Abstract

Objective

The purpose of this study was to optimize the thread pattern of orthodontic microimplants.

Methods

In search of an optimal thread for orthodontic microimplants, an objective function stability quotient (SQ) was built and solved which will help increase the stability and torsional strength of microimplants while reducing the bone damage during insertion. Selecting the AbsoAnchor SH1312-7 microimplant (Dentos Inc., Daegu, Korea) as a control, and using the thread height (h) and pitch (p) as design parameters, new thread designs with optimal combination of h and p combination were developed. Design soundness of the new threads were examined through insertion strain analyses using 3D finite element simulation, torque test, and clinical test.

Results

Solving the function SQ, four new models with optimized thread designs were developed (h200p6, h225p7, h250p8, and h275p8). Finite element analysis has shown that these new designs may cause less bone damage during insertion. The torsional strength of two models h200p6 and h225p7 were significantly higher than the control. On the other hand, clinical test of models h200p6 and h250p8 had similar success rates when compared to the control.

Figures and Tables

Fig. 1

Configuration of the Absoanchor SH1312-07 microimplant together with important dimensional data.

Fig. 2

Geometry of microimplant and cortical bone specimen. A, Geometry model (unit: mm); B, shape and dimensional data of cortical bone specimen, constructed of tetrahedral elements; C, sectional view of cortical bone specimen, where p is the thread pitch for each of the 5 microimplants and d is the inner bone diameter made by the microimplant (0.7 mm and 0.9 mm for self drilling and self tapping simulations respectively).

Fig. 3

SQ values varying as a function of two design parameters: thread height (h) and thread pitch (p).

Fig. 4

SEM images of four experimental microimplant models together with important dimensions: A, h200p6; B, h225p7; C, h250p8; D, h275p8 models.

Fig. 5

Radial strain development in the adjacent cortical bone at the final stage of self drilling placement of A, h200p6; B, h225p7; C, h250p8; D, h275p8; E, control models.

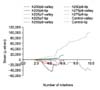

Fig. 6

Radial strain development in cortical bone near the tip (0.05 mm ahead of tip) and valley (0.1 mm apart from shank) of each of the 5 microimplant models during the course of self drilling microimplant placement.

Fig. 7

Radial strain development in the adjacent cortical bone at the final stage of self tapping microimplant placement of A, h200p6; B, h225p7; C, h250p8; D, h275p8; E, control models.

References

1. Ludwig B, Baumgaertel S, Bowman SJ. Mini-implants in orthodontics. Innovative anchorage concepts. 2008. 1st ed. London: Quintessence Publishing;23.

2. Ramaswamy R, Evans S, Kosashvili Y. Holding power of variable pitch screws in osteoporotic, osteopenic and normal bone: are all screws created equal? Injury. 2010. 41:179–183.

3. Saka B. Mechanical and biomechanical measurements of five currently available osteosynthesis systems of self-tapping screws. Br J Oral Maxillofac Surg. 2000. 38:70–75.

4. Miyawaki S, Koyama I, Inoue M, Mishima K, Sugahara T, Takano-Yamamoto T. Factors associated with the stability of titanium screws placed in the posterior region for orthodontic anchorage. Am J Orthod Dentofacial Orthop. 2003. 124:373–378.

5. Miyamoto I, Tsuboi Y, Wada E, Suwa H, Iizuka T. Influence of cortical bone thickness and implant length on implant stability at the time of surgery-clinical, prospective, biomechanical, and imaging study. Bone. 2005. 37:776–780.

6. Uhthoff HK. Mechanical factors influencing the holding power of screws in compact bone. J Bone Joint Surg Br. 1973. 55:633–639.

7. Motoyoshi M, Hirabayashi M, Uemura M, Shimizu N. Recommended placement torque when tightening an orthodontic mini-implant. Clin Oral Implants Res. 2006. 17:109–114.

8. Büchter A, Wiechmann D, Koerdt S, Wiesmann HP, Piffko J, Meyer U. Load-related implant reaction of mini-implants used for orthodontic anchorage. Clin Oral Implants Res. 2005. 16:473–479.

9. Park HS. Orthodontic treatment using micro-implant: clinical applications of micro-implant anchorage. 2006. Seoul: DaehanNare Publishing;5–33.

10. Meredith N. Assessment of implant stability as a prognostic determinant. Int J Prosthodont. 1998. 11:491–501.

11. Yu W, Kyung HM. Torque and mechanical failure of orthodontic micro-implant influenced by implant design parameters. Korean J Orthod. 2007. 37:171–181.

12. Chun HJ, Cheong SY, Han JH, Heo SJ, Chung JP, Rhyu IC, et al. Evaluation of design parameters of osseointegrated dental implants using finite element analysis. J Oral Rehabil. 2002. 29:565–574.

13. Hansson S, Werke M. The implant thread as a retention element in cortical bone: the effect of thread size and thread profile: a finite element study. J Biomech. 2003. 36:1247–1258.

14. Nam O, Yu WJ, Kyung HM. Cortical bone strain during the placement of orthodontic microimplant studied by 3D finite element analysis. Korean J Orthod. 2008. 38:228–239.

15. Park JS, Yu WJ, Kyung HM, Kwon OW. Finite element analysis of cortical bone strain induced by self-drilling placement of orthodontic microimplant. Korean J Orthod. 2009. 39:203–212.

16. You ZH, Bell WH, Schneiderman ED, Ashman RB. Biomechanical properties of small bone screws. J Oral Maxillofac Surg. 1994. 52:1293–1302.

17. Kincaid B, Schroder L, Mason J. Measurement of orthopedic cortical bone screw insertion performance in cadaver bone and model materials. Exp Mech. 2007. 47:595–607.

18. Krenn MH, Piotrowski WP, Penzkofer R, Augat P. Influence of thread design on pedicle screw fixation. Laboratory investigation. J Neurosurg Spine. 2008. 9:90–95.

19. Brinley CL, Behrents R, Kim KB, Condoor S, Kyung HM, Buschang PH. Pitch and longitudinal fluting effects on the primary stability of miniscrew implants. Angle Orthod. 2009. 79:1156–1161.

20. Motoyoshi M, Yano S, Tsuruoka T, Shimizu N. Biomechanical effect of abutment on stability of orthodontic mini-implant. A finite element analysis. Clin Oral Implants Res. 2005. 16:480–485.

21. Park HS, Jeong SH, Kwon OW. Factors affecting the clinical success of screw implants used as orthodontic anchorage. Am J Orthod Dentofacial Orthop. 2006. 130:18–25.

22. Chen Y, Kyung HM, Zhao WT, Yu WJ. Critical factors for the success of orthodontic mini-implants: a systematic review. Am J Orthod Dentofacial Orthop. 2009. 135:284–291.

23. Song YY, Cha JY, Hwang CJ. Mechanical characteristics of various orthodontic mini-screws in relation to artificial cortical bone thickness. Angle Orthod. 2007. 77:979–985.

24. Song YY, Cha JY, Hwang CJ. Evaluation of insertion torque and pull-out strength of mini-screws according to different thickness of artificial cortical bone. Korean J Orthod. 2007. 37:5–15.

25. Hwang CJ, Choi BJ, Kim KN, Kim KM, Lee YK. Orthodontic materials and clinical technique. 2003. Seoul: DaehanNare Publishing;24.

PDF

PDF ePub

ePub Citation

Citation Print

Print

XML Download

XML Download