Abstract

Objective

The purposes of this study were to evaluate the force and stress depending on the type, deflection and thickness of the materials and to evaluate the mechanical properties of thermoplastic materials after repeated loading.

Methods

Four types of thermoplastic products were tested. Force until the deflections of 2.0 mm and the stress when the materials were restoring to its resting position were evaluated. The mechanical properties of thermoplastic materials evaluated after 5 repeated loading cycles.

Results

The interaction was observed between the thickness and the deflection (p < 0.05) from the regression equation. Thickness and amount of deflection rather than products and materials showed the largest effect on force and stress. In all products, at least 159 gf of force was required for more than 1.0 mm deflection or when materials with 1.0 mm thickness were deflected. The stress recorded was more than 19 gf/mm2. During repeated loading, each group showed significant difference on the force and the stress p < 0.01), 10 - 17% reduction of force and 4 - 7% reduction of stress in average.

Figures and Tables

Fig 2

Experimental procedure used in this study. A, Universal test machine, Instron®; B, schematic diagram of 3 point bending test.

Fig 3

Increase in bending force and recovery stress level depending on the thickness and amount of deflection for all four types of products (Lt, Force (gf); Rt, recovery stress (gf/mm2)).

Fig 4

Graph showing bending force and recovery stress changes after repeated loading (Lt, Force (gf); Rt, recovery stress (gf/mm2)).

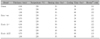

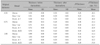

Table 4

Factors associated with bending force and recovery stress (top) and multiple regressions for interaction among products, thickness, and deflection rate (bottom)

References

1. Rinchuse DJ, Rinchuse DJ. Active tooth movement with Essix-based appliances. J Clin Orthod. 1997. 31:109–112.

2. McNamara JA, Kramer KL, Juenker JP. Invisible retainers. J Clin Orthod. 1985. 19:570–578.

5. Nahoum HI. The vacuum formed dental contour appliance. NY State Dent J. 1964. 9:385–390.

6. Fernandez Sanchez J, Pernia Ramirez I, Martin Alonso J. Osamu active retainer for correction of mild relapse. J Clin Orthod. 1998. 32:26–28.

7. Yoshii O. Introducing in new retainer-soft retainer and case reports. J Orthod Pract. 1992. 8:25–42.

8. Sheridan JJ, LeDoux W, McMinn R. Essix retainers: fabrication and supervision for permanent retention. J Clin Orthod. 1993. 27:37–45.

9. Boyd RL, Miller RJ, Vlaskalic V. The Invisalign system in adult orthodontics: Mild crowding and space closure cases. J Clin Orthod. 2000. 34:203–212.

10. Bollen AM, Huang G, King G, Hujoel P, Ma T. Activation time and material stiffness of sequential removable orthodontic appliances. Part 1: ability to complete treatment. Am J Orthod Dentofacial Orthop. 2003. 124:496–501.

11. Chenin DA, Trosien AH, Fong PF, Miller RA, Lee RS. Orthodontic treatment with a series of removable appliances. J Am Dent Assoc. 2003. 134:1232–1239.

12. Vlaskalic V, Boyd R. Orthodontic treatment of a mildly crowded malocclusion using the invisalign system. Aust Orthod J. 2001. 17:41–46.

13. Lee GW, Kim HJ. Tooth morphology. 1997. Seoul: Jisung;126–146.

14. Kwon JS, Lee YK, Lim BS, Lim YK. Force delivery properties of thermoplastic orthodontic materials. Am J Orthod Dentofacial Orthop. 2008. 133:228–234.

15. Ryokawa H, Miyazaki Y, Fujishima A, Miyazaki T, Maki K. The mechanical properties of dental thermoplastic materials in a simulated intraoral environment. Orthodontic Waves. 2006. 65:64–72.

16. Gardner GD, Dunn WJ, Taloumis L. Wear comparison of thermoplastic materials used for orthodontic retainers. Am J Orthod Dentofacial Orthop. 2003. 124:294–297.

17. Tuncay OC. The invisalign system. 2006. Graften road, New Malden: Quintessence Publishing Co, Ltd;187–194.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download