Abstract

PURPOSE

The purpose of this study was to evaluate and compare the translucency of shaded zirconia all-ceramic systems.

MATERIALS AND METHODS

Translucency of 3 different zirconia all-ceramic systems colored by different techniques was compared with a lithium disilicate glass-ceramic (IPS e.max Press). Square-shaped specimens with 0.5 mm thickness were fabricated from In-Ceram YZ, ICE Zirkon and Katana systems in A1, A2 and A3.5 shades according to Vitapan Classical shade tab (n=11). Specimens were then veneered and glazed with corresponding veneer ceramic recommended by each zirconia system manufacturer and the total thickness was set to 1.5 mm. Translucency measurements were performed with VITA Easyshade Compact spectrophotometer after each stage and translucency parameter was calculated. Data were statistically analyzed with repeated measures ANOVA and Tukey multiple comparison test.

RESULTS

The control group was significantly more translucent than the zirconia systems (P<.05). ICE Zirkon cores showed the least translucency; neither In-Ceram YZ nor Katana systems were superior to each other in terms of translucency. Translucency of all specimens was decreased after veneering, and the translucency rankings were changed.

CONCLUSION

Coloring technique did not have a significant effect on translucency of zirconia cores. Although zirconia systems were less translucent than lithium disilicate glass ceramic, they had partial translucency and there were translucency differences among the zirconia systems. Chroma affected the translucency of precolored zirconia cores.

An esthetically pleasing restoration should mimic the natural tooth in terms of shade, shape, size, surface texture and translucency.1 Although porcelain fused to metal restorations have a long history of clinical success, the opaque metal substructure causes undesirable light reflection and accordingly, esthetically unpleasant restoration.2 The increased demand of patients for natural looking restorations has resulted in the development of new all-ceramic systems.3,4 The absence of opaque metal substructure in all-ceramic restorations provides a deeper translucency similar to natural tooth2 which was described as one of the primary factors in controlling esthetics.5

Among the all-ceramic systems, zirconia-based ceramics are highly attractive for clinicians,6 since they fulfill the biomechanical requirements; namely, chemical and dimensional stability, high mechanical strength, and fracture toughness.4,7 However, increasing the crystalline content of all-ceramic materials to achieve a greater strength results in greater opacity5,8 because of the different refractive indices and the inhomogeneity of crystals.9 When compared to other all-ceramic systems, zirconia cores have poor translucency and too white for an esthetic appearance.10,11,12,13 Therefore, shaded zirconia cores were developed in order to improve the optical behavior of the restorations.7,14,15,16

Two main techniques are available for coloring zirconia. In one technique, various metal oxides are added to Y-TZP powder before sintering at high temperature. The other technique involves immersion of the machined restorations in chloride solutions of rare earth elements before sintering.15,17 The concentration of the solution influenced the final shade6,15 while duration of immersion did not.15

The effects of coloring on mechanical properties,15,16,18 microstructure,15 and surface microhardness16 of the zirconia have been investigated. The available data on the translucency of shaded zirconia cores are limited.19,20 In a recent study,21 it has been reported that coloring liquids decreased the translucency of zirconia frameworks. Coloring method may also affect the intensity of the shade and therefore translucency of the material. However, to the best of authors' knowledge, there is no literature regarding the effect of coloring techniques on the translucency of zirconia. The purpose of this in vitro study was to evaluate the translucency of zirconia core specimens in 3 different shades and veneered specimens of different zirconia-based all-ceramic systems, and compare the coloring techniques in terms of translucency. The hypothesis tested was that the coloring technique would affect the translucency of specimens and precolored specimens would show a greater translucency.

In the present study, 3 different zirconia-based all-ceramic systems [In-Ceram YZ (VYZ), ICE Zirkon (ICE), Katana (KTN)] were tested and a lithium disilicate all-ceramic system (IPS e.max Press) served as the control group (Table 1).

Thirty-three square-shaped (12 mm × 12 mm × 0.5 mm) specimens were fabricated for each zirconia-based all-ceramic system and control group (totally 132) following the manufacturers' instructions. Specimens were further divided into 3 groups (n=11) for coloring to A1, A2 and A3.5 shades according to Vitapan Classical Shade Guide (VITA Zahnfabrik, Bad Säckingen, Germany).

For fabricating IPS core specimens, square-shaped wax patterns were prepared 12 mm × 12 mm × 1 mm and invested in a phosphate-bonded investment (IPS Press Vest Speed, Ivoclar Vivadent, Schaan, Liechtenstein) by using a crucible provided by the manufacturer, and burned out in a furnace (VITA Vacumat 300; VITA Zahnfabrik, Bad Sächingen, Germany) at 850℃. Medium opacity (MO) ingots MO1, MO2 and MO3 were used to obtain A1, A2, and A3.5 shades, respectively. The specimens were heat-pressed (Ivoclar EP600 Combi, Ivoclar Vivadent, Schaan, Liechtenstein), and then left at room temperature for 30 minutes. The remnants of the investment material were removed by using airborne-particle abrasion with 50-µm glass beads (Strahlmittel Abrasives, Rolloblast, Boley, Germany). For surface finishing, a polishing machine (Phoenix Beta, Buehler, IL, USA) and 400, 600, 800, 1000 and 1200 grades of silicon carbide papers (Buehler Abrasives, Düsseldorf, Germany) were used. The thicknesses of the specimens were controlled with a digital caliper (Max-Extra Professional Tools, Guangzhou, China) with an accuracy of 0.01 mm during the procedures and final thickness was set to 0.5 ± 0.05 mm.

Thirty-three VYZ core specimens were fabricated from In-Ceram YZ blocks (VITA In-Ceram 2000 YZ CUBES for inLab) milled with CAD/CAM system (Cerec inLab, Sirona Denatl Systems, Bensheim, Germany) in partially sintered state. Specimens were subdivided into 3 groups and immersed in coloring liquids LL1, LL2, and LL3 (Coloring Liquid for VITA In-Ceram 2000 YZ CUBES, Bad Säckingen, Germany) equivalent to A1, A2, and A3.5 shades, respectively, for 2 minutes. Specimens were left to dry and then sintered in a sintering furnace (Thermo-Star GmbH, Aachen, Germany) according to manufacturer's heat and time instructions. At the end of the process, the thicknesses of specimens were controlled with the digital caliper and specimens with the dimensions of 12 mm × 12 mm × 0.5 mm were obtained.

ICE specimens were fabricated with a manual copy-milling machine (Zirkograph 025 ECO, ZirkonZahn, Bruneck, Italy). Individual tray material light cured hybrid resin composite (Plaque Photo, W+P Dental, Hamburg, Germany) was used to prepare specimens before the copy-milling. 12 mm × 12 mm specimens were cut from resin composite plaques and polymerized (Tray Lux, Ampac Dental, Rockdale, Australia). The specimens were ground and polished and the thicknesses of specimens were set to 0.5 ± 0.05 mm. Zirconia specimens were milled according to resin composite samples from ICE Zirkon blocks (Prettau Zirconia Blank 12). Milled specimens were immersed in coloring liquids (Color Liquid Prettau, ZirkonZahn, Bruneck, Italy) in shades A1, A2, and A3.5 for 10 seconds. After drying process, the specimens were sintered in furnace (Zirkonofen, Zirkon Zahn, Bruneck, Italy) according to manufacturer's heat and time instructions. Thicknesses of the specimens were controlled with the digital caliper.

The KTN specimens were designed in CAD software (Dentalwings Inc., Montreal, Quebec, Canada) of the system according to desired dimensions. Precolored blocks in shades of KT12, KT13, and KT14 (Zirconia Block) that are equivalent to A1, A2, and A3.5 shades, respectively, were milled with CAD/CAM system (DWX-50N, Noritake Dental, Aichi, Japan) at presintered stage. Sintering process was performed according to manufacturer's instructions. After sintering, the thicknesses of the specimens were controlled with the digital caliper.

Before translucency measurements, all of the specimens were ultrasonically cleaned in distilled water for 10 minutes, and then dried with compressed air.

Prior to translucency measurements, thicknesses of the specimens were controlled with a digital caliper and the thicknesses of all specimens were set to 0.5 ± 0.05 mm (Fig. 1). Translucency measurements were performed with a clinical spectrophotometer (VITA Easyshade Compact, VITA Zahnfabrik, Bad Säckingen, Germany). VITA Easyshade Compact is a cordless hand-held spectrophotometer with a contact probe tip that has a diameter of 5 mm. During the measurement process, the illumination of the specimen is achieved by directing the LED light from the periphery of the tip into the specimen surface. The display presents the closest VITA shade in the VITA Classical or VITA 3D-MASTER shade guide designation and CIE L*a*b* color system. CIE L*a*b* color system defines color space by L*, a*, and b* coordinates. L* represents the lightness, or black/white character of the color. The coordinates a* and b* describe the chromatic characteristics of the color. The a* coordinate represents the red-green axis and b* coordinate represents the yellow-blue axis.

Translucency was evaluated with translucency parameter (TP). Measurements were performed in the viewing booth under D65 illumination. Specimens were placed over white (L* = 96.3, a* = 0.1, b* = 1.9) and black (L* = 8.9, a* =-0.7, b* = 1.2) tiles and "tooth single" mode was selected (Fig. 2). Measurements were repeated 3 times for each specimen on each background and the mean CIE L*a*b* values were recorded for both backgrounds. TP was obtained by calculating the color difference between the specimen over the white background and that over the black background with the following formula:22

TP = [(L*B - L*W)2+(a*B - a*W)2+(b*B - b*W)2]1/2

Subscript B corresponds to the color coordinates over the black background and subscript W corresponds to those over the white background. If the material is absolutely opaque, TP value is zero; if the material is totally transparent, TP value is 100. The greater the TP value, the higher the translucency of the material.

After translucency measurements core specimens were veneered and glazed by a single dental technician using ceramics (A1, A2, and A3.5 shades) recommended by manufacturers (Table 1). Veneering was carried out with dentin ceramic in accordance to the manufacturer's instructions for mass preparation, condensing, baking temperature and time (Table 2).

The overall thicknesses of the veneered core specimens with dentin ceramic were aimed to be 1.5 mm with single firing process. Therefore, approximately 1.5 mm dentin ceramic in thickness was applied on core specimen with layering technique considering the firing shrinkage of the ceramics. Veneering ceramic slurry was condensed and hand-vibrated; excess moisture was removed with absorbent paper tissue to minimize porosity. After firing the veneered specimens in a ceramic furnace (Programat P300, Ivoclar Vivadent, Schaan, Liechtenstein), the thicknesses of the specimens were controlled with the digital caliper. Excess ceramic material was removed with a diamond rotary cutting instrument (863-204-016; Gebr Brasseler GmbH, Lemgo, Germany) until the desired thickness of dentin ceramic was achieved. A thin layer of glazing liquid was applied on veneered specimens, and specimens were glazed in the ceramic furnace following the manufacturers' instructions (Table 2). All of the specimens were ultrasonically cleaned in distilled water for 10 minutes and then dried with compressed air before the translucency measurements. After veneering and glazing procedures, the thicknesses of the specimens were controlled again with a digital caliper and the thicknesses of all specimens were set to 1.5 ± 0.05 mm. Afterwards, translucency measurements were repeated and TP was calculated as previously described.

Normality of the data distribution was checked by the Shapiro-Wilks test and parametric tests were chosen since the data were distributed normally. TP values of A1, A2 and A3.5 shaded core, veneered, and glazed specimens of the same all-ceramic system (intragroup comparison) and TP values of the same shaded core, veneered, and glazed specimens of different all-ceramic systems (intergroup comparison) were analyzed by repeated-measures ANOVA using the SPSS software version 10.0 (SPSS Inc., Chicago, IL, USA). Post hoc comparisons were performed by using the Tukey test when significance was detected. Values of P<.05 were accepted as statistically significant.

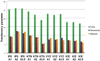

Comparison of the TP values of core, veneered and glazed ceramics are shown in Fig. 3. The mean TP values and standard deviations obtained for each group are summarized in Table 3. The translucencies of zirconia core specimens were significantly lower than the glass ceramic for all shades (P<.05). ICE core specimens were the least translucent group among the tested systems. For A1 shaded core specimens, TP values of KTN core specimens were higher than VYZ specimens; despite that, the TP values of A3.5 shaded VYZ specimens were higher than KTN specimens. However, there was no statistically significant translucency difference between A2 shaded VYZ and KTN specimens (P>.05). The translucencies of IPS, VYZ and ICE core specimens were not affected by the chroma, whereas, for KTN specimens, the greater the chroma of the core, the lower the TP values.

Statistical analysis revealed that veneering decreased the TP values of all specimens. The translucency level of veneering ceramic affected the overall translucency of the specimens. A3.5 shaded KTN core specimens were more translucent than ICE core specimens. However, after veneering, the TP values of A3.5 shaded ICE specimens were higher than A3.5 shaded KTN specimens (P<.01).

Significant differences were also found in the TP values of glazed specimens. Ranging from most translucent to the least, the rankings for A1 shaded specimens were IPS, KTN, VYZ > ICE; for A2 shaded specimens were IPS > KTN, VYZ > ICE and for A3.5 shaded specimens were IPS > VYZ > ICE > KTN. A slight decrease or increase in TP values of veneered specimens after glazing were detected, however, the difference between the TP values of veneered and glazed specimens was not statistically significant (P>.05).

In the present study, lithium disilicate based glass ceramic specimens showed higher translucency compared to zirconia-based all-ceramic systems. The hypothesis that coloring technique of zirconia would affect the translucency and precolored zirconia cores would have a greater translucency was partially rejected because the statistical analysis revealed that precolored KTN core specimens were more translucent than ICE core specimens; however, VYZ and KTN core specimens were not superior to each other in terms of translucency. Therefore, according to the results of the present study, it cannot be suggested that precolored zirconia cores have a greater translucency.

The zirconia all-ceramic systems compared in this study were preferred because of the differences among the systems in terms of coloring method or milling process. KTN system has precolored blocks in 9 different shades and the core materials are milled by a CAD/CAM system. VYZ and ICE systems use coloring liquids for shading zirconia cores. The difference between VYZ and ICE systems is the milling process of zirconia. VYZ cores are fabricated with a CAD/CAM system while ICE cores are milled by a manual copy-milling machine. IPS is a lithium disilicate all-ceramic system of which physical properties and translucency are improved in comparison to other press-ceramics.4 Similar to a previous study13 IPS system was preferred as control group in this study since it may be a good alternate to zirconia ceramics in esthetic regions. MO ingot of the system was chosen which is indicated for slightly discolored teeth and layering technique of veneer ceramics.

To achieve an esthetic appearance, the total optical behavior of the restoration should be similar to that of the natural tooth by controlling the light absorption, reflection, and transmission in the ceramic material.2 Therefore, the translucency level of the core and veneer material is of great concern for all-ceramic systems. Three methods are present for evaluating the translucency of dental ceramics: direct transmission, total transmission, and spectral reflectance.23 In the present study TP method was used in which the spectral reflectance was determined. The TP defines the difference between reflected colors of a material with a uniform thickness over a black and a white background, and provides a value corresponding directly to human visual perception of translucency.22 Spectrophotometers has been used generally for instrumental translucency determination.11,24,25,26,27 However, spectrophotometers with small window size may cause edge loss phenomenon which affects the accuracy of measurements.28 Lim et al.23 compared the TP values obtained by a spectrophotomer and a spectroradiometer and found that the values showed a high correlation; however the authors suggested that TP values obtained by the spectroradiometer have greater clinical relevance. Therefore, in further studies, the translucency of the materials tested in the present study should also be evaluated with a spectroradiometer.

Chen et al.11 evaluated the relative translucency of core ceramics and suggested that zirconia-based ceramic (Cercon) and 33%-volume zirconia-toughened alumina (In-Ceram Zirconia) were highly opaque. Heffernan et al.10 also reported that the translucency of In-Ceram Zirconia was equal to those of metal ceramics. However, Baldissara et al.13 compared the translucencies of zirconia-based core ceramics and lithium disilicate glass ceramic and stated that even the glass ceramic showed significantly higher translucency, all of the zirconia based ceramics evaluated might be considered translucent to a certain degree. There are other studies19,20,29 in the literature that support the data of aforementioned study.13 Moreover, Pecho et al.20 suggested that zirconia-based ceramics (IPS e.max ZirCAD and LAVA) had translucency similar to human dentine. The findings of the present study were also in agreement with the previous studies.13,19,20,29

In the present study, core specimens were veneered with the dentin ceramics recommended by the manufacturer's instruction. Translucency of the veneer ceramics were not known because as a limitation of the study, TP values of veneer ceramics were not evaluated separate from the core ceramics. However, the data obtained from this study showed that the translucency of veneer ceramic is as important as the translucency of core material since the TP values decreased and the translucency ranking of the systems changed after veneering. A previous study by Heffernan et al.30 also reported that the opacity of core specimens increased after they were veneered. The authors30 suggested that the crystal volume and size of veneer ceramic, increased specimen thickness, reflectance at the interface between the core and veneer ceramic, and the changes occurred in core material after additional firing might cause the translucency difference. According to the results of this study, it can be suggested that the translucency of veneer ceramics should also be considered in evaluation of the overall translucency of the zirconia-based all-ceramic systems. However, glazing did not cause a significant change in the translucency of the veneered specimens.

To evaluate the effect of the chroma on translucency, the core specimens were prepared in 3 different shades and compared within each system. Among the tested systems, statistically significant difference was detected between the different shaded core specimens of KTN system. TP values decreased with the increase of the chroma of core specimens. This might be due to the more or darker pigmentation in the specimens with high chroma that affected the light reflection.19 Coloring method may also affect the intensity of the pigmentation since it has been shown that the concentration of the coloring solution affect the final shade.6,15 Therefore, precolored blocks might provide more homogeneous and more intense shade than the immersion method. This finding should be taken into consideration when a restoration in higher chroma is planned to fabricate with KTN system. When the veneered specimens were evaluated, a statistically significant translucency difference between the different shaded specimens of control group was found. This finding also indicated the potential effect of veneering ceramic on the overall translucency of the specimen.

It has been shown that thickness of the core material had an effect on the translucency of all-ceramics.10 As a limitation of this study, all of the core specimens were fabricated in a single thickness of 0.5 mm. The tablet shape of the specimens may be another limitation since the specimens in coping form may be of greater clinical relevance. Further studies are required to evaluate shaded zirconia core specimens in coping forms with different core/veneer thicknesses.

Significant translucency differences were detected among the zirconia-based all-ceramic systems tested in this study. For esthetic appearance, more translucent zirconia systems like VYZ and KTN may be preferred whereas for masking discoloration less translucent systems may be more advantageous. Besides the esthetics, translucency of the all-ceramics systems should be considered when deciding the cement type. Light transmission through the ceramics was found to be efficient on the polymerization degree of resin cements.31 For less translucent all-ceramics as ICE system, dual-cured resin cements may be preferred instead of light-cured resin cements for sufficient curing.

Within the limitations of the present study, translucencies of zirconia all-ceramic systems were found significantly lower than lithium disilicate glass-ceramic. ICE Zirkon was the least translucent system among the zirconia-based all-ceramic systems. Neither VYZ nor KTN systems were superior to each other in terms of translucency. Coloring technique did not have an effect on the translucency of the shaded zirconia cores. However, chroma affected the translucency of precolored zirconia specimens.

Figures and Tables

Fig. 2

Translucency measurements of the specimens with a spectrophotometer over white (A) and black (B) backgrounds.

Table 1

Materials tested

Table 2

Firing procedures of ceramics

Table 3

Mean TP values and standard deviations of core, veneered and glazed specimens. Same letters show no statistically significant difference

References

1. Rosenstiel SF, Land MF, Fujimoto J. Contemporary fixed prosthodontics. St. Louis, Mo: Mosby Elsevier;2006. p. 774.

2. Raptis NV, Michalakis KX, Hirayama H. Optical behavior of current ceramic systems. Int J Periodontics Restorative Dent. 2006; 26:31–41.

3. Raigrodski AJ. Contemporary materials and technologies for all-ceramic fixed partial dentures: a review of the literature. J Prosthet Dent. 2004; 92:557–562.

4. Conrad HJ, Seong WJ, Pesun IJ. Current ceramic materials and systems with clinical recommendations: a systematic review. J Prosthet Dent. 2007; 98:389–404.

5. Kelly JR, Nishimura I, Campbell SD. Ceramics in dentistry: historical roots and current perspectives. J Prosthet Dent. 1996; 75:18–32.

6. Denry I, Kelly JR. State of the art of zirconia for dental applications. Dent Mater. 2008; 24:299–307.

7. Aboushelib MN, de Jager N, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Dent Mater. 2005; 21:984–991.

8. Holloway JA, Miller RB. The effect of core translucency on the aesthetics of all-ceramic restorations. Pract Periodontics Aesthet Dent. 1997; 9:567–574. quiz 576.

9. Jiang L, Liao Y, Wan Q, Li W. Effects of sintering temperature and particle size on the translucency of zirconium dioxide dental ceramic. J Mater Sci Mater Med. 2011; 22:2429–2435.

10. Heffernan MJ, Aquilino SA, Diaz-Arnold AM, Haselton DR, Stanford CM, Vargas MA. Relative translucency of six all-ceramic systems. Part I: core materials. J Prosthet Dent. 2002; 88:4–9.

11. Chen YM, Smales RJ, Yip KH, Sung WJ. Translucency and biaxial flexural strength of four ceramic core materials. Dent Mater. 2008; 24:1506–1511.

12. Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Effect of zirconia type on its bond strength with different veneer ceramics. J Prosthodont. 2008; 17:401–408.

13. Baldissara P, Llukacej A, Ciocca L, Valandro FL, Scotti R. Translucency of zirconia copings made with different CAD/CAM systems. J Prosthet Dent. 2010; 104:6–12.

14. Manicone PF, Rossi Iommetti P, Raffaelli L. An overview of zirconia ceramics: basic properties and clinical applications. J Dent. 2007; 35:819–826.

15. Shah K, Holloway JA, Denry IL. Effect of coloring with various metal oxides on the microstructure, color, and flexural strength of 3Y-TZP. J Biomed Mater Res B Appl Biomater. 2008; 87:329–337.

16. Hjerppe J, Närhi T, Fröberg K, Vallittu PK, Lassila LV. Effect of shading the zirconia framework on biaxial strength and surface microhardness. Acta Odontol Scand. 2008; 66:262–267.

17. Kulkarni NK, Sampath S, Venugopal V. Studies on stabilised zirconia as host phase for the fixation of actinides, rareearths and sodium. Ceram Int. 2001; 27:839–846.

18. Pittayachawan P, McDonald A, Petrie A, Knowles JC. The biaxial flexural strength and fatigue property of Lava Y-TZP dental ceramic. Dent Mater. 2007; 23:1018–1029.

19. Spyropoulou PE, Giroux EC, Razzoog ME, Duff RE. Translucency of shaded zirconia core material. J Prosthet Dent. 2011; 105:304–307.

20. Pecho OE, Ghinea R, Ionescu AM, CardonaJde L, Paravina RD, Pérez Mdel M. Color and translucency of zirconia ceramics, human dentine and bovine dentine. J Dent. 2012; 40:e34–e40.

21. Tuncel I, Eroglu E, Sari T, Usumez A. The effect of coloring liquids on the translucency of zirconia framework. J Adv Prosthodont. 2013; 5:448–451.

22. Johnston WM, Ma T, Kienle BH. Translucency parameter of colorants for maxillofacial prostheses. Int J Prosthodont. 1995; 8:79–86.

23. Lim HN, Yu B, Lee YK. Spectroradiometric and spectrophotometric translucency of ceramic materials. J Prosthet Dent. 2010; 104:239–246.

24. Ahn JS, Lee YK. Difference in the translucency of all-ceramics by the illuminant. Dent Mater. 2008; 24:1539–1544.

25. Kurtulmus-Yilmaz S, Cengiz E, Ulusoy N, Ozak ST, Yuksel E. The effect of home-bleaching application on the color and translucency of five resin composites. J Dent. 2013; 41:e70–e75.

26. Spink LS, Rungruanganut P, Megremis S, Kelly JR. Comparison of an absolute and surrogate measure of relative translucency in dental ceramics. Dent Mater. 2013; 29:702–707.

27. Kim MJ, Ahn JS, Kim JH, Kim HY, Kim WC. Effects of the sintering conditions of dental zirconia ceramics on the grain size and translucency. J Adv Prosthodont. 2013; 5:161–166.

28. Bolt RA, Bosch JJ, Coops JC. Influence of window size in small-window colour measurement, particularly of teeth. Phys Med Biol. 1994; 39:1133–1142.

29. Kumagai N, Hirayama H, Finkelman MD, Ishikawa-Nagai S. The effect of translucency of Y-TZP based all-ceramic crowns fabricated with difference substructure designs. J Dent. 2013; 41:e87–e92.

30. Heffernan MJ, Aquilino SA, Diaz-Arnold AM, Haselton DR, Stanford CM, Vargas MA. Relative translucency of six all-ceramic systems. Part II: core and veneer materials. J Prosthet Dent. 2002; 88:10–15.

31. Ilie N, Hickel R. Correlation between ceramics translucency and polymerization efficiency through ceramics. Dent Mater. 2008; 24:908–914.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download