Abstract

Purpose

Recently implant surgical guides were used for accurate and atraumatic operation. In this study, the accuracy of two different types of surgical guides, positioning device fabricated and stereolithography fabricated surgical guides, were evaluated in four different types of tooth loss models.

Materials and methods

Surgical guides were fabricated with stereolithography and positioning device respectively. Implants were placed on 40 models using the two different types of surgical guides. The fitness of the surgical guides was evaluated by measuring the gap between the surgical guide and the model. The accuracy of surgical guide was evaluated on a pre- and post-surgical CT image fusion.

Results

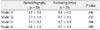

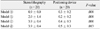

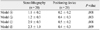

The gap between the surgical guide and the model was 1.4 ± 0.3 mm and 0.4 ± 0.3 mm for the stereolithography and positioning device surgical guide, respectively. The stereolithography showed mesiodistal angular deviation of 3.9 ± 1.6°, buccolingual angular deviation of 2.7 ± 1.5° and vertical deviation of 1.9 ± 0.9 mm, whereas the positioning device showed mesiodistal angular deviation of 0.7 ± 0.3°, buccolingual angular deviation of 0.3 ± 0.2° and vertical deviation of 0.4 ± 0.2 mm. The differences were statistically significant between the two groups (P<.05).

Figures and Tables

| Fig. 1Models for study. A: Partial edentulous models, ⓐ: Single missing model, ⓑ: Kennedy Class-IV model, ⓒ: Kennedy Class-I model, ⓓ: Kennedy Class-III model. B: Gutta-percha markers. |

| Fig. 2The radiographic guide and designing the surgical guide with stereolithography. A: Radiographic guide for stereolithography, B: Design the surgical guide with Osstem Quickguide®. |

| Fig. 3Fabricating the surgical guide with stereolithography. A: Fabricating the surgical guide after fusing the two groups of CBCT DICOM files. B: Stereolithography fabricated surgical guide. |

| Fig. 4The radiographic guide and designing the surgical guide with positioning device. A: Radiographic guide for positioning device, B: Design the surgical guide with Simplant®. |

| Fig. 5Fabricating surgical guide with positioning device. A: Fabricating the surgical guide with positioning device, B: Laboratory fabricated surgical guide with positioning device. |

| Fig. 6Flapless implant surgery with surgical guides. A: Flapless implant surgery with sereolithography fabricated surgical guide, B: Flapless implant surgery with laboratory fabricated surgical guide. |

| Fig. 8Evaluating the accuracy of surgical guides. A: Image fusioning of pre- and post- operational image, B: The accuracy of surgical guide was evaluated. |

References

1. Choi BH, Jeong SM, Kim J, Engelke W. Flapless implantology. 2010. London: Quintessence Publishing Co;66–71.

2. Van Assche N, van Steenberghe D, Guerrero ME, Hirsch E, Schutyser F, Quirynen M, Jacobs R. Accuracy of implant placement based on pre-surgical planning of three-dimensional conebeam images: a pilot study. J Clin Periodontol. 2007. 34:816–821.

3. Valente F, Schiroli G, Sbrenna A. Accuracy of computer-aided oral implant surgery: a clinical and radiographic study. Int J Oral Maxillofac Implants. 2009. 24:234–242.

4. Horwitz J, Zuabi O, Machtei EE. Accuracy of a computerized tomography-guided template-assisted implant placement system: an in vitro study. Clin Oral Implants Res. 2009. 20:1156–1162.

5. Fortin T, Champleboux G, Bianchi S, Buatois H, Coudert JL. Precision of transfer of preoperative planning for oral implants based on cone-beam CT-scan images through a robotic drilling machine. Clin Oral Implants Res. 2002. 13:651–656.

6. Behneke A, Burwinkel M, Behneke N. Factors influencing transfer accuracy of cone beam CT-derived template-based implant placement. Clin Oral Implants Res. 2012. 23:416–423.

7. Park JM, Yi TK, Jung JK, Kim Y, Park EJ, Han CH, Koak JY, Kim SK, Heo SJ. Accuracy of 5-axis precision milling for guided surgical template. J Korean Acad Prosthodont. 2010. 48:294–300.

8. Stumpel LJ. Deformation of stereolithographically produced surgical guides: an observational case series report. Clin Implant Dent Relat Res. 2012. 14:442–453.

9. Winder J, Bibb R. Medical rapid prototyping technologies: state of the art and current limitations for application in oral and maxillofacial surgery. J Oral Maxillofac Surg. 2005. 63:1006–1015.

10. Di Giacomo GA, Cury PR, de Araujo NS, Sendyk WR, Sendyk CL. Clinical application of stereolithographic surgical guides for implant placement: preliminary results. J Periodontol. 2005. 76:503–507.

11. Ruppin J, Popovic A, Strauss M, Spüntrup E, Steiner A, Stoll C. Evaluation of the accuracy of three different computer-aided surgery systems in dental implantology: optical tracking vs. stereolithographic splint systems. Clin Oral Implants Res. 2008. 19:709–716.

12. Van Steenberghe D, Malevez C, Van Cleynenbreugel J, Bou Serhal C, Dhoore E, Schutyser F, Suetens P, Jacobs R. Accuracy of drilling guides for transfer from three-dimensional CT-based planning to placement of zygoma implants in human cadavers. Clin Oral Implants Res. 2003. 14:131–136.

13. Dreiseidler T, Neugebauer J, Ritter L, Lingohr T, Rothamel D, Mischkowski RA, Zöller JE. Accuracy of a newly developed integrated system for dental implant planning. Clin Oral Implants Res. 2009. 20:1191–1199.

14. Schneider D, Marquardt P, Zwahlen M, Jung RE. A systematic review on the accuracy and the clinical outcome of computer-guided template-based implant dentistry. Clin Oral Implants Res. 2009. 20:73–86.

15. Misch CE, Qu Z, Bidez MW. Mechanical properties of trabecular bone in the human mandible: implications for dental implant treatment planning and surgical placement. J Oral Maxillofac Surg. 1999. 57:700–706.

16. Sohmura T, Hojo H, Nakajima M, Wakabayashi K, Nagao M, Iida S, Kitagawa T, Kogo M, Kojima T, Matsumura K, Nakamura T, Takahashi J. Prototype of simulation of orthognathic surgery using a virtual reality haptic device. Int J Oral Maxillofac Surg. 2004. 33:740–750.

17. Vakharia KT, Natoli NB, Johnson TS. Stereolithography-aided reconstruction of the mandible. Plast Reconstr Surg. 2012. 129:194e–195e.

18. Schultes G, Gaggl A, Kärcher H. Results of measurement of preand postoperative milling models of orthodontic-surgical treatment of dysgnathia patients. Mund Kiefer Gesichtschir. 1998. 2:S139–S144.

19. Ciocca L, Mazzoni S, Fantini M, Marchetti C, Scotti R. The design and rapid prototyping of surgical guides and bone plates to support iliac free flaps for mandible reconstruction. Plast Reconstr Surg. 2012. 129:859e–861e.

20. Chiarelli T, Franchini F, Lamma A, Lamma E, Sansoni T. From implant planning to surgical execution: an integrated approach for surgery in oral implantology. Int J Med Robot. 2012. 8:57–66.

21. van Steenberghe D, Naert I, Andersson M, Brajnovic I, Van Cleynenbreugel J, Suetens P. A custom template and definitive prosthesis allowing immediate implant loading in the maxilla: a clinical report. Int J Oral Maxillofac Implants. 2002. 17:663–670.

22. Choi SH, Samavedam S. Modelling and optimisation of Rapid Prototyping. Comput Ind. 2002. 47:39–53.

23. Widmann G, Zangerl A, Keiler M, Stoffner R, Bale R, Puelacher W. Flapless implant surgery in the edentulous jaw based on three fixed intraoral reference points and image-guided surgical templates: accuracy in human cadavers. Clin Oral Implants Res. 2010. 21:835–841.

24. Nguyen E, Boychuk D, Orellana M. Accuracy of cone-beam computed tomography in predicting the diameter of unerupted teeth. Am J Orthod Dentofacial Orthop. 2011. 140:e59–e66.

25. Nejatidanesh F, Lotfi HR, Savabi O. Marginal accuracy of interim restorations fabricated from four interim autopolymerizing resins. J Prosthet Dent. 2006. 95:364–367.

26. Ozan O, Turkyilmaz I, Ersoy AE, McGlumphy EA, Rosenstiel SF. Clinical accuracy of 3 different types of computed tomography-derived stereolithographic surgical guides in implant placement. J Oral Maxillofac Surg. 2009. 67:394–401.

27. Chen X, Yuan J, Wang C, Huang Y, Kang L. Modular preoperative planning software for computer-aided oral implantology and the application of a novel stereolithographic template: a pilot study. Clin Implant Dent Relat Res. 2010. 12:181–193.

28. Pfluger T, Vollmar C, Wismüller A, Dresel S, Berger F, Suntheim P, Leinsinger G, Hahn K. Quantitative comparison of automatic and interactive methods for MRI-SPECT image registration of the brain based on 3-dimensional calculation of error. J Nucl Med. 2000. 41:1823–1829.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download