Abstract

STATEMENT OF PROBLEM

The poor chemical bonding of a denture base resin to cast titanium framework often introduces adhesive failure and increases microleakage.

PURPOSE

This study evaluated the shear bond strengths of a heat cure denture base resin to commercially pure titanium, Ti-6Al-4V alloy and a cobalt-chromium alloy using two adhesive primers.

MATERIAL AND METHODS

Disks of commercially pure titanium, Ti-6Al-4V alloy and a cobalt-chromium alloy were cast. Specimens without the primer were also prepared and used as the controls. The shear bond strengths were measured on a screw-driven universal testing machine.

RESULTS

The primers significantly (P < .05) improved the shear bond strengths of the heat cure resin to all metals. However, the specimens primed with the Alloy primer® (MDP monomer) showed higher bond strength than those primed with the MR bond® (MAC-10 monomer) on titanium. Only adhesive failure was observed at the metal-resin interface in the non-primed specimens, while the primed specimens showed mixed failure of adhesive and cohesive failure.

CONCLUSIONS

The use of appropriate adhesive metal primers makes it possible not only to eliminate the need for surface preparation of the metal framework before applying the heat cure resins, but also reduce the need for retentive devices on the metal substructure. In particular, the Alloy primer®, which contains the phosphoric acid monomer, MDP, might be clinically more acceptable for bonding a heat cure resin to titanium than a MR bond®, which contains the carboxylic acid monomer, MAC-10.

Polymethylmethacrylate (PMMA) is the material of choice for constructing denture bases (95%). However, there are problems with the integrity of, not of the between metal and PMMA interfaces.1 Despite many disadvantages of PMMA, such as few sites for chemical bonding to the metals used in removable and complete arch fixed frameworks, it is one of the materials most often used for conventional removable and implant-supported prosthodontics. The integrity of the bond at the PMMA-to-metal interface is important for the service longevity of a prosthesis.2

The mechanical retention of a denture resin (PMMA) in a removable prosthesis is usually provided by the framework design in the denture base, for example, using beads, posts, bars, an open lattice, a mesh, or some macroscopic retentive design.3,4 The correct positioning of the finish lines and the sharp undercut line angles of the denture resin margin are also essential for preventing failure of the resin at the junction with the framework.1,5 Chemical bonding between the metal framework and the denture base resin is also important. Poor chemical bonding in that area is a significant clinical problem, which often introduces adhesive failure and the increasing microleakage of oral fluids in the finish lines, which causes the accumulation of oral debris, microorganisms, and stains.1,2 As a result, the propagation of microorganisms contributes to an unfavorable soft tissue response.

The bonding of resin to dental alloys has improved significantly over the last decade, and various bonding methods and techniques have been developed for base metal alloys, such as electrolytic etching, chemical etchant, and silica coating. The availability of adhesive primer for base metals that are capable of chemically bonding to a casting dental alloy has simplified the surface preparation of base metal alloys.

For approximately 20 years, the application of a 4-methacryloxyethyl trimellitate anhydride (4-META) bonding system to removable partial dentures (RPDs) has been examined as a way to prevent the problems previously mentioned.5,6 Yasuda et al. reported that a higher bond strength was obtained for cobalt-chromium (Co-Cr) alloys with a 4-META bonding system and also suggested in a longitudinal in vivo research study that the formation of bonds between these materials is clinically stable.6,7

Co-Cr alloys are commonly used for RPDs and complete dentures that incorporate metal components. Compared with alternative type IV gold alloys, Co-Cr alloys are relatively inexpensive, and are approximately twice as rigid. However, they may contain elements (Co and or Cr) that have been alleged to produce sensitivity or allergic reactions in some patients.8 Because of the potential of titanium to reduce and eliminate some of these reported problems associated with Co-Cr alloys; titanium has been used increasingly in clinical practice for removable prosthesis.

Many studies have evaluated the adhesion of composites to CP titanium with adhesive primers, and high bond strength being reported.9-15 However, few studies have evaluated the adhesion of denture base resin to primed titanium for use in RPDs.20-22 In particular, there are few reports on the evaluation of the bond strength of a heat cure denture base resin to a primed titanium sample.

This study examined the shear bond strength of a heat cure resin as a denture base resin to cast CP titanium and Ti-6Al-4V alloy using two adhesive primers. These results were compared with those obtained with a Co-Cr alloy.

Table I lists the materials used in this study. Disc-shaped wax patterns (10.0 mm in diameter and 2.5 mm thick) of CP titanium, Ti-6Al-4V alloy (Kobesteel Co., Japan) were cast using a magnesia-based investment (Selevest CB, Selec Co., Japan) in an argon arc-centrifugal casting machine (Ticast Super R, Selec Co.) according to the manufacturer's instructions.

For comparison, disc patterns (the same size as Ti-6Al-4V alloy) of a Co-Cr alloy (Biosil F, Degussa co., Ltd) were conventionally cast using a silica-based investment (Univest Silky, Shofu Dental Corp.) in a centrifugal induction melting machine (Neutrodyn Easyti, Manfred, Italy). Thirty cast discs were made for each alloy.

After casting, the disk surfaces were finished with No. 600 silicon carbide paper under water followed by 250 µm grain-sized aluminum oxide for 5 seconds using grit blaster (Micro sand blaster. Phoenix electric company Korea). The emission pressure was 4.5 kgf/cm2 with the nozzle positioned approximately 5 mm from the surface of the metal adherent. The grit-blasted cast disks were washed in acetone for 10 minute using ultrasonic cleaner (Ultraschall. KRUPP Corp, Germany).

First, a hexagonal shape (2.5 mm edge) wax was attached to the discs to fabricate a part of the resin tap. The waxes were fixed in the same dimension by preparing silicone models and pouring the melted waxes. Ninety wax specimens in the same parameter were fabricated.

The waxes adhered to the dried specimens. The specimens were then invested in the conventional way. After hardening the investment, the remaining waxes were removed by hot water.

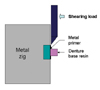

Immediately after drying the cleaned discs, two metal conditioners were applied to the air-abraded surfaces using a sponge pellet according to the manufacturer's directions. The specimens with unprimed disc surfaces were also prepared as controls (Fig. 1). The resin separator was brushed on the investment and the heat cure resin applied.

Heat cure resin (Vertex-Vertex Dental B.V. co., Netherland) was polymerized according to the manufacturer's instructions, i.e. in a heat curing unit (SE KI Dental Co. Korea) at 70℃ for 60 min followed by 100℃ for 30 min and then cooling for 120 min. All the specimens were immersed in water at 37℃ for 24 h (Fig. 2).

The shear bond strengths were measured using a screw-driven universal testing machine (STM-5, United Calibration, USA) at a crosshead speed of 1.0 mm/min. The means and standard deviations (SD) of the shear bond strength (n = 5) were calculated and statistically analyzed with a 2-way analysis of variance (ANOVA).

The factors for analysis were primer and metal. Then 2-way ANOVA, 1-way ANOVA and the Scheffe multiple comparison test were performed at a significance level of α= .05. After testing, the fracture surfaces of the specimens were observed using an optical microscope (BX51 TRF, LYMPUS, JAPAN) at × 50 magnification to assess the type of bond failure. The failure modes were categorized s either A (adhesive failure at the metal-PMMA interface) or M (mixed adhesive and cohesive failure) (Fig. 3).

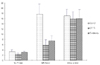

Fig. 4 and Table II shows the effect of the adhesive primers on the shear bond strength of the heat cure resin to the cast titanium and cobalt-chromium alloy. Table III shows the means and standard deviations (SD) of the shear bond strengths (MPa) of the 3 metals along with the statistical comparisons of the groups. Table IV shows the types of bond failure classified as A or M for each group of specimens. Application of the primers significantly (P < .05) improved the shear bond strengths of the heat cure resin to all metals (Table II, III).

The specimens primed with the Alloy primer® showed a significantly higher bond strength (P < .05) than the specimens primed with the MR bond® on titanium. However, there was no significant difference between the Alloy primer® and MR bond® on the Co-Cr alloy.

Titanium is a relatively new material in removable partial denture frameworks, and will most likely become more popular with the advancements in casting procedures and materials. Since the introduction of the first fixed partial denture retained by implants, a type III gold alloy has been recommended metal for the substructure because it is nontoxic, no allergenic, corrosion resistant, easy to use, has adequate strength, and is relatively inexpensive. Commercially pure titanium and Ti-6Al-4V alloy have similar desirable mechanical and physical properties. Clinical trials of titanium substructures are underway to identify the variables that might negatively affect the life expectancy of an implant and the use of the prostheses. A failure of the bond at the PMMA-titanium interface can result in prosthetic failure and create space between the metal and PMMA, where oral debris, microorganism, and stains can accumulate. A poor bond between a titanium framework and PMMA can compromise the quality of the prosthesis and potentially place the patients at risk of an infection from opportunistic microorganism.

In order to evaluate the value of commercially pure (CP) titanium as a material for cast partial denture frameworks, Yamauchi et al. examined the results of a follow-up examination of patients who had used titanium prosthesis.16 They reported that there were no clinical problems with cast CP titanium partial denture frameworks. However, there was some dye penetration from the finish line found despite the use of an adhesive resin containing 4-META (META-DENT, Sun Medical, Kyoto, Japan) as a denture base resin. In a study of this phenomenon, Matsumura et al. reported the bond strength of 4-META containing an adhesive resin to pure titanium decreased considerably after thermocycling.17 Jemt and Linden also showed that implant-supported prostheses with machined titanium had bonding problems between the machined surface and the PMMA.18 Therefore, conventional bonding between an acrylic resin denture base and a titanium framework may not be sufficient to prevent microleakage.

The surface of pure titanium metal is usually coated with a titanium oxide that is stable in an atmospheric environment. This indicates that the primers actually adhere to titanium oxide rather than to pure titanium. Some metal oxides can react with carboxylic or phosphoric acid derivatives to form a chemical bond.

Kojima et al.19 synthesized the 6-4-vinylbenzyl-n-propyl)amino-1,3,5-triazine-2,4-dithione monomer, which does not contain a free mercapto group, and reported that the VBATDT primer improved the bond durability of an MMA-PMMA-TBBO resin joined to precious metal alloys. However, VBATDT was ineffective in increasing the bond strength of MMA-TBB resin to base metal dental casting alloys such as Co-Cr and nickel-chromium. It was for this reason that MAC-10 (11-methacryloyloxyundecan-1,1-decarboxylic acid) and MDP (10-methacryloyloxydecyl dehydrogen phosphate) were used in this study (Fig. 6).

Regarding the bond strength, the use of any of the primers in previous studies would be acceptable for achieving clinically durable bonds to titanium frameworks. However, cast titanium frameworks, particularly CP titanium, are more flexible (lower elastic modulus) than the Co-Cr alloy. Denture deflection during use can cause debonding between the denture base resin and the framework, and resulting eventually in resin fracture. Therefore, titanium frameworks should also be designed (and fabricated) to be hard enough so that denture deflection is kept to a minimum. It was for this reason that Ti-6AL-4V alloy ASTM Grade V was used in this study.

The aim of this study was to evaluate the shear bond strengths of a PMMA denture base resin to cast pure titanium, Ti-6Al-4V, and a cobalt-chromium alloy using two adhesive primers (MR bond®: MAC-10, Alloy primer®: MDP, VBATDT).

The difference in shear bond strengths of the primed and unprimed specimens was significant (P < .05) (Table III). May et al.20 suggested that the shear bond strength of heat-processed PMMA bonded to a machined surface of wrought CP titanium with 110 µm alumina air abrasion and a silane coating was 63% higher than the specimens with no pretreatment. Other studies21,22 reported that the application of Rocatec bonding material (ESPE GmbH, Seefeld/Oberbay, Germany) increased the bond strength by 68% compared with the control. The application of heat-cured PMMA containing 4-META (META-DENT) demonstrated a 3.7 fold higher bond strength than the control group. Shiragami et al.23 evaluated the tensile bond strengths of a similar resin to cast Ti-6Al-4V alloy with 3 adhesive primers. They used the original Metal Primer, Meta Base M, and Cesead Opaque Primer materials and found greater bond strength than with the untreated specimens.

In this study, the shear bond strength of heat cure denture base resin to a metal surface treated with an adhesive primer was greater than the specimens with no treatment. Therefore, the two metal conditioners had a significant effect on the bond between the heat cure denture base resin and both alloys (Fig. 4 and Table II). While the shear bond strengths of the Alloy primer® were higher than those of the MR bond® on cast pure titanium, Ti-6Al-4V alloy, there was no significant difference observed on the Co-Cr alloy. It is possible that the chemical bond of MDP to the titanium oxide is superior to that of MAC-10. Moreover, these results may be attributed to the differences in their composition, polymerization procedure or mechanical properties. However, further research will be needed to answer this question.

The fractured site revealed bonding failure between the denture base resin and metal interface in all comparative samples that had not been treated with a metal surface conditioner were observed. The reason for the failure was that the comparative, which showed a lower bonding strength than the resin strength. This is similar to the results reported by Ohkubo et al., who showed that bonding failure occurred between the resin and metal interface24. Mixed failure appeared in the resin and metal interface, which is considered to be the result between chemical bonding of metal and resin.

This study evaluated the effect of adhesive primers on the shear bond strength of heat cure denture base resin to a cast titanium and cobalt-chromium framework. CP titanium, Ti-6Al-4V, or Co-Cr alloy discs were cast, and the bonding surfaces of the metal disk (10 mm diameter, 2.5 mm thick) were treated with 2 different metal primers (MR bond®, Alloy primer®). The specimens without the primer were also prepared as the control.

The shear bond strengths were determined at a crosshead speed of 1.0 mm/min. The application of any one of the two primers tested, regardless of the brand used, significantly improved the shear bond strength of the denture base resin to any of the cast metals tested (CP titanium, Ti-6Al-4V, and Co-Cr alloy). The specimens primed with the Alloy primer showed higher bond strength than those primed with the MR bond on titanium. However, significant difference was not observed on the Co-Cr alloy. Only adhesive failure was evident at the metal-resin interface of all the non-primed specimens, while the primed specimens showed mixed failure of adhesive and cohesive failure.

With the use of appropriate adhesive metal primers, it is possible not only to eliminate the need for surface preparations of the metal frameworks before the application of heat cure resins but also to reduce the need for retentive devices on the metal substructure.

In particular, the Alloy primer®, which contains the phosphoric acid monomer, MDP, is clinically more acceptable for bonding heat cure resin to titanium than the MR bond®, which contains the carboxylic acid monomer, MAC-10.

Figures and Tables

Fig. 5

A: Adhesive failure at non-primed specimens.

M: Mixed failure of adhesive and cohesive failures at Primed specimens. ×50: The fracture surface of the specimens were observed with and optical microscope.

References

1. Jacobson TE, Chang JC, Keri PP, Watanabe LG. Bond strength of 4-META acrylic resin dentrue base to cobalt chromium alloy. J Prosthet Dent. 1988. 60:570–576.

2. Jacobson TE. The significance of adhesive denture base resin. Int J Prosthodont. 1989. 2:163–172.

3. Dunny JA, King GE. Minor connector disigns for anterior acrylic resin bases; a preliminary study. J Prosthet Dent. 1975. 34:496–502.

4. Brown DT, Desjardins RP, Chao EY. Fatigue failure in acrylic resin retaining minor connectors. J Prosthet Dent. 1987. 58:329–335.

5. Sasaki M, Yasuda N, Mogi T, Ai M. Influence between metal and resin on the finishing line of cobalt-chromium denture. Part 3. Studies on finishing line structure. J Jpn Prosthodont Soc. 1994. 38:191–197.

6. Yasuda N, Sasaki M, Mogi T, Ai M, Nakabayashi N. Influence between metal and resin on the finishing line of cobalt-chromium denture. Part 2. Effect of 4-META on preventing dye penetration at the finishing line. J Jpn Prosthodont Soc. 1978. 22:761–765.

7. Yasuda N, Sasaki M, Shinogaya T, Ai M, Nakabayashi N. Influence between metal and resin on the finishing line of cobalt-chromium denture. Part 7. A clinical evaluation of 4-META system : a five-year report. J Jpn Prosthodont Soc. 1985. 29:761–765.

8. Kononen M, Rintanen J, Waltimo A, Kempainen P. Titanium framework removable partial denture used for patients allergic to other metals: a clinical report and literature review. J Prosthet Dent. 1995. 73:4–7.

9. Fujishima A, Fujimori S, Tamaki Y, Miyazaki T, Fujishima Y, Shiba A. A basic study on the fabrication of titanium veneered crown with resin composites. (Part 2). Effect of surface treatments on bonding of resin composites. (Part 2). Effect of surface treatment on bonding of resin composites with titanium. J Jpn Dent Mater. 1995. 14(special issue):78–79.

10. Hansson O. Strength of bond with Comspan Opaque to three silicoated alloys and titanium. Scand J Dent Res. 1990. 98:248–256.

11. Fujishima A, Fujishima Y, Ferracane JL. Shear bond strength of four commercial bonding systems to cp Ti. Dent Mater. 1995. 11:82–86.

12. Yoshida N. Clinical application of resin facing titanium crown by the non-retention method-bond strength of composite resin materials for veneering to titanium. Ohu Dent J. 1997. 24:1–20.

13. Hansson O, Moberg LE. Evaluation of three silicoating methods for resin-bonded prostheses. Scand J Dent Res. 1993. 101:243–251.

14. Kern M, Thompson VP. Durability of resin bonds to pure titanium. J Prosthodont. 1995. 4:16–22.

15. Kurtz K, Kabcenell J, Watanabe I, Okabe T. Shear bond strength of polymer-glass to cast titanium. J Dent Res. 1998. 77:272. Abstract 1331.

16. Yamauchi M, Sakai M, Kawano J. Clinical application of pure titanium for cast plate dentures. Dent Mater J. 1988. 7:39–47.

17. Matsumura H, Kojima K, Kadoma Y, Masuhara E. Studies on dental self-curing resins (26). Effect of 4-META and 4-MET addition to the MMA-TBBO resin. Shika Zairyo kikai. 1984. 3:480–489. [in Japanese].

18. Yoshida K, Taira Y, Matsumura H, Atsuta M. Effect of adhesive metal primers on bonding a prosthetic composite resin to metals. J Prosthet Dent. 1993. 69:357–362.

19. Kojima K, Kadoma Y, Imai Y. Adhesion to precious metals utilizing triazine dithione derivative monomer. J Jpn Soc Dent Mater Devices. 1987. 6:702–707.

20. May KB, Russell MM, Razzoog ME, Lang BR. The shear strength of polymethyl methacrylate bonded to titanium partial denture framework material. J Prosthet Dent. 1993. 70:410–413.

21. May KB, Fox J, Razzoog ME, Lang BR. Silane to enhance the bond between polymethyl methacrylate and titanium. J Prosthet Dent. 1995. 73:428–431.

22. May KB, Van Putten MC, Bow DA, Lang BR. 4-META polymethyl methacrylate shear bond strength to titanium. Oper Dent. 1997. 22:37–40.

23. Shiragami N, Kozono Y, Morikawa M. Bond of resin materials to titanium. Part 1. Effects of surface treatment. J Jpn Prosthodont Soc. 1994. 88(special issue):73.

24. Ohkubo C, Watanabe I, Hosoi T, Okabe T. Shear bond strengths of polymethylmethacrylate to cast titanium and cobalt-chromium frameworks using five metal primers. J Prosthet Dent. 2000. 83:50–57.

25. Shimizu H, Kurtz KS, Tachii Y, Takahashi Y. Use of metal conditioners to improve bond strengths of autopolymerizing denture base resin to cast Ti-6Al-7Nb and Co-Cr. J Dent. 2006. 34:117–122.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download