Abstract

Objective

NiTi closed coil springs were reported to have relatively constant unloading forces. However, the characteristics of NiTi closed coil springs from various manufacturers have not been elucidated. The purpose of this study was to compare load-deflection characteristics of various NiTi closed coil springs and to find out the optimal range of extension.

Methods

Seven kinds of NiTi closed coil springs from five manufacturers were tested. Load deflection curves were obtained at extension ranges from 2 mm to 30 mm. Also, springs were kept extended during a 4 week period, and then load deflection curves were obtained again.

Results

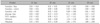

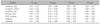

Sentalloy (Tomy) and Jinsung blue (Jinsung) showed superelasticity in every extension ranges tested and showed plastic deformation of less than 1 mm. Ni-Ti (Ormco) showed superelasticity only after the springs were extended at or more than 10 mm, thereby meaning that clinicians should extend these springs at or more than 10 mm to utilize the superelasticity. Orthonol (RMO) and Nitanium (Ortho Organizers) did not show superelasticity. After 4 weeks of extension, all springs showed plastic deformation less than 1 mm when the extension was at or under 25 mm.

Figures and Tables

Fig. 1

A, Schematic drawing of universal testing machine and water bath setup; B, Jigs used in this study.

Fig. 2

Load-deflection curve illustrating superelasticity of NiTi spring. σSIM, Transformation threshold point; σR, reverse transformation finish point; H, hysteresis (loading force - unloading force at midpoint of extension); PD, plastic deformation.

Fig. 3

Load-deflection curves of NiTi springs. X axis, Deflection (mm); Y axis, Load (N). 1st cycle, initial test; 2nd cycle, after 4 week extension.

Fig. 4

Change in transformation threshold point (σSIM) and reverse transformation finish point (σR) according to the amount of spring extension. X axis, Deflection (mm); Y axis, Load (N). σSIM L, transformation threshold point load; σSIM E, transformation threshold point extension; σR L, reverse transformation finish point load; σR E, reverse transformation finish point extension. *2 mm, 5 mm σSIM and 2 mm, 5 mm, 30 mm σR of Ni-Ti medium was not measured due to their ambiguity.

References

1. Kusy RP. A review of contemporary archwires: their properties and characteristics. Angle Orthod. 1997. 67:197–207.

2. Andreasen G, Heilman H, Krell D. Stiffness changes in thermodynamic Nitinol with increasing temperature. Angle Orthod. 1985. 55:120–126.

3. Santoro M, Beshers DN. Nickel-titanium alloys: stress-related temperature transitional range. Am J Orthod Dentofacial Orthop. 2000. 118:685–692.

4. Kim YB. A reassessment of orthodontic wire selection. J Korean Found Gnathol Orthod Res. 1995. 2:151–197.

5. Drake SR, Wayne DM, Powers JM, Asgar K. Mechanical properties of orthodontic wires in tension, bending, and torsion. Am J Orthod. 1982. 82:206–210.

6. Khier SE, Brantley WA, Fournelle RA. Bending properties of superelastic and nonsuperelastic nickel-titinium orthodontic wires. Am J Orthod Dentofacial Orthop. 1991. 99:310–318.

7. Cha BK, Choi DS, Lee NK. Simplification of orthodontic treatment process utilizing superelastic Nickel-titanium archwire: one wire system. Korean J Clin Orthod. 2005. 4:82–89.

8. Miura F, Mogi M, Ohura Y, Karibe M. The super-elastic Japanese NiTi alloy wire for use in orthodontics Part III Studies on the Japanese NiTi alloy coil springs. Am J Orthod Dentofacial Orthop. 1988. 94:89–96.

9. Nattrass C, Ireland AJ, Sherriff M. The effect of environmental factors on elastomeric chain and nickel titanium coil springs. Eur J Orthod. 1998. 20:169–176.

10. Dixon V, Read MJ, O'Brien KD, Worthington HV, Mandall NA. A randomized clinical trial to compare three methods of orthodontic space closure. J Orthod. 2002. 29:31–36.

11. Proffit WR, Fields HW. Proffit WR, editor. Mechanical principles in orthodontic force control. Contemporary orthodontics. 2000. 3rd ed. St. Louis: Mosby;329–330.

12. Shape memory alloy's development committee. Shapr memory alloy's development committee. How to use shape memory alloy. Shape memory alloy and its application. 1991. Seoul: Kijunyonkusa;37.

13. Storey E, Smith R. Force in orthodontics and its relation to tooth movement. Aust J Dent. 1952. 56:11–18.

14. Kim DS, Kim YJ, Choi JH, Han JH. A study of Korean Norm about tooth size and ratio in Korean adults with normal occlusion. Korean J Orthod. 2001. 31:505–515.

15. Heo CH, Sung JH, Kwon OW, Kyung HM. Elastic force degradation of synthetic elastomeric chain. Korean J Orthod. 2003. 33:371–380.

16. Schneevoigt R, Haase A, Eckardt Vl, Harzer W, Bourauel C. Laboratory analysis of superelastic NiTi compression springs. Med Eng Phys. 1999. 21:119–125.

17. Burstone CJ, Qin B, Morton JY. Chinese NiTi wire--a new orthodontic alloy. Am J Orthod. 1985. 87:445–452.

18. Chang MH, Lim BS, Lee YK, Kim CW, Rhee SH, Yang HC. Force degradation behavior and plastic deformation of NiTi closed coil springs. J Korean Res Soc Dent Mater. 2004. 31:133–141.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download