INTRODUCTION

Self-ligating brackets were first introduced in the 1930s and several types of these brackets have become commercially available in the past 20 years.

1 Self-ligating brackets can be classified into two groups according to their closing mechanism: passive clips and interactive clips.

2

The clips of self-ligating brackets are made of stainless steel, nickel-titanium, or cobalt-chromium alloys.

3 In the past, the body of a self-ligating bracket was made of conventional stainless steel. However, the use of ceramic self-ligating brackets made of polycrystalline alumina has been rapidly increasing because of the increasing number of patients who use esthetic brackets.

The body of the ceramic self-ligating bracket is white, and the clip is visible when light is reflected because it is metallic. Therefore, some clips in a ceramic self-ligating bracket may be coated with a white coating material to improve esthetics.

3 However, the white coating can change the roughness and friction of the metal surface.

4 Despite this, there have been no studies regarding the surface chemical composition or surface roughness of various ceramic self-ligating bracket clips. It is clinically important to study the effect of the white coating of ceramic self-ligating bracket clips on the surface roughness and friction of the metal surface.

Scanning electron microscopy (SEM) with energy-dispersive X-ray spectroscopy (EDS) has been widely used to analyze the surface chemical composition of bracket bodies.

567 It can also be used to analyze the surface chemical composition of bracket clips.

SEM and a profilometer have been used to analyze the surface roughness of bracket bodies.

891011 In recent years, atomic force microscopy (AFM) has been used to study the roughness of bracket bodies, which has several advantages over the use of SEM and a profilometer.

1213 During orthodontic treatment, friction is induced between the bracket slot and the archwire. The greater the friction, the slower the treatment. In addition, the tooth under treatment can move in an undesirable direction. Therefore, several studies have researched friction between the bracket slot and the wire.

14 Friction between the inner surface of the metal clip and the archwire is important in orthodontic treatment, because the self-ligating bracket clip serves as the fourth wall of the slot. However, there have been no studies that measure the friction of the inner surface of various ceramic self-ligating bracket clips.

Lateral force microscopy (LFM) is an AFM technique that is used to identify the relative difference in surface friction. LFM is also known as friction force microscopy, as it measures the lateral bending of the cantilever depending on the frictional force acting on the tip.

15 During scanning in the contact mode, the cantilever not only bends in the vertical direction along the surface as a result of repulsive Van der Waals interactions, but also undergoes lateral deformation.

The purpose of this study was to analyze the effect of white coating on ceramic self-ligating bracket clips on the surface roughness and friction of the metal surface using AFM-LFM and SEM-EDS.

MATERIALS AND METHODS

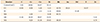

One type of interactive metal self-ligating bracket was examined as a control specimen, i.e., mini-Clippy® (mC; Tomy, Tokyo, Japan), and five types of interactive ceramic self-ligating brackets were examined in the experimental group, i.e., Clippy-C® (CC; Tomy), Empower clear® (EC; American Orthodontics, Sheboygan, WI, USA), MACH® (MA; World Bio Tech, Seongnam, Korea), QuicKlear® (QK; Forestadent, Pforzheim, Germany), and WOW-A® (WA; Hubit, Uiwang, Korea) (

Figure 1).

QK, EC, and MA had facial holes in which an explorer can be inserted to open the clip, while CC and WA had a notch. The recently developed CC had both a facial hole and a notch. The facial hole offers an easy-access primary opening method. CC and EC had ball-shaped gingival tails, and QK, WA, and MA had a rounded, rectangular gingival tail. The gingival tail keeps the clip locked in the bracket body and provides a secondary opening method. QK had a single chamfered slot entrance in the middle of the clip, and the QK clip covered only a portion of the middle of the slot. CC, EC, MA, and WA had a double-chamfered slot entrance on both sides of the clip, and the clip covered the entire slot. The chamfered slot entrances eliminate sharp corners to reduce wire binding.

The sample size of each bracket was 30 in this study, and the clip was removed from each bracket. A pilot study and power analysis showed that a sample size of at least 14 brackets per group was needed for a 20% effect size change to represent a statistically significant difference in the surface roughness. The sample size was calculated a power of 0.80 at a significance level α of 0.05.

AFM-LFM measurements

The optical microscope was used at 500× magnification to determine the area to be observed on the inner and outer surfaces of each clip.

Contact-mode AFM topographical-deflection and LFM frictional images of the outer and inner surfaces of each bracket clip were obtained using a commercial AFM system (TT-AFM; Probes Inc., Seoul, Korea). AFM and LFM were performed using a cantilever PPP-LFMR (NANO-SENSORSTM, Neuchatel, Switzerland). The scanned images were analyzed using Gwyddion (ver. 2.47 for Windows; Czech Metrology Institute, Brno, Czech Republic). In this program, the roughness measurement plane (z = 0 plane or xy plane) was determined via planification.

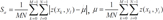

The mean values (Sa in AFM, Fa in LFM) were used as parameters to analyze the roughness and relative friction on the surface of each clip. The mean values represent the average of the differences in the average height for the z-axis of the scanned area. This is the most commonly used parameter expressing the degree of roughness with respect to the z-axis height of the scanned area.

Where M and N are the pixel sizes. The pixels of 256 × 256 were scanned in this study; hence, M and N are 256 (Equation 1).

SEM-EDS measurements

The morphologies of each bracket clip were characterized using an S-4700 field-emission SEM (FE-SEM; Hitachi, Tokyo, Japan) at an accelerating voltage of 5 kV. A 7200-H EDS (HORIBA, Northampton, UK) was used to examine the elemental compositions of each clip.

Statistics

All statistical analyses were performed using SPSS ver. 12.0 (SPSS Inc., Chicago, IL, USA). The Shapiro-Wilks and Levene's tests were used to examine the normality of the distributions and the equality of variances between groups, respectively. One-way ANOVAs were used to compare the Sa and Fa values of the six types of bracket clips, which were followed by Scheffe analysis. The statistical significance was considered for p-values less than 0.05.

DISCUSSION

The friction between the bracket and archwire may lead to delayed and undesirable tooth movement. Several studies have been conducted to study the surface roughness and friction in bracket slots among the factors that influence the friction between the bracket and archwire. However, few studies have focused on the surface roughness and friction of self-ligating bracket clips, even though the self-ligating bracket clip serves as the fourth wall of the slot. This study was the first to observe the surface chemical composition, surface roughness, and relative friction of various ceramic self-ligating bracket clips using AFM-LFM and SEM-EDS.

Albuquerque et al.

4 highlighted manufacturing methods that have been developed to improve the esthetic quality of archwires to make them less perceptible. One of the methods is to cover the metal surface with polytetrafluoroethylene or epoxy resin. Another is to cover the metal surface with gold and rhodium, denominated white metals.

4 Some clips of the ceramic self-ligating bracket may be coated with white coating material in an effort to improve esthetics such as an esthetic archwire.

3 It has been stated that the main components of CC clips are cobalt, nickel, and chromium, but the surface is rhodium-coated.

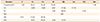

3 Similarly, the results of the present study showed that the main components of the outer and inner surfaces of the CC clip were rhodium (43.76% and 57.46%, respectively) and aurum (gold). Cobalt (1.26% and 9.88%), nickel (1.21% and 8.87%), and chromium (0.58% and 6.09%) were rarely observed on the outer and inner surfaces, respectively, of the CC clip, because of the extensive rhodium-aurum coating. There have been no previous studies on the surface composition of EC, MA, and WA. This study showed for the first time that the main components on the outer and inner surfaces of EC (69.04% and 88.24%, respectively), MA (82.72% and 100%, respectively), and WA (48.10% and 71.33%, respectively) was rhodium, similar to CC. The study also showed that the main components on the surface of clip in QK were cobalt, chromium, and nickel and that the surface was not rhodium-coated, which was consistent with the previous study.

3

White coating such as rhodium coating on a metal surface can change the roughness and friction of the surface.

4 Therefore, we analyzed the surface roughness and friction of a ceramic self-ligating bracket clip using AFM-LFM. AFM was performed using a spring deflection system with a tip (SiN) at the end of a spring cantilever (

Figure 4). When the tip scans the bracket clip, van der Waal forces act between the tip and the surface of the bracket clip causing the cantilever to bend. The laser beam incident on the back of the cantilever is deflected and detected by a photodetector; thus, the surface structure of the bracket clip can be represented in three dimensions in terms of the atomic unit size, and the surface roughness can be observed in real time.

14

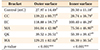

In the present study, there was no significant difference between the surface roughness on the outer surface of the QK and mC clips, because the QK clips did not have a surface coating and their surface composition was similar to that of the mC clips. The greater roughness of the outer surfaces of CC, EC, MA, and WA compared to that of mC may have been due to the rhodium coating. Rudge et al.

16 found that a rhodium-coated archwire was rougher than uncoated control wires and Albuquerque et al.

4 reported that a rhodium-coated archwire was ~2.5 times rougher than an uncoated archwire. In the present study, the outer surface of the rhodium-coated clips was approximately 3.7 (MA) to 5 times (CC) rougher than that of the mC clip. The inner surface of the rhodium-coated clips was approximately 1.4 (CC) to 4.9 times (EC) rougher than that of the mC clip, which was consistent with the description of Albuquerque et al.

4 The difference in surface roughness among the various rhodium-coated clips appears to be due to differing rhodium contents (43.76%–82.72% and 57.46%–100% for the outer and inner surfaces, respectively) and manufacturing techniques. Although the CC clip is rhodium-coated, the lack of statistical difference in the Sa of the inner surface of the CC clip and the mC clip may have been due to the polishing process.

During AFM in the contact mode, the cantilever not only bends vertically along the surface, but also undergoes lateral deformation. LFM was used to measure the lateral bending of the cantilever depending on the frictional force acting on the tip.

15 Misra et al.

17 reported the first observation of a reduction in the nanoscale relative surface friction of Sc3 hydrophobin protein modified polymeric surfaces using LFM, and Choi et al.

15 investigated the relative friction acting on archwires using LFM. Friction on the inner surface of the self-ligating bracket clip is important in orthodontic treatment, because the inner surface of the clip serves as the fourth wall of the slot. The relative friction acting on the ceramic self-ligating bracket clip was analyzed using LFM for the first time in the present study.

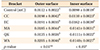

There was no significant difference in the friction between the inner surface of the QK clips and the mC clips because these clips have a similar surface composition, as they are not coated with rhodium. Among the rhodium-coated ceramic self-ligating brackets, the inner surfaces of EC, MA, and WA experienced significantly more surface friction than mC. The results of the present experiment are similar to those of Rudge et al.'s experiment

16 in which coated archwires generally exhibited higher friction than the uncoated controls.

The relative friction on the inner surface of the CC clip was the lowest followed by those of QK, WA, MA, and EC. The greater the surface roughness of the inner surface, the greater the relative friction. According to Choi et al.'s study,

15 the archwire with a high surface roughness experienced a large amount of surface friction. He stated that the change in the LFM-acquired frictional resistance was similar to that of the AFM-acquired surface roughness. Nanjundan and Vimala

18 concluded that a significant positive correlation was observed between the frictional force, bracket slot roughness, and wire roughness. The results of the present experiment are consistent with those of Choi et al.

15 and Nanjundan and Vimala.

18

The relative friction on the inner surface of the rhodium-coated clips was approximately 1.1 (CC) to 1.7 times (EC) higher than that on the mC. Therefore, the difference in the relative friction (1.1–1.7 times) on the inner surface of various ceramic self-ligating bracket clips was lower than the difference in the surface roughness (1.4–4.9 times).

Various studies have investigated the relationship between the surface roughness and the friction of brackets. Proffit et al.

19 and Kusy

20 found that a polycrystal-line alumina ceramic bracket had a rougher surface than a stainless steel bracket because the former was difficult to polish during production. This also resulted in the former experiencing more friction than the latter. Angolkar et al.

21 reported that the surface of a monocrystalline alumina bracket was as smooth as that of a stainless steel bracket but it experienced more friction than the latter because of the chemical interaction between the archwire and the bracket material. Saunders and Kusy

10 found no significant difference between the friction in the polycrystalline alumina bracket and monocrystalline alumina bracket, although the surface of the former was rougher than that of the latter, because of the internal chemical structure of the ceramic bracket. In this study, rhodium-coated clips except the CC clip were found to have a rougher surface and higher friction on the outer and inner surfaces than the mC clip. However, the friction is likely to be caused by several factors, and hence, it is not solely determined by the surface roughness.

16 Further research is needed to understand these other factors better. In addition, the friction between the self-ligating bracket and the archwire occurs not only in the bracket clip but also in the bracket slot; hence, further research is needed to determine the surface roughness and friction of the bracket slot. The clinical performance of brackets also depends on diverse synergistic effects, including corrosion due to saliva, mouth-washing solutions, and galvanic corrosion between two materials.

22 These effects of the oral environment cannot be simulated in an

in-vitro investigation.

23 In-vivo studies are required to examine the intraoral exposure effects on the frictional force and surface characteristics of self-ligating brackets.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download