This article has been

cited by other articles in ScienceCentral.

Abstract

PURPOSE

The aim of the study was to evaluate the effect of 3 silicone primers and 3 surface characterization of acrylic resin surface on bond strength between silicone elastomer and acrylic resin.

MATERIALS AND METHODS

96 Cosmesil silicones bonded to heat-curing acrylic resin were fabricated with the dimension of 75 × 10 × 3 mm. The 3 primers used in this study were G611 platinum primer, A-330 Gold platinum primer, and cyanoacrylates resin. Specimens without primer were used as control. The 3 types of surface characterization done were retentive holes with 1.5 mm in diameter and 0.5 mm deep, retentive beads of 0.6 mm diameter and the third type which was plain without any characterization. The specimens were then checked for bond strength by subjecting them to 180° peel test on a universal testing machine. The obtained results were then subjected to statistical analysis using 2-way ANOVA and Scheffé multiple post hoc procedures. The statistical significance was set at 5% level of significance.

RESULTS

The maximum bond strength was seen for samples in which A-330G primer was used followed by G611 primer. The control group showed the minimum bond strength. Surface characterization of retentive holes increased the bond strength considerably as compared to retentive beads and samples without any surface characterization.

CONCLUSION

Within the limitations of the study, A-330G primer was more compatible with Cosmesil M511 silicone and has better bonding of Cosmesil to acrylic resin. Retentive holes made on acrylic surface increased the bond strength considerably than those without any surface characterization.

Keywords: Silicone elastomer, Primers, Acrylic resin

INTRODUCTION

Medical-grade skin adhesives, eyeglasses, and tissue undercuts have been traditionally used in the rehabilitation of patients with extra-oral defects. However, with the development and advancement of craniofacial implants and greater predictable aesthetics, improved prosthesis retention and stability is now a reality.

1,

2

A retentive matrix to hold clips and magnets is mandatory when using implant retained extra-oral prosthesis. This retentive matrix is made using acrylic resin to which the elastomer of extra-oral prosthesis is processed. This demands acrylic resin matrix to be securely bonded to flexible soft material of prosthesis. That means that denture resins may be used as a rigid base into which retention components are embedded, while the facial surface supports the silicone component of facial prosthesis. The rigid base or framework is usually fabricated with auto-polymerizing, heat-polymerizing, or visible light-curing denture resin. So it is apparent that for a serviceable and functional prosthesis, adequate bond strength is vital.

1,

3

The bond of silicone elastomer to the acrylic resin component must be sufficiently tenacious to withstand the substantial forces acting upon the bond interface, not only during placement and removal of the prosthesis, but also during mould opening and deflasking procedures as this is the weakest link in the restoration.

2 Maxillofacial silicone elastomers are dimethyl siloxane polymers and have different chemical structure from that of PMMA denture base resin. Thus, an adhesive is supplied to aid their bonding to the denture base. It is likely that adhesive primers have an organic solvent and an adhesive agent that reacts with both silicone and resin materials.

4 They activate the surfaces via etching or promoting hydrogen bonding and covalent coupling, increasing the wettability of the substrate and by impregnating the surface layer with the polymeric ingredients.

5

Singer et al.

6 found that bond strength was enhanced using a combination of MDX 4-4210 silicone and either S-2260 or A-4040 primers. Primer 1205 showed better bond strength than 1205 irrespective of the polymerization method or primer reaction time.

7 Polyzois

8 reported that the curing method (microwave irradiation and dry heat) did not significantly affect the bond strength of silicone elastomers to acrylic denture resin unlike, the type of silicone elastomers. Frangou et al.

9 stated that the compatibility and affinity of primer composition with the selected silicone elastomer is important for efficient bonding. Polyzois and Frangou

2 found that higher bond strength was achieved when the resin base was finished with 80-grit SiC paper than when it was finished with 240, 260, 600 or 1000-grit SiC paper. In another study, Frangou et al.

9 also claimed that when the bonding surface of the resin specimens were finished with a polishing machine using 80-grit SiC paper under a constant flow of water, the bond strength increased. On the contrary, Amin et al.

10 reported that sandblasting the acrylic resin base weakened the bond between the resin and the silicone. Similar results were reported by Miami et al.

4 who proved that roughening of the denture surface with air- particle abrasion was not effective for enhancing failure load and maintaining longevity of the silicone and acrylic resin. The best way to prepare a denture resin base is unclear. Further studies should be carried out to find the proper preparation of resin surfaces to increase the bond strength between silicone elastomer and resin bases.

There is a lack of evidence that compares the effect of primers on silicone-acrylic bond strength using various surface characteristics. The aim of this study was to evaluate the effect of 3 different commercially available bonding agents and surface alterations on the bond strength of silicone to acrylic resin with the null hypothesis that no difference would exist in the bond strength between them.

MATERIALS AND METHODS

The bond strength between heat polymerizing acrylic resin (Trevalon H; Dentsply, Mumbai, India) and silicone elastomer (Cosmesil M511; Principality, UK) was evaluated using 3 different commercially available bonding agents. G611 platinum primer (Principality Medical; Newport, UK), A-330 Gold platinum primer (Factor 2; Phoenix, AZ, USA), and cyanoacrylates resin (Fevi kwik; Pidilite Industries, Mumbai, India.) were used as bonding agents.

The bond strength between silicone elastomer and heat polymerized acrylic resin substrate was tested using a acrylic resin blank as a test specimen with the dimension of 75 mm × 10 mm × 3 mm. Silicone elastomer was bonded to a part of specified area on the acrylic resin blank. A total of 96 test specimens were fabricated, which were then divided into 4 main groups (A, B, C and CT) with 24 specimens each. Primer G611 constituted the Group A, primer A-330 constituted the Group B, cyanoacrylate resin Group C and the CT group represented the control group without any primer. These groups were further divided into subgroups 1, 2, and 3 with 8 specimens each. Specimens of subgroup 1 had no surface alteration (plain) on the acrylic resin blank, subgroup 2 specimens had retentive beads on the area of acrylic resin blank where the silicone elastomer was bonded and specimens of the subgroup 3 had retentive holes.

Prefabricated acrylic sheet of 3 mm thickness was cut into required dimension of 75 mm (length) × 10 mm (width). The cut acrylic strips were invested using the conventional compression molding technique. The members of the dental flask were separated and the acrylic strips were removed. The mold cavity, thus obtained was used to fabricate the heat polymerizing acrylic resin blank. The heat polymerizing acrylic resin was packed into the mold and the plain resin blanks without any surface alteration were fabricated for the subgroup 1 (

Fig. 1).

Fabrication of acrylic resin blank for the subgroup 2

For each specimen, 0.01 mg of retentive beads of 0.6 mm diameter were used. Prior to flasking the prefabricated acrylic sheet were modified. Each blank was measured and marking was done at a length of 25 mm where silicone had to be bonded. In the area of 25 mm × 10 mm of the blank, adhesive was applied for the retentive beads which were provided by the manufacturer and the measured amount (0.01 mg) of retentive beads (Retentionen, Renfert, Chicago, IL, USA) were spread evenly throughout the marked area and allowed to dry. The modified sheets with beads were then flasked, packed, polymerized and polished (

Fig. 2).

Fabrication of acrylic resin blank for the subgroup 3

Plain acrylic blanks were fabricated as mentioned before for subgroup 1. After the acrylic blanks were finished and polished, they were measured and marked for a length of 25 mm × 10 mm, where silicone had to be bonded. Horizontal lines were marked in this area at a distance of 3 mm and vertical lines were marked at a distance of 2.5 mm. At the intersection of these lines, 24 holes were made of diameter 1.5 mm and depth of 0.5 mm using a round tungsten carbide bur of diameter 1.5 mm (

Fig. 3).

Preparation of mold for silicone elastomer packing

On the acrylic resin blanks fabricated (with and without surface characterization) above, another acrylic blank of the same dimension (75 mm × 10 mm × 3 mm in length, width and thickness respectively) was overlapped and the borders were sealed neatly with wax to seal the gap between the two blanks. The combined thickness of both the blanks was 6 mm. The fused acrylic blanks were then flasked with the first pour covering till the junction of the two blanks. The plaster was allowed to set and later petroleum jelly was applied all over followed by which the second pour was done using dental stone and the flask was clamped and stone was allowed to set. Later the flask was opened, dewaxed and the overlapped acrylic blank from the upper member of the flask was removed from the mold. The lower member of the flask contained the acrylic blank with the required surface characteristic and the upper member of the flask contained mold of overlaped resin blank in which silicone was packed. Specimens of the control group were packed without the primer and cured.

Preparation done prior to packing silicone

All the acrylic blanks in the lower member were initially cleaned with water. Next, an adhesive tape was applied to define the area over which the silicone elastomer was to be bonded to the acrylic substrate. The tape covered an area of 50 mm × 10 mm leaving an uncovered area of 25 mm×10 mm (surface characterization was done) where the silicone had to be bonded to the acrylic substrate. The uncovered area of acrylic blank was cleaned with acetone and then left to air dry. The procedure mentioned above was carried with all the 96 specimens. Different primers were applied to their corresponding group specimens according to the manufacturer's instruction and Cosmesil M511 silicone elastomer was packed and cured according to manufacturer's instructions. Only for the Group C the silicone was packed without the application of primer. After finishing of the cured silicone strip, a uniform layer of cyanoacrylate resin was applied on the area of acrylic resin blank to be bonded to silicone and the cured silicone strip was immediately placed in its correct position on the acrylic resin blank and a weight of 1 kg was placed on the specimens for 15 minutes, then the silicone had bonded to the resin blank.

All the test groups were subjected to an 180° peel strength test on Hounsfeild universal testing machine (HT-400). The test was carried out according to the ASTM D-903 specifications. In each specimens, the silicone strip was bonded to acrylic denture base at one end (25 mm × 10 mm × 3 mm) and left free at the other (50 mm × 10 mm × 3 mm). The free end of the strip was turned back at 180° so that the hard acrylic base was clamped in the lower clamp and the soft free silicone strip was gripped in the upper clamp (

Fig. 4).

The force needed to cause bond failures was recorded.

Peel strength (N/mm) was determined using the formula

Where F = maximum force recorded (N); W = Width of specimens (mm); λ = Extension ratio of silicone elastomer (the ratio of stretched to primary length)

The results obtained were then subjected to statistical analysis using a 4 × 3 general factorial analysis of variance (2-way ANOVA). Pair wise comparison of 4 groups and 3 altered surfaces with respect to bond strength was analyzed by using Scheffé multiple comparison test procedures. The statistical analysis was performed using STATA 10.0 (Stata Corp LP, San Diego, TX, USA) statistical software.

RESULTS

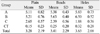

The groups of primers G611 and A-330G failed either adhesively or cohesively while the control group and those of cyanoacrylate showed adhesive bond failure. The mean and standard deviations of the adhesion in peel force measurements are presented in

Table 1. The primer A-330G with retentive holes showed the maximum mean peel strength among all the groups (6.50 ± 0.52 Mpa). The control group without surface characterization/plain showed the least mean peel strength (0.15 ± 0.23 MPa).

Table 2 represents the two way interactions between the primers and surface characterizations using 2-way ANOVA. There was statistically significant difference between the peel strengths of different primers used (P=.0000*) at 5% level of significance and also between the different surface characterizations used (P=.0320*) at 5% level of significance. This analysis also revealed that two way interaction, primers by surface characterizations was highly significant (P=.0001*) at 5% level of significance.

Further pair wise Scheffé multiple post hoc analysis was done for all the 4 primers. For all the surfaces, significant difference was seen between all the primers and control group (P=.0000*) at 5% level of significance. Significant difference was also seen between primers G611 and A-330G when compared to cyanoacrylate (P=.0000*) at 5% level of significance as displayed in

Table 3. As presented in

Table 4 the pair wise comparison also revealed, significant difference between peel strength of retentive holes and that of plain surface of all the primers (P=.0343*) at 5% level of significance.

DISCUSSION

The bond of elastomer to the acrylic resin component must be sufficiently tenacious to withstand the substantial forces acting upon the bond interface, not only during placement and removal of the prosthesis, but also during mold opening and deflasking procedures.

2

However, the chemical structure of maxillofacial silicone elastomers (dimethyl siloxane polymers) and PMMA denture base resin is different, exhibiting poor bond characteristics.

2,

11 Hence, primers are provided to increase the bond strength between silicone elastomer and acrylic resin thereby preventing delamination of silicone and enhancing the longevity of the prosthesis. They increase the bond strength by activating the surfaces via etching or promoting hydrogen bonding and covalent coupling, increasing the wettability of the substrate and by impregnating the surface layer with the polymeric ingredients.

5

Bond strength can be measured and evaluated by tensile test, shear test and peel test.

12 A horizontal component of detaching forces are generated when the patient removes the craniofacial implant retained prosthesis. This type of force is well simulated in the peel test.

3,

4 For this reason, 180° peel test was used in this study to evaluate the bond strength.

In the present study, the type of bond failure was assessed visually and designated as adhesive or cohesive. Test showed that specimens of primer G-611 and primer A-330G were separated either cohesively or adhesively, whereas all test specimens of cyanoacrylate and control group showed adhesive type of bond failure. For cohesive failures, the peel bond strength between the silicone and the denture base was stronger than the strength of the silicone material. Although the peel test has the advantage of being the only method in which failure proceeds at a controlled rate and the peel force is a direct measure of the work of detachment, cohesive peel bond test failures should be interpreted with caution. It is likely that the cohesive failures were initiated by small imperfections or voids in the silicone mixture.

Specimens with both the primer G-611 and A-330G showed good bond strength with mean peel strength of 5.11 N/mm and 5.21 N/mm, respectively. Although previous study conducted by Hatamleh and Watts

1, showed lower bond strength of 1.30 N/mm and 2.36 N/mm, they stated A-330G produced the maximum peel strength among the primers, which was in accordance with our study. The increased bond strength of A-330 primer could be due to increased chemical affinity in comparison to G-611 as they vary in composition.

Specimens with cyanoacrylate produced bond strength of 2.65 N/mm which was significantly less than the bond strength produced by G-611 and A-330G primers. Yet it produced satisfactory bond strength in which the result being 0.15 N/mm without the use of primers.

In surface characteristics where retentive holes were used, the maximum peel bond strength was produced with primer G-611 and primer A-330G in comparison to plain acrylic resin substrate. This is in accordance with the study conducted by Craig and Gibbons.

13 They advocated a roughened surface to improve the adhesive bond. They reported that adhesive values obtained by roughening were approximately double those of smooth surfaces because of a slightly irregular surface provided mechanical locking for the soft material.

On the contrary Jagger et al.

14 claimed that roughening the resin surface with an acrylic bur weakened the bond because of the stress concentration caused by discontinuities of the surface and entrapped air or gas at the interface, which could further weaken the bond by the created voids. However, if the surface roughening is done in a definite pattern, with adequate intervals of plain surface and roughness, then the possibility of stress concentration and weakening of the acrylic resin substrate may be reduced. Also, if the packing of silicone into the mold is done with appropriate equalization of pressure ensuring the proper flow of silicone elastomer into the depressions created on the acrylic substrate, air or gas entrapment will be prevented. Increase in bond strength with primer G-611 and primer A-330G with retentive holes could be due to the mechanical interlocking of peg like extension of silicone material into the holes made on acrylic substrate, also the provision of holes provided increased surface area for the silicone elastomer to bond with acrylic resin substrate.

Similarly, surface characteristics of retentive beads showed increased bond strength although it was not significant in comparison to plain surface with specimens of G-611 and A-330 G, which is in accordance with a study conducted by Taft et al.,

3 who found that the mean force required in adhesion in peel test for 1205 primer without beads was 35.7 N and for 1205 primer with beads was 40.2 N. The results showed increase in bond strength with beads but showed no statistical significance.

Cyanoacrylates had decreased bond strength. Decrease in the bond strength with surface characteristics in cyanoacrylate specimens could be due to the method of sample fabrication, where silicone is peeled from the acrylic substrate from the bonding area, bonding agent is applied and the silicone elastomer had to be placed back in the same original position so that the irregularities, elevations and depressions of the two materials will correspond to each other, which is highly difficult. This produced an area of voids and spaces between the acrylic and silicone elastomer, producing a weak bond between the two.

This study gives scope for further research to evaluate, the biocompatibility of using cyanoacrylate as a bonding agent in maxillofacial prosthesis. Since the prosthesis is worn extraorally the effect of outdoor weathering on the bond strength between silicone and acrylic resin with respect to the bonding agent need to be evaluated. Depth of 0.5 mm holes was found to improve the bond strength, but further research is needed to evaluate the variation of bond strength as the depth of the retentive holes varies. Further research is also required to evaluate the long term effect of cyanoacrylate on both acrylic resin and silicone elastomer along with its mode of bonding. Coloring pigments added to silicone can change surface properties of silicone, which in turn, can affect its bond strength and therefore need to be evaluated as well.

CONCLUSION

Within the limitations of the study, the following conclusions were drawn.

Primers G-611 and A-330 produced much better bond strength between silicone elastomer and acrylic resin than cyanoacrylate.

Amongst all the primers tested, A-330G produced the highest bond strength and was the most compatible with Cosmesil M511 Silicone.

Among the primers, the use of retentive holes significantly increased the bond strength in comparison to specimens with no surface characteristics.

Surface characterization used in case of cyanoacrylate was found to decrease the bond strength unlike in case of primers G-611 and A-330G.

As satisfactory bond strength with cyanoacrylate was achieved though it was less than the primers G-611 and A-330G. Cyanoacrylate can be used as chair side bonding agent.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download