Abstract

PURPOSE

The aim of this study was to evaluate the interface accuracy of computer-assisted designed and manufactured (CAD/CAM) titanium abutments and implant fixture compared to gold-cast UCLA abutments.

MATERIALS AND METHODS

An external connection implant system (Mark III, n=10) and an internal connection implant system (Replace Select, n=10) were used, 5 of each group were connected to milled titanium abutment and the rest were connected to the gold-cast UCLA abutments. The implant fixture and abutment were tightened to torque of 35 Ncm using a digital torque gauge, and initial detorque values were measured 10 minutes after tightening. To mimic the mastication, a cyclic loading was applied at 14 Hz for one million cycles, with the stress amplitude range being within 0 N to 100 N. After the cyclic loading, detorque values were measured again. The fixture-abutment gaps were measured under a microscope and recorded with an accuracy of ±0.1 µm at 50 points.

RESULTS

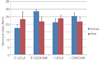

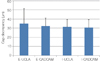

Initial detorque values of milled abutment were significantly higher than those of cast abutment (P<.05). Detorque values after one million dynamic cyclic loadings were not significantly different (P>.05). After cyclic loading, detorque values of cast abutment increased, but those of milled abutment decreased (P<.05). There was no significant difference of gap dimension between the milled abutment group and the cast abutment group after cyclic loading.

Computer-aided design/computer-aided manufacturing (CAD/CAM) technology allows restorative dentists to create a custom-made restoration in a short period of time that has only been possible through mass production. CAD/CAM technology has quickly begun replacing conventional manufacturing processes in commercial use in the early 1970s. The first CAD/CAM dental restoration was produced in 1983, and its applicability expanded into restorative aspects of implant dentistry in the early part of the 1990s.1-4

As the international gold price surged from the late 1970s to the early 1980s during the United States' economic depression, various all-ceramic restorations, including Dicor, Inceram, and Empress system were introduced into the market. With the recent rapid rise of the price of gold, the CAD/CAM technology and zirconia restorations have become more prominently developed and introduced. CAD/CAM titanium abutments offer the advantages of cast abutments, such as anatomic contour and correction of angulations. In comparison to cast abutments, there is no need for complicated and time-consuming casting and post-casting manipulations that may produce inaccuracies. There is also no need to buy high-priced abutment inventory.5 On the other hand, there are still several disadvantages of CAD-CAM abutments such as misfit between abutment base and fixture top portion depending on the manufacturer, relative strength problem of the titanium abutment compared to fixture, and limited applicability to cementation type prosthesis.

Wiskott et al.6 has mentioned that the screw joint stability depends on the relationships between the pretension of abutment screw, mating surface preload, and friction upon screw tightening. The screw joint stability improves with the increase of preload, but the preload cannot exceed the elastic limit of the screw material. Other researchers have reported that the screw joint stability also depends on the rotational movement of abutment and fit tolerances of the flat-to-flat of the implant hexagon to the abutment internal hexagon walls.7-9 Numerous studies have indicated that after implant osseointegration, abutment screw loosening appears to be the most common problem. The two most probable causes of abutment screw loosening is excessive bending of the joint and the settling effect of screw interfacial surfaces.10,11 Screw loosening occurs when the joint-separating forces acting on the screw joint are greater than the clamping forces holding the screw unit together. Excessive forces can cause slippage between threads of the screw and the bore, resulting in a loss of preload and screw loosening.11 The mechanism of "settling effect" is based on the fact that every machined surface exhibits some degree of microroughness. Under a dynamic load, micromovement may bring two surfaces of screw interface closer together. Thus, screw loosening will occur when the total settling effect is greater than the elastic elongation of the screw.

For cement-retained prostheses, abutment screw could be loosen in cases of too tapered abutments or failure to achieve passivity of the prosthesis. Meanwhile, misfit of the prostheses could induce metal fatigue, and finally screw loosening or fracture could happen in screw-retained type. Thus, each system has their characteristic problem, there has been trial to solve these by combining both system, such as screw- and cement-retained prostheses (SCPs). However, little is known about accuracy of fit and its correlation with stress transfer and even screw loosening.

There are several methods of assessing the screw joint stability and possibility of screw loosening of various implant systems. Martin and colleagues have recorded the micromotion of the screw joint interface after dynamic loading with strain gauge, while Cibirka et al. measured detorque value of abutment screw with a digital torque gauge.9,12,13

Several investigations have attempted to measure the fixture-abutment gap. One method is to measure the gap around the outer perimeter of the fixture-abutment connection. The other is to study the adaptation as a function of radius for more accuracy.14 According to Coelho, using the ground sections observed under a microscope at ×1000 magnification, adaptation values of interface as a function of radius were measured.15 The average gap distances found for all implants were constantly below 10 µm to the outer radius similar to previously published data. Because there may be morphologic aberrations, large variations can be present when measuring gaps. It is therefore of practical interest to know the minimal number of measurements necessary for determining gap sizes. Groten et al.16 reported that approximately fifty measurements along the margin yielded clinically relevant information and a consistent estimate for the gap size. The lower boundary for the minimum number of measurements did not depend on the size of the gap.17-21

The aim of this study was to assess the screw joint stability of CAD/CAM titanium and conventional gold-cast UCLA abutment with both external and internal connections. This was achieved by means of measuring the detorque values and the gaps between fixture and abutment after cyclic loading.

Two types of implant system (n=20) were used. Brånemark Mark III implant system (Nobel biocare, USA) as a representative of the external connection system (n=10), and Replace Select implant system (Nobel biocare, USA) which has the characteristic triangular internal connection structure (n=10) were selected for this study. For the superstructure of each system, Five of Mark III fixtures and five of Select fixtures were connected to the milled titanium abutment custom made by commercial manufacturer (ADDTECH, South Korea) with the CAD/CAM technology. Milling machine processed the titanium rod into the customized abutment. At first, the engaging connection part was precisely milled. Then, the rod was rotated upside-down and fixed. Finally, the remaining titanium around abutment top was cut out. The other 10 fixtures were connected to the UCLA abutment (Nobel biocare, USA) which was carved after wax add-up, burned out, and casted to the gold structure. One individual completed all waxing and castings for consistency.

To compensate for the different abutment height and width of specimens, custom crowns of the same height (8 mm) were fabricated by means of a lost wax technique. The upper surface of each crown was carved to make an even linear contact to the metal cylinder of the loading system. In the ease of removal after a cyclic loading, a small ball was added to the crown. The jig was customized by the ISO standard so that the force could be applied to the custom crown at 30 degrees off-axis to produce a clinically severe single tooth bending force or cantilever load. The specimen holder was fabricated to hold an implant body firmly and to set a distance from the loading action point to the exposed position of the fixture at 11 mm (Fig. 1).

Torque values and detorque values were measured by a digital torque gauge (MGT12, MARK-10 corp., Copiague, NY, USA), the details of which were as follows: the maximum measurement was 135 Ncm, the scale was 0.1 Ncm and the measurement error was 0.5%. The implant fixture and abutment were tightened to a torque of 35 Ncm using a digital torque gauge. Initial detorque values were measured 10 minutes after tightening using a digital torque gauge. After cyclic loading, the detorque values were measured by a digital torque gauge (Fig. 2).

After temporarily filling the screw hole with cotton and Caviton (GC corp., Tokyo, Japan), the custom crown was cemented temporarily with Cavitec (Kerr, Romulus, MI, USA). The prepared sample was fixed to the MTS loading machine.23,24 The programmable hydraulic loading machine (Mini Bionix II Test System, MTS; MTS systems corp., Eden Prairie, Minn., USA) was set under constant temperature (18℃) and humidity (38%). The load was set such that the stress amplitude range would be within a 0 N to 100 N range of the static strength, which is within the physiologic clinical range with a pulsating load of the sine wave.22 Cyclic loading was applied at 14 Hz for one million cycles, or the approximate equivalent of 1-year mastication (Fig. 3).

The fixture-abutment gap was evaluated with an optical microscope using image-processing software (Acura 2000; INTEK PLUS, Taejon-City, Korea) at the original magnification ×240. The accuracy of the optical microscope was +/-0.1 µm. The specimens were fixed horizontally under a microscope after the abutment screw was retightened to 35 Ncm. The gap was measured as the minimum distance from one point of the fixture edge to a line determined by the least squares of points at the abutment edge. All measurements and the least squared lines were computed by the programmed macro provided by Acura 2000 software system. The fixture-abutment gaps were measured and recorded with an accuracy of ±0.1 µm at 50 points. The means and standard deviations of the fixture-abutment fit were rounded to 1 µm level (Fig. 4).

SPSS statistical Software for Windows (release 12.0, SPSS Inc., Chicago, IL, USA) was used for statistical analysis. The means and standard deviations per group were calculated and statistical inferences among the groups were made using Mann-Whitney test at .05 level of significance.

The mean detorque values and standard deviations found in all groups before and after 106 cycles of loading are shown in Table 1. Initial detorque values of the CAD/CAM milled abutment groups were significantly higher than those of the UCLA cast abutment group. After excessive dynamic loading, neither the implants nor the abutments loosened and there were no signs of mechanical failure in the experimental model. In addition, the abutments did not show any signs of deformation or fracture. Detorque values after one million dynamic cyclic loadings were not significantly different among the groups. After the cyclic loading, detorque values of UCLA abutment increased, but those of CAD/CAM milled abutment decreased (Fig. 5).

CAD/CAM technology has been introduced in an attempt to overcome limitations of stock and custom cast abutments. The CAD/CAM titanium abutments fabricated in this study were milled to the desired morphological size and shape from solid blanks of titanium. There is no need to merge the prefabricated connection component and solid titanium blank together because of the precise milling process enabling the replication of the connection part. The CAD/CAM titanium abutment manufacturing process begins with a model fabrication from a fixture level impression. Using a laser scanner, the 3D data of a master model is put into the workstation computer. At this time, the precise location and angulation of the fixture top is recorded. After checking occlusion of a virtual tooth from the CAD program, the height, width, and the angulation of abutment are adjusted to maintain an ideal space between the virtual tooth and abutment. Finally, the titanium rod is milled into the customized abutment and the abutment is evaluated on the master cast.

The UCLA abutment used in this study is the premachined abutments made of gold alloy, which can be cast directly onto to allow integration of the restoration with the abutment. It has the advantages of overcoming angulation and esthetic problem, but it may reflect difficulties with distortions introduced by the casting technique, and/or porcelain firing cycles or limitations inherent in the finishing procedures. Byrne and his colleagues reported a lesser screw contact in premachined UCLA abutments cast onto and subjected to porcelain firing cycles than in the same abutments that were not cast onto or subjected to porcelain firing cycles.14 Possible reasons for this finding relate to stress release within the premachined abutments induced with heat during the procedures or distortion induced by contraction of the surrounding casting. These may lead to changes at the implant-abutment interface. A poor fit with resultant lack of frictional resistance to rotation may be a possible cause of screw loosening.25 For this reason, the comparative studies between the premachined UCLA abutment and the CAD/CAM milled titanium abutment were performed by measuring detorque values and gap dimensions.

Two implant designs from the same manufacturer were selected in this study to represent both the external and internal designs in the screw joint stability. The Brånemark Mark III implant was used for the design of the external connection, and hexagonal feature for rotational resistance, indexing, and lateral stabilization. The Replace Select implant has an internal cylindrical connection with three cams that fit into slots in the inner implant wall. Quek and his colleagues26 evaluated the load fatigue performance of four implant-abutment interface designs. While one abutment screw fracture and two implant fractures were noted out of 15 samples of the Brånemark group, there was no abutment screw fracture and one implant failure out of 15 Replace Select samples, and load fatigue failure occurred at the weakest point of the implant. Steinebrunner et al.27 reported that tube-in-tube connection of the Replace Select and Camlog implant system showed significantly longer survival times under dynamic loading than the other tested implant groups. In their study, the increased length of the implant-abutment joint was suggested as a reason for the good outcome. While the ratio of the tube diameter to the length of the joint is 1.36 in the Replace Select system, that of the Brånemark system is 0.16. The longer the internal lever arm, the less force is transferred to the internal wall, and the force is distributed more evenly. In combination with the cam-slot fixation, this structure may minimize micromovement at the screw joint and prevent screw loosening. In this study, although not statistically significant, the absolute deviation of detorque value in the internal connection group is smaller than that of the external connection group (Table 1). This result shows that most of the tensile force may be transferred to the internal wall instead of the abutment screw and the abutment screw can be subjected to little force for the tube-in-tube connection design implants.

Dimensions, properties, or conditions may vary within certain practical limits without significantly affecting the function of equipment or a process. Tolerances are specified to allow reasonable leeway for imperfections and inherent variability without compromising performance. Dimensional tolerance is related to fit in mechanical engineering, which is a designed-in clearance or interference between two parts.28 The CAD/CAM titanium abutment fabricated in this study was milled with the dimensional tolerance recommended by the manufacturer. The significantly higher mean initial detorque value of the CAD/CAM milled abutment than that of the UCLA abutment was due to the narrow dimensional tolerance of the CAD/CAM abutment manufacturer, which is different from Nobel biocare recommendations. Closer or tighter tolerances are more difficult, and hence costly, to achieve. Conversely, larger or looser tolerances may significantly affect the operation of the device. It is important to determine how wide the tolerances may be without affecting the fitness of abutment-implant interface.

Cold welding is a solid-state welding process in which joining takes place without fusion at the interface of the two parts to be welded. Because of the plastic deformation involved, it is necessary that at least one of the mating parts be ductile. Exposure to oxygen or certain other reactive compounds produces surface layers that reduce or eliminate the cold welding effect. This is especially true if, for example, a metal oxide has mechanical properties similar to those of the parent element, in which case surface deformations do not crack the oxide film. The reason cold welding does not normally occur between metals is that there is a very fine layer of oxidized metal. For the same reason, the interface is degreased, wire-brushed, and wiped to remove oxide smudges prior to the intentional cold welding.29 Sutter et al.30 demonstrated that the loosening torque of ITI Morse taper design was 124% of the tightening torque at a clinically relevant level of 25 Ncm; however, little information was given as to the nature of the apparatus to record this data. Norton31 evaluated the loosening torque and for clinically relevant levels of tightening touque (20 to 40 Ncm), the loosening torque decreased and cold welding did not occur. In this study, detorque values of all the gold UCLA abutment samples increased after cyclic loading. We suggest that the increase of detorque value may be the cause of cold welding of ductile gold to titanium after one million cycles of pulsating loads equivalent to a one-year mastication.

Meanwhile, there were more gap discrepancy in external type implant for both UCLA & CAD/CAM abutments comparing to the internal type implant. There seems relatively more stress for the external-implant abutment connection comparing to the internal type, which is caused by the different load transfer mechanism. Also, joint instability caused by the micromovement may induce more gap discrepancy as well in the external type implant-abutment joint.

In this study, the fifty gap measurements around the outer perimeter of the fixture-abutment connection for each specimen were performed with a microscope. The minimum of 50 measurements necessary for determining gap sizes is based on a report by Groten.16 This survey was originally performed to measure single crowns. Because the morphologic aberrations of implant components are unnoticeable and the gap discrepancy of fixture-abutment interface is smaller than that of a tooth-crown margin, a number of 50 are sufficient for the consistent estimate of the mean gap discrepancy.

The results of these experiments demonstrate that CAD/CAM titanium abutments can be fabricated with sufficient accuracy to permit screw joint stability between abutment and fixture comparable to that of the traditional gold cast UCLA abutment. These findings may have important implications, since the price for fabrication can be reduced once the process becomes organized. The occlusal force is distributed in a complex manner in vector and magnitude in vivo. For this study, the load was applied on a single implant crown with an already determined magnitude and vector for a limited time. The actual preload achieved in the components is dependent on the friction between components, finish of the interfacial surface, and material properties. Even within the same prosthetic components, there may be differences in the actual preload. For this study, we focused solely on abutment and connection design, and did not consider those factors mentioned above. In addition to the earlier limitations, investigations involving more realistic loading conditions and larger sample sizes are necessary for future research.

Although the CAD/CAM milled titanium abutment was more resistant to screw loosening than the UCLA abutment immediately after initial tightening, it was more difficult to loosen the UCLA abutment after one million cycles of loading. This may be the result of a cold welding not anticipated with the CAD/CAM titanium abutment. There was also no gap dimension difference between the CAD/CAM milled abutment group and the UCLA abutment group.

Figures and Tables

| Fig. 3Cyclic loading application (Mini Bionix II Test System and mounted implant-abutment-crown complex). |

| Fig. 7Fixture-abutment gap discrepancy shown under light microscope of Acura 2000 system (×240). There was no major morphologic aberration at the fixture-abutment gap in all groups. A: External/UCLA, B: External/CADCAM, C: Internal/UCLA, D: Internal/CADCAM. |

Table 1

Detorque values before and after 106 cycles of loading

References

1. Duret F, Blouin JL, Duret B. CAD-CAM in dentistry. J Am Dent Assoc. 1988; 117:715–720.

2. Priest G. Virtual-designed and computer-milled implant abutments. J Oral Maxillofac Surg. 2005; 63:22–32.

3. Calamia JR. Advances in computer-aided design and computer-aided manufacture technology. J Philipp Dent Assoc. 1996; 48:31–40.

4. Duke ES. The status of CAD/CAM in restorative dentistry. Compend Contin Educ Dent. 2001; 22:968–972.

5. Grossmann Y, Pasciuta M, Finger IM. A novel technique using a coded healing abutment for the fabrication of a CAD/CAM titanium abutment for an implant-supported restoration. J Prosthet Dent. 2006; 95:258–261.

6. Wiskott HW, Belser UC, Scherrer SS. The effect of film thickness and surface texture on the resistance of cemented extracoronal restorations to lateral fatigue loading. Int J Prosthodont. 1999; 12:255–262.

7. Binon PP. Evaluation of machining accuracy and consistency of selected implants, standard abutments, and laboratory analogs. Int J Prosthodont. 1995; 8:162–178.

8. Binon PP, McHugh MJ. The effect of eliminating implant/abutment rotational misfit on screw joint stability. Int J Prosthodont. 1996; 9:511–519.

9. Cibirka RM, Nelson SK, Lang BR, Rueggeberg FA. Examination of the implant-abutment interface after fatigue testing. J Prosthet Dent. 2001; 85:268–275.

10. Jörnéus L, Jemt T, Carlsson L. Loads and designs of screw joints for single crowns supported by osseointegrated implants. Int J Oral Maxillofac Implants. 1992; 7:353–359.

11. McGlumphy EA, Mendel DA, Holloway JA. Implant screw mechanics. Dent Clin North Am. 1998; 42:71–89.

12. Haack JE, Sakaguchi RL, Sun T, Coffey JP. Elongation and preload stress in dental implant abutment screws. Int J Oral Maxillofac Implants. 1995; 10:529–536.

13. Martin WC, Woody RD, Miller BH, Miller AW. Implant abutment screw rotations and preloads for four different screw materials and surfaces. J Prosthet Dent. 2001; 86:24–32.

14. Byrne D, Houston F, Cleary R, Claffey N. The fit of cast and premachined implant abutments. J Prosthet Dent. 1998; 80:184–192.

15. Coelho AL, Suzuki M, Dibart S, DA Silva N, Coelho PG. Cross-sectional analysis of the implant-abutment interface. J Oral Rehabil. 2007; 34:508–516.

16. Groten M, Girthofer S, Pröbster L. Marginal fit consistency of copy-milled all-ceramic crowns during fabrication by light and scanning electron microscopic analysis in vitro. J Oral Rehabil. 1997; 24:871–881.

17. Groten M, Axmann D, Pröbster L, Weber H. Determination of the minimum number of marginal gap measurements required for practical in-vitro testing. J Prosthet Dent. 2000; 83:40–49.

18. Sorensen JA. A standardized method for determination of crown margin fidelity. J Prosthet Dent. 1990; 64:18–24.

19. Anusavice KJ, Carroll JE. Effect of incompatibility stress on the fit of metal-ceramic crowns. J Dent Res. 1987; 66:1341–1345.

20. Rinke S, Hüls A, Jahn L. Marginal accuracy and fracture strength of conventional and copy-milled all-ceramic crowns. Int J Prosthodont. 1995; 8:303–310.

21. Yeo IS, Yang JH, Lee JB. In vitro marginal fit of three all-ceramic crown systems. J Prosthet Dent. 2003; 90:459–464.

22. Richter EJ. In vivo vertical forces on implants. Int J Oral Maxillofac Implants. 1995; 10:99–108.

23. Sakaguchi RL, Douglas WH, DeLong R, Pintado MR. The wear of a posterior composite in an artificial mouth: a clinical correlation. Dent Mater. 1986; 2:235–240.

24. Hakimeh S, Vaidyanathan J, Houpt ML, Vaidyanathan TK, Von Hagen S. Microleakage of compomer class V restorations: effect of load cycling, thermal cycling, and cavity shape differences. J Prosthet Dent. 2000; 83:194–203.

25. Lewis S, Beumer J 3rd, Hornburg W, Moy P. The "UCLA" abutment. Int J Oral Maxillofac Implants. 1988; 3:183–189.

26. Quek HC, Tan KB, Nicholls JI. Load fatigue performance of four implant-abutment interface designs: effect of torque level and implant system. Int J Oral Maxillofac Implants. 2008; 23:253–262.

27. Steinebrunner L, Wolfart S, Ludwig K, Kern M. Implant-abutment interface design affects fatigue and fracture strength of implants. Clin Oral Implants Res. 2008; 19:1276–1284.

28. Pyzdek T. Quality engineering handbook. In : Keller PA, editor. Planning, controlling, and assuring product and process quality. 2nd ed. New York: Marcel Dekker;2003. p. 226–230.

29. Kalpakjian S. Manufacturing engineering and technology. In : Schmid S, editor. Cold welding and roll bonding. 5th ed. Upper Saddle River, NJ: Pearson/Prentice Hall;2006. p. 981.

30. Sutter F, Weber HP, Sorensen J, Belser U. The new restorative concept of the ITI dental implant system: design and engineering. Int J Periodont Res Dent. 1993; 13:409–431.

31. Norton MR. An in vitro evaluation of the strength of an internal conical interface compared to a butt joint interface in implant design. Clin Oral Implants Res. 1997; 8:290–298.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download