Abstract

PURPOSE

The objective of the present study was to evaluate the effect of five different metal framework designs on the fracture resistance of the metal-ceramic restorations.

MATERIALS AND METHODS

For the purpose of this study, the central incisor tooth was prepared, and the metal analogue of it and a master die were fabricated. The counter die with the 0.5 mm clearance was used for fabricating the wax patterns for the metal copings. The metal copings with five different metal framework designs were designed from Group 1 to 5. Group 1 with the metal collar, Group 2, 3, 4 and 5 with 0 mm, 0.5 mm, 1 mm and 1.5 mm cervical metal reduction respectively were fabricated. Total of fifty metal ceramic crown samples were fabricated. The fracture resistance was evaluated with the Universal Testing Machine (Instron model No 1011, UK). The basic data was subjected to statistical analysis by ANOVA and Student's t-test.

RESULTS

Results revealed that the fracture resistance ranged from 651.2 to 993.6 N/m2. Group 1 showed the maximum and Group 5 showed the least value.

CONCLUSION

The maximum load required to fracture the test specimens even in the groups without the metal collar was found to be exceeding the occlusal forces. Therefore, the metal frameworks with 0.5 mm and 1 mm short of the finish line are recommended for anterior metal ceramic restoration having adequate fracture resistance.

The esthetic appearance of a restoration as well as its functional efficiency is of prime importance in anterior teeth restorations. The patients expect the restoration to restore their esthetic appearance along with longitivity. The metal ceramic restoration is one of such restorations that derives its excellent esthetics from highly translucent natural appearance of porcelain and strength from metal substructure. The ceramic being brittle must be adequately supported by the metal substructure, to reinforce and optimize its strength to reduce the risk of fracture. Thus, both requirements are achieved in this kind of restoration.1,2

The metal ceramic crown restoration was first described by Brecker3 in 1956. He described the use of a circumferential metal collar. He had suggested that cervical esthetics can be improved by eliminating the cervical metal collar and fabricating the restoration with porcelain cervical margins. The metal collar serves as a truss that strengthens the casting and enables it to resist the deformation during the ceramic firing cycles. But it produces dark line or shadow beneath the gingival tissue hampering the esthetic appearance.4 Thus, the alternate designs of metal framework substructure were developed. Warpeha et al.5 emphasized that the design of the underlying metal substructure had a significant relation to the ultimate fracture strength. O'Boyle et al.6 suggested that the reduction in 1 mm of labial metal framework diminishes the darkening effect and also enhances esthetics without compromising fracture strength of restoration. Goodacre4 suggested that fabrication of the metal ceramic restoration without the cervical metal collar so that the structural advantages of metal for strength and esthetic qualities of porcelain were utilized in restoration. Prince and Donovan7 suggested that the esthetic demand in the region of the labial margin combined with the strength of conventional metal ceramic restoration may explain the increased popularity of collarless metal ceramic restoration. O'Boyle et al.6 concluded that 1 mm facial axial reduction of the metal framework may assist in providing better gingival esthetics without substantial reduction in fracture strength of the metal ceramic restorations.

Thus, recommendations were made with regard to the framework designs that maximized the esthetic characteristics without affecting the strength of metal ceramic restorations. Due to the brittle nature of porcelain, even if it is reinforced it may lead to fracture, when subjected to the shear or compressive stresses. In the present study the labial extension of metal copings with the metal collar 0 mm, 0.5 mm, 1 mm and 1.5 mm short in length from the shoulder finish line were used so as to eliminate the unesthetic appearance of the metal at the cervical finish lines of the anterior metal ceramic restoration. As the unsupported ceramic without the metal backing extends like cantilever, it may result in fracture when subjected to load palatally or incisally, and magnitude of load required may be related to the length of shoulder porcelain used. Therefore, the objective of this study was to evaluate the effect of metal substructure extension on the fracture resistance of metal ceramic crown.

Maxillary central incisor tooth was prepared for metal ceramic restoration, with a 1.5 mm wide facial shoulder at 90° angle to the axial surface, as per the specification. The tooth was prepared using KaVo Milling Machine (Parallelometer, Leutkirch West Germany Model D 7970, Type 992) to ensure uniform taper of 3° all over. Metal die of the same prepared maxillary central incisor tooth was fabricated.

A counter die for the fabricated metal die with 0.5 mm clearance was fabricated (NTTF, Dharwad) for making the wax pattern for the metal copings. Thus, the metal copings thickness was standardized (Fig. 1). The counter die was made in two halves for facilitating easy removal of the wax pattern (Fig. 1). The metal rings of the thickness of 0.5, 1 and 1.5 mm were fabricated and were used to limit the cervical extension of the wax pattern. The metal copings were made short of finish line by 0.5, 1 and 1.5 mm respectively on the labial aspect. Fifty wax (Schuler-Dental, Germany) patterns for the Group 1 to 5 metal copings were made. Such that Group 1 with metal collar, Group 2 with 0 mm metal reduction, Group 3 with 0.5 mm metal reduction, Group 4 with 1mm metal reduction and Group 5 with 1.5 mm metal reduction were made (Schematic diagram 1 - 5). The wax patterns extensions were standardized by measuring the distance between the finish line and the cervical extension of the coping, using the traveling microscope (Fig. 2). The remargination of the wax patterns was done with the soft wax (Dentaurum). Wax patterns for the copings were invested using Bellavest (Batch No.; 12605, Bego Company, Germany) investment material. Fifty castings were made using Nickel Chromium metal pellets (Batch No.; 102-403-05, Bellabond plus, Bego Company, Germany) with the high frequency induction casting machine. All these castings were subjected to minimal finishing and polishing. All the copings were numbered and five groups were made as per the metal coping design.

The metal copings were standardized by measuring the cervical extensions under the Traveling Microscope. The distance between the finish line and the cervical extension of the metal coping on the labial aspect was measured as 0.5, 1 and 1.5 mm for Group 3, 4 and 5 respectively.

The thickness of porcelain application was standardized by Silicone counter parts having 1.5 mm clearance. Porcelain application and condensation were standardized as much as possible within the confines of usual laboratory techniques for fabricating metal ceramic restorations. For the castings of the Groups 3, 4 and 5 margin porcelain (Vita Vmk 95, Duceram, Germany) was applied and condensed and then carved to eliminate over contouring of the final restoration. This layer was dried and fired. The margin porcelain firing shrinkage was compensated as far as possible by adding second corrective layer of margin porcelain for all the group specimens (Fig. 3).

The specimens were tested by using a universal testing machine (Model No. 1011, Instron, UK) (Fig. 4) for evaluating the maximum load (N/m2) required to fracture the porcelain fused to metal restorations. The load was directed at the lingual incisal line angle at an angulation of 130° to the long axis of the specimen until catastrophic porcelain fracture occurred.23,24 This direction of force application was selected to reproduce the occlusal forces directed at the upper central incisor by the lower central incisor. A metal jig (NTTF, Dharwad) was fabricated with its base at an angulation of 130° (Schematic diagram 6, Fig. 5) to support and stabilize the metal die along with the metal ceramic restoration. A 5 mm diameter flat end steel plunger (NTTF, Dharwad) was used for load application at the linguoincisal line angle of the specimen. The load was applied with the 5 mm diameter flat end steel plunger at the cross head speed of 1 mm/min.6,24,25 Load at failure of each crown was recorded. The mode of fracture in the Group 1 and 2 was from the point of load application towards the cervical margin. However, the cervical porcelain margin was not much affected in the most of the specimens. In the Groups 3, 4 and 5 the cervical porcelain margin fracture was observed in most of the test specimens (Fig. 6).

The basic data was used to derive mean and standard deviation and further statistical analysis. Analysis of variance (ANOVA) was used to compare the fracture resistance, and the Student's t-test was used to compare all five groups with each other.

The mean of the maximum load required to fracture the specimens of different groups reveal that 993.6 N/m2 of Group 1 was maximum and 651.2 N/m2 of Group 5 was least. It was observed that load required to fracture the specimens with the metal collar was more than those without the cervical metal collar.

The tables below reveals the results of statistical analysis (Student's t-test) of maximum load (N/m2) to fracture porcelain fused to metal specimens of different metal frame work designs. It can be observed that there was no statistically significant difference in the mean fracture resistance of test specimens of the Group 1 and Group 2. Whereas there is statistically significant difference in the mean fracture resistance between the test specimens of different test groups.

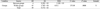

The Table 1 reveals the mean, SD, SE, minimum, maximum and CV of different test groups. Group 1 showed the maximum fracture resistance and Group 5 had the minimum fracture resistance.

The Table 2 reveals the results of statistical analysis (ANOVA) of maximum load required to fracture porcelain fused to metal specimens of different metal frame work designs. It can be observed that there was statistically significant difference in the mean fracture resistance within the groups.

The metal ceramic restoration derives its esthetics from being highly translucent, natural appearance of the porcelain and its strength from a metal substructure.6 However, optimum esthetics is not achieved consistently with conventional porcelain fused to metal restorations particularly in the area of the labiogingival margin. There are many clinical situations in which the metal cervical collar at the facial margin can be unesthetic and undesirable.6

Earlier researchers have advocated that the metal collar of metal cemamic crown reduces light transmission into adjacent tooth tissue, leading to darkened appearance of both root surface and gingival tissue. In metal ceramic restoration, the cervical shoulder margin has a tendency to have insufficient translucency because of the influence of high reflectivity from the opaque layer, which is less in thickness near the margin.6,8,10,23 This led to the development of a new concept of fabricating metal ceramic restoration without cervical metal collar on the labial side.8,10,12 These restorations possess the strength of metal ceramic crown with excellent esthetic qualities of the complete porcelain labial margin. The advancements in the shoulder porcelain material, led to the development of material similar to body porcelain in shade, texture and strength.25

In the present study the metal copings with 0.5 mm, 1 mm and 1.5 mm reduction in cervical extension were fabricated. The shoulder porcelain was used for building the cervical extensions of these copings without the metal substructure support. This alternate method of fabricating the metal ceramic restorations was done to eliminate the unesthetic effect of cervical metal collar. These metal ceramic specimens were subjected to fracture resistance testing using the universal testing machine so as to evaluate whether these restorations with the cervical shoulder porcelain can withstand the masticatory forces without fracture.

As it has been observed in intraoral conditions, the forces applied from the palatal aspect result in tensile and shear stresses accumulating at the cervical margins of the restoration, causing semilunar or lunar fracture of cervical porcelain. The specimens were subjected to evaluate fracture resistance, using the Instron testing machine. The load was applied using a flat end plunger 5 mm in diameter, with the cross head speed of 1 mm/min to allow time for the distribution of the applied forces throughout the porcelain. The plunger was placed almost in the central part whenever it contacts the linguo incisal line angle of the tooth. The mesiodistal width of the lower central incisor was considered to simulate occlusal contact relations.6,23,25 In the present study load was applied at an angulation of 130° to the long axis of the tooth, at the linguoincisal line angle of the tooth, to reproduce the occlusal forces.23,24 O'Boyle et al.6 and Ulusoy and Toksavul25 had applied the load vertical to the long axis of the tooth in their studies. The mode of fracture in the Group 1 and 2 was from the point of load application towards the cervical margin. Where as in the Groups 3, 4 and 5 fracture of the cervical porcelain margin was observed in most of the test specimens (Fig. 6).

The Table 1 depicts the mean of the maximum load (N/m2) required to fracture the test specimens of five different groups.

The statistical analysis (one-way ANOVA) showed significant difference in the maximum load (N/m2) required to fracture the test specimens of five different test Groups, with the f value 375.88 and 'P' value 0.0000. The statistical comparison Student's t-test between the mean maximum load required to fracture the test specimens of Group 1 with those Groups 3, 4 and 5 gave the 'P' value as 0.000, that is a statistically significant difference between the groups. The statistical comparison between the mean maximum load required to fracture the test specimens of Group 2 with Groups 3, 4 and 5; Group 3 with Groups 1, 2, 4 and 5; Group 4 with Groups 1, 2, 3 and 5 and Group-5 with Groups 1, 2, 3 and 4 gave the 'P' value as 0.000, respectively. The statistical analysis between the test Groups 3, 4 and 5 also depicts that there is a statistically significant difference in maximum load required to fracture the test specimens of the respective groups (Table 3). This emphasizes that the fracture resistance of the porcelain fused to metal restorations depends on the extent of metal substructure.

These findings justify the physical and mechanical laws of cantilever extension of marginal ceramic with respect to length. The fracture resistance was found to be decreasing as the length of the cantilever extension of marginal ceramic increases. However, the maximum failure load may vary due to the variation in condensation, thickness of porcelain and extension of shoulder porcelain onto the opaque layer.23 That is a statistically significant difference between the different test groups. The analysis depicts that there is a statistically significant difference in maximum load required to fracture the test specimens between the control Group 2 and Group 3, 4, and 5. The results of statistical analysis reveal that there is a difference in maximum load required to fracture the test specimens with metal collar and with the reduced metal collar (by length) Group 3, 4 and 5.

The maximum load required to fracture the test specimens of five different test groups observed in this study were exceeding the normal biting forces as reported in the literature. Gibbs et al.26 stated that the occlusal loads were 263 N during normal chewing and 297 N during swallowing. In another study Waltimo and Könönen30 reported that the mean maximal incising force to be 263 N for men and 243 N for women. Thus, the results emphasize that the metal ceramic restorations with cervical shoulder porcelain cantilever extensions, with the 0.5 mm to 1 mm cervical metal reduction can withstand masticatory forces without failure.

1. The metal ceramic restorations without the metal collar that is with 0.5 mm and 1 mm metal reduction by length showed higher fracture resistance than the specimens with 1.5 mm metal reductions but definitely less in comparison to the restorations with the metal collar.

2. The metal ceramic restorations with the metal collar reduction of 0.5 to 1 mm (by length) on the labial aspect has been advocated instead of the conventional porcelain fused to metal to achieve optimum esthetics.

3. The restorations with optimum esthetics can be fabricated with normal clinical and laboratory set up. It is advocated that preference should be given to the collarless metal ceramic restorations as marginal discrepancy could be compensated by additional correction firings and the restorations are less expensive and affordable.

Figures and Tables

Fig. 1

Metal die, counter die, metal rings and silicone mold used for fabricating the test specimens.

References

1. Rosenstiel SF, Land MF, Fujimoto J. Contemporary fixed prosthodontics. 2001. 3rd ed. St Louis: Mosby; Elsevier publishers.

2. Anusavice KJ. Philip's science of dental materials. 2003. 11th ed. Saunders; Elsevier publishers.

3. Brecker SC. Porcelain baked to gold a new medium in prosthodontics. J Prosthet Dent. 1956. 6:801–810.

4. Goodacre CJ, Van Roekel NB, Dykema RW, Ullmann RB. The collarless metal-ceramic crown. J Prosthet Dent. 1977. 38:615–622.

5. Warpeha WS Jr, Goodkind RJ. Design and technique variables affecting fracture resistance of metal-ceramic restorations. J Prosthet Dent. 1976. 35:291–298.

6. O'Boyle KH, Norling BK, Cagna DR, Phoenix RD. An investigation of new metal framework design for metal ceramic restorations. J Prosthet Dent. 1997. 78:295–301.

7. Prince J, Donovan T. The esthetic metal-ceramic margin: a comparison of techniques. J Prosthet Dent. 1983. 50:185–192.

8. Sozio RB, Riley DJ. A precision ceramic-metal restoration with a facial butted margin. J Prosthet Dent. 1977. 37:517–521.

9. Toogood GD, Archibald JF. Technique for establishing porcelain margins. J Prosthet Dent. 1978. 40:464–466.

10. Vryonis P. A simplified approach to the complete porcelain margin. J Prosthet Dent. 1979. 42:592–593.

11. Hamaguchi H, Cacciatore A, Tueller VM. Marginal distortion of the porcelain- bonded-to-metal complete crown: an SEM study. J Prosthet Dent. 1982. 47:146–153.

12. Prince J, Donovan TE, Presswood RG. The all-porcelain labial margin for ceramometal restorations: a new concept. J Prosthet Dent. 1983. 50:793–796.

13. Oram DA, Davies EH, Cruickshanks-Boyd DW. Fracture of ceramic and metalloceramic cylinders. J Prosthet Dent. 1984. 52:221–230.

14. Anusavice KJ, Hojjatie B. Stress distribution in metal-ceramic crowns with a facial porcelain margin. J Dent Res. 1987. 66:1493–1498.

15. Richter-Snapp K, Aquilino SA, Svare CW, Turner KA. Change in marginal fit as related to margin design, alloy type, and porcelain proximity in porcelain-fused-to-metal restorations. J Prosthet Dent. 1988. 60:435–439.

16. Hinrichs RE, Bowles WF 3rd, Huget EF. Apparent density and tensile strength of materials for facially butted porcelain margins. J Prosthet Dent. 1990. 63:403–407.

17. Belles DM, Cronin RJ Jr, Duke ES. Effect of metal design and technique on the marginal characteristics of the collarless metal ceramic restoration. J Prosthet Dent. 1991. 65:611–619.

18. Campbell SD, Pelletier LB. Thermal cycling distortion of metal ceramics: Part I-Metal collar width. J Prosthet Dent. 1992. 67:603–608.

19. Lund PS, Barber BA. The effect of porcelain veneer extension on strength of metal ceramic crowns. Int J Prosthodont. 1992. 5:237–243.

20. Boyle JJ Jr, Naylor WP, Blackman RB. Marginal accuracy of metal ceramic restorations with porcelain facial margins. J Prosthet Dent. 1993. 69:19–27.

21. Smith TB, Kelly JR, Tesk JA. In vitro fracture behavior of ceramic and metal-ceramic restorations. J Prosthodont. 1994. 3:138–144.

22. Lehner CR, Männchen R, Schärer P. Variable reduced metal support for collarless metal ceramic crowns: a new model for strength evaluation. Int J Prosthodont. 1995. 8:337–345.

23. Gardner FM, Tillman-McCombs KW, Gaston ML, Runyan DA. In vitro failure load of metal-collar margins compared with porcelain facial margins of metal-ceramic crowns. J Prosthet Dent. 1997. 78:1–4.

24. Ku CW, Park SW, Yang HS. Comparison of the fracture strengths of metal-ceramic crowns and three ceromer crowns. J Prosthet Dent. 2002. 88:170–175.

25. Ulusoy M, Toksavul S. Fracture resistance of five different metal framework designs for metal-ceramic restorations. Int J Prosthodont. 2002. 15:571–574.

26. Gibbs CH, Mahan PE, Lundeen HC, Brehnan K, Walsh EK, Holbrook WB. Occlusal forces during chewing and swallowing as measured by sound transmission. J Prosthet Dent. 1981. 46:443–449.

27. Silver M, Klein G, Howard MC. An evaluation and comparison of porcelain-fused-to-cast metals. J Prosthet Dent. 1960. 10:1055–1064.

28. Nielsen JP, Tuccillo JJ. Calculation of interfacial stress in dental porcelain bonded to gold alloy substrate. J Dent Res. 1972. 51:1043–1047.

29. Hinrichs RE, Bowles WF 3rd, Huget EF. Apparent density and tensile strength of materials for facially butted porcelain margins. J Prosthet Dent. 1990. 63:403–407.

30. Waltimo A, Könönen M. A novel bite force recorder and maximal isometric bite force values for healthy young adults. Scand J Dent Res. 1993. 101:171–175.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download