Abstract

Lost wax technique of casting wax patterns has been used principally to make metal frameworks of removable partial dentures. Since the development of digital technology and CAD, metal frameworks can be built through digital surveying and framework designing. Many cases proved that resin patterns made by CAD printing method were well adapted to internal oral structure and final metal frameworks also showed good internal adaptation as well. The metal frameworks of a removable partial denture were made by both lost wax technique and CAD technique and were applied to a patient with severe alveolar bone loss. Using CAD data and fit checker, internal adaptation of both metal frameworks were evaluated by comparing the gap between surveyed crown and its structure. This study is to prove that metal frameworks by both techniques showed adaptation that can be applied in clinical field.

Figures and Tables

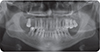

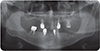

| Fig. 1Pre-operative intraoral view showing diastema and supra eruption. (A) Occlusal view of maxilla, (B) Lateral view (right side), (C) Frontal view, (D) Lateral view (left side), (E) Occlusal view of mandible. |

| Fig. 3Removable partial denture framework designed by CAD. (A) Scan data opening, (B) Undercut check, (C) Block out, (D) Mesh coverage setting, (E) Shape adjustment of major connector, (F) Clasp design, (G) Finish line setting, (H) Final framework design. |

| Fig. 4Resin pattern of RPD framework. (A) Resin pattern of maxillary RPD framework was fabricated through rapid prototyping, (B) Metal framework fitted the model well, (C) Resin pattern of mandibular RPD framework was fabricated through rapid prototyping, (D) Metal framework fitted the model well. |

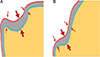

| Fig. 5Discrepancy measurement between rest and rest seat. (A) Section line of #13, #23 cingulum rest of maxilla, (B) Section line of #32, 43 cingulum rest and #46 occlusal rest of mandible. |

| Fig. 6(A) Occlusal rest; 1 measurement for center of rest (thick arrow), 2 for peripheries of rest (thin arrow), (B) Cingulum rest; 1 measurement for center (thick arrow), 2 for peripheries (thin arrow). |

| Fig. 7Measurement of gap between model and framework. (A) Overlapping the cast and the scan data of framework by using exocad Dental CAD, (B) Measuring the distance between framework and surveyed crown by slicing scan data of #46 occlusal rest, (C) Partial denture, including internal registration material, removed with alginate impression material, (D) Section line of replica, (E) Measuring the thickness of fit checker by magnifying cingulum rest. |

References

1. Eggbeer D, Bibb R, Williams R. The computer-aided design and rapid prototyping fabrication of removable partial denture frameworks. Proc Inst Mech Eng H. 2005; 219:195–202.

2. Park JM, Hong YS, Park EJ, Kim SK, Koak JY, Heo SJ. Study on the accuracy of digital removable partial denture and the comparison with the CAD model: A pilot study. Biomater Res. 2012; 16:102–107.

3. McGuire MK, Nunn ME. Prognosis versus actual outcome. II. The effectiveness of clinical parameters in developing an accurate prognosis. J Periodontol. 1996; 67:658–665.

4. McGuire MK, Nunn ME. Prognosis versus actual outcome. III. The effectiveness of clinical parameters in accurately predicting tooth survival. J Periodontol. 1996; 67:666–674.

5. Faggion CM Jr, Petersilka G, Lange DE, Gerss J, Flemmig TF. Prognostic model for tooth survival in patients treated for periodontitis. J Clin Periodontol. 2007; 34:226–231.

6. Park SA, Koak JY, Heo SJ, Kim SK, Park JM. RPD framework fabrication using computer-aided design (CAD) and rapid prototyping. J Korean Acad Prosthodont. 2017; 55:94–99.

7. Lee JW, Park JM, Park EJ, Heo SJ, Koak JY, Kim SK. Accuracy of a digital removable partial denture fabricated by casting a rapid prototyped pattern: A clinical study. J Prosthet Dent. 2017; 04. 04.

8. Fasbinder DJ. Clinical performance of chairside CAD/CAM restorations. J Am Dent Assoc. 2006; 137:22S–31S.

9. Dunham D, Brudvik JS, Morris WJ, Plummer KD, Cameron SM. A clinical investigation of the fit of removable partial dental prosthesis clasp assemblies. J Prosthet Dent. 2006; 95:323–326.

10. Wu J, Wang X, Zhao X, Zhang C, Gao B. A study on the fabrication method of removable partial denture framework by computer-aided design and rapid prototyping. Rapid Prototyp J. 2012; 18:318–323.

11. Kattadiyil MT, Mursic Z, AlRumaih H, Goodacre CJ. ntraoral scanning of hard and soft tissues for partial removable dental prosthesis fabrication. J Prosthet Dent. 2014; 112:444–448.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download