Abstract

STATEMENT OF PROBLEM

Use of custom tray and tray adhesive is clinically recommended for elastomeric impression material. However there is not clear mention of drying time of tray adhesive in achieving appropriate bonding strength of tray material and impression material.

PURPOSE

This study is to investigate an appropriate drying time of tray adhesives by evaluating tensile bonding strength between two types of polyvinylsiloxane impression materials and resin tray, according to various drying time intervals of tray adhesives, and with different manufacturing company combination of impression material and tray adhesive.

MATERIAL AND METHODS

Adhesives used in this study were Silfix (Dentsply Caulk, Milford, Del, USA) and VPS Tray Adhesive (3M ESPE, Seefeld, Germany) and impression materials were Aquasil Ultra (monophase regular set, Dentsply Caulk, Milford, Del, USA) and Imprint II Garant (regular body, 3M ESPE, Seefeld, Germany). They were used combinations from the same manufacture and exchanged combinations of the two. The drying time was designed to air dry, 5 minutes, 10 minutes, 15 minutes, 20 minutes, and 25 minutes. Total 240 of test specimens were prepared by auto-polymerizing tray material (Instant Tray Mix, Lang, Wheeling, Il, USA) with 10 specimens in each group. The specimens were placed in the Universal Testing machine (Instron, model 3366, Instron Corp, University avenue, Nowood, MA, USA) to perform the tensile test (cross head speed 5 mm/min). The statistically efficient drying time was evaluated through ANOVA and Scheffe test. All the tests were performed at 95% confidence level.

RESULTS

The results revealed that at least 10 minutes is needed for Silfix-Aquasil, and 15 minutes for VPS Tray Adhesive-Imprint II, to attain an appropriate tensile bonding strength. VPS Tray Adhesive-Imprint II had a superior tensile bonding strength when compared to Silfix-Aquasil over 15 minutes. Silfix-Aquasil had a superior bonding strength to VPS Tray Adhesive-Aquasil, and VPS Tray Adhesive-Imprint II had a superior tensile bonding strength to Silfix-Imprint II at all drying periods.

CONCLUSION

Significant increase in tensile bonding strength with Silfix-Aquasil and VPS Tray adhesive-Imprint II combination until 10 and 15 minutes respectively. Tray adhesive-impression material combination from the same company presented higher tensile bonding strength at all drying time intervals than when using tray adhesive-impression material of different manufactures.

Many clinicians prefer using rubber based impression materials to attain an accurate impression outcome. Among various rubber impression materials polyvinylsiloxane impression material is mostly used due to its high reproducibility and volumeric stability.1,2 In order to attain uniform thickness and use minimum amount of impression material for adequate marginal fitness, an individual tray is necessary.3,4-6 Manufacturing companies usually recommend using tray adhesives to either stock trays or individual trays and using tray adhesives provides more accurate and stable impression bodies.7-10

Several studies determined the bonding strength of tray adhesives between impression materials and tray resin materials.7,8,9,11-16,19 However, bonding strength was not mentioned there. The exact time for drying the tray adhesives before impression taking is also not known.16 Manufactures recommend from 5 to 20 minutes per tray adhesives to dry completely. Controversy results are reported regarding to this recommended time. Cho et al.16 reported that the tray adhesives should be applied at least 7 minutes before taking impressions. Dixon et al.17 described the bonding strength between the tray adhesive and tray material to be the greatest at 48 hours after application. In the study by Davis et al.18, results presented the drying time of the tray adhesive did not affect the bonding strength between 15 minutes to 72 hours after application. However, within 15 minutes of application the bonding strength was reduced, so it was not recommended to take impressions 15 minutes before application. Hogans and Agar15 reported that the bonding strength between the adhesive and the tray was not affected even when only 5 minutes was given for drying, and presented that there is a minimum relationship between bonding strength and drying time.

Tray adhesives are usually manufactured from the same manufacturing company as the impression material. However, studies present that using an adhesive from the same manufacturing company as the impression material is not always an ideal combination. Bindra and Heath13 evaluated the tensile bonding strength between tray adhesives and additional silicone impression materials of different manufacturing companies and reported that tensile bonding strength with different company combination was greater than that with the combination of the same company.

The objective of the present study was to determine an appropriate drying time of tray adhesives by evaluating tensile bonding strength between two types of polyvinylsiloxane impression materials and resin tray, according to various drying time intervals of tray adhesives, and with different manufacturing company combination of impression material and tray adhesive.

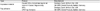

The product name and company of the impression materials and tray adhesives used in this study are presented in Table I.

Self curing individual tray impression material (Instant Tray Mix, Lang, Wheeling, Il, USA) was mixed according to manufacturer's guideline. A three dimensional rectangular specimen was prepared using 20 mm wide and 30 mm thick silicon mold. Three specimens were prepared with one measuring spoon, provided by the manufacturer. A brass hook was dipped on the middle of the tray resin specimen to attach the measuring instrument.

The materials used in the study were divided into 4 groups according to their manufacture's combinations. Groups A and D were tray adhesive-impression materials combination of the same company. Groups B and C were tray adhesive-impression materials combination of the different company (Table II).

Ten specimens in each group and the drying time of tray adhesives was designed within 5 minutes interval, with air dry for 5, 10, 15, 20, 25 minutes. A total of 240 specimens were used. In the case of air dry, the tray was dried by spraying compressed air syringe until the outer surface of the tray adhesive was dried after applying the impression material. The surface of the resin tray specimen was standardized by polishing the surface with 220-grit sandpaper (resin coated abrasive, Deer, Korea abrasive IND. CO., LTD., 290, Gaiwa-4dong, Seo-gu, Incheon, Korea). In order to prevent tearing of the impression material a polyvinylchloride (PVC) pipe with an inner diameter of 19mm was used for impression material housing, and the impression material allowed to be maintained in the PVC pipe, 20 holes were uniformly drilled with No. 8 round bur, and retention grooves were created by placing them at perpendicular direction to length of the inner surface of the pipe. At the other end of the PVC pipe, a metal rod was pierced to connect a hook and fixed to lower vice of universal testing machine (Fig. 1).

Tray adhesive was applied with a brush provided by the manufacturing company and a layer of material applied as thin as possible. The tray adhesive was dried according to chosen time interval and PVC pipe housing was placed in the middle of tray resin specimen. The specimen was fixed by hand to avoid excess impression material from leakage and impression material was applied with an automatic mixing tip and left to set for 7 minutes at room temperature.

Tensile force was applied on the specimen and the force for separation was measured by universal testing machine (Instron, model 3366, Instron Corp, University avenue, Nowood, MA, USA). The tensile bonding strength was calculated by dividing the force of resin specimen and impression material separation by surface area (9.52 × 3.14 mm2). The cross head speed of universal testing machine was set to 5 mm/min.

The separation patterns of the specimens were evaluated with naked eye after measurements, and were grouped as failure in adhesion, failure in cohesion or combination of two of them. The specimens presenting separation at impression material and tray adhesive, separation at tray material and tray adhesive or a combination of them was included as failure in adhesion. Specimens presenting tearing of the impression material were grouped as failure in cohesion. However, these specimens were excluded for analysis since they were not closely related to bonding strength. In specimens presenting both failure in adhesion and cohesion, the specimens were grouped as combination type and were also excluded for analysis.

Statistical analysis using ANOVA was performed to evaluate the difference in drying time intervals within groups A, B, C, D and difference in groups A, B, C, D according to each drying time period. And Scheffe test was performed for post hoc analysis (P < .05).

The means of tensile bonding strength between tray resin and tray adhesive according to drying time period were calculated for each group (Fig. 2).

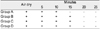

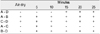

In Silfix-Aquasil combination, there was statistically significant increase in tensile strength till 10 minutes of drying, but no more significant increase after this time interval. In VPS Tray adhesive-Aquasil combination, tensile bonding strength significantly increased till 15 minutes, but no significant increase afterwards. Similar findings were also presented with Silfix-Imprint II combination, where the tensile bonding strength increased till 15 minutes and no significant change at 15, 20 and 25 minutes. However, there was a significant difference in comparing 15 and 25 minutes time interval. In VPS Tray adhesive-Imprint II combination, tensile bonding strength increased till 15 minutes without significant difference at further time periods (Table III, IV, V).

A clinically adequate bonding strength needed between tray adhesive and tray resin, and between tray adhesive and polyvinylsiloxane impression material has not mentioned clearly yet. Instead, results of previous studies on tensile bonding strength between tray adhesive and tray material reported to be 0.13 to 2.1 MPa.7,8,9,11,16 The results of the present study revealed mean value range of 0.12 - 0.47 MPa which is in the range of the previous studies.

Failure in adhesion was presented as separation between impression material and tray adhesive, and between resin tray and tray adhesive.

The result of the present study showed an increase in tensile bonding strength as the drying time increased. Each test group was evaluated for its difference in bonding strength with various drying time periods using ANOVA and Scheffe tests. Silfix-Aquasil combination showed a statistically significant increase in tensile bonding strength from 0 to 5 minutes and from 5 to 10 minutes without significant change in bonding strength after 10 minutes. Hence, when using Silfix-Aquasil combination, drying time of at least 10 minutes is recommended. In VPS Tray adhesive-Imprint II group, there was an increase in bonding strength from 0 minute to 15 minutes with 5 minutes interval. However, there was no significant change after 15 minutes. Therefore, in VPS Tray adhesive-Imprint II combination, at least 15 minutes of drying time is recommended. In case of changing the manufacturing companies of the tray adhesive-impression material combination, in VPS Tray adhesive-Aquasil group tensile bonding strength increased up to 15 minutes significantly, but not after 15 minutes. Therefore, at least 15 minutes of drying time is recommended. Silfix-Imprint II group also showed a significant increase in tensile bonding strength, but no significant increase between 15 to 20 minutes and 20 to 25 minutes, but statistical significant difference between 15 and 25 minutes. Hence, in VPS Tray adhesive-Aquasil combination, at least 15 minutes of drying time is needed but more favorable results could be achieved after 25 minutes.

Bindra and Heath13 compared tensile bonding strength of two types of additional silicone impression materials and their tray adhesives by changing the combination of their manufacturing companies. The results presented that changing the combination of the manufacturing companies showed higher bonding strength than in combination of the same manufacturing company, and concluded that using a tray adhesive and impression material combination of a same company does not always provide an ideal choice. Therefore, in the present study, the study was designed in such way that tray adhesive-impression material combination of same company and of different companies were evaluated for its tensile bonding strength according to different drying time.

In the case of tray adhesive-impression material combination of the same company, those are groups A and D, higher tensile bonding strength was achieved with VPS Tray adhesive-Imprint II combination after 15 minutes of tray adhesive dryness than in Silfix-Aquasil combination. When Aquasil impression material and two different tray adhesives, groups A and B, were compared for their tensile bonding strength, Silfix-Aquasil combination showed higher tensile bonding strength than Silfix-Imprint II at all drying time periods. When Imprint II impression material and two different tray adhesives, groups C and D, were compared, tensile bonding strength of VPS Tray adhesive-Imprint II showed higher values than VPS Tray adhesive-Aquasil, representing that higher tensile bonding strength could be achieved by using the tray adhesive-impression material of the same company. In comparing groups A and C with Silfix tray adhesive and two different impression materials, tensile bonding strength changed only between 5 and 10 minutes and no significant change at other time periods was mentioned. Hence, from these results we could find out that impression material does not seem to act as a variable factor to tensile bonding strength when Silfix tray adhesive is used. In comparing groups B and D, that is VPS Tray adhesive and two different impression materials, VPS Tray adhesive-Imprint II presented higher tensile bonding strength than VPS Tray adhesive-Aquasil from 5 minutes drying period. Therefore, when using VPS Tray adhesive, Imprint II impression material seems to produce better results than with Aquasil impression material.

Although not being considered in the present study, tray material could also be an affecting factor to bonding strength of tray adhesives. Dixon et al.17 compared tensile bonding strength of tray adhesives using three different tray materials. Results presented higher bonding strength with light curing tray resin than self curing tray resin. In addition, in the experiment performed by Peregrina et al.19, 5 types of tray adhesives were evaluated by using two types of tray materials and three types of polyvinylsiloxane impression materials. The results presented no significant difference in self curing resin and light curing resin trays.

In order to find out an appropriate method in using tray adhesives, further studies with different types of tray material, surface treatment of the tray material and various tray adhesive-impression material combinations should be performed.

The results presented a significant increase in tensile bonding strength with Silfix-Aquasil and VPS Tray adhesive-Imprint II combination until 10 and 15 minutes respectively. In addition, using tray adhesive-impression material of the same manufacturing company presented higher tensile bonding strength at all drying time intervals than when using tray adhesive-impression material of different manufactures.

Figures and Tables

References

1. Frazier KB, Mjor IA. The teaching of all-ceramic restorations in North American dental schools: materials and techniques employed. J Esthet Dent. 1997. 9:86–93.

2. Chee WW, Donovan TE. Polyvinyl Siloxane impression materials: a review of properties and techniques. J Prosthet Dent. 1992. 68:728–732.

3. Williams PT, Jackson DG, Bergman W. An evaluation of the time-dependent dimensional stability of eleven elastomeric impression materials. J Prosthet Dent. 1984. 52:120–125.

4. Eames WB, Sieweke JC, Wallace SW, Rogers LB. Elastomeric impression materials: effect of bulk on accuracy. J Prosthet Dent. 1979. 41:304–307.

5. Sandrik JL, Vacco JL. Tensile and bond strength of putty-wash elastomeric impression materials. J Prosthet Dent. 1983. 50:358–361.

6. Gordon GE, Johnson GH, Drennon DG. The effect of tray selection on the accuracy of elastomeric impression materials. J Prosthet Dent. 1990. 63:12–15.

7. Nicholson JW, Porter KH, Dolan T. Strength of tray adhesives for elastomeric impression materials. Oper Dent. 1985. 10:12–16.

8. Tjan AH, Whang SB. Tensile and peel bond strengths of tray treatment on the accuracy of dies. J Prosthet Dent. 1987. 58:175–178.

9. Grant BE, Tjan AH. Tensile and peel bond strengths of tray adhesives. J Prosthet Dent. 1988. 59:165–168.

10. Bomberg TJ, Goldfogel DJ, Hoffman W Jr, Bomberg SE. Considerations for adhesion of impression materials to impression trays. J Prosthet Dent. 1988. 60:681–684.

11. Sulong MZ, Setchell DJ. Properties of the tray adhesive of an addition polymerizing silicone to impression tray materials. J Prosthet Dent. 1991. 66:743–747.

12. Payne JA, Pereira BP. Bond strength of two nonaqueous elastomeric impression materials bonded to two thermoplastic resin tray materials. J Prosthet Dent. 1995. 74:563–568.

13. Bindra B, Heath JR. Adhesion of elastomeric impression materials to trays. J Oral Rehabil. 1997. 24:63–69.

14. Dixon DL, Breeding LC, Bosser MJ, Nafso AJ. The effect of custom tray material type and surface treatment on the tensile bond strength of an impression material/adhesive system. Int J Prosthodont. 1993. 6:303–306.

15. Hogans WR 3rd, Agar JR. The bond strength of elastomer tray adhesives to thermoplastic and acrylic resin tray materials. J Prosthet Dent. 1992. 67:541–543.

16. Cho GC, Donovan TE, Chee WW, White SN. Tensile bond strength of polyvinyl siloxane impressions bonded to a custom tray as a function of drying time: Part I. J Prosthet Dent. 1995. 73:419–423.

17. Dixon DL, Breeding LC, Brown JS. The effect of custom tray material type and adhesive drying time on the tensile bond strength of an impression material/adhesive system. Int J Prosthodont. 1994. 7:129–133.

18. Davis GB, Moser JB, Brinsden GI. The bonding properties of elastomer tray adhesives. J Prosthet Dent. 1976. 36:278–285.

19. Peregrina A, Land MF, Wandling C, Johnston WM. The effect of different adhesives on vinyl polysiloxane bond strength to two tray materials. J Prosthet Dent. 2005. 94:209–213.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download