Abstract

PURPOSE

The aim of this study was to evaluate the biaxial flexural strength (BFS) of one zirconia-based ceramic used with various veneering ceramics.

MATERIALS AND METHODS

Zirconia core material (Katana) and five veneering ceramics (Cerabien ZR; CZR, Lava Ceram; LV, Cercon Ceram Kiss; CC, IPS e.max Ceram; EM and VITA VM9; VT) were selected. Using the powder/liquid layering technique, bilayered disk specimens (diameter: 12.50 mm, thickness: 1.50 mm) were prepared to follow ISO standard 6872:2008 into five groups according to veneering ceramics as follows; Katana zirconia veneering with CZR (K/CZR), Katana zirconia veneering with LV (K/LV), Katana zirconia veneering with CC (K/CC), Katana zirconia veneering with EM (K/EM) and Katana zirconia veneering with VT (K/VT). After 20,000 thermocycling, load tests were conducted using a universal testing machine (Instron). The BFS were calculated and analyzed with one-way ANOVA and Tukey HSD (α=0.05). The Weibull analysis was performed for reliability of strength. The mode of fracture and fractured surface were observed by SEM.

Nowadays, zirconia-based restoration is widely used as a promising dental ceramic due to its excellent biocompatibility, high mechanical properties, good esthetics, and long-term stability.1234 The most frequently used type of dental zirconia is yttria tetragonal zirconia polycrystal (Y-TZP) because of its phase transformation toughens property as tetragonal phase transforms to monoclinic phase in excellent proportion.3 Y-TZP is a fully tetragonal fine-grained zirconia ceramic material made of 100% small metastable tetragonal grains after adding approximately 3 mol% of yttrium oxide (Y2O3) as a stabilizer.5 The mechanical properties of zirconia were proved to be higher than all other dental ceramics.

Zirconia coping for crown or bridge framework requires the application of veneering ceramic for excellent esthetic. The study of Larsson and Wennerberg showed the high success rate on zirconia crown at 96% and 97% on toothsupported and implant-supported, respectively.6 The retrospective study of Håff et al.7 showed the high success rate in fixed partial dentures (FPDs) of 94 % in the average observed time of 9.6 years. Three FPDs (9.7%) exhibited veneer chipping, while the fracture of zirconia coping did not occur. However, clinical studies of Schmitter et al.8 in long-span FPDs reported approximately 27% of veneering ceramic chipping, and also found framework fracture in 2 FPDs out of thirty FPDs for five years. These studies have shown less problem of zirconia core fracture, but higher rate of veneering ceramic chipping.7910

Many studies indicate the reasons of zirconia/veneer problems such as mismatch of coefficient of thermal expansion (CTE) between zirconia and veneering ceramic, low fracture toughness of veneering ceramic, residual tensile stress in veneering ceramic and etc.11 Due to the manufacturers' data, zirconia core materials have the CTE around 10.1 - 11 × 10-6K-1. They also provide the veneering ceramics with a slight mismatch (Δα) between their veneering ceramic and zirconia, with approximately 1α unit (ΔL/L × 10-6K-1) lower than their zirconia, like the protocol in metal/ceramic restoration (Table 1).5 Most manufacturers recommend to use zirconia core combined with veneering ceramic from the same manufacturer for the best result. However, there are various manufacturers that provide ceramics for veneering on zirconia. Cross-matching between zirconia and veneering ceramic of different manufacturers was found occasionally as shown in the review study of Larsson and Wennerberg.6 A survey conducted by the authors also found that dental laboratories in Bangkok used veneering ceramic with zirconia core from different manufacturers. There are significant differences among veneering ceramics for zirconia in terms of strength as found in the study of Fischer et al.12 Furthermore, the studies of bond strength when matching zirconia with various veneering ceramics by Fazi et al.,13 Aboushelib et al.14 and Blatz et al.15 found that zirconia with veneering ceramic from the same manufacturer had lower bond strength than that from different manufacturer. Ozkurt et al.16 investigated the shear bond strength (SBS) of three veneering ceramics to four types of zirconia cores and found that the bonding strength of veneering ceramic which was recommended by manufacturer to zirconia core showed various results according to type of zirconia and veneering ceramic. From these studies, it is questionable for the necessity of matching zirconia core with veneering ceramic from the same manufacturer for the optimal strength. Therefore, the aim of this study is to evaluate the strength of zirconia-based ceramic (Y-TZP) when used with various veneering ceramic from the same and different manufacturers by measuring biaxial flexural strength (BFS).

Zirconia core (Katana zirconia, Kuraray Noritake Dental Inc., Tokyo, Japan) and five veneering ceramics were used: Cerabien ZR; CZR (Kuraray Noritake Dental Inc., Tokyo, Japan), Lava Ceram; LV (3M ESPE, St. Paul, MN, USA), Cercon Ceram Kiss; CC (Degudent GmbH, Hanau-Wolfgang, Germany), IPS e.max Ceram; EM (Ivoclar Vivadent AG, Schaan, Liechtenstein) and VITA VM9; VT (VITA Zahnfabrik H. Rauter GmbH & Co. KG, Bad Sackingen, Germany). CZR was made by the same manufacturer as Katana. Next to that, LV, CC, EM and VT were selected because these veneering ceramics have been most frequently used in dental laboratories surveyed in Bangkok. The specimens were constructed with bilayered zirconia/veneer disks (diameter 12.50 mm, thickness 1.50 mm: core 0.75 mm and veneer 0.75 mm), as shown in Fig. 1A. The specimens were prepared according to recommendations of manufacturers (n = 12, for each group). Materials used in this study are shown in Table 2. Five experimental groups were shown as follows: Katana/Cerabien ZR (K/CZR), Katana/Lava Ceram (K/LV), Katana/Cercon Ceram Kiss (K/CC), Katana/IPS e.max Ceram (K/EM) and Katana/VITA VM9 (K/VT).

The core specimens were prepared by cutting a Katana zirconia block into oversized disk shapes. Zirconia disks were sintered according to recommendation of manufacturers as shown in Fig. 1B, and then their surfaces were finished and polished with wet abrasive papers No. 360, 600, 800 and 1,000, respectively. Digital vernier caliper was used to measure the diameter (12.50 ± 0.05 mm) and thickness of the cores (0.75 ± 0.005 mm). VITA In-Ceram testing liquid (Lot no. 63523, VITA Zahnfabrik H. Rauter GmbH & Co. KG, Bad Sackingen, Germany) was used to find possible crack line on all of the cores. The crack test excluded any cores which had crack line. Sandblasting with aluminum oxide powder (110 µm at 3.5 psi) was done at a distance of 10 mm from the tip to the side that planed to contact with the veneering ceramic, at 45° to the flat surface. Then, all zirconia cores were ultrasonically cleaned in acetone solution for 15 minutes, which cleaned and removed residual greasy substance.

After drying, veneering ceramics were veneered to the zirconia cores with a powder/liquid layering technique in an enlarged silicone mold to compensate for shrinkage. This followed by sintering according to manufacturer's instructions (Table 3). Sintered specimens were finished, polished and measured for the final thickness of 1.50 ± 0.05 mm. The same ceramic technician performed all procedures to produce the bilayered specimen. A crack test was repeated to check whether cracks were developed or not. Then, the specimens were thermocycled for 20,000 cycles of alternating temperature between 55℃ for 30 seconds and 5℃ for 30 seconds. This treatment mimics the condition of oral function for a period of two years.17

The BFS was measured using a piston on three balls in a universal testing machine (Servo hydraulic system model 8872, Instron, England) according to ISO standard 6872: 2008 (Fig. 2).18 The test was carried out by placing the zirconia core at the bottom side and using a crosshead speed at 0.5 mm/min until failure. Between the piston and the specimen, a thin plastic sheet (thickness 0.05 mm) was placed to distribute the load and minimize stress concentration. The load at the time of fracture was recorded and the BFS was calculated by using formula for bilayered disk1920 shown in Fig. 3. The mean and standard deviation of BFS data were collected for each group. Statistical analyses were performed with one-way ANOVA and Tukey post hoc multiple comparison tests (α = .05) using SPSS version 17.0 (SPSS Inc., Chicago, IL, USA). The reliability of strength was analyzed with the Weibull distribution. The Weibull modulus was obtained from the slope by plotting the probability of survival of each specimen and fracture stresses as follows:21

Pf value is the probability of failure at an obtained flexural stress, σ, while σθ is the characteristic strength at the fracture probability of 63.2% and m is Weibull modulus. 95% of confidence interval was used to compare the Weibull parameters. The higher value of m shows higher homogeneity and greater reliability of strength. The fractured specimens were observed for the mode of failure and scanning electron microscope, SEM (JSM-5410LV Scanning Microscope, JEOL DATUM, Tokyo, Japan) of 200 magnifications investigated the surface of fracture.

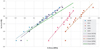

The results of the BFS test and Weibull analysis are shown in Table 4 and Fig. 4. Statistical analysis showed that K/CC had the highest BFS which was significantly higher than K/LV (P = .04). The BFS of K/CZR, K/EM and K/VT were not significantly different from each other, but they were significantly lower than K/CC and K/LV.

The Weibull plots which perform from the BFS results showed that m value of K/LV was the highest, followed by K/CC. The m values of K/CZR, K/EM and K/VT were in the similar range. The results of reliability from Weibull plots also corresponded to the results of the BFS.

Due to the pattern of failure, the specimen crack was observed radially in both materials but more pieces of veneering ceramic, combined with debonding of veneering ceramic from core material as shown in Fig. 5. Most of the debonding pattern was adhesive failure between core and veneering ceramic. Crush of veneering ceramic at the loaded surface was observed. In this study during the BFS test, veneering ceramic was crushed before the failure of zirconia core. Moreover, the higher number of zirconia core's fragments was counted, the higher value of BFS was recorded. The SEM at the fracture surface of the specimen from each group showed the porosities found in all veneering ceramics especially in CC and LV (Fig. 6).

The results of the BFS values could be divided into three significant groups. The highest group was K/CC (705.94 MPa), followed by the group of K/LV (602.55 MPa) and the lowest groups were K/EM, K/CZR and K/VT, respectively (496.94, 489.56 and 483.72 MPa). In calculation for BFS of bilayered specimen, Young modulus and Poisson's ratio are the key factors for the strength. For ceramics, Poisson's ratio is considered to be the same. Therefore, the BFS is greatly depends on Young modulus value of the veneering ceramic at the upper side because the zirconia core at the bottom side was the same material. The Young modulus values of the veneering ceramics in this study were in the range of 65 to 95 GPa (Table 2). EM shows the highest value, followed by LV, CZR, VT and CC. The higher value of the Young modulus, the greater strength was expected to be obtained. Additionally, the more differences of Young modulus between core and veneering ceramic also increase debonding between layers which are more prone to fracture of the whole specimen.22 However, results of the BFS did not correspond to the ranking of the Young modulus values. During BFS test, the failure occurred from the bottom side of the zirconia core, and the crack propagated upward to the interface between two materials before it continued to the veneering ceramic on the upper side. Hence, the bonding ability between the Katana zirconia core and each veneering ceramic might have also played an important role of the results.

Various factors affect the bond strength between veneering ceramic and zirconia core. Mechanical retention and ability of bonding between these two materials are factors that increase good bond strength. Fischer et al.23 investigated shear strength of twelve veneering ceramics to one type of zirconia, and found that shear strength ranged from 21 to 31 MPa which they indicate the importance of CTE and glass transition temperature also was considered in other studies.1424 Initial cracks could be generated by mismatches of CTE between the core materials and veneering ceramics. Firing shrinkage of the veneering ceramic, improper fabrication during grinding or other machining, undesirable heating and cooling rates are also concerned.25 The effect of cooling rate on SBS was studied by Komine et al.25 by using three veneering ceramics to Katana zirconia and found that it might affect the SBS differently on each veneering ceramic from different manufacturers. Tuccillo and Neilsen explained that firing temperature of veneering ceramic might be related to shear stresses which were sufficient to affect the bond strength between core and veneer.26 Saito et al.27 also studied about relationship between CTE and SBS of Katana zirconia and veneering ceramics which were almost similar to this study. They found that Cerabien ZR showed the highest SBS, followed by VITA VM9, while Cercon Ceram Kiss and IPS e.max Ceram had significantly lower SBS than Cerabien ZR group. They concluded that SBS of veneering ceramics and zirconia core was related to the discrepancies of CTE mismatch. The thermal mismatch of two ceramics may increase development of tensile stress in veneering ceramic, therefore, it is advisable to have the difference in thermal expansion of two ceramics as small as possible.28 The study of Swain showed that the higher rates of veneering ceramic chipping on all-ceramic restorations might result from residual stress from the mismatch of the CTE, and explained or supposed the increase of thermal mismatch between zirconia core and veneering ceramic was due to low thermal conductivity of zirconia which was compared to metal.24 Among the veneering ceramics used in this study, the CTE of CZR and VT were the most different from the Katana zirconia core and the values of BFS of these two ceramics showed the lowest results. This might be one of the reasons explaining the obtained result. From these studies, CTE mismatch should be considered as one of the factors that might affect the strength of bilayered zirconia-based restorations.

There are another factors that affect the whole strength of the bilayered restoration such as; core-to-veneer ratio, residual stress, interfacial bonding strength, CTE, interfacial transformation toughening of zirconia, thickness of core or veneer, direction or position of loading, modulus of elasticity and fracture resistance of each layer, areas of porosities etc.2829303132333435363738 There might have been the factors due to sintering procedures which influenced the result of this study such as the sintering frequency, sintering temperature, and tempering associated with rapid cooling of the veneering ceramics.24 It was due to the different characteristics of each veneering ceramics in terms of composition, strength, CTE or firing shrinkage. On the other hand, surface characteristics of each zirconia core material in terms of grain size, shape, composition, density and hardness affected the bond strength of final structure that responded to the strength of the bilayered specimen.16

In this study, a piston-on-three-ball test assesed the BFS. This test was less sensitive than other tests to the undetectable defect of the material at loaded position. Load was applied in the center of specimen where the defects at the edges were less likely to influence the outcome. In addition, its easy use resulted in fewer errors than other tests.123940 The core/veneer ratio of 1 : 1 was specified for appropriate strength, and core material was put at the bottom side while conducting the test to determine overall strength of the restoration.3222941 In this study, surface treatment of zirconia core before veneering with ceramic was carried out by only airborne abrasion. It was recommended and conducted as a routine procedure in the laboratory process for increasing the surface roughness and removing the deposits on the zirconia surface before applying veneering ceramic.4243 Thermocycling of 20,000 cycles was performed to mimic the condition of oral function for two years.17 This protocol has been a widely used to investigate the mechanical properties of ceramics as same as the mechanical test that was intended to simulate conditions of the masticatory function.44 Thermocycling could induce the stress at the interface between different materials due to temperature changes and set off adhesive failures which reduce the strength, resulting in the failure of the dental ceramics.1745

When observing fracture pattern of the specimen, most of cracks happened radially, which were with adhesive failure at the interface of core and veneering ceramic. The radial cracks developed in both materials, but more small pieces were observed in veneering ceramic (Fig. 5). At the fracture surface, the SEM observed the different homogeneity of veneering ceramic. The study of Wakabayashi and Anusavice explained the fracture pattern of bilayered ceramic specimen that initial crack was developed on the surface of veneering ceramic, then expanded to core and shifted along the interfacial surface. At the same time, crack was developed on the core surface and expanded to veneering ceramic, leading to the failure of whole specimen and crushed state of veneering ceramic.46

In clinical situations, the fracture of bilayered zirconia restoration has been usually found by chipping of veneering ceramic.9 This is because the strong core of zirconia can resist to high masticatory load. Therefore, the crack does not directly go to the core, but deflects into the weak point between interfaces of zirconia and veneering ceramic. The cracks are unlikely to propagate from a low-modulus, low-toughness ceramic to a high-modulus, high-toughness ceramic. The interlaminar crack indicates a poor bonding of zirconia-veneering ceramic.4247 This finding corresponds to the fatigue studies of Studart et al. that outer layer of veneer was more prone to failure due to subcritical crack growth than the tough core framework.3037 Residual stresses were found in anatomical form of crown or FPDs with various thickness of veneering ceramic due to cooling rate.248 Most studies suggested the protocol of slow cooling rate should improve the life time of zirconia-based ceramic restorations.4950 In present study, most of the ceramics used fast cooling protocol according to recommendations of manufactures except CZR (Table 3).

The result of this study can note that the use of veneering ceramic CZR from same manufacturer with Katana zirconia, showed the values of BFS in the lowest groups. The similar results were also shown in other studies. Fazi et al.13 compared microtensile bond strength (MTBS) between groups of bilayered zirconia/veneer specimens, and found that Lava zirconia veneering with Lava Ceram from the same manufacturer reported the lowest MTBS. This was significantly lower than veneering with VITA VM9 and Creation ZI from different manufacturers. Aboushelib et al.14 investigated MTBS between Cercon base zirconia and seven different veneer ceramics, and found that the MTBS of Cercon-based veneering with Cercon Ceram S from the same manufacturer was significantly lower than Nobel Rondo and Lava Ceram from different manufacturers. The present study suggests that matching the zirconia core with veneering ceramic of the same manufacturer should not be always recommended. For matching of veneering ceramic to zirconia core, many other influential factors, such as CTE, firing temperature, tempering associated with rapid cooling, and thickness of the veneering ceramic, all of which would be different according to each manufacturer, should be taken into consideration. The dental laboratories should concern the factors mentioned above to choose proper veneering ceramic for the zirconia core material.

Figures and Tables

Fig. 1

Design of the bilayered zirconia/veneer disk specimen (A) and firing program of Katana zirconia-based on the recommendation of manufacturers (B).

Fig. 2

BFS test conducted on bilayered zirconia/veneer specimens using a universal testing machine according to ISO standard 6872:2008.

Fig. 3

The formulation of BFS for bilayered disk.

*R = equivalent radius of loading, M = maximum bending moment (N), W = work load (N), P = maximum work load (N), n = Poisson's ratio (0.25), A = support circle's radius (5 mm), B = piston's radius (0.75 mm), C = specimen's radius (6.25 mm), d = specimen's thickness (1.50 mm), ta = upper layer's thickness (0.75 mm), tb = lower layer's thickness (0.75 mm), Ea = Young's modulus of upper layer, veneering porcelain, (CZR = 76, LV = 80, CC = 65, EM = 95 and VT = 65.52 GPa), Eb = Young's modulus of lower layer, Katana zirconia core (205 GPa).

Fig. 6

Scanning electron micrographs at fracture surface of tested specimen from each group. Note that the porosities were observed in veneering ceramic especially in CC and LV.

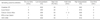

Table 1

CTE of zirconia core materials and their veneering ceramics

Table 2

Young modulus and CTE of materials used in this study

Table 3

Firing schedules for veneering ceramics used in this study

Table 4

Mean values and statistical analysis of biaxial flexural strength and Weibull analysis

ACKNOWLEDGEMENTS

We thank to Professor Vincent Everts for critical reviewing and editing English in this article.

References

1. Kelly JR. Dental ceramics: what is this stuff anyway? J Am Dent Assoc. 2008; 139:4S–7S.

2. Baldassarri M, Stappert CF, Wolff MS, Thompson VP, Zhang Y. Residual stresses in porcelain-veneered zirconia prostheses. Dent Mater. 2012; 28:873–879.

3. Salimee P, Thummawasi T. Biaxial flexural strength of zirconia-based ceramic with different core: veneer ratio. CU Dent J. 2011; 34:75–86.

4. Piconi C, Maccauro G. Zirconia as a ceramic biomaterial. Biomaterials. 1999; 20:1–25.

5. Denry I, Kelly JR. State of the art of zirconia for dental applications. Dent Mater. 2008; 24:299–307.

6. Larsson C, Wennerberg A. The clinical success of zirconiabased crowns: a systematic review. Int J Prosthodont. 2014; 27:33–43.

7. Håff A, Löf H, Gunne J, Sjögren G. A retrospective evaluation of zirconia-fixed partial dentures in general practices: an up to 13-year study. Dent Mater. 2015; 31:162–170.

8. Schmitter M, Mussotter K, Rammelsberg P, Gabbert O, Ohlmann B. Clinical performance of long-span zirconia frameworks for fixed dental prostheses: 5-year results. J Oral Rehabil. 2012; 39:552–557.

9. Raigrodski AJ, Hillstead MB, Meng GK, Chung KH. Survival and complications of zirconia-based fixed dental prostheses: a systematic review. J Prosthet Dent. 2012; 107:170–177.

10. Kelly JR, Tesk JA, Sorensen JA. Failure of all-ceramic fixed partial dentures in vitro and in vivo: analysis and modeling. J Dent Res. 1995; 74:1253–1258.

11. Beuer F, Schweiger J, Eichberger M, Kappert HF, Gernet W, Edelhoff D. High-strength CAD/CAM-fabricated veneering material sintered to zirconia copings-a new fabrication mode for all-ceramic restorations. Dent Mater. 2009; 25:121–128.

12. Fischer J, Stawarczyk B, Hämmerle CH. Flexural strength of veneering ceramics for zirconia. J Dent. 2008; 36:316–321.

13. Fazi G, Vichi A, Ferrari M. Microtensile bond strength of three different veneering porcelain systems to a zirconia core for all ceramic restorations. Am J Dent. 2010; 23:347–350.

14. Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Part II: Zirconia veneering ceramics. Dent Mater. 2006; 22:857–863.

15. Blatz MB, Bergler M, Ozer F, Holst S, Phark JH, Chiche GJ. Bond strength of different veneering ceramics to zirconia and their susceptibility to thermocycling. Am J Dent. 2010; 23:213–216.

16. Ozkurt Z, Kazazoglu E, Unal A. In vitro evaluation of shear bond strength of veneering ceramics to zirconia. Dent Mater J. 2010; 29:138–146.

17. Fischer J, Zbären C, Stawarczyk B, Hämmerle CH. The effect of thermal cycling on metal-ceramic bond strength. J Dent. 2009; 37:549–553.

18. ISO 6872:2008. Dentistry-ceramic materials. Geneva; Switzerland: ISO;2008.

19. Lin WS, Ercoli C, Feng C, Morton D. The effect of core material, veneering porcelain, and fabrication technique on the biaxial flexural strength and weibull analysis of selected dental ceramics. J Prosthodont. 2012; 21:353–362.

20. Fleming GJ, El-Lakwah SF, Harris JJ, Marquis PM. The effect of core:dentin thickness ratio on the bi-axial flexure strength and fracture mode and origin of bilayered dental ceramic composites. Dent Mater. 2005; 21:164–171.

21. Quinn JB, Quinn GD. A practical and systematic review of Weibull statistics for reporting strengths of dental materials. Dent Mater. 2010; 26:135–147.

22. Guazzato M, Proos K, Quach L, Swain MV. Strength, reliability and mode of fracture of bilayered porcelain/zirconia (Y-TZP) dental ceramics. Biomaterials. 2004; 25:5045–5052.

23. Fischer J, Stawarzcyk B, Trottmann A, Hämmerle CH. Impact of thermal misfit on shear strength of veneering ceramic/zirconia composites. Dent Mater. 2009; 25:419–423.

24. Swain MV. Unstable cracking (chipping) of veneering porcelain on all-ceramic dental crowns and fixed partial dentures. Acta Biomater. 2009; 5:1668–1677.

25. Komine F, Saito A, Kobayashi K, Koizuka M, Koizumi H, Matsumura H. Effect of cooling rate on shear bond strength of veneering porcelain to a zirconia ceramic material. J Oral Sci. 2010; 52:647–652.

26. Tuccillo JJ, Nielsen JP. Shear stress measurements at a dental porcelain-gold bond interface. J Dent Res. 1972; 51:626–633.

27. Saito A, Komine F, Blatz MB, Matsumura H. A comparison of bond strength of layered veneering porcelains to zirconia and metal. J Prosthet Dent. 2010; 104:247–257.

28. De Jager N, Pallav P, Feilzer AJ. The influence of design parameters on the FEA-determined stress distribution in CAD-CAM produced all-ceramic dental crowns. Dent Mater. 2005; 21:242–251.

29. Papanagiotou HP, Morgano SM, Giordano RA, Pober R. In vitro evaluation of low-temperature aging effects and finishing procedures on the flexural strength and structural stability of Y-TZP dental ceramics. J Prosthet Dent. 2006; 96:154–164.

30. White SN, Miklus VG, McLaren EA, Lang LA, Caputo AA. Flexural strength of a layered zirconia and porcelain dental all-ceramic system. J Prosthet Dent. 2005; 94:125–131.

31. Zeng K, Odén A, Rowcliffe D. Evaluation of mechanical properties of dental ceramic core materials in combination with porcelains. Int J Prosthodont. 1998; 11:183–189.

32. Thompson GA. Influence of relative layer height and testing method on the failure mode and origin in a bilayered dental ceramic composite. Dent Mater. 2000; 16:235–243.

33. Taskonak B, Mecholsky JJ Jr, Anusavice KJ. Residual stresses in bilayer dental ceramics. Biomaterials. 2005; 26:3235–3241.

34. Aboushelib MN, de Jager N, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Dent Mater. 2005; 21:984–991.

35. Isgrò G, Wang H, Kleverlaan CJ, Feilzer AJ. The effects of thermal mismatch and fabrication procedures on the deflection of layered all-ceramic discs. Dent Mater. 2005; 21:649–655.

36. Yoshinari M, Dérand T. Fracture strength of all-ceramic crowns. Int J Prosthodont. 1994; 7:329–338.

37. Studart AR, Filser F, Kocher P, Gauckler LJ. In vitro lifetime of dental ceramics under cyclic loading in water. Biomaterials. 2007; 28:2695–2705.

38. Ohlmann B, Rammelsberg P, Schmitter M, Schwarz S, Gabbert O. All-ceramic inlay-retained fixed partial dentures: preliminary results from a clinical study. J Dent. 2008; 36:692–696.

39. Anusavice KJ, Kakar K, Ferree N. Which mechanical and physical testing methods are relevant for predicting the clinical performance of ceramic-based dental prostheses? Clin Oral Implants Res. 2007; 18:218–231.

40. Ban S, Anusavice KJ. Influence of test method on failure stress of brittle dental materials. J Dent Res. 1990; 69:1791–1799.

41. Lawn BR, Deng Y, Thompson VP. Use of contact testing in the characterization and design of all-ceramic crownlike layer structures: a review. J Prosthet Dent. 2001; 86:495–510.

42. Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Effect of zirconia type on its bond strength with different veneer ceramics. J Prosthodont. 2008; 17:401–408.

43. Kim HJ, Lim HP, Park YJ, Vang MS. Effect of zirconia surface treatments on the shear bond strength of veneering ceramic. J Prosthet Dent. 2011; 105:315–322.

44. Wiskott HW, Nicholls JI, Belser UC. Stress fatigue: basic principles and prosthodontic implications. Int J Prosthodont. 1995; 8:105–116.

45. Zhang Y, Lawn B. Long-term strength of ceramics for biomedical applications. J Biomed Mater Res B Appl Biomater. 2004; 69:166–172.

46. Wakabayashi N, Anusavice KJ. Crack initiation modes in bilayered alumina/porcelain disks as a function of core/veneer thickness ratio and supporting substrate stiffness. J Dent Res. 2000; 79:1398–1404.

47. Miyazaki T, Nakamura T, Matsumura H, Ban S, Kobayashi T. Current status of zirconia restoration. J Prosthodont Res. 2013; 57:236–261.

48. Al-Amleh B, Neil Waddell J, Lyons K, Swain MV. Influence of veneering porcelain thickness and cooling rate on residual stresses in zirconia molar crowns. Dent Mater. 2014; 30:271–280.

49. Paula VG, Lorenzoni FC, Bonfante EA, Silva NR, Thompson VP, Bonfante G. Slow cooling protocol improves fatigue life of zirconia crowns. Dent Mater. 2015; 31:77–87.

50. Belli R, Frankenberger R, Appelt A, Schmitt J, Baratieri LN, Greil P, Lohbauer U. Thermal-induced residual stresses affect the lifetime of zirconia-veneer crowns. Dent Mater. 2013; 29:181–190.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download