Abstract

PURPOSE

All-ceramic crowns are subject to fracture during function. To minimize this common clinical complication, zirconium oxide has been used as the framework for all-ceramic crowns. The aim of this study was to compare the fracture strengths of two computer-aided design/computer-aided manufacturing (CAD/CAM) zirconia crown systems: Lava and Digident.

MATERIALS AND METHODS

Twenty Lava CAD/CAM zirconia crowns and twenty Digident CAD/CAM zirconia crowns were fabricated. A metal die was also duplicated from the original prepared tooth for fracture testing. A universal testing machine was used to determine the fracture strength of the crowns.

RESULTS

The mean fracture strengths were as follows: 54.9 ± 15.6 N for the Lava CAD/CAM zirconia crowns and 87.0 ± 16.0 N for the Digident CAD/CAM zirconia crowns. The difference between the mean fracture strengths of the Lava and Digident crowns was statistically significant (P<.001). Lava CAD/CAM zirconia crowns showed a complete fracture of both the veneering porcelain and the core whereas the Digident CAD/CAM zirconia crowns showed fracture only of the veneering porcelain.

The esthetics of dental restorations, as well as their functionality, are crucial, especially for anterior restorations.1 Increasing demand for esthetics and concern for health and the environment have led to the introduction and advancement tooth-colored restorations without metallic components.2 In contrast to metallic restorations, all-ceramic restorations exhibit advantages such as realistic appearance,3 biocompatibility,4 wear resistance, and color stability.5

However, they also show susceptibility to fracture, and their ability to withstand occlusal forces is affected by 2 inherent flaws:6 1) defects in fabrication, which can produce internal voids, porosities, or microstructural defects during processing; and 2) surface cracks that result from the machining and grinding processes.7 Fracture of the crowns may be a continuation of those inherent flaws that arise when additional loads are applied to existing defects or because of impact forces or subcritical growth.8,9

Among the clinical complications of all-ceramic crowns, crown fractures are reported most commonly.10 Therefore, several attempts have been made to increase the fracture strength of all-ceramic restorations, including the use of yttrium oxide partially stabilized zirconia because of its higher flexural strength.11

Zirconia exhibits a phenomenon called "transformation toughening," which disables the progress of crack growth and increases toughness against fractures. The tetragonal crystals of zirconium oxide are metastable and the stress applied to cracks or flaws can transform them into larger monoclinic crystals.12

In the Digident CAD/CAM system, the digitization of the models is performed using an optical scanner (DigiScan L) with white-light stripe projection technique. Copings are fabricated using a 4 axis milling machine (DigiCut), which mills a fully sintered block of partially stabilized dense zirconia in a process known as: hot isostatic pressing (HIP).13

The Lava CAD/CAM system, by contrast includes an optical scanner (Lava Scan), a CAM machine (Lava Form) and a sintering oven (Lava Therm). The CAM machine mills a partially sintered block of yttrium tetragonal zirconia polycrystal (Y-TZP) into an enlarged framework structure to compensate for the shrinkage encountered during sintering.14

After the copings are fabricated, they must be overlaid with suitable veneering porcelain to improve the esthetic appearance.15 Unfortunately, this multi-layer procedure changes the stress distribution pattern into a completely different and complex pattern that makes its performance to be hardly predictable in clinical situations.2

The complex pattern of stress distribution on multi-layer arrangements combined with the scarce literature comparing systems that process different blanks of zirconia led to the execution of this experiment. The purpose of this study was to evaluate and compare the fracture strengths of 2 different zirconia all-ceramic crowns in the anterior region and analyze their fracture patterns.

One extracted maxillary central incisor, which was not treated endodontically and had no previous restoration or carious lesion, was selected and cleaned. The long axis of the tooth was adjusted and fixed perpendicular to the bottom surface. Its root portion was embedded in autopolymerizing resin block.

The tooth was cut and reduced to prepare an all-ceramic crown with a high-speed handpiece and milling machine. This resulted in an incisal reduction of 2-3 mm, an approximately 1 mm axial reduction, a 1 mm shoulder margin with 12° tapered angles, and an approximate height of 7 mm.

To produce a metal tooth analog for the zirconia framework fabrication and fracture strength test, an impression of the prepared tooth was made with polyvinyl siloxane impression material (Examixfine; GC Corp., Tokyo, Japan). The metal tooth analog was casted from a nickel-chromium alloy (Rexillium III; Pentron Laboratory Technologies, LLC., Wallingford, CT, USA) using a wax pattern from the impression (Fig. 1).

A preliminary impression of the metal tooth analog was made using irreversible hydrocolloid impression material (Aroma Fine Plus; GC Corp., Tokyo, Japan) for the plaster (Samwoo plaster; Samwoo Corp., Seoul, Korea) model. Forty customized impression trays were fabricated using acrylic resin (Quicky; Nissin Dental Products Inc., Kyoto, Japan) with 2- sheet baseplate wax (Pemaco 3000 base plate wax; Pemaco Inc., St. Louis, MO, USA) relief on the plaster cast. Final impressions of metal tooth analog with polyvinyl siloxane (Examixfine; GC Corp., Tokyo, Japan) and customized trays, and 40 master stone (Rhombrock; Ryoka Dental Co., Ltd., Yokkaichi, Japan) dies from the final impression were made.

Forty 0.5 mm thickness zirconia copings (20 copings per group) were fabricated with 20 µm cemental space from Digizon HIP zirconia (Amann Girrbach GmbH, Pforzheim, Germany) for 20 Digident CAD/CAM zirconia crowns and from Lava™ Frame (3M ESPE, Seefeld, Germany) for 20 Lava CAD/CAM zirconia crowns (Table 1).

The Lava™ Ceram (3M ESPE, Seefeld, Germany) for Lava CAD/CAM zirconia crowns and Creation ZI (Creation Willi Geller International AG, Baar, Switzerland) for Digident CAD/CAM zirconia crowns were veneered layer by layer on the corresponding coping by a dental technician experienced in both systems (Table 1). To fabricate standardized zirconia crowns, the thickness of veneered porcelain, the contour of the final crown and the firing cycle (3 times the typical number of a laboratory procedure) were controlled by the same experienced dental technician.

A universal testing machine (STM-5; United Calibration Corp., Huntington Beach, CA, USA) was used for the fracture strength test. The load was applied to the lingual fossa at 30 degrees to the long axis of the specimen until catastrophic failure occurred (Fig. 2). Catastrophic failure was defined as exhibition of visible cracks, load drops and acoustic events of chipping or fracture. Each specimen was positioned and fixed in a matrix to maintain identical loading position and angle during the fracture strength test. The force was applied to the artificial crown with a 5 mm diameter spherical steel rod at a crosshead speed of 1 mm per minute.

Statistical analysis was performed using an independent-samples t-test to compare the fracture strengths of the crowns made from the 2 materials with a 95% confidence level.

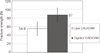

The mean fracture strengths were as follows: 54.9 ± 15.6 N for the Lava CAD/CAM zirconia crowns and 87.0 ± 16.0 N for the Digident CAD/CAM zirconia crowns (Fig. 3). The greater fracture resistance of the Digident CAD/CAM crowns compared to the Lava CAD/CAM crowns was statistically significant (P<.001). It was also possible to observe that the Lava CAD/CAM zirconia crowns always showed a complete fracture of both the veneering porcelain and the core (Fig. 4 and 5A), while in the Digident crowns, only a fracture of the veneering porcelain was observed consistently (Fig. 4 and 5B).

All-ceramic crowns are subject to fracture during function. To minimize this common clinical complication, zirconium oxide is the material of choice used for the framework of all-ceramic crowns. However, because zirconium oxide ceramic systems have only recently been introduced into the market, information about the fracture strengths of these systems is lacking in the literature.16-20

Kelly suggested several recommendations for a clinically relevant in vitro load-to-failure test for all-ceramic restorations: use of a die material with elastic modulus similar to dentin, failure test under wet cyclic loading, preparation of the teeth or dies according to clinical guidelines and use of all-ceramic crowns with clinically relevant dimensions.21 In the current study, some experimental conditions were different from Kelly's recommendations. The elastic modulus of the die material (218 GPa) in this research is higher than that of dentin (12 GPa).22 However, natural teeth are hard to be standardized in size, mineralization, internal cracks, pulpal chamber dimension, and mechanical properties and would have fractured under the high compressive loads exerted during the test.23 Luting agents were not used in this study because of the limited number of metal dies available for testing. Clinically, restorations are subjected to dynamic complex loading in saliva, which contains both organic and inorganic components. These conditions are quite different from the conditions used in this study; thus, further investigation should be carried out using stress corrosion or corrosion fatigue methodology so that the long-term performance of restorations can be predicted.23

According to the material properties provided by the manufacturers, the flexural strength of Lava Frame (>1,100 MPa) and Lava Ceram (>100 MPa) exhibit higher values than that of Digizon HIP zirconia (>900 MPa) and Creation ZI (90 MPa), respectively (Table 1). During milling of dense sintered ceramic blanks, there is also the danger of unwanted surface and structural defects on the ceramic. Machining HIP zirconia decreases overall restoration strength and jeopardizes the bond between the core and the veneering porcelain.14 Nonetheless, in current study, the Lava CAD/CAM crowns (Lava Frame and Lava Ceram complex) exhibited lower fracture strength than the Digident CAD/CAM zirconia crowns (Digizon HIP zirconia and Creation ZI complex). The main reason for the lower strength may have been that the difference in the thermal expansion coefficient between Lava Frame (10.5 ± 0.2 ppm) and Lava Ceram (9.5 ppm) is greater than that between Digizon HIP zirconia (10.0 ± 0.5 ppm) and Creation ZI (9.5 ± 0.3 ppm) (Table 1). The difference in the thermal expansion coefficient between crown core and its veneering material has been intentionally introduced to produce the compressive stress in the veneering porcelain whereas it also produces the tensile stress in the crown core.24 As the difference in thermal expansion coefficient increases, the residual compressive stress in the veneering porcelain and the tensile stress in the crown core also increases assuming a good bond between the core material and the veneering porcelain. In current study, the fractured areas of CAD/CAM zirconia crowns were consistent with the labial surface veneering porcelain in Digident crowns for both crown core and veneering porcelain, initiating from proximal surfaces in the Lava crowns. Labial surfaces seemed to have been under compressive stress during the fracture test, whereas proximal surfaces might have been under tensile stress. Consequently, Lava CAD/CAM zirconia crowns seem to be prone to fracture at lower fracture strength owing to the increased residual compressive stress of their labial surfaces and tensile stress of their proximal surfaces, despite the higher flexural strength of their core material and veneering porcelain compared toDigident CAD/CAM zirconia crowns. These results are also supported by Rosentritt et al.,25 which state that the clinical survival of all-ceramic crowns mainly depends on the surface quality of the veneering (strength, fracture toughness, surface roughness) and, to a lesser extent, on the bond at the veneering and core interface, but not on the strength of the underlying core structures.

In the present study, Lava CAD/CAM zirconia crowns showed a fracture pattern in which both the veneering porcelain and the core were fractured. The Digident CAD/CAM zirconia crowns showed a different pattern of fracture; it was possible to observe chipping and fracture of the veneering porcelain at the veneer-core interface, which was observed mainly at the cervical area of the labial surface. As mentioned above, the fracture strength test induced tensile stress in proximal area and compressive stress in labial surface simultaneously. As long as the interfacial bonding strength between core material and veneering porcelain and the cohesive strength of veneering porcelain resisted the compressive stress of labial surface, the failure of the tested zirconia crown would initiate in proximal area. Otherwise, if the zirconia core overcame the tensile stress during the fracture test, the failure area would be the labial surface of the crown. More precisely, if there is a good interfacial bond between crown core and veneering porcelain, the cohesive fracture of the veneering porcelain (chipping) would be exhibited. If not, interfacial failure (delamination of veneering porcelain) would occur. A reasonable explanation of the fracture pattern of Digident CAD/CAM crowns is that its cores had enough strength to overcome tensile stress during the fracture test but insufficient interfacial bonding strength to show cohesive chipping of the veneering porcelain. In the Lava CAD/CAM crowns, the crown cores would not prevail over proximal tensile stress during the fracture test resulting in core fracture pattern. Contrary to our results, Rosentritt et al.25 found that Lava CAD/CAM zirconia crowns showed chipping and fracture within the porcelain veneer. This difference seems to have come from omitting the cementation procedure with luting or bonding agents in the present study, because the cementation of crowns to abutment analogs could decrease tensile stress in proximal area and peak loading stress. Interfacial failure was the cause most strongly related to the failure of zirconium crowns in other in vitro studies adopting the cementation procedure.18-20 Another explanation of the different fracture pattern would be the strength of veneering porcelain. Beuer et al. stated that the zirconia-based all-ceramic crowns with a relatively weak veneering porcelain - assuming a good bond - tend toward more cohesive chipping, whereas higher strength veneering porcelain provokes core fracture, or total fracture of zirconia-based crowns.26 In this research, the flexural strength of Lava Ceram (>100 MPa), the veneering porcelain of Lava CAD/CAM crowns, is slightly higher than that of Creation ZI (90 MPa), the veneering porcelain of Digident CAD/CAM crowns. Lava Ceram with greater strength would provoke more crown core fractures than Creation ZI.

In the current study, the fracture strengths (around 100N) of zirconia CAD/CAM crowns exhibited lower values compared to those shown in other zirconia research (around 1000 N).18-27 The main reason for this differences seem to be the absence of cementation; other aspects were small diameter loading rod and the absence of stress-buffer material between the loading rod and the crown, such as polyethylene foil and aluminum foil. These aspects contribute to decreased loading stress peaks and distribute the applied forces over a larger area. However, the extremely low fracture strength of zirconia CAD/CAM crowns without luting or bonding agents could implicate the possibility of jeopardizing whole restorations in clinical practice, especially when under excessive setting pressure before completing cementation or verifying the accurate fit of zirconia restorations.

In the present study, the mean fracture strength of Digident CAD/CAM zirconia crowns was found to be significantly greater (P<.001) than that of the Lava CAD/CAM zirconia crowns, and the fractures occurred only as chipping and delaminating of the veneering porcelain at the porcelain-core interface. This leads us to deduce that the material lying on the bottom surface does not indeed control the strength of the restoration. The results obtained in the present study demonstrated that the Digident CAD/CAM system provided a core with lower flexural strength than did the Lava CAD/CAM system, in which the crowns including both the veneering porcelain and the core fractured completely.

Within the limitation of this research, notwithstanding the superior flexural strength of the core material and veneering porcelain, the Lava CAD/CAM crowns showed poorer fracture strength due to a fabrication process that introduces great residual stress from the incomplete compatibility of thermal expansion coefficient. Research investigating the reduction of residual stress from the adhesion between zirconium oxide ceramics and their veneering porcelains may lead to improved whole restoration stability.

Figures and Tables

| Fig. 2Schematic view of the fracture strength determination procedure with CAD/CAM zirconia crowns. The direction of the load applied was 30°, and the loading points were consistently maintained by repositioning the metal die. |

| Fig. 3Fracture strengths of Lava CAD/CAM and Digident CAD/CAM zirconia crowns, expressed as mean (standard deviation). |

| Fig. 4Modes of failure of all-ceramic crowns. There were 3 modes of failure: chipping, fracture at the core-veneer interface, and fracture of the crown core. |

References

1. Ku CW, Park SW, Yang HS. Comparison of the fracture strengths of metal-ceramic crowns and three ceromer crowns. J Prosthet Dent. 2002; 88:170–175.

2. Zahran M, El-Mowafy O, Tam L, Watson PA, Finer Y. Fracture strength and fatigue resistance of all-ceramic molar crowns manufactured with CAD/CAM technology. J Prosthodont. 2008; 17:370–377.

3. Rosenstiel SF, Land MF, Fujimoto J. Contemporary fixed prosthodontics. St. Louis: Mosby;2001. p. 262–271.

4. Sjögren G, Sletten G, Dahl JE. Cytotoxicity of dental alloys, metals, and ceramics assessed by millipore filter, agar overlay, and MTT tests. J Prosthet Dent. 2000; 84:229–236.

5. Siervo S, Pampalone A, Siervo P, Siervo R. Where is the gap? Machinable ceramic systems and conventional laboratory restorations at a glance. Quintessence Int. 1994; 25:773–779.

6. Drummond JL. Ceramic behavior under different environmental and loading conditions. In : Eliades G, Eliades T, Brantley WA, Watts DC, editors. Dental materials in vivo: aging and related phenomena. Chicago: Quintessence;2003. p. 35–45.

7. Rosenstiel SF, Land MF, Fujimoto J. Contemporary fixed prosthodontics. St. Louis: Mosby;2001. p. 643–672.

8. Evans AG. Slow crack growth in brittle materials under dynamic loading conditions. Int J Fract. 1974; 10:251–259.

9. Evans AG, Johnson H. The Fracture stress and its dependence on slow crack growth. J Mater Sci. 1975; 10:214–222.

10. Goodacre CJ, Bernal G, Rungcharassaeng K, Kan JY. Clinical complications in fixed prosthodontics. J Prosthet Dent. 2003; 90:31–41.

11. Guazzato M, Quach L, Albakry M, Swain MV. Influence of surface and heat treatments on the flexural strength of Y-TZP dental ceramic. J Dent. 2005; 33:9–18.

12. Guazzato M, Albakry M, Ringer SP, Swain MV. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dent Mater. 2004; 20:449–456.

13. Steger T. Digident CAD/CAM production--growing with the possibilities. Int J Comput Dent. 2004; 7:77–84.

14. Piwowarczyk A, Ottl P, Lauer HC, Kuretzky T. A clinical report and overview of scientific studies and clinical procedures conducted on the 3M ESPE Lava All-Ceramic System. J Prosthodont. 2005; 14:39–45.

15. White SN, Miklus VG, McLaren EA, Lang LA, Caputo AA. Flexural strength of a layered zirconia and porcelain dental all-ceramic system. J Prosthet Dent. 2005; 94:125–131.

16. Luthardt RG, Sandkuhl O, Reitz B. Zirconia-TZP and alumina--advanced technologies for the manufacturing of single crowns. Eur J Prosthodont Restor Dent. 1999; 7:113–119.

17. Snyder MD, Hogg KD. Load-to-fracture value of different all-ceramic crown systems. J Contemp Dent Pract. 2005; 6:54–63.

18. Sundh A, Sjögren G. A comparison of fracture strength of yttrium-oxide-partially-stabilized zirconia ceramic crowns with varying core thickness, shapes and veneer ceramics. J Oral Rehabil. 2004; 31:682–688.

19. Vult von Steyern P, Ebbesson S, Holmgren J, Haag P, Nilner K. Fracture strength of two oxide ceramic crown systems after cyclic pre-loading and thermocycling. J Oral Rehabil. 2006; 33:682–689.

20. Wood KC, Berzins DW, Luo Q, Thompson GA, Toth JM, Nagy WW. Resistance to fracture of two all-ceramic crown materials following endodontic access. J Prosthet Dent. 2006; 95:33–41.

21. Kelly JR. Clinically relevant approach to failure testing of all-ceramic restorations. J Prosthet Dent. 1999; 81:652–661.

22. Scherrer SS, de Rijk WG. The fracture resistance of all-ceramic crowns on supporting structures with different elastic moduli. Int J Prosthodont. 1993; 6:462–467.

23. Potiket N, Chiche G, Finger IM. In vitro fracture strength of teeth restored with different all-ceramic crown systems. J Prosthet Dent. 2004; 92:491–495.

24. Baldassarri M, Stappert CF, Wolff MS, Thompson VP, Zhang Y. Residual stresses in porcelain-veneered zirconia prostheses. Dent Mater. 2012; 28:873–879.

25. Rosentritt M, Behr M, Thaller C, Rudolph H, Feilzer A. Fracture performance of computer-aided manufactured zirconia and alloy crowns. Quintessence Int. 2009; 40:655–662.

26. Beuer F, Schweiger J, Eichberger M, Kappert HF, Gernet W, Edelhoff D. High-strength CAD/CAM-fabricated veneering material sintered to zirconia copings-a new fabrication mode for all-ceramic restorations. Dent Mater. 2009; 25:121–128.

27. Guazzato M, Proos K, Quach L, Swain MV. Strength, reliability and mode of fracture of bilayered porcelain/zirconia (Y-TZP) dental ceramics. Biomaterials. 2004; 25:5045–5052.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download