This article has been corrected. See "Erratum: The effect of various sandblasting conditions on surface changes of dental zirconia and shear bond strength between zirconia core and indirect composite resin" in Volume 7 on page 506.

Abstract

PURPOSE

To measure the surface loss of dental restorative zirconia and the short-term bond strength between an indirect composite resin (ICR) and zirconia ceramic after various sandblasting processes.

MATERIALS AND METHODS

Three hundred zirconia bars were randomly divided into 25 groups according to the type of sandblasting performed with pressures of 0.1, 0.2, 0.4 and 0.6 MPa, sandblasting times of 7, 14 and 21 seconds, and alumina powder sizes of 50 and 110 µm. The control group did not receive sandblasting. The volume loss and height loss on zirconia surface after sandblasting and the shear bond strength (SBS) between the sandblasted zirconia and ICR after 24-h immersion were measured for each group using multivariate analysis of variance (ANOVA) and Least Significance Difference (LSD) test (α=.05). After sandblasting, the failure modes of the ICR/zirconia surfaces were observed using scanning electron microscopy.

RESULTS

The volume loss and height loss were increased with higher sandblasting pressure and longer sandblasting treatment, but they decreased with larger powder size. SBS was significantly increased by increasing the sandblasting time from 7 seconds to 14 seconds and from 14 seconds to 21 seconds, as well as increasing the size of alumina powder from 50 µm to 110 µm. SBS was significantly increased from 0.1 MPa to 0.2 MPa according to the size of alumina powder. However, the SBSs were not significantly different with the sandblasting pressure of 0.2, 0.4 and 0.6 MPa. The possibilities of the combination of both adhesive failure and cohesive failure within the ICR were higher with the increases in bonding strength.

The majority of all-ceramic restorations have a two-layer structure that is comprised of a weak ceramic veneer laid over a strong supporting core.1 In restorative dentistry, zirconia is commonly used as the core material in the manufacture of crowns, fixed dental prostheses (FDPs), and full-contour crowns because of its excellent esthetics, biocompatibility, and mechanical properties.2 In clinical practice, yttria tetragonal zirconia polycrystalline (Y-TZP) materials are widely used as the core materials in all-ceramic crowns and FDPs because of their similarity to tooth color, high strength of 900-950 MPa, and high elastic modulus of 200 GPa.3 However, veneer porcelains are susceptible to fractures because of their brittleness, which causes the chipping of the veneer porcelain. This problem is the main reason for the failure of zirconia-based restorations.4 Indeed, the failure rate of all-ceramic crowns is so high that it limits the lifetime performance.5 The percentages of clinical failures, including the chipping and delamination of veneered Y-TZP frameworks, were 13.0% and 15.2% after three and five years, respectively,67 whereas the 10-year failure rates of metal ceramic FDPs were between 8% and 10%.8 For patients with parafunction habits such as bruxism, the failure rate is even higher.8 Moreover, the replacement of a failed restoration is not recommended if the cost, compromised tooth structure, and additional trauma to the tooth are considerable.9

Indirect composite resin (ICR) materials are widely used in dentistry for the fabrication of aesthetic restorations, dentures, and orthodontic appliances in recent years10 and considered one of the most popular and preferred dental material for patients as well as dentists11 due to adequate flexibility and maneuverability,10 lower cost and similar aesthetic property compared with ceramics.12 The failure rate of composite-veneered restorations does not significantly differ from that of metal-ceramic restorations, but is lower than that of porcelain-veneered restorations.13 Also, ICR shows better marginal adaptation than ceramics due to the lower polymerization shrinkage.14 When compared to porcelain or porcelain-fused-to-metal restorations, the transfer of masticatory forces of ICR is proven to be substantially less.14 ICR have shown a larger capacity to absorb compressive loading forces and reduce the impact force by 57% compared to that of porcelain.14 This property can prevent overmuch occlusal force from being transmitted to the marginal of the crowns and damaging the marginal and that is why it can maintain the marginal integrity to occlusal loading.15 Also, ICR is proven to have a lower possibility to appear marginal chipping than ceramics.16 The ability to distribute the stress was 15% greater than that of porcelain or gold alloy.17 The bond strength between an ICR material and zirconia ceramic outperforms the threshold for clinically acceptable composite-metal and ceramic bonds.18 Thus, as an alternative to porcelain, a high-load ICR has been introduced to zirconia-based restorations based on its great advantages over porcelain.

Bonding between the veneering material and zirconia ceramic framework remains a key factor in limiting the successful performance of framework/veneer bilayered restorations. 2 Many manufacturers recommend sandblasting for the surface treatment of zirconia,2 which might be a necessary and irreplaceable method of obtaining durable bond strengths in zirconia ceramics.19 Sandblasting can improve the adhesion of veneering ceramics by increasing the surface roughness and providing undercuts.20 Sandblasting can also improve interfacial adhesion by cleaning the zirconia surface or enhancing high surface energy and wettability.21 It has been confirmed that sandblasting plays a positive role in increasing veneer-to-zirconia bond strength.22

However, sandblasting is considered a double-edged sword. Sandblasting affects the mechanical properties and reliability of zirconia because it causes surface damage and phase transformation (tetragonal to monoclinic) by introducing flaws and reshaping the surface.23 Sandblasting removes a significant amount of material from restorations, which could affect clinical adaptation.24 The abrasion or surface removal ability is assumed to be different depending on the setting of sandblasting parameters. It may be too aggressive in certain conditions to maintain the net-shape or dimension of zirconia substrates.24 However, few previous studies have assessed the effects of various sandblasting conditions on the surface loss of dental zirconia and bond strength of ICR used as a veneering material on a zirconia framework.

Different methods, including flexure strength tests, tensile tests, and shear tests have been adopted to evaluate the bond strength of core-veneer. The use of shear bond strength (SBS) test to determine core-veneer bond strength yields more standardized data because the applied forces are perpendicular to the bonding area.2526 In addition, the small cross-sectional area of the bonded surface in SBS eliminates the possible incorporation of structural flaws, which significantly affects the test results.2526

The purpose of the present study was to measure the surface loss of a zirconia-based core material and to characterize changes on the surface after various sandblasting processes. In addition, the short-term SBS between the ICR and the zirconia ceramic was evaluated after various sandblasting processes.

Commercial grade 3% mol Y-TZP zirconia powder (TOSOH, Tokyo, Japan) was pressed, sintered, and diamond-polished into discs, which were then cut into 300 bar specimens (6 mm × 4 mm × 2 mm) (Fig. 1). Sintering was done at 1350℃ in a furnace (Cercon Heat, Degussa, Germany), according to the manufacturer's recommendations. Each specimen was polished using #600, #800, #1000 and #1200 consecutively with wet aluminum oxide sandpaper (3M Corporation, Shanghai, China) with water-cooling.

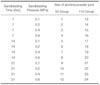

The specimens were then divided into 25 groups (n = 12) for modification by sandblasting with alumina particles, as follows:

Group 0 was the control group, which was polished without sandblasting.

Groups 1-24 received different types of sandblasting on the surface of zirconia (Table 1).

The sandblasting procedures were conducted using a P-001 sandblasting machine (Pudeng Enterprises Co., Ltd., Hsinchu, Taiwan). Its air compressor (Tornado 70, Durr Dental GmbH, Bietigheim-Bissingen, Germany) was adjusted for use in this study. The spray mouth was fixed, and a platform was constructed to keep the zirconia specimens 10 mm away from the spray mouth; the sandblasted surface of each specimen was vertical to the spray mouth.

Ceramage ICR (Shofu Inc., Tokyo, Japan) was used as the veneer material. The thickness of the ICR was set at 2.20 mm, which took into account the polymeric volume shrinkage rate of 2.5%. The ICR was then cured in a light-curing unit (Solidilite EX, Shofu Inc., Tokyo, Japan) for 1 minute of temporary light-curing and 5 minutes of final light-curing, according to the manufacturer's recommendations for the fabrication procedure. The predesinged final dimension of the ICR specimen was 5 mm × 4 mm × 2 mm (Fig. 1). The excess material was removed by hand finishing with wet aluminum oxide sandpaper (3M Corporation, Shanghai, China).

Both the zirconia and ICR specimens were polished and paralleled. All the specimens were ultrasonically cleaned with 95% ethanol for 10 minutes, and then treated with distilled water for 10 minutes to remove residual particles in preparation for the mechanical testing.

The mass of each specimen was measured three times with a BP211D electronic analytical balance (precision 0.00001 g, Sartorius, Goettingen, Germany) before (M1) and after (M2) sandblasting. The results were expressed as the mean of three measurements. The mass change was converted into volume loss as follows:

Volume loss (mm3) = 1000 (M1-M2)/ρ

wherer = 6.0 g/cm3 is the density of zirconia ceramic.

The average height loss was calculated as follows:

Average height loss (µm) = volume loss (mm3) ×103/40 (mm2)

The effects of various sandblasting conditions on the surface roughness of the specimens were assessed using a profilometer (SRT6200, Lantai, Guangzhou, China). Ra, which is generally regarded as the international parameter of roughness, was derived from the arithmetic mean of the absolute departures of the roughness profile from the mean line.29 Three readings were taken using a traveling distance of 2 mm across the modified surface of each specimen, and the mean value was calculated.

The surface morphology was examined using a Scanning Electron Microscope (SEM; FEI, Philips, Amsterdam, Holland) operating at an accelerating energy of 10-11 kV. In this test, two representative specimens were randomly selected from each group.

The remaining zirconia core and veneering ICR were chemically adhered using a bonding agent containing 10-methacryloyloxydecyl dihydrogen phosphate (MDP) (Clearfil SA, Kuraray Corporation, Tokyo, Japan) following the manufacturer's instruction. All specimens were immersed in water at 37℃ for 24 hours. The specimens were divided into 25 groups: Group 0-veneer to Group 24-veneer (Group 0V to Group 24V, n = 10) according to the different combinations of surface treatment.

After immersion for 24 hours, the shear bond strength of each specimen was measured. Each specimen was positioned in a steel mold, and the SBS was measured using a universal testing machine (Model 5565, Instron, Norwood, MA, USA) at a crosshead speed of 0.5 mm/min (Fig. 1). The ultimate load (N) of each specimen was recorded. The SBS was calculated as follows:

SBS (MPa) = load (N)/area (mm2)

The fractured surfaces were visually examined using an optical microscope at a ×30 magnification (SMZ1000, Nikon, Tokyo, Japan) to evaluate the failure mode of specimens. The failure modes were categorized as follows30:

Group A: Adhesive fracture on the interface between the core and veneer;

Group C: Cohesive fracture within the veneer ICR;

Group AC: Combined adhesive fracture and cohesive fracture within the ICR.

After the SBS test, representative specimens were observed using the SEM analyzer at 15 kV.

The collected data were analyzed by SPSS 17.0 (SPSS Inc., Chicago, IL, USA) using a multivariate analysis of variance (ANOVA) and a Least Significant Difference (LSD) test to evaluate the between-group differences in volume/height loss, surface roughness, and SBS. The differences in failure modes between the groups were evaluated using a chi-square test. The significance level was set at P<.05 for all statistical procedures.

The volume loss and height loss of zirconia surface were significantly increasedin all the sandblasted groups (Groups 1 to 24) compared to Group 0. Air pressure, powder size, and sandblasting time significantly affected the volume loss and the height loss of T-YZP zirconia. Regarding the powder size, when the sandblasting time and pressure were constant, significantly more zirconia was removed by 50 µm powder than by 110 µm powder. When the pressure and powder size were constant, significantlymore zirconia was removed with the sandblasting time increasing from 7 to 14 seconds and from 14 to 21 seconds. The removed amount of zirconia was significantly higher when the sandblasting pressure increased from 0.1 to 0.2 MPa, 0.2 to 0.4 MPa and 0.4 to 0.6 MPa (Fig. 2).

Compared to Group 0, the sandblasting significantly improved the roughness of the zirconia surface. When the time and pressure were constant, the surface roughness was enhanced by increasing the powder size from 50 µm to 110 µm. The surface roughness was enhanced with the increasing sandblasting time from 7 to 14 seconds and 14 to 21 seconds when the powder size and pressure were constant. When time and powder size were constant, the surface roughness between groups increased significantly as the pressure increased from 0.1 to 0.2 MPa, 0.2 to 0.4 MPa and 0.4 to 0.6 MPa (Fig. 3).

The SEM showed that the polished zirconia (Group 0) had a smooth surface with scratches caused by the wet grinding. After different types of sandblasting, the zirconia surfaces were rough. The comparison of these SEM images showed that the increase in powder size, pressure, and time created a relatively rougher surface, but the difference was insignificant between groups. No defects or flaws were observed in any groups. Some representative SEM images are shown in Fig. 4.

There is a significant improvement after sandblasting in SBS compared to Group 0. When the time and pressure were constant, the SBS significantly increased as the powder size increased from 50 to 110 µm. When the pressure and powder size were constant, the SBS increased significantly with the sandblasting time increasing from 7 to 14 seconds and 14 to 21 seconds. When powder size and time were constant, the SBS pressure significantly increased from 0.1 to 0.2 MPa. However, when time and powder size were constant, SBS did not significantly change when the pressure was increased from 0.2 to 0.4 MPa (P=.533) or from 0.4 and 0.6 MPa (P=.621) (Fig. 5).

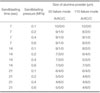

Regarding the failure mode, more combined failure mode occurred at larger powder size, longer time or at the pressure larger than 0.1 MPa (Table 2). However, there was no significant difference between the pressures 0.2 and 0.4 MPa, or between 0.4 and 0.6 MPa. Representative SEM images of fracture interfaces after SBS test are shown in Fig. 6.

The clinical significance of volume loss can only be estimated when the above data are calculated into the wear (substance loss in µm) in a restoration.2728 One example is the inner surface of the retainer wing of a cast resin-bonded prosthesis, which is also called the Maryland bridge.2728 The mean retention surface of a Maryland bridge is between 30 and 50 mm2 in the anterior retainers. Sizes are generally smaller in the lower arch and are larger in the upper arch.2728 Thus, in the present study, the average retention surface of 40 mm2 was selected to calculate the height loss. We found that the height loss of the surface decreased as the powder size increased, but it increased as time or pressure increased. It could be assumed that a larger volume of powder led to the lower loss of the material on the abraded surface. This explanation might help with the allegation that in a blasting pipe system of known size, a fine powder of about 50 µm fills the pipe and flows out of the spray tip with a greater number of particles than coarse powder of about 110 µm does.2728 Consequently, a greater number of particles are left on the surface of the tested materials, and surface substance may be lost, showing that fine powder is more abrasive than course powder. In the present study, this analysis could explain why the 110 µm particles caused less surface loss than the 50 µm particles did. Also, the total powder-zirconia contact areas are bigger with smaller powders, which may be another reason why more surface substances were lost.

Previous studies have rarely reported the surface loss of dental zirconia by sandblasting. Kern and Thompson27 employed silica coating machines to compare the volume loss in a glass-infiltrated alumina ceramic (In-Ceram Alumina) with a leucite-reinforced feldspathic glass ceramic (IPS Empress) after processing by using 110 µm alumina powder at 0.25 MPa for 14 seconds at a distance of 10 mm. The results revealed that the volume loss of In-Ceram Alumina was 0.384 mm3, which was similar to that of noble alloys. However, the loss in IPS Empress was 36 times greater than In-Ceram.27 When the blasting time was reduced to 7 seconds, the volume loss in IPS Empress decreased from 12% to 6.3%, and the height loss was 19 µm. Under the same sandblasting condition, the volume losses were 0.179, 0.184, and 0.307 mm3 for NiCr, CoCr, and AuAgCu dental alloys, respectively.28 The results showed that when 250 µm powder was used in sandblasting, it caused greater surface loss of the alloys than 110-µm powder did, which was opposite to our findings. This discrepancy may have been due to the size of 250 µm powder, the clinical ramifications28 of which are significant. When particles of 250 µm powder hit the material, there is an increased possibility of flaws or microcracks on the surface of the material.31 Several previous studies demonstrated the possibility that larger particles would initiate larger damage based on substantial particle-abrasion damage that was 4 µm deep in the zirconia.2432 This damage might lead to the reduction of elastic modulus in the near surface of sandblasted zirconia and greater substance loss of materials.24 This could explain why 250 µm powder causes more surface loss than 110 µm powder does.

It should be noted that the thickness of the supporting substrate plays the most important role in selecting the mechanical resistance to bite force, particularly at the margins of restorations or copings.33 The thickness of zirconia copings is from 0.5 to 0.7 mm.3435 It is even smaller in some brands of zirconia or at the marginal edges.33 Hence, sandblasting should avoid the fragile margins. The direction of sandblasting, which might not be vertical to the surfaces, especially at the inner side of the copings, could induce different surface reductions where the inner occlusal surface may be removed more.34 Operators should never stop moving the spray tip or let it point to a given area and keep the sandblasted areas overlap to prevent significant local recess and fracture of the restorations.3435 If these sandblasting conditions were applied to the inner surfaces of a ceramic crown for more than a few seconds, it would be possible to jeopardize the fit of the restoration and affect the adaptation of the restorations on the prepared teeth, which might cause the failure of the restorations. However, with brief sandblasting under gentler conditions,36 volume loss might be acceptable in the intraoral repair of restorations. The height loss of ceramic less than 20 µm was clinically acceptable2728 and not critical to the clinical fit of restorations. Thus, in the present study, the height loss in groups 1, 2, 5, 6, 9, 10, 13-15, 17-19, 21, and 22 were acceptable. However, it is emphasized that repeated sandblasting for any reason might influence the fit.2728

The present study demonstrated that sandblasting with alumina resulted in significantly higher bond strength than did the process of polishing without sandblasting. Therefore, sandblasting is an important surface treatment method that could improve the bond strength between zirconia and veneer materials. This conclusion is consistent with several previous studies. However, the present study has also shown that the bond strength between ICR and zirconia ceramics could be influenced by the various types of sandblasting treatment, including pressure, powder size, and time.

After sandblasting at pressures of 0.2, 0.4, or 0.6 MPa, the bond strengths were significantly higher than at 0.1 MPa. This finding indicates that in order to achieve superior bond strength between an ICR and the zirconia core, the sandblasting pressure should be ≥ 0.2 MPa. A possible reason is that under increasing pressure, the surface roughness, the bonding area, and the wetting behavior of adhesives were improved.33 In addition, the previous studies showed that high-pressure sandblasting removed a greater amount of organic contaminant from the ceramic surface, which facilitated the chemical activation of the bonding surface.37 Thus, higher sandblasting pressure produced higher bonding strengths. However, the results showed that the bond strengths of the zirconia/ICR specimens were unchanged even when the sandblasting pressure exceeded 0.2 MPa, which was consistent with the results of a previous study38 that considered zirconia and porcelain veneer. A possible reason is that under increased pressure, the probability of surface defects and flaws increased, which then might negatively affect the surface bonding.32 However, previous studies showed the opposite. Kern et al. concluded that 0.05 MPa was effective in sufficiently modifying the zirconia, which could enhance resin bonding.39 Komine et al.38 found no significant difference of bonding strengths at 0.1, 0.2, 0.4, and 0.6 MPa between the zirconia framework and ICR. This discrepancy might have been caused by the differences in zirconia and the sandblasting devices. For example, the variety of sizes of suction valves and blasting pipes might result in different flow volumes of alumina powder through the spray tips.

The present study also showed that as the powder size and sandblasting time increased, the bond strengths between zirconia and ICR also increased. The surface roughness clearly increased as particle size and sandblasting time increased. In addition, the increased roughness led to higher bonding strengths because wider contact areas were available for bonding.20 Moreover, compared with flat or smooth surfaces, greater amounts of surface-free energy were provided.40 The results showed that by using different particle sizes, the roughness achieved in 3Y-TZP and a zirconia composite (Nanozr) sandblasted with 125 µm SiC particles was twice as large as in sandblasting with 70 µm alumina particles.41 A rougher surface of zirconia was produced by using 110-µm alumina particles than by using 50 µm particles.42

In the present study, the SBS generally ranged from 9.10 to 13.11 MPa, depending on sandblasting pressure, time, and powder size. An adequate bond in metal ceramic restorations occurred when the fracture stress was greater than 25 MPa.43 Until the present study, an adequate bond strength of all-ceramic materials had not yet been determined. Several researchers have suggested that the clinically acceptable range of bond strengths for composite-ceramics and composite-metal bonds is between 10 and 13 MPa,44 which means that in the present study, the SBS between zirconia framework and ICR in most groups were acceptable.

Regarding the failure modes, with increasing powder size, time or pressure, the possibility of the occurrence of combined fractures increased, probably because of the improved bonding strength on the interface.4344 In other words, when the bonding strengths reached a relatively high level, the fracture mode of the veneer specimens was mainly the combined of adhesive failure at the interface and cohesive failure in the veneering material.45 On the other hand, only adhesive failure at the interface occurred when the bonding strength was at a relatively low level. These results are consistent those found by a previous study.38 The chipping of the veneer ceramic occurred more frequently than did the failure of the core material of zirconia-based restorations, which could be due to weaker interface adhesion and the greater resistance of zirconia to fractures that can stop, turn, and propagate cracks along the interface.45 Thus, the higher possibility of adhesive occurring at the interface would lead to a the greater possibility of the occurrence of chipping in the veneer material.

In summary, the bond strengths at 0.2, 0.4, and 0.6 MPa were higher than at 0.1 MPa, but did not significantly differ at 0.2, 0.4 and 0.6 MPa. However, it is proved that more microcracks and defects that can be stress concentration sources are generated during sandblasting with the sandblasting pressure increasing, which is more likely to impair the strength of zirconia and cause the failure of zirconia. 324647 Also, higher sandblasting pressure can cause larger volume expansion which alters the coefficient of thermal expansion of the surface layer of the zirconia, thus leading to more possibility of the failure of bonding strength between porcelain and zirconia framework.4849 That is, the higher the pressure was, the greater the risk of failure was. Kern et al.39 suggested reducing the pressure during air-abrasion can be advantageous in reducing the negative surface effects caused by sandblasting. Thus, the pressure of 0.2 MPa is the best for promoting bonding between zirconia and ICR. In addition, the bonding strengths were improved as the sandblasting time and powder size of the alumina increased. SEM did not reveal flaws or defects in any group. In other words, the powder size of 110 µm with a sandblasting time of 20 seconds might be safe for bonding at higher strengths. The volume loss and height loss increased as the powder size decreased and the time and pressure increased but the largest height loss should not exceed 20 µm. Therefore, sandblasting with a particle size of 110 µm, a time of 20 seconds, and a pressure of 0.2 MPa is recommended for bonding between zirconia and ICR within a certain range.

However, all in vitro studies have limitations with respect to clinical relevance and influential parameters. This study has limitations regarding its ability to stimulate clinical loading forces on restorations and changes to oral environments. The loading was monotonic rather than cyclic, and the temperature and moisture of the oral cavity were not simulated. Furthermore, the specimens were not thermally cycled. In further studies, the aging parameters should be included to explore the viability of ICR-zirconia restorations.

The results of the present study demonstrate that the volume loss and height loss in the zirconia surface increase according to decreased powder size and increased time and pressure. Sandblasting with alumina can improve the bonding strengths between zirconia and indirect composite resin (ICR). Sandblasting at a pressure ≥ 0.2 MPa, longer blasting times, and larger powder sizes increase short-term bond strengths. The risk of failure increases with increased pressure. Based on these results, sandblasting with alumina at 0.2 MPa for 20 seconds with 110 µm particles is recommended for dental applications conducted to improve the bonding between the zirconia core and ICR within a certain range.

Figures and Tables

Fig. 2

Volume loss (A) and height loss (B) of Y-TZP zirconia after polishing (Group 0) or after different types of sandblasting (* means there is a statistical significance between groups while the other two factors are constant).

Fig. 3

Surface roughness of Y-TZP zirconia after polishing (G0) or after different types of sandblasting (* means there is a statistical significance between groups while the other two factors are constant).

Fig. 4

SEM images of representative groups after surface polishing or sandblasting. (A) zirconia surface after polishing without sandblasting. Grooves caused by the polishing are visible. Zirconia surfaces after sandblasting at pressure, sandblasting time, and particle size of: (B) 0.1 MPa, 7 seconds, and 50 µm; (C) 0.1 MPa, 21 seconds and 50 µm; (D) 0.1 MPa, 7 seconds and 110 µm; (E) 0.6 MPa, 7 seconds and 50 µm; (F) 0.2 MPa, 21 seconds and 110 µm (recommended sandblasting condition).

Fig. 5

Shear bond strength of bilayered structures of Y-TZP zirconia core with veneer indirect composite resin after polishing (Group 0) or after different types of sandblasting. (* means there is a statistical significance between groups while the other two factors are constant; + means there is not statistical significance between groups while the other two factors are constant).

Fig. 6

SEM images (A-C) and optical telescope images (D-F) of failure mode after SBS test of zirconia and indirect composite resin. A and D show adhesive fractures on the interface between the core and veneer. The indirect composite resin of the veneer has been completely removed from the zirconia surface (marked as Zirconia) after the shear-bond strength test. B, C, E, and F show combined adhesive failures and cohesive failure within the indirect composite resin. There was some residual indirect composite resin (marked as Resin) bonding on the zirconia surface (marked as Zirconia) after the shear-bond strength test.

Table 1

Groups receiving different types of sandblasting on the surface of zirconia

Table 2

SBS test of failure modes after different types of sandblasting

References

1. Dong JK, Luthy H, Wohlwend A, Schärer P. Heat-pressed ceramics: technology and strength. Int J Prosthodont. 1992; 5:9–16.

2. Luangruangrong P, Cook NB, Sabrah AH, Hara AT, Bottino MC. Influence of full-contour zirconia surface roughness on wear of glass-ceramics. J Prosthodont. 2014; 23:198–205.

3. Choi JE, Waddell JN, Torr B, Swain MV. Pressed ceramics onto zirconia. Part 1: Comparison of crystalline phases present, adhesion to a zirconia system and flexural strength. Dent Mater. 2011; 27:1204–1212.

4. Lawn BR, Pajares A, Zhang Y, Deng Y, Polack MA, Lloyd IK, Rekow ED, Thompson VP. Materials design in the performance of all-ceramic crowns. Biomaterials. 2004; 25:2885–2892.

5. Lawna BR, Denga Y, Miranda P, Pajares A, Chai H, Kim DK. Overview: Damage in brittle layer structures from concentrated loads. J Mater Res. 2002; 17:3019–3036.

6. Sailer I, Fehér A, Filser F, Lüthy H, Gauckler LJ, Schärer P, Franz Hämmerle CH. Prospective clinical study of zirconia posterior fixed partial dentures: 3-year follow-up. Quintessence Int. 2006; 37:685–693.

7. Sailer I, Fehér A, Filser F, Gauckler LJ, Lüthy H, Hämmerle CH. Five-year clinical results of zirconia frameworks for posterior fixed partial dentures. Int J Prosthodont. 2007; 20:383–388.

8. Scurria MS, Bader JD, Shugars DA. Meta-analysis of fixed partial denture survival: prostheses and abutments. J Prosthet Dent. 1998; 79:459–464.

9. Kim BK, Bae HE, Shim JS, Lee KW. The influence of ceramic surface treatments on the tensile bond strength of composite resin to all-ceramic coping materials. J Prosthet Dent. 2005; 94:357–362.

10. Taira Y, Hatono H, Tokita M, Sawase T. Thickness and surface structure of a ceramic layer created on three indirect resin composites with aerosol deposition. J Prosthodont Res. 2010; 54:168–172.

11. Kirmali O, Barutcugil C, Harorli O, Kapdan A, Er K. Resin cement to indirect composite resin bonding: Effect of various surface treatments. Scanning. 2015; 37:89–94.

12. Leinfelder KF. Indirect posterior composite resins. Compend Contin Educ Dent. 2005; 26:495–503.

13. Takahashi Y, Hisama K, Sato H, Chai J, Shimizu H, Kido H, Ukon S. Probability of failure of highly filled indirect resin-veneered implant-supported restorations: an in vitro study. Int J Prosthodont. 2002; 15:179–182.

14. Nandini S. Indirect resin composites. J Conserv Dent. 2010; 13:184–194.

15. Ereifej N, Silikas N, Watts DC. Edge strength of indirect restorative materials. J Dent. 2009; 37:799–806.

16. Tsitrou EA, Northeast SE, van Noort R. Brittleness index of machinable dental materials and its relation to the marginal chipping factor. J Dent. 2007; 35:897–902.

17. Ciftçi Y, Canay S. The effect of veneering materials on stress distribution in implant-supported fixed prosthetic restorations. Int J Oral Maxillofac Implants. 2000; 15:571–582.

18. Kobayashi K, Komine F, Blatz MB, Saito A, Koizumi H, Matsumura H. Influence of priming agents on the short-term bond strength of an indirect composite veneering material to zirconium dioxide ceramic. Quintessence Int. 2009; 40:545–551.

19. Blatz MB, Sadan A, Kern M. Resin-ceramic bonding: a review of the literature. J Prosthet Dent. 2003; 89:268–274.

20. Guazzato M, Albakry M, Quach L, Swain MV. Influence of surface and heat treatments on the flexural strength of a glass-infiltrated alumina/zirconia-reinforced dental ceramic. Dent Mater. 2005; 21:454–463.

21. Wang G, Zhang S, Bian C, Kong H. Effect of zirconia surface treatment on zirconia/veneer interfacial toughness evaluated by fracture mechanics method. J Dent. 2014; 42:808–815.

22. Liu D, Matinlinna JP, Tsoi JK, Pow EH, Miyazaki T, Shibata Y, Kan CW. A new modified laser pretreatment for porcelain zirconia bonding. Dent Mater. 2013; 29:559–565.

23. Karakoca S, Yilmaz H. Influence of surface treatments on surface roughness, phase transformation, and biaxial flexural strength of Y-TZP ceramics. J Biomed Mater Res B Appl Biomater. 2009; 91:930–937.

24. Zhang Y, Lawn BR, Rekow ED, Thompson VP. Effect of sandblasting on the long-term performance of dental ceramics. J Biomed Mater Res B Appl Biomater. 2004; 71:381–386.

25. Aboushelib MN, de Jager N, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Dent Mater. 2005; 21:984–991.

26. Aboushelib MN, Kleverlaan CJ, Feilzer AJ. Microtensile bond strength of different components of core veneered all-ceramic restorations. Part 3: double veneer technique. J Prosthodont. 2008; 17:9–13.

27. Kern M, Thompson VP. Sandblasting and silica-coating of dental alloys: volume loss, morphology and changes in the surface composition. Dent Mater. 1993; 9:151–161.

28. Kern M, Thompson VP. Sandblasting and silica coating of a glass-infiltrated alumina ceramic: volume loss, morphology, and changes in the surface composition. J Prosthet Dent. 1994; 71:453–461.

29. Boccaccini AR, Winkler V. Fracture surface roughness and toughness of Al2O3-platelet reinforced glass matrix composites. Compos Part A Appl Sci Manuf. 2002; 33:125–131.

30. Saka M, Yuzugullu B. Bond strength of veneer ceramic and zirconia cores with different surface modifications after microwave sintering. J Adv Prosthodont. 2013; 5:485–493.

31. Kosmač T, Oblak Č, Marion L. The effects of dental grinding and sandblasting on ageing and fatigue behavior of dental zirconia (Y-TZP) ceramics. J Eur Ceram Soc. 2008; 28:1085–1090.

32. Zhang Y, Lawn BR, Malament KA, Van Thompson P, Rekow ED. Damage accumulation and fatigue life of particle-abraded ceramics. Int J Prosthodont. 2006; 19:442–448.

33. Ford C, Qasim T, Bush MB, Hu X, Shah MM, Saxena VP, Lawn BR. Margin failures in crown-like brittle structures: off-axis loading. J Biomed Mater Res B Appl Biomater. 2008; 85:23–28.

34. Fischer H, Weber M, Marx R. Lifetime prediction of all-ceramic bridges by computational methods. J Dent Res. 2003; 82:238–242.

35. de Oyagüe RC, Monticelli F, Toledano M, Osorio E, Ferrari M, Osorio R. Influence of surface treatments and resin cement selection on bonding to densely-sintered zirconium-oxide ceramic. Dent Mater. 2009; 25:172–179.

36. Wolf DM, Powers JM, O›Keefe KL. Bond strength of composite to porcelain treated with new porcelain repair agents. Dent Mater. 1992; 8:158–161.

37. Quaas AC, Yang B, Kern M. Panavia F 2.0 bonding to contaminated zirconia ceramic after different cleaning procedures. Dent Mater. 2007; 23:506–512.

38. Komine F, Fushiki R, Koizuka M, Taguchi K, Kamio S, Matsumura H. Effect of surface treatment on bond strength between an indirect composite material and a zirconia framework. J Oral Sci. 2012; 54:39–46.

39. Kern M, Barloi A, Yang B. Surface conditioning influences zirconia ceramic bonding. J Dent Res. 2009; 88:817–822.

40. Watanabe T, Ino S, Okada S, Katsumata Y, Hamano N, Hojo S, Teranaka T, Toyodo M. Influence of simplified silica coating method on the bonding strength of resin cement to dental alloy. Dent Mater J. 2008; 27:16–20.

41. Ban S. Reliability and properties of core materials for all-ceramic dental restorations. Jpn Dent Sci Rev. 2008; 44:3–21.

42. Li T, Zhang ZF, Zhou M, Wang H. Research progress on sandblasting technique in the dental ceramic restorations. Int J Stomatol. 2010; 37:206–209.

43. Craig RG, Powers JM, Wataha JC. Dental materials: properties and manuplation. 8th ed. St. Louis: Mosby;2004. p. 578–580.

44. Matsumura H, Yanagida H, Tanoue N, Atsuta M, Shimoe S. Shear bond strength of resin composite veneering material to gold alloy with varying metal surface preparations. J Prosthet Dent. 2001; 86:315–319.

45. Ozkurt Z, Kazazoglu E, Unal A. In vitro evaluation of shear bond strength of veneering ceramics to zirconia. Dent Mater J. 2010; 29:138–146.

46. Uo M, Sjögren G, Sundh A, Goto M, Watari F, Bergman M. Effect of surface condition of dental zirconia ceramic (Denzir) on bonding. Dent Mater J. 2006; 25:626–631.

47. Kosmač T, Oblak Č, Marion L. The effects of dental grinding and sandblasting on ageing and fatigue behavior of dental zirconia (Y-TZP) ceramics. J Eur Ceram Soc. 2008; 28:1085–1090.

48. Nakamura T, Wakabayashi K, Zaima C, Nishida H, Kinuta S, Yatani H. Tensile bond strength between tooth-colored porcelain and sandblasted zirconia framework. J Prosthodont Res. 2009; 53:116–119.

49. Fischer J, Stawarczyk B, Tomic M, Strub JR, Hämmerle CH. Effect of thermal misfit between different veneering ceramics and zirconia frameworks on in vitro fracture load of single crowns. Dent Mater J. 2007; 26:766–772.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download