Introduction

Mycoplasma (M.) hyopneumoniae is recognized as the causative agent of enzootic pneumonia, and is a primary contributor to the porcine respiratory disease complex resulting in considerable economic losses [5]. Concurrent infection with M. hyopneumoniae and viral pathogens, including porcine reproductive and respiratory syndrome virus or porcine circovirus type 2, increases the severity and duration of mycoplasmal pneumonia. Due to the importance of M. hyopneumoniae in respiratory disease, eradication is often a goal and making an accurate diagnosis of the organisim important [16]. However, more than 60% of Korean pigs are infected with this organism [11]. We also confirmed that polyclonal antibodies produced by mycoplasma vaccination do not prevent M. hyopneumoniae-induced increases in [Ca2+]i [9,14]. Vaccination and antibacterial therapy are therefore the essential strategies for the prevention and control of mycoplasmal pneumonia.

The surface protein of intact M. hyopneumoniae is clearly critical for the interaction of these organisms with their host cells [15]. These bacteria are known to colonize respiratory ciliated epithelial cells, thereby inducing an inflammatory response [1,3,9]. Intact pathogenic M. hyopneumoniae have been used as a vaccine but culturing the organism is difficult due to its requirements for specific and elaborate culture media and prolonged incubation period [8,17].

Optimization of culture medium is a very important aspect in the field of food microbiology and fermentation to improve product yield and reduce process variability, as well as reducing development time and overall costs [13]. Due to the complexity of the culture media, long growth time, and slow agitation for producing M. hyopneumoniae, it is practically impossible for a one-dimensional search to identify an optimum combination of culturing conditions using a finite number of experiments [4]. Response surface methodology (RSM) is another approach that can be used to study the effect of several variables and to seek the optimum conditions for a multivariable system. Therefore, the aim of this investigation was to search for the optimal medium composition of intact pathogenic M. hyopneumoniae for mass production by using the statistical tools mentioned above.

Materials and Methods

Media

Glucose, thallium acetate, and yeast extract were obtained from Sigma-Aldrich (USA), and horse and porcine serum were purchased from Gibco (USA). Fresh yeast extract was prepared by boiling and filtration, and porcine serum was prepared by acidification and filtration.

Mycoplasma culture and protein determination

Pathogenic M. hyopneumoniae (ATCC 25934) was cultured in Friis medium [4] to logarithmic phase, and harvested by centrifugation at 15,000 × g for 30 min at 4℃. The pellets were washed three times in PBS and then dispersed through a 27-gauge needle [4,13]. As measured by the bicinchoninic acid method (Pierce, USA), 0.3 mg/mL protein corresponded to 1011 CCU (colour changing units)/mL. CCU representing the mycoplasma number in the culture were determined by serial dilutions in tubes containing Friis medium [14].

One factor at a time (OFAT) technique

This initial step served as a screening test to identify which defined factors of the medium had a significant effect on the production of M. hyopneumoniae. In this step beginning with a base line set of factor levels and measuring the response for each experimental factor in turn, the level of each factor was changed while all other experimental factors remained constant. In this case, responses to five experimental factors (glucose, thallium acetate, fresh yeast extract, and horse and porcine sera) were measured at five base line set factors levels with one additional basal mycoplasmal media culture as the control.

Experimental design

RSM was applied to optimize the production of mycoplasmal protein with the intent of simultaneously evaluating the influence of three pre-selected variables which had been found to have significant effects on protein production of mycoplasma through a preliminary study using the OFAT technique. The independent variables included fresh yeast extract, horse serum, and porcine serum with a dependent variable of mycoplasmal protein production. A central composite design (CCD) was used for optimizing the independent variables at each of the five levels (Table 1). A factorial design for three variables 23 factorial design was combined with four replications of the center point and six axial points where one factor was set at an extreme level (±α) and the other two factors were set at center point level. With this arrangement, a set of 18 experiments was performed. The ranges of the extreme and central points were based from OFAT results in this study.

The CCD is given in Table 2 with the results of the experimental and predicted values from the actual variables. A statistical test for the data generated from the CCD was performed using ANOVA. For calculating the optimal point, a second order polynomial equation was fitted to the experimental results of CCD as it represents the behavior of such a system more appropriately.

This equation was:

Y = β0 + β1X1 + β2X2 + β3X3 + β1β1X12 + β2β2X22 + β3β3X32 + β1β2X1X2 + β1β3X1X3 + β2β3X2

where Y is the response variable, β0 is the intercept/constant; β1, β2 and β3 are the linear coefficients; β12, β22 and β32 are the squared/quadratic coefficients; β1β2, β1β3 and β2β3 are the interaction coefficients; and X1, X2, X3, X12, X22, X32, X1X2, X1X3 and X2X3 are the levels of the independent variables.

Data analysis

SAS/Statistics software (Version 9.2; SAS, USA) was used for the regression analysis of the experimental data obtained. The quality of the fit of the polynomial model equation was expressed by the coefficient of determination R2, and its statistical significance was verified by an F-test. The significance of the regression coefficient was determined by a t-test. The significance was defined as p < 0.05. A differentiation calculation was then employed for predicting the optimum point.

Results

OFAT approach

The preliminary screening tests for bacterial mycoplasmal protein production defined the variables that most affected protein production, i.e., fresh yeast extract, horse serum, and porcine serum. Glucose and thallium acetate had insignificant effects on the production of bacterial mycoplasmal protein (p < 0.05).

Fig. 1 shows the effect of five factors on mycoplasmal protein yield by a OFAT approach. In this procedure, when the effect of one factor was examined, the other four factors were kept constant. With this approach, each factor effect was studied at five different concentration levels. The approximated values were set at a middle level in the CCD for further optimization.

CCD

The approximately optimized values determined by a OFAT approach were set at central levels for further optimization of three variables: fresh yeast extracts, horse serum, and porcine serum concentrations. CCD of RSM was used to optimize the culture conditions for the production of mycoplasmal protein. A total of 18 experimental runs with different combinations of the three factors were performed (Table 2). For each run, the experimental responses along with the predicted responses from the actual variables obtained from the regression equation of the 18 combinations are shown. The regression analysis of the transformed data obtained after the experiment resulted in a final response equation of the second order polynomial that represented a suitable model equation for mycoplasmal protein production. The equation is:

Y = 0.053482X1 + 0.029669X2 - 0.006795X3 - 0.000207X12 - 0.000032474X1X2 - 0.000090516X22 - 6.73516E-8X1X3 + 0.000014144X2X3 + 0.000014087X32 - 2.385201

where Y is the concentration of bacterial protein; and X1, X2, and X3 represent the coded levels of fresh yeast extract, horse serum, and porcine serum, respectively.

The model equation adequacy was assessed by the lack of fit (F-test) and the coefficient of determination, R2. The F-value of 0.74 at the 99% level was insignificant, indicating that the obtained model was adequate. The coefficient of determination (R2) was 0.8119 for mycoplasmal protein production, indicating that equations of the statistical model could explain 81.19% of variability in the response. This proved that the model equation provided a suitable model to describe the response of the experiment pertaining to M. hyopneumoniae protein production. The experimental and predicted values in Table 2 show higher resemblance demonstrating the validity of the response model.

The conical analysis of the response surface for mycoplasmal protein production showed that the estimated surface does not have a unique optimum, having saddle points as a maximum, which was predicted to have a value of 2.5 mg/L. However, three dimensional response surface plots for any two of the three factors, drawn with a vertical line (Z-axis) representing mg/L of mycoplasmal protein production and two horizontal lines (X and Y axes) representing the actual values of the two experimental explanatory factors, had shown a range of optimized area. In each plot, the factor which did not represent the two horizontal axes was fixed at the actual optimum level.

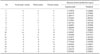

All three response surface plots were made (Figs. 2A-C). It is evident from the analysis of the response surface (Fig. 2C) that yeast extract and horse serum supplementation had a minimal effect, but still resulted in a better production compared to the basal media, and this production showed its optimum at the '0' level beyond which the protein yield declined. Concentrations of 109.5 mL (10.95%), 150 mL (15%), and 315 mL (31.5%) of the fresh yeast extract, horse serum, and porcine serum, respectively, resulted in maximum production (Figs. 2A and B) which was consistent with the highest results of the CCD experiment (Table 2) validating the analysis of the dimensional response surface plots. Separate experiments performed with the optimized conditions of CCD resulted in 2.96 mg/L mycoplasmal protein which is a three-fold increase from the basal media and a significant increase compared to the modified Friis media (Fig. 3).

Discussion

The most frequently encountered Mollicutes in pigs are M. hyopneumoniae, M. flocculare, M. hyorhinis, M. hyosynoviae, and Eperythrozoon suis. Among these Mollicutes, M. hyopneumoniae is of highest concern as the etiological agent of porcine enzootic pneumonia. M. hyopneumoniae causes chronic respiratory disease and enzootic pneumonia in industrialized livestock resulting in considerable economic losses [10]. Mycoplasma species have been notoriously difficult to cultivate [6]. Making media for culturing mycoplasma species is important for the control and elimination of the disease through mass production of mycoplasma for vaccination [7]. The RSM that we used for statistical optimizations of mycoplama in our study had been used for several purposes including optimization of medium, metabolites production, and extraction condition. Li et al. [10] reported that optimization of the cultural medium for bacteriocin production by Lactococcus lactis could be accomplished using RSM, and Sunitha et al. [16] set seed and induction conditions to enhance phytase production by recombinant Escherichia coli [16].

With the OFAT technique, thallium acetate and glucose were determined to have insignificant effects on the growth and/or production of M. hyopneumoniae. This coincides with other studies indicating that thallium acetate is associated with high toxicity, and other selective substitutes for thallium acetate are being investigated for selective growth of mycoplasma [2]. The central composite result from our study also showed optimized culture media conditions with a significant increase in mycoplasmal protein production compared to the basal media. Experimenting alone with the optimized conditions determined by CCD resulted in a 2.96 mg/L yield, which is a three-fold increase from the basal media. Compared to the results of the enhancement of propagation of M. hyopneumoniae by culture in a biphasic medium [7], the optimized yield show similar fold increment to the base media.

In summary, we confirmed for the first time that the CCD of the response surface analysis is a useful tool to determine the optimum levels of fresh yeast extract, horse serum, and porcine serum for mycoplasmal protein production. A high similarity was observed between the predicted and experimental yields which reflected the accuracy and applicability of RSM for such optimization. Among five variables (glucose, thallium acetate, fresh yeast extract, horse serum, and porcine serum) tested in this investigation, fresh yeast extract and horse serum at their 0 coded levels (10.9% and 15%, respectively) and porcine serum at its 1.68 coded level (31.5%) were the major factors influencing mycoplasmal protein production.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download