whereas Epoxy and bis-GMA are the most widely used resin bases. But recently studies are also found to be going on for polyimide as possible material for the fiber post resin base as a substitute for the conventional materials.

Some teeth are severely mutilated because of caries, trauma or even as a result of previous large restorations. In case of an evident horizontal loss of clinical crown, most of the teeth could be unable to retain the final restoration without some additional support. If only a ferrule of minimal thickness can be achieved from remaining coronal tooth structure, a post and core build up following endodontic treatment could be of great assistance for retaining and supporting the future restoration.1,2 Post and core system has therefore been very popular and widely used for such teeth and have been in practice for a long time already.

As a result of rising demands for tooth-colored posts, in the recent years, conventional metallic posts are gradually being replaced by various non-metallic posts. Amongst them, epoxy resin posts reinforced with carbon fibers, epoxy or methacrylate resin posts reinforced with quartz or glass fibers, zirconia posts, and polyethylene fiber-reinforced posts are notable.3,4 This review is aimed at gathering the general information on the fiber post system and evaluating available articles related to the resin bases used in the fabrication of such posts. Also the possibility of any new material for the resin base will be taken into consideration.

History of fiber posts guides us to as far as 1989, when the producers claim to have introduced their original carbon fiber post-Composi post and they were started being used clinically, in France. However, the first evidence of a published article on the dental fiber posts was in 1990, by Duret et al.4-6 The initial fiber posts consisted of carbon/graphite fibers considering their good mechanical properties,7,8 such as high stiffness, tensile strength and conductivity to electricity and comparatively lower toxicity.7-9 The introduction of fiber posts brought an revolution in the field of dentistry, providing a reliable substitute to metal posts for the first time, of all types (casted or pre-fabricated). The material had modulus of elasticity much closer to dentin in contrast to that of the metallic posts and the clinical studies performed on fiber posts generated convincing outcomes.4,6,10 Over the time elapsed after the introduction of fiber posts, they have gained popularity in the dental market because of their benefits regarding ease in manipulation, mechanical properties, esthetics and removability, offering predictable clinical performance in several ways. However, the initially introduced posts had some drawbacks regarding their esthetic usage, as they were radiolucent and difficult to conceal under all-ceramic or composite restorations.4,6 Especially in case of the anterior teeth, the color would reveal from an otherwise perfect definitive restoration. Successively, radiopaque fiber posts were obtained and more esthetic posts using the quartz and glass fibers were introduced to overcome this problem by being incorporated in the resin base. These fiber posts are white or translucent, more favorable for conditions with high esthetic demands. Besides, fibers have elasticity, high tensile strength, low electrical conductivity, resistance to solubility, and resistance to biochemical degradation. These quality claims highly advocated for the severe change for the acceptance of fiber posts.

Ideal properties for the post material include physical properties like modulus of elasticity, compressive strength, flexural strength and thermal expansion, similar to that of dentin. It should esthetically resemble and bond efficiently to the dentine.7,11 Due to the difference in the modulus of elasticity of the dentin and the selected post, there are possible areas of stress concentration in the dentin leading to potential root cracking followed by fracture, as in the case of metal and zirconium post.

Posts which have modulus of elasticity similar to that of the dentin are chosen over others for relatively uniform pattern of stress distribution, dropping the risk of root fracture.4,8 Many laboratory researches show that carbon and glass fiber posts have modulus of elasticity (about 20 GPa) similar to that of dentin(about 18 GPa).6,8,10 Similar modulus of elasticity thus provides with a similar physical properties of fiber post to that of the natural dentin.

The pattern of stress distribution in an otherwise healthy tooth with a vital pulp, cannot be recreated. Especially when endodontic posts are introduced into the root canal, there is a totally different and unnatural structure that has totally dissimilar stiffness to that of the pulp.10 Therefore, it is favorable to use materials with mechanical properties closely resembling that of natural dentin.6,10 Posts reinforced with fibers have an modulus of elasticity of approximately 20 GPa, whereas cast metal alloy posts and prefabricated metal posts have about 200 GPa and ceramic posts about 150 GPa.10 Thus, fiber reinforced posts have mechanical properties similar to that of natural dentin (which has a flexural modulus of about 18 GPa).8,10 Akkayan and Gülmez,12 calculated the fracture resistance of 40 extracted, root canal treated teeth, restored with different posts systems. The results revealed that the teeth restored with fiber post showed favorable and repairable fractures on the contrarily, those restored with titanium and zirconia's posts demonstrated catastrophic fractures.10,12 Also many of the fiber post failure have been limited to the post dislodgment rather than tooth fracture in case of the fiber post restored teeth. Seefeld et al,13 carried out a study for comparing the fractural and structural features of different fiber post, in this study most of the samples of the fiber posts showed the flexural strength above 800 MPa with only one of the sample post showing the least flexural strength of 565 MPa.

Metal posts with their stiff and hard nature; transfer the forces along their long axis creating a wedge effect on the tooth structure, acting similar to a metal wedge on a piece of wood. Fiber posts having similar modulus of elasticity as dentin, avoid this condition to a considerable extent.6 In case where the endodontic treatment has to be redone, fiber posts can be easily removed with little or no tooth removal, providing the dentist with options for further treatment.

In addition to that, due to their natural translucency, aesthetic demands of full-ceramic restorations are better met by the recent fiber posts at the same time the shortcomings of ceramic and zirconium posts are also fulfilled by them with their elastic modulus allowing the homogenous stress distribution thereby greatly reducing the failure of the post due to fracture of the teeth. Thus, it would not be inappropriate to say that the fiber posts have superior performance and are the best choice for the treatment of severely damaged teeth, compared to conventional post systems.

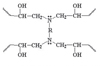

Currently available fiber-based posts are essentially composite materials. They consist of prestretched fibers of carbon or silica bounded by a matrix of polymer resin. Most of the fiber-reinforced posts contain epoxy resin or bis-GMA matrix along with some fillers.14

Fiber-reinforced post systems contain a high volume percentage of continuous fibers embedded in polymer matrixes, which are commonly epoxy polymers with high degree of conversion and a highly cross-linked structure that binds the fibers.10,12 Carbon fiber posts are prepared from continuous and unidirectional carbon fibers in an epoxy resin matrix.15 Drawback of carbon-fiber posts to provide desired esthetics with all-ceramic restorations resulted in the production of translucent and tooth colored silica-fiber posts. These are also called glass-fiber and quartz-fiber reinforced posts. Manufacturers suggest that these posts hold similar biomechanical properties as carbon-fiber posts,16 Glass fiber posts could contain different types of glass, such as E-glass (electrical glass), and S-glass (high-strength glass). Also, glass fiber posts could also be made from quartz fiber, which is pure silica in a crystallized form8,10 and provide better esthetic results.10,12,15

It was discouraging that not many articles could be retrieved concerning the resin base materials and/or their properties.

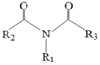

The synthesis of aromatic monomer BisGMA (bisphenol A glycidyl methacrylate) brought about a revolution in the form of dental resin composites. They have been widely in use as matrix component.17 Debates are undergoing as for whether bisGMA based material in dentristry are safe or not. The presence of bisphenolA, a contaminant in the bisGMA resin based materials, is said to produce allergic reactions or induce estrogenic effect.18 However, as in the case of fiberpost, the end product might be spared from the contaminants.

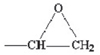

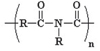

BisGMA has been commonly used as a resin base material for the glass fiber post. Such glass fiber post have been reported to have a flexure strength in the range of 453-936 MPa.14 Molecular structure of the epoxy resin is presented in Fig. 1 and Fig. 2.

Epoxy resins are thermosetting polymers profoundly used as a matrix material in fibrous composites. The usage applies in various fields as in adhesives, paints, coatings, medical implants, and electrical devices. Epoxy, also known as polyepoxide, is formed by the reaction of an epoxide (base) with polyamine (reactor). Epoxy resin is widely used resin base for the dental fiber posts.

Other material used for the resin base, bis-GMA (bisphenol A glycidyl methacrylate), based glass fiber posts were compared by Soares et al., with epoxy resin based carbon fiber post.7 They observed that the glass fibers deformed more than carbon fibers because of their lower modulus of elasticity. Thus, the carbon fiber post system could perform better. Also due to the higher fiber content in both the post systems than the matrix, during the flexural strength test, the bisGMA matrix experiences greater stress due to its stiffer nature than that of epoxy matrix.7,17 The fiber arrangement in fiber-reinforced composite posts offers high tensile strength, meanwhile the resin matrix is resists compressive stresses.19,20 Moreover, it is the matrix that takes in the emergent stresses from throughout the post system.17 Due to the difference in the moduli of elasticity of the fibers and the matrix, stresses normally generate at the fiber-matrix interface,9,21 and transmit along the surfaces of the fibers when the posts are in function.7 Generally factors such as direction of the fibers, volume fraction and proportion of the fibers impregnated into the matrix resin, the bonding between the matrix resin and the fibers, the polymerization shrinkage of the resin, and the individual properties of the fibers and the matrix, contribute to the mechanical strength of the fiber posts.14 However, structural defects such as voids, cracks, or micro bubbles in the fibers and the matrix, resulting during the manufacturing process, weaken the post.7,20,22 Since the resin matrix is less resistant to tensile stress, it fractures first. Failure of the restoration in endodontically treated teeth is supposedly an outcome of fatigue process. The cause of common clinical failure, such as post fracture, can be associated to the mechanical properties of the posts.23 High elastic limit can greatly decrease the strain generated and the adequate strength contributes lower risk of fracture of the post.24

Eye, nose throat and skin irritation, skin allergies and asthma are the commonly encountered effects due to overexposure of chemicals in epoxy resin systems. Finished, hardened epoxy products are basically non-toxic unless they are cut, sanded, or burned.25

Sensitization to the hardener and allergic reaction over a period of time is the primary risk associated with the usage of epoxy. Sometimes delayed hypersensitivity could also be observed after few days from exposure. Epoxy is also the leading cause for the occupational asthma for users of plastics. Bisphenol A, which is used in epoxy resin, is a known 'endocrine disruptor.'

The mutagenicity of epoxides such as ethylenoxide and epichlorhydrin was first shown in fruit flies and has subsequently been demonstrated in a variety of organisms. Epoxy resins are diepoxides and bifunctional alkylating agents, and bifunctional alkylating epoxides have been identified to be mutagenic. Mutagens are suspected of having a carcinogenic effect because of the relationship between carcinogenicity and mutagenicity and most diepoxides are carcinogenic in mice and rats. Andersen et al. report that aromatic epoxy resins are mutagenic in Salmonella typhimurium, and may thus represent a cancer risk in human as well.26

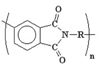

Polyimides are a class of representative high-performance polymers consisting of the cyclic imide and aromatic groups in the backbone chains. Aromatic polyimide became popular since early 1960. Aromatic polyimides have been extensively investigated due to their excellent thermal stability, mechanical properties, along with their good chemical resistance and dielectric properties.27,28 Therefore, they are also considered favorable for use in fiber reinforced composites as a resin matrix.28

Polyimides are mostly infusible and insoluble owing to their planar aromatic and hetero-aromatic structures29 thus processing is frequently done from solvent route.

Matsumoto et al. synthesized and tested the characters of polyimide.30 There was 5%-weight loss at temperatures over 450℃. The glass transition temperature of the polyimide films ranged from 211 to 385℃, tensile modulus from 1.5-2.6 GPa, tensile strength ranging from 52-96 MPa. The polyimide films were entirely colorless showing cutoffs below the wavelength of 320 nm. The polyimide films remained to be colorless up to 200℃ on heating in air and to 400℃ N2 atmosphere.30

The hybrid films of polyimide containing small amount of organoclay exhibited high transparency. The hybrid polyimide films also exhibited acceptable thermal properties, the glass transition temperature ranging from 236-245℃. Insignificant thermal decomposition was observed below 450℃. Those polyimide hybrids also showed low coefficients of thermal expansion.31

Polyimide has been claimed by the producers to offer the durability and reliability needed for applications in extreme environments and withstand extreme temperatures ranging from -269℃ to up to 400℃ without any change in its properties. In aerospace industry, it is used as insulation for aircraft and spacecraft wiring. It provides lighter weight, reduced volume, durability and environmental resistance.

Polyimide film is used as the primary insulator on the electrical cables used in the joints connecting the different crucial components in the rocket for their well-functioning.

Because of the high tensile modulus, polyimide has also been considered as a probable resin base material for fiber post. Gao et al.32 tested the mechanical property and biocompatibility of polyimide based composite resin reinforced by high-strength carbon fiber, and the results showed that elastic modulus of carbon fiber reinforced polyimide composites was similar to that of natural tooth root (flexural strength is in between 1160-1550 MPa, elastic modulus between 6.4-8.8 GPa), and the cytotoxicity of carbon fiber reinforced polyimide composites was grade I and the hemolysis rates were less than 5%. Thus concluded that polyimide has good mechanical and biological properties ideal enough for the base material of fiber post. Polyimides demonstrate superior physical and mechanical properties through a wide range of temperature and remarkably high resistance to radiation and semiconductor properties.

Using the testing protocols approved by "the National Institutes of Health Guidelines for Blood-Material Interactions", various commercially available polyimide materials were evaluated in-vitro by Richardson et al.33 Procedures involved electron spectroscopy for chemical analysis and contact angle characterization surface studies, and protein adsorption, cell culture cytotoxicity, clotting time and hemolysis biocompatibility testing. The cytotoxicity and hemolysis was negligible and the clotting times ranged from 63 to 98% of normal.

Fiber post itself is a new advancement in the field of dentistry. The unfavorable transmission of stress from post to tooth structure resulting from the high modulus of elasticity of the metal post leading to frequent decementation or even fracture of the tooth can be attributed for failure of the metal post system.14 This led to decreasing preference of metal post and rising popularity of fiber posts. Many researches have been done and numerous papers published concerning the fiber posts and their different properties.1,3,4 Various papers concern the comparison of fiber post to the conventional metallic post. Also articles based on comparison of different commercially available fiber post systems are also remarkable though most of the studies are done in-vitro. Most of them favored fiber post to other post systems.

This review has roughly involved the basic information and mainly aimed to focus on the resin base materials. Nevertheless very few has been done in the way of publishing regarding the resin base materials, clearly further research is required for this area. Possible results are yet still awaited. Still it is little encouraging to know that researches are in process for development of newer resin base materials.

Epoxy resin has been providing very good results for the success of fiber posts. However polyimide is being used as a substitute for epoxy polymers in many industries due to its superior qualities over epoxy resin. Polyimides are used in a broad application ranging from microelectronics to aerospace. Aromatic polyimides have been popular due to their excellent thermal stability, mechanical and electronic properties thus have been considered suitable for resin base material. Carbon fiber reinforced polyimide composites produced from the imide solution, were found to have good quality with high glass transition temperature Tg up to 347℃ and no voids observed through the optical micrograph.28 Hence the efforts for investigation of possibility of polyimide as a new resin base material also must be considered and appreciated. The results from Gao et al. in the development of novel polyimide based carbon fiber reinforced composites have also been encouraging with good mechanical property and biological performance which could offer great clinical success in future.

Figures and Tables

References

1. Monticelli F, Goracci C, Ferrari M. Micromorphology of the fiber post-resin core unit: a scanning electron microscopy evaluation. Dent Mater. 2004; 20:176–183.

2. Ferrari M, Vichi A, García-Godoy F. Clinical evaluation of fiber-reinforced epoxy resin posts and cast post and cores. Am J Dent. 2000; 13:15B–18B.

3. Glazer B. Restoration of endodontically treated teeth with carbon fibre posts-a prospective study. J Can Dent Assoc. 2000; 66:613–618.

4. Goracci C, Ferrari M. Current perspectives on post systems: a literature review. Aust Dent J. 2011; 56:77–83.

5. Duret B, Reynaud M, Duret F. New concept of coronoradicular reconstruction: the Composipost (1). Chir Dent Fr. 1990; 60:131–141.

6. Bateman G, Ricketts DN, Saunders WP. Fibre-based post systems: a review. Br Dent J. 2003; 195:43–48.

7. Soares CJ, Santana FR, Pereira JC, Araujo TS, Menezes MS. Influence of airborne-particle abrasion on mechanical properties and bond strength of carbon/epoxy and glass/bis-GMA fiber-reinforced resin posts. J Prosthet Dent. 2008; 99:444–454.

8. Lassila LV, Tanner J, Le Bell AM, Narva K, Vallittu PK. Flexural properties of fiber reinforced root canal posts. Dent Mater. 2004; 20:29–36.

9. Goldberg AJ, Burstone CJ. The use of continuous fiber reinforcement in dentistry. Dent Mater. 1992; 8:197–202.

10. Novais VR, Quagliatto PS, Bona AD, Correr-Sobrinho L, Soares CJ. Flexural modulus, flexural strength, and stiffness of fiber-reinforced posts. Indian J Dent Res. 2009; 20:277–281.

11. Cheung W. A review of the management of endodontically treated teeth. Post, core and the final restoration. J Am Dent Assoc. 2005; 136:611–619.

12. Akkayan B, Gülmez T. Resistance to fracture of endodontically treated teeth restored with different post systems. J Prosthet Dent. 2002; 87:431–437.

13. Seefeld F, Wenz HJ, Ludwig K, Kern M. Resistance to fracture and structural characteristics of different fiber reinforced post systems. Dent Mater. 2007; 23:265–271.

14. Drummond JL, Bapna MS. Static and cyclic loading of fiberreinforced dental resin. Dent Mater. 2003; 19:226–231.

15. Hedlund SO, Johansson NG, Sjögren G. A retrospective study of pre-fabricated carbon fibre root canal posts. J Oral Rehabil. 2003; 30:1036–1040.

16. Cagidiaco MC, Radovic I, Simonetti M, Tay F, Ferrari M. Clinical performance of fiber post restorations in endodontically treated teeth: 2-year results. Int J Prosthodont. 2007; 20:293–298.

17. Asmussen E, Peutzfeldt A. Influence of UEDMA BisGMA and TEGDMA on selected mechanical properties of experimental resin composites. Dent Mater. 1998; 14:51–56.

18. Söderholm KJ, Mariotti A. BIS-GMA - based resins in dentistry: are they safe? J Am Dent Assoc. 1999; 130:201–209.

19. Ferrari M, Vichi A, Mannocci F, Mason PN. Retrospective study of the clinical performance of fiber posts. Am J Dent. 2000; 13:9B–13B.

20. Lassila LV, Vallittu PK. The effect of fiber position and polymerization condition on the flexural properties of fiber-reinforced composite. J Contemp Dent Pract. 2004; 5:14–26.

21. Eick JD, Smith RE, Pinzino CS, Kotha SP, Kostoryz EL, Chappelow CC. Photopolymerization of developmental monomers for dental cationically initiated matrix resins. Dent Mater. 2005; 21:384–390.

22. Grandini S, Balleri P, Ferrari M. Scanning electron microscopic investigation of the surface of fiber posts after cutting. J Endod. 2002; 28:610–612.

23. Baran G, Boberick K, McCool J. Fatigue of restorative materials. Crit Rev Oral Biol Med. 2001; 12:350–360.

24. Asmussen E, Peutzfeldt A, Heitmann T. Stiffness, elastic limit, and strength of newer types of endodontic posts. J Dent. 1999; 27:275–278.

25. Padmaja S. Biohazards associated with materials used in prosthodontics. Niger J Clin Pract. 2013; 16:139–144.

26. Andersen M, Kiel P, Larsen H, Maxild J. Mutagenic action of aromatic epoxy resins. Nature. 1978; 276:391–392.

27. Chen D, Liu T, Zhou X, Tjiu WC, Hou H. Electrospinning fabrication of high strength and toughness polyimide nanofiber membranes containing multiwalled carbon nanotubes. J Phys Chem B. 2009; 113:9741–9748.

28. Liaw DJ, Wang KL, Huang YC, Lee KR, Lai JY, Ha CS. Advanced polyimide materials: Syntheses, physical properties and applications. Prog Polym Sci. 2012; 37:907–974.

29. Ratta V. Polymides: chemistry & structure-property relationships - literature review. Faculty of Virginia Polytechnic Institute and State University;1999. 3–28. PhD Thesis.

30. Matsumoto T, Kurosaki T. Soluble and colorless polyimides with polyalicyclic structures. React Funct Polym. 1996; 30:55–59.

31. Min U, Chang JH. Colorless and transparent polyimide nanocomposite films containing organoclay. J Nanosci Nanotechnol. 2011; 11:6404–6409.

32. Gao H, Zhang ZT, Fan L, Wang DS, Zuo HJ, Sheng Y. Development of novel polyimide composite core materials reinforced with carbon fiber. Chinese J Prosthodont. 2007; 3:210–212.

33. Richardson RR Jr, Miller JA, Reichert WM. Polyimides as biomaterials: preliminary biocompatibility testing. Biomaterials. 1993; 14:627–635.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download