INTRODUCTION

The prosthodontic rehabilitation of partially and completely edentulous patients using implants is a biocompatible and predictable treatment modality.1-3 Dental implants can successfully be used to rehabilitate maxillofacial defects.4 Defects due to trauma often cause hard and soft tissue loss and result in esthetic problems and functional disorders.5 Rehabilitation of the traumatic defect is a significant challenge for the prosthodontist and surgeon. The goals of treatment are restoration of the esthetics, structural integrity, and function.

The importance of precision of fit for implant restorations has been reported by several authors.6-8 Framework misfit causes stress to implant frameworks and the surrounding bone.7 Screw-retained implant prosthesis frameworks cast by dental alloys involve certain risks such as distortion and stress from heating and cooling during lost-wax technique.7,8 To obtain passive fit, it is often necessary to section and solder the framework. Several other methods for improving passive fit were introduced, including modified casting technique, sparkerosion, and laser welding. However, these methods are technique sensitive and may cause errors.

Recently, milled zirconium oxide frameworks using computer-aided design and computer-aided manufacturing (CAD-CAM) technology are widely used in implant dentistry, which present better fit than framework made by traditional casting techniques.9 Zirconium oxide has good physicochemical properties such as, low thermal conductivity, high corrosion rsistance, and high flexural strength (900-1200 MPa).10,11 In addition, zirconium oxide present enhanced biocompatibility.10-12 The cost related to the considerable use of high noble metal alloys for frameworks can be reduced by using milled zirconium oxide framework with CAD-CAM technology. Problems associated with the casting method, such as distortion and shrinkage also can be avoided.

It was reported that a sufficient amount of keratinized tissue around implants was important for long-term peri-implant health.13 Split-thickness skin grafts at the surgically reconstructive site are often needed for enhancing the peri-implant soft tissue condition.14 At the time of surgery, to keep the split thickness skin graft in close approximation to the recipient site during the initial stage is important.15 Without close contact, the graft may not adhere to the recipient site because a hematoma may form between the skin and periosteum. Therefore, the device or mold to hold skin graft in place, such as bolsters and stents, are required.16

This clinical report describes the use of prefabricated acrylic stent after split thickness skin graft and implant-supported screw-retained fixed restorations using CAD-CAM technology of a patient who presented unilateral mandibular defect after trauma.

CASE REPORT

A 54-year-old man was referred to the Department of Prosthodontics at Kyung Hee University to restore the mandibular left missing area. The patient had been in a motor vehicle accident about 20 years ago and had received a number of reconstruction surgeries due to the mandibular traumatic defect of the left side.

Comprehensive intraoral and radiographic examination revealed significant bone loss of the mandibular left side. The floor of the mouth was firm, and lingual vestibule of left side was very shallow. The patient also presented shallow mandibular buccal vestibule and insufficient amount of keratinized tissue. The premolars and molars on the left mandible were missing. Mandibular central, lateral incisor and canine on the left side were shown to be hopeless (Figs. 1, 2).

Hard and soft tissue loss was needed to be restored by prosthetic rehabilitation. Several treatment options were suggested and discussed with the patient. Removable dental prosthesis was not considered as a treatment option because of poor tissue condition and lack of support. In spite of alveolar bone loss, inserting dental implants in the alveolar ridge was possible. Also the patient was expecting fixed restoration. Therefore, implant-supported fixed prosthesis was planned. A treatment plan was designed for fabrication of a fixed prosthesis supported by 4 dental implants.

Prior to implant surgery, a split-thickness skin graft combined with vestibuloplasty at the defect site was planned due to lack of keratinized tissue and shallow vestibule. To improve graft adherence, an intraoral stent was fabricated. Preliminary cast of type III stone (New Plaston; GC Co., Tokyo, Japan) of the mandible was prepared, and the left buccal vestibule was trimmed to the expected depth (Fig. 3). The stent was processed in clear acrylic resin (Vertex Rapid Simplified; Vertex Dental, Zeist, Netherlands), which was extended to the expected vestibular depth (Fig. 4A).

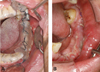

One month after the extraction of mandibular lateral incisor and canine on the left side, a split-thickness skin graft (12 cm × 5 cm) was harvested from the right upper thigh and secured with 3-0 silk sutured. Then stent was positioned on the grafted site and ligatured into the mandibular anterior teeth to stabilize the stent (Fig. 4B). The patient was in loss of posterior support on the left side for the healing period. This allowed better adaptation and healing of the skin graft to the underlying recipient site. The stent was removed 10 days after operation. There were no complications in the graft recipient or donor sites. The interim denture was then relined with tissue conditioning material (Soft-liner; GC Co., Tokyo, Japan).

Three months after the skin graft, 4 implants (US II, Osstem, Seoul, Korea) with dimensions of 3.3 × 10 mm in the lateral incisor, 4.0 × 10 mm in the first premolar and first molar, and 4.0 × 8 mm in the second molar were placed in the left mandible using a surgical guide to support an implant-supported fixed restoration (Fig. 5). Simultaneously, bone graft (Bio-Oss, Geistlich AG, Wolhusen, Switzerland) was performed. All implants had primary stability at the time of placement. The healing abutments were hand-tightened on all implants. Three months after surgery, the definitive prosthesis was fabricated because none of the implants demonstrated mobility or clinical signs of infection.

Non-hexed impression copings were connected to the implants and diagnostic irreversible hydrocolloid impression (Alginate; GC Co., Tokyo, Japan) was made, and preliminary cast fabricated. Pick-up type impression copings (ICFR500N, Osstem, Seoul, Korea) were placed on the preliminary cast and splinted with each other with autopolymerizing acrylic resin (GC Pattern Resin, GC America Inc., Alsip, IL, USA) and then sectioned to be reconnected intraorally. The impression copings were connected to the implants and reconnected with autopolymerizing acrylic resin to compensate for polymerization shrinkage. A definitive impression was made using a pick-up impression technique with a custom tray and polyether impression material (Impregum Pentasoft; 3M ESPE, St. Paul, MN, USA).

A bite block was then fabricated on the definitive cast (Fujirock EP; GC America Inc., Alsip, IL, USA) using pick-up type impression copings (ICFR500N, Osstem, Seoul, Korea) and autopolymerizing acrylic resin (Pattern resin; GC America, Inc., Alsip, IL, USA) (Fig. 6). Maxillomandibular relationship records were obtained using the bite block and silicon occlusal registration material (Geni Bite; Sultan Healthcare, Hackensack, NJ, USA). The definitive casts were then transferred to a semiadjustable articulator (KaVo-PROTARevo 7; KaVo, Biberachan der Riss, Germany).

Non-hexed temporary abutments (PSM100, Osstem) were connected to the implant analogs (FAM300, FAR300, Osstem) on the definitive cast and full contour wax-up was made. Full contour waxing was then cut back for veneering porcelain and converted into an acrylic resin framework (GC Pattern resin; GC America Inc.) using putty index (Lab Putty; Contene/Whaledent, Inc., Cuyahoga Falls, OH, USA) to be scanned into the computer. This acrylic prosthesis was then copied into zirconia prosthesis (Prettau, Zirkonzahn, South Tyrol-Gais, Italy) with a computer-controlled milling machine (Zirkograph 025 ECO, Zirkozahn).

At the next appointment, passive fit of the screw-retained zirconia framework was evaluated intraorally (Fig. 7). Periapical radiograph were made for verifying of the implant-abutment interface. Then the zirconia framework was veneered with feldspathic porcelain (Creation Zi-F; Creation Willi Geller Intl GmbH, Meiningen, Austria). Individual cement-type zirconia crowns (LAVA, 3M ESPE, ST. Paul, MN, USA) were designed in the left premolar and first molar region (Fig. 8). Maxillary first molar was made of conventional screw-type metal ceramic restoration.

At the appointment of insertion, the definitive screw retained mandibular zirconia prosthesis was evaluated intraorally, and the abutment screws were tightened to the torque of 35 Ncm. The patient was satisfied with the esthetic and functional end results of the definitive restorations (Fig. 9).

The screw access holes were sealed with photopolymerizing provisional material (Fermit; Ivoclar Vivadent, Schann, Liechtenstein) and composite resin (Z100 Restorative; 3M ESPE). The single zirconium oxide crowns were cemented to the framework with provisional cement (Tempbond; Kerr Corporation, Orange, CA, USA).

The patient was instructed on maintenance of interproximal gingival health with the use of Super-floss (Oral-B Inc., Iowa City, IA, USA) and Water Jet (Water Pik Inc., Fort Collins, CO, USA). The patient presented satisfactory oral hygiene for the 12 months follow-up period. No clinical complications were observed during the follow-up period (Fig. 10).

DISCUSSION

For the surgical procedure of skin graft, intimate contact between the split-thickness skin graft and the underlying periosteum in vestibuloplasty is crucial. Failure of the skin graft may be due to circumstances that negate intimate contact of the graft to the recipient site.15 A stent used for the skin graft must hold the split thickness skin graft in close approximation to the underlying periosteum for the initial healing period. Furthermore, minimum bulk is necessary to increase patient's comfort when the stent is placed. The prefabricated acrylic stent used in this case successfully held the graft in place and patient's discomfort was minimal during the initial stage.

Combinations of different restorative materials have been reported to be used in rehabilitation of partially and complete edentulous arches with implant-supported prosthesis.17-19 Metal-resin implant-fixed complete dental prosthesis can be used for this case. However, this type of restoration may pose problems, such as loosening of the acrylic teeth and wear of the occluding surface over time. Replacement of teeth and maintenance of the prostheses are often needed.17

In this case, zirconium oxide milled framework using CAD/CAM technology was used for screw-type implant supported restoration. Although failures in bonding between core and veneering porcelain have frequently occurred,20 there are advantages of this technology, including reduction in laboratory time and less technique sensitivity compared with traditional lost-wax techniques.21 The maxillary first molar was restored with conventional screw-type metal ceramic restoration. However, implant-supported fixed prosthesis with long span of the mandibular defect area, as in this situation, often requires prosthetic challenges such as sectioning and soldering. However, these extra procedures may be eliminated with zirconium oxide milled framework with CAD/CAM technology. Esthetics was enhanced as individual cementable all-ceramic restorations were fabricated for implants with unfavorable positions for screw-type restorations. Considering the maintenance of the shallow mandibular vestibule and skin grafted area, rehabilitation with all-ceramic implant-supported prosthesis may provide a high predictability.

CONCLUSION

This clinical report describes the oral rehabilitation of a patient with post-traumatic mandibular defect. The patient underwent split-thickness skin graft, implant placement, and fabrication of implant-supported fixed prostheses using CAD/CAM technology. A multidisciplinary approach was crucial for the optimum result. The definitive prosthetic rehabilitation improved esthetics and function of the patient and presented favorable prognosis.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download