This article has been

cited by other articles in ScienceCentral.

Abstract

Objective

To investigate the dimensional accuracy of digital dental models obtained from the dental cone-beam computed tomography (CBCT) scan of alginate impressions according to the time elapse when the impressions are stored under ambient conditions.

Methods

Alginate impressions were obtained from 20 adults using 3 different alginate materials, 2 traditional alginate materials (Alginoplast and Cavex Impressional) and 1 extended-pour alginate material (Cavex ColorChange). The impressions were stored under ambient conditions, and scanned by CBCT immediately after the impressions were taken, and then at 1 hour intervals for 6 hours. After reconstructing three-dimensional digital dental models, the models were measured and the data were analyzed to determine dimensional changes according to the elapsed time. The changes within the measurement error were regarded as clinically acceptable in this study.

Results

All measurements showed a decreasing tendency with an increase in the elapsed time after the impressions. Although the extended-pour alginate exhibited a less decreasing tendency than the other 2 materials, there were no statistically significant differences between the materials. Changes above the measurement error occurred between the time points of 3 and 4 hours after the impressions.

Conclusions

The results of this study indicate that digital dental models can be obtained simply from a CBCT scan of alginate impressions without sending them to a remote laboratory. However, when the impressions are not stored under special conditions, they should be scanned immediately, or at least within 2 to 3 hours after the impressions are taken.

Keywords: Digital dental model, Alginate impression, Dental cone-beam computed tomography, Dimensional accuracy

INTRODUCTION

Dental study models are essential records for orthodontic diagnosis, planning, and treatment evaluations. However, the plaster models are prone to damage and loss, require storage space, and are inefficient in terms of retrieval and transfer. Recent advances in digital technology have led to the replacement of the plaster casts with digital models to eliminate the drawbacks of plaster models.

1

The most popular method of fabricating digital dental models is optical or laser scanning of a plaster cast obtained from an alginate impression. More recently, direct scanning of alginate impressions using cone-beam computed tomography (CBCT) has been introduced to eliminate the need for plaster pouring. Many studies

234 have investigated the validity of CBCT scanning of alginate impressions. Their results proved that the CBCT technique is accurate enough for the measurements in orthodontic diagnosis. Naidu et al.

2 reported that tooth width measurements from digital models obtained by CBCT scanning of alginate impressions were as reproducible as those obtained from plaster models with calipers. White et al.

3 studied 16 sets of maxillary and mandibular vinylpolysiloxane and alginate impressions that were converted into CBCT scanned dental models to evaluate the accuracy of intra- and interarch measurements. The results indicated that digital orthodontic models obtained from CBCT scanning of both alginate and vinylpolysiloxane impressions provided dimensionally accurate representations of intra-arch relationships for orthodontic evaluation. Wiranto et al.

4 assessed the validity of digital models obtained from the CBCT scanning of alginate impressions in tooth width measurements in 22 subjects, and concluded that tooth-width measurements on digital models did not differ significantly from those on plaster models.

Although all these studies showed the validity of CBCT scanning of alginate impressions, the impressions were sent to the laboratory for the scan. All these studies used DigiModel (OrthoProofUSA, Albuquerque, NM, USA), which is currently the main provider of this service. OrthoProof uses an industrial CBCT to digitize alginate impressions.

234 However, with the recent popularity of dental CBCT, many practitioners now have access to CBCT scanners in clinics, negating the need to send impressions to a remote laboratory. No published study has evaluated the accuracy of digital dental models obtained from a dental CBCT scanner.

On the other hand, another new alternative for digital dental model fabrication is direct scanning of the dentition with an intraoral scanner.

5678 However, the validity of the intraoral scan data has not yet achieved consensus among professionals, particularly when they are scanned

in vivo, whereas scanning plaster models

in vitro shows relatively reliable accuracy.

9 Furthermore, this system still requires a long duration to scan the entire dentition, although some research has demonstrated a reduction in scanning time.

10 A recent study

8 assessing the time and patient acceptance of an intraoral scanner concluded that alginate impressions are still the preferred method with respect to chair time and patient acceptance. In cases where successive laboratory work using an actual dental model, such as fabrication of indirect bonding trays, is needed, additional three-dimensional (3D) printing should be performed to create a physical model from virtual images. However, with CBCT scanning of the alginate impression, both the digital model and actual plaster cast can be obtained from a single impression, which results in a marked reduction in clinical workload.

In addition, there is no need to use an extended-pour alginate material when impressions are scanned using the CBCT scanners in clinics. Regarding the accuracy of digital dental models, few studies dealt with the models made from traditional alginate materials. Torassian et al.

11 used traditional alginates together with alginate substitute materials in a study assessing the dimensional accuracy of digital models. In their study, the impressions for each material were taken and sent to the laboratory for digital model fabrication 72 hours later. The results showed that digital models were significantly smaller in all dimensions compared with plaster models. Although significant changes were found in the impressions, the authors could not evaluate when the change occurred within the experimental time period because the impressions were sent to the laboratory for the scan. No published study has evaluated the dimensional accuracy of digital models on a consecutive hourly basis after the impression was taken. The purpose of this study was to investigate the dimensional accuracy of a digital dental model obtained from a CBCT scan of alginate impressions according to the time elapse.

MATERIALS AND METHODS

Twenty adults (8 men and 12 women; mean age, 26.5 years) with normal occlusion and no missing teeth were enrolled in the study. All subjects provided informed consent to participate in this study. Three different alginate impression materials were selected including two traditional alginates and one extended-pour alginate: 1) Alginoplast (Heraeus Kulzer GmbH, Hanau, Germany), 2) Cavex Impressional (Cavex Holland BV, Haarlem, the Netherlands), and 3) Cavex ColorChange (Cavex Holland BV). Cavex ColorChange was used as the extended-pour alginate material.

After mixing the 3 types of alginate impression materials according to their respective manufacturer's instructions, maxillary impressions of each subject were taken using a plastic impression tray (President Impression Tray System; Coltene/Whaledent AG, Altstatten, Switzerland). Any impurities and saliva were rinsed away under running water and excess material beyond the impression tray was trimmed without damaging the cervical areas of the dentition. With a gentle air blow, water collected on the surface of the impression was removed. Each obtained impression was then stored in a room that reflected an ordinary clinical situation where the temperature ranged from 16℃ to 21℃ and humidity ranged from 45% to 55% relative humidity (RH) without any sealing device.

Each alginate impression was scanned with a CBCT scanner (Alphard Vega; Asahi Roentgen Ind. Co., Kyoto, Japan) immediately after taking the impression, and after 1, 2, 3, 4, 5, and 6 hours under the following conditions: 80 kV; 5 mA; voxel size, 0.2 × 0.2 × 0.2 mm; field of view (FOV), 102 × 102 mm. The reason why the scanning time was extended up to 6 hours was that the extended-pour alginate material was used together with the traditional alginates. The data scanned immediately after taking the impression, which was obtained within 5 minutes after impressions, were used as controls in this study. The Digital Imaging and Communications in Medicine (DICOM) file obtained from the CBCT was reconstructed into 3D images and then converted to stereolithography (STL) format using V-works program (version 4.0; CyberMed, Seoul, Korea) with application of identical Hounsfield unit (-175) to each image. Then, the images were imported into a 3D reverse engineering software program (Rapidform™2006; Inus, Seoul, Korea). The negative of the alginate impression image was transformed to a positive image by using the reverse normal function in the program (

Figure 1).

Using the image scanned immediately after impression taking as the reference image, all images taken according to the time elapse were reoriented to obtain a consistent 3D orientation using the surface registration function of the program. Three linear measurements were made on each digital model with the use of Rapidform 2006 software in three dimensions: anterior-posterior, transverse, and vertical. The anterior-posterior dimension was evaluated by measuring the incisor to molar from the mesiobuccal cusp tip of the upper right first molar to the maxillary midline. The transverse dimension was measured using the intermolar width, the line between the mesiobuccal cusp tip of the upper right first molar and the same point on the upper left first molar. The vertical dimension was evaluated using the incisor height, which was measured from the incisal edge at the midline of the maxillary right central incisor to the gingival margin (

Figure 2).

Statistical analysis

In order to assess the measurement errors, 20 images were selected randomly, and the measurements were obtained twice at an interval of two weeks by an examiner. The method errors of double registration of all the measurements were calculated using the Dahlberg's formula.

12 The results were as follows: 0.29 mm for the incisor to molar, 0.29 mm for the intermolar width, and 0.27 mm for the incisor height. In addition, intraclass correlation coefficients (ICC) were evaluated using a two-way mixed-effects model with absolute agreement to evaluate the reliability of intra-examiner measurements. The ICC values for the 3 linear measurements according to the time elapse were 85% to 95%. The Shapiro-Wilks test for normality showed that all measurements were normally distributed.

The means and standard deviations of the actual measurements were calculated for each material and for each time period. Pair-wise comparisons were carried out using the t-test to identify differences between the control and each digital model according to elapsed time. The means and standard deviations of changes in measurements according to the time elapse were calculated. The changes within the measurement error (0.29 mm for the incisor to molar, 0.29 mm for the intermolar width, and 0.27 mm for the incisor height) were regarded as clinically acceptable in this study. The changes within the measurement error were assessed to evaluate the time point at which clinically relevant differences began to appear. Differences in the measurement change between the materials were also evaluated within the setting time. All statistical analyses were carried out using the IBM SPSS Statistics software (version 20.0; IBM Co., Armonk, NY, USA).

RESULTS

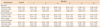

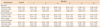

The means and standard deviations of the measurements for each material and each elapsed time are presented in

Table 1. All measurements showed a decreasing tendency with an increase in the elapsed time after the impression. The comparison of each image obtained at different elapsed times with the control showed no statistically significant differences at the time point of 1 hour. Statistically significant differences began to appear from the time point of 2 hours after the impression in all three materials (

Table 1).

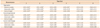

The differences in the measurement change between the materials are presented in

Figure 3. Cavex ColorChange, which is an extended-pour alginate material, exhibited a less severe decreasing tendency than the other two traditional alginates. However, there were no statistically significant differences between the materials within the setting time.

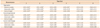

Table 2 presents the changes in measurements according to the time elapse. Only descriptive statistics was used in

Table 2. In the evaluation of the difference in measurements based on the measurement errors (0.29 mm for the incisor to molar and the intermolar width, and 0.27 mm for the incisor height), the changes were found to exceed the measurement error between the time points of 3 and 4 hours after the impression (

Figure 3,

Table 2).

DISCUSSION

Current clinical orthodontic practices are becoming more dependent on digital records including radiographs, clinical photographs and dental models. The use of a digital dental model is particularly advantageous considering the storage space required for traditional plaster casts and the ease of retrieval.

13 The most popular way to obtain a digital dental model is to have it created at a laboratory that provides commercial digitizing service. Diagnostic impressions of the patient's dentition are mailed to the company, and the impressions are scanned using various technologies unique to the company. Some companies produce digital orthodontic dental models by laser scanning or CBCT imaging of plaster models (OrthoCAD by Cadent, Carlstadt, NJ, USA; emodel by GeoDigm, Chanhassen, MN, USA). To use these systems, practitioners are required to fabricate plaster dental models from alginate impressions and send them to the company. During transportation, plaster models are not only inaccessible but also subject to loss and fracture. Other companies use CBCT scanning of dental impressions to produce digital dental models (DigiModel by OrthoProofUSA, Albuquerque, NM, USA). However, a drawback of this system is that additional 3D printing needs to be performed to produce a physical model from virtual images in cases where successive laboratory work is needed, such as in the fabrication of indirect bonding trays.

Alginate materials undergo syneresis and imbibition over time when exposed to the environment. The dimensional stability of traditional alginate material is the main concern when shipping alginate impressions to a distant laboratory is required, since the duration between taking the impression and CBCT scanning is 2 to 3 days.

14 To overcome the dimensional instability of traditional alginates, manufacturers have invented new extended-pour alginate impression materials, and claim that these new alginates are dimensionally stable for up to several days. In addition, digital model providers recommend using either a vinylpolysiloxane material or at least an extended-pour alginate material while traditional alginates are generally used in orthodontic clinics. The present study used a common CBCT scanner which is becoming more widely available in clinics and enabled the use of traditional alginate materials, as shipment to a laboratory was not required.

The present study used 3 different alginate materials, including two commonly used traditional alginate materials and an extended-pour alginate material, Cavex ColorChange. Some previous studies have validated the dimensional stability of extended-pour alginate materials.

1516 In this study, however, the alginate impressions were not stored under ideal conditions such as in 100% humidity, which is recommended by most manufacturers. In a clinical situation, plaster pouring or the scanning of impressions can be delayed under ambient conditions, and few studies investigating the effects of ambient storage conditions have been performed. Therefore, the present study aimed to evaluate dimensional changes in alginate impressions made using both traditional and extended-pour alginates under ambient conditions.

As expected, the results of the present study showed a gradual decrease in the measurement values in all dimensions within the setting time, indicating that the alginate materials underwent shrinkage over time. A similar study was performed by Todd et al.

17 in which two extended-pour alginates (Kromopan; Lascod, Florence, Italy; and TriPhasix; Parkell, Edgewood, NY, USA), two traditional alginates (Jeltrate; Dentsply-Caulk, York, PA, USA; and Kromatica; Matech, Sylmar, CA, USA), and one vinylpolysiloxane (VP Mix; Henry Schein, Melville, NY, USA) were studied to evaluate the dimensional accuracy of the impression materials. The distance between score lines on the impressions was measured at 10 minutes, 24 hours, and 100 hours. The authors concluded that all alginate impression materials in their study exhibited significant changes at 24 and 100 hours. Our study focused more on identifying the precise time point at which actual dimensional changes began to occur, especially when placed under ambient conditions. The results of the present study showed that a statistically significant difference was not observed for 1 hour and a difference was observed from 2 hours after the impression. This confirmed that impressions should be scanned as soon as possible after being obtained to provide dimensional accuracy when the impressions are not stored under special conditions.

On the other hand, it is interesting to note that there were no significant differences among the materials. The extended-pour alginate material did not show a statistically significant difference from the other two traditional alginates although decreasing tendency with increased elapsed time was less with the extended-pour alginate. This indicates that the use of extended-pour alginate material is meaningless under ambient conditions although it might be effective under special conditions such as 100% humidity.

In the present study, to identify the time point at which clinically relevant differences begin to appear, the changes within the measurement error were regarded as clinically acceptable. The findings revealed that the changes exceeding the measurement error occurred between the time points of 3 and 4 hours after the impression. The results suggest that if a CBCT scan of alginate impressions is planned for the production of a digital dental model, the impressions should be scanned immediately after the impression or at least within 2 to 3 hours. On the other hand, it should be noted that all experiments were performed under ambient conditions in this study. This indicates that special storage conditions might not be critical if the impressions are scanned within 2 to 3 hours. In clinics equipped with CBCT scanners, alginate impressions can be scanned first to create a digital model, followed by plaster pouring to obtain a physical model for successive laboratory work. This workflow strategy will significantly reduce the time and cost previously required to send impressions or plaster models to a remote laboratory.

The present study evaluated the dimensional accuracy of digital dental models obtained from CBCT scan of alginate impressions according to the time elapsed after impressions were taken. Each image obtained at a different elapsed time after impression taking was compared with an image scanned immediately after impression taking. The dimensional accuracy observed in this study does not necessarily mean that the digital dental models obtained in this study are accurate or detailed enough because inaccuracy might also result from many other procedures, such as impression taking. In addition, the scanned image obtained immediately after impression cannot be a perfect gold standard because it was scanned after a lapse of 5 minutes. This should be taken into consideration when interpreting the results of this study. On the other hand, the study evaluated dimensional changes in alginate impressions under ambient conditions. Further research is needed to evaluate time-related changes in alginate impressions stored under ideal conditions, such as in 100% humidity.

CONCLUSION

The results of this study indicate that digital dental models can be obtained simply from a CBCT scan of alginate impressions without sending them to a remote laboratory. However, the impressions should be scanned immediately or at least within 2 to 3 hours after impression taking to provide dimensional accuracy when the impressions are not stored under special conditions.

Figures and Tables

Figure 1

The process of creating a digital dental model using a cone-beam computed tomography-scanned alginate impression. A, Stereolithography file was imported into the Rapidform 2006 program (Inus, Seoul, Korea). B, The negative of the impression was converted into the positive form. C, Excessive area over the impression tray was trimmed to complete fabrication of the digital dental model.

Figure 2

Linear measurements made on each digital model. A, Incisor to molar; B, intermolar width; C, incisor height.

Figure 3

Graphic presentations of time-related changes and comparisons between the materials. There were no statistically significant differences between the materials although the extended-pour alginate material (Cavex ColorChange; Cavex Holland BV, Haarlem, the Netherlands) exhibited a less severe decreasing tendency than the other 2 traditional alginates. A Incisor to molar; B, intermolar width; C, incisor height.

Table 1

Measurement data (unit: mm) and comparisons of each image obtained at different elapsed times with the control

Table 2

Time-related changes in the measurements (unit: mm)

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download